Washing machine control method and washing machine

A washing machine and washing water technology, which is applied to the control device of washing machine, other washing machines, washing devices, etc., can solve the problems of inability to filter washing water, micro lint, environmental pollution, etc., and achieve the effect of ensuring drainage efficiency and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The following will take the drum washing machine as an example to introduce its specific structure:

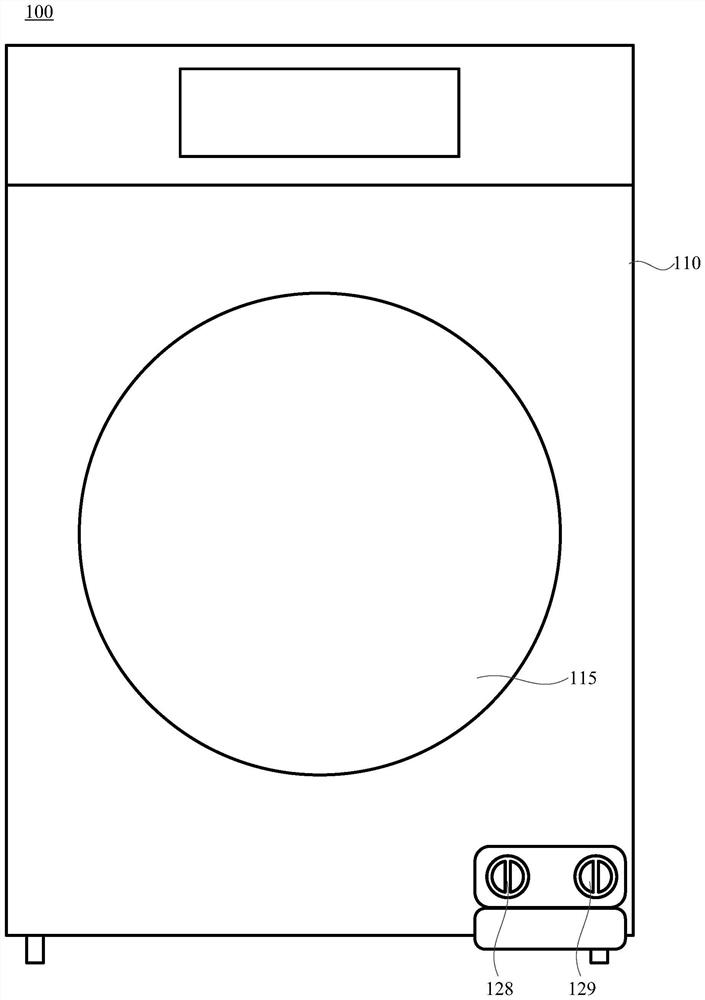

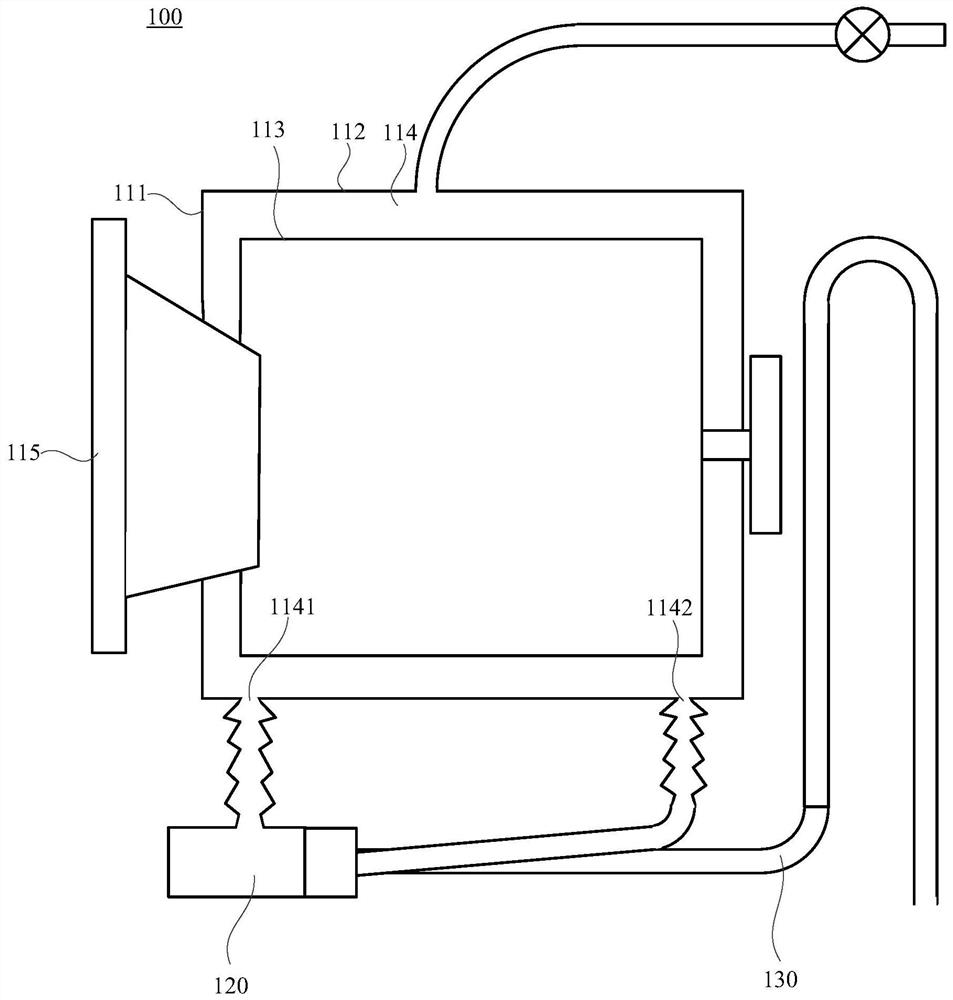

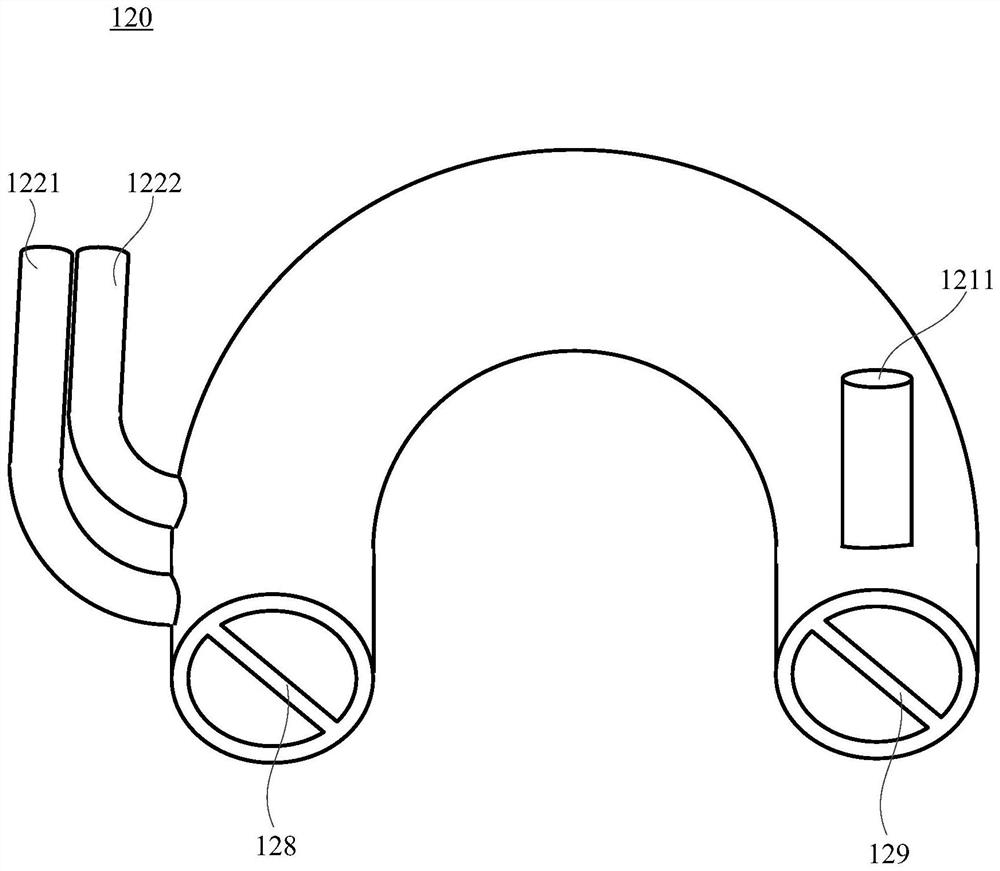

[0050] figure 1 is the front schematic diagram of the washing machine provided by the embodiment of the present application; figure 2 is a schematic diagram of the internal structure of the washing machine provided by the embodiment of the present application; image 3 It is a schematic structural diagram of the drainage filter in the washing machine provided by the embodiment of the present application; Figure 4 Yes image 3 Schematic diagram of the internal structure. like figure 1 and figure 2 As shown, the embodiment of the present application provides a washing machine 100, including: a main body 110, and the main body 110 has a washing cavity 114 for accommodating washing water. Specifically, the body 110 includes a casing 111, and the casing 111 has a accommodating space, and the accommodating space is provided with an outer cylinder 112 and an inner cyl...

Embodiment 2

[0087] Figure 7 This is a schematic flowchart of the control method of the washing machine provided by the embodiment of the present application. like Figure 7 As shown, the embodiment of the present application also provides a control method for a washing machine, which is used in the washing machine provided in the above-mentioned embodiment, and the method specifically includes:

[0088] Step S101: Drain the washing water in the washing chamber into the first filter chamber of the drain filter, so as to filter the lint in the washing water entering the first filter chamber.

[0089] Wherein, the first filter cavity is provided with a first filter element, for example, a filter element with a relatively large filter mesh hole, which is used for filtering thick lint, cloth strips, etc. in the washing water.

[0090] Step S102: Drain the washing water filtered by the first filter chamber into the second filter chamber of the drainage filter, so as to filter the lint in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com