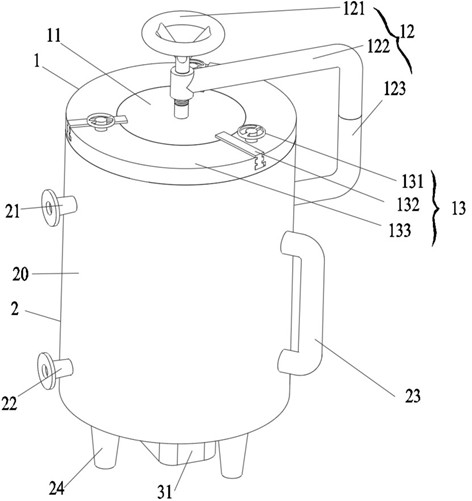

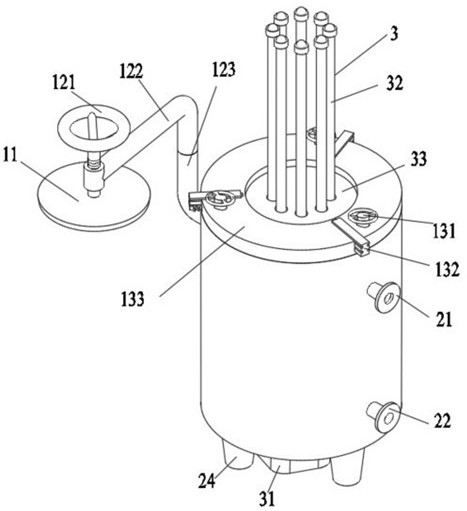

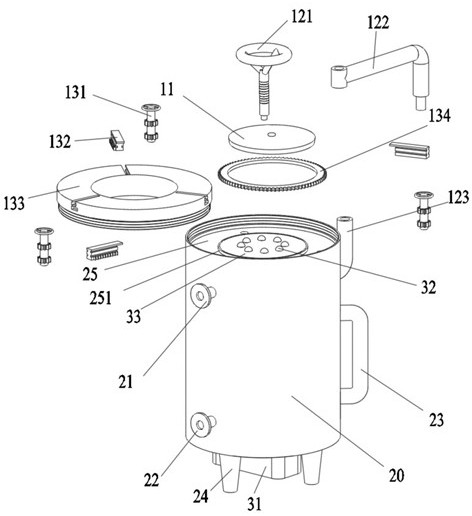

Natural gas filtering and purifying device

A technology for filtering and purifying natural gas, applied in the fields of gas fuel, transportation and packaging, mechanical equipment, etc., it can solve the problems of tank collision, large floor space, difficult operation, etc., to achieve easy installation and removal, and reduce floor space. , easy to detect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The descriptions involving "first", "second", "upper", "lower", "inner", "outer", etc. in the present invention are only for descriptive purposes, and should not be construed as indicating or implying their relative importance Or implicitly indicate the number of technical features indicated. Therefore, the features defined as "first" and "second" may explicitly or implicitly include at least one of the features, "upper" and "lower" are subject to the actual placement position, and "inside" refers to the part close to the center of each component. Position, "outer" refers to a position away from the center of each part. In addition, the technical solutions between the various embodiments can be combined with each other, but must be based on the realization by those of ordinary skill in the art. When the technical solutions between the embodiments can be combined, it is within the protection scope of the present invention. Inside.

[0037] The present invention will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com