Diesel oil engine turbine resonance composite pressurization system

A technology for supercharging systems and diesel engines, applied in mechanical equipment, combustion engines, machines/engines, etc., can solve problems such as hindering the start and acceleration of diesel engines, low input and output power of turbochargers, and lag in response of diesel engines, so as to improve engine speed. The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

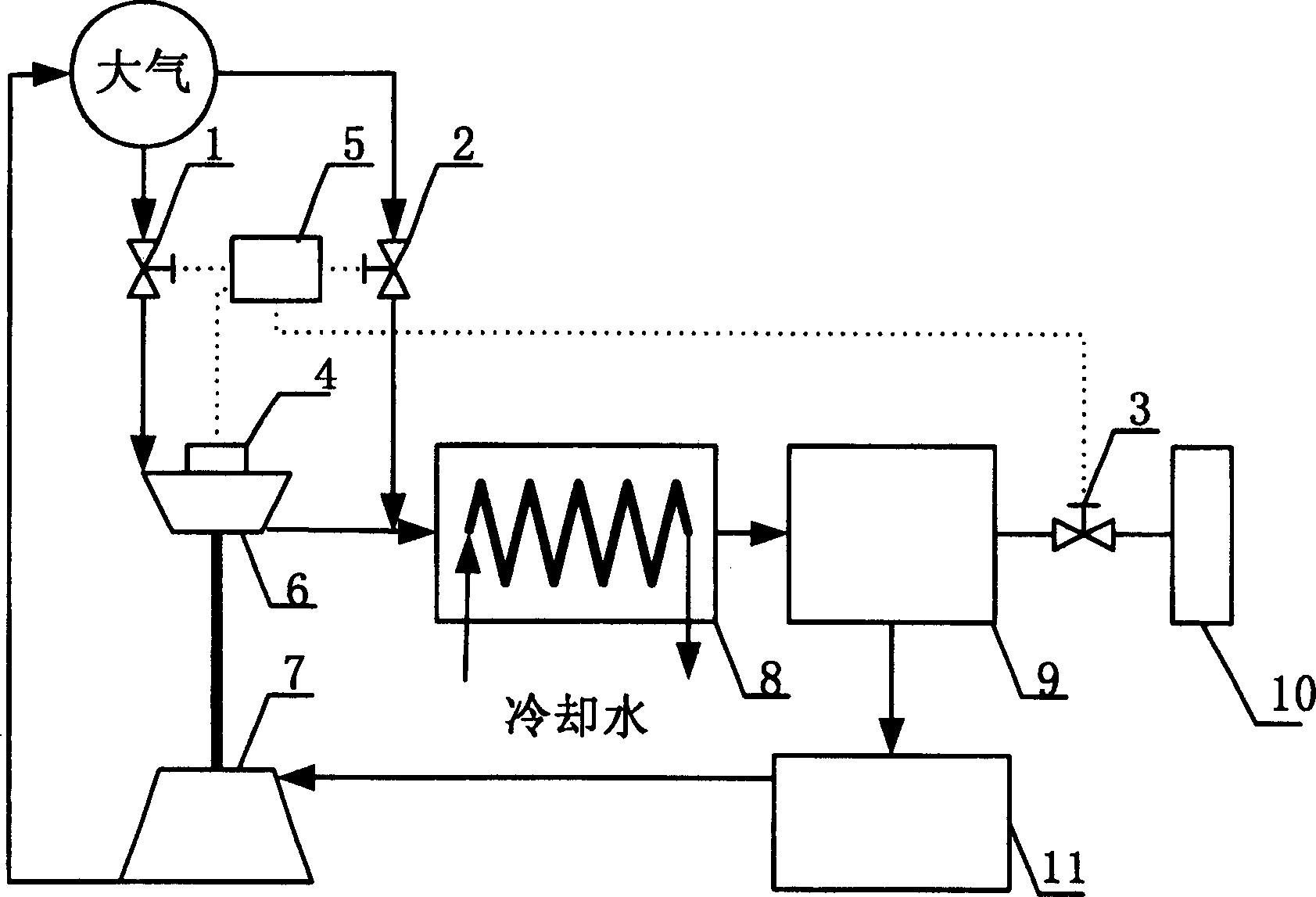

[0009] Such as figure 1 As shown, the present invention includes a first electromagnetic shut-off valve 1, a second electromagnetic shut-off valve 2, a third electromagnetic shut-off valve 3, a speed sensor 4, a controller 5, a supercharger 6, a turbine 7, an intercooler 8, and a resonant cavity 9. Additional volume cavity 10, diesel engine 11. The intercooler 8 adopts a shell-and-tube heat exchanger, and the resonant cavity 9 and the additional volume cavity 10 are cylindrical or cuboid cavities made of thin metal plates. The supercharger 6 and the turbine 7 are coaxially connected, and the speed sensor 4 adopts a magnetoelectric speed sensor, and the speed sensor 4 is installed near the outer edge of the impeller of the supercharger 6 . The control ends of the first electromagnetic cut-off valve 1 , the second electromagnetic cut-off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com