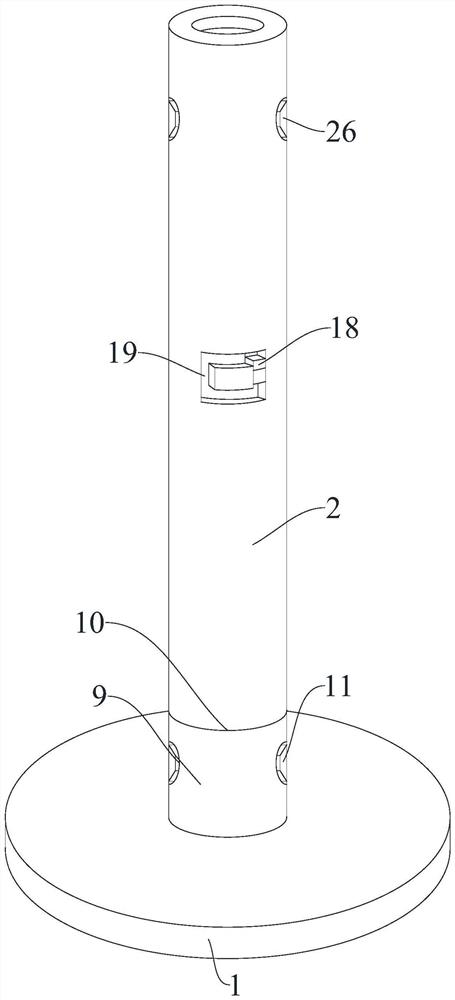

Valve rod connecting piece with internal protection mechanism

A protection mechanism and connecting piece technology, applied in the direction of engine components, valve devices, valve details, etc., can solve the problems of inability to deal with the water hammer effect of valves, limited valve structure and specifications, troublesome installation, disassembly and maintenance, etc., to facilitate early assembly and Later replacement and maintenance, elimination of water hammer effect, and better cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

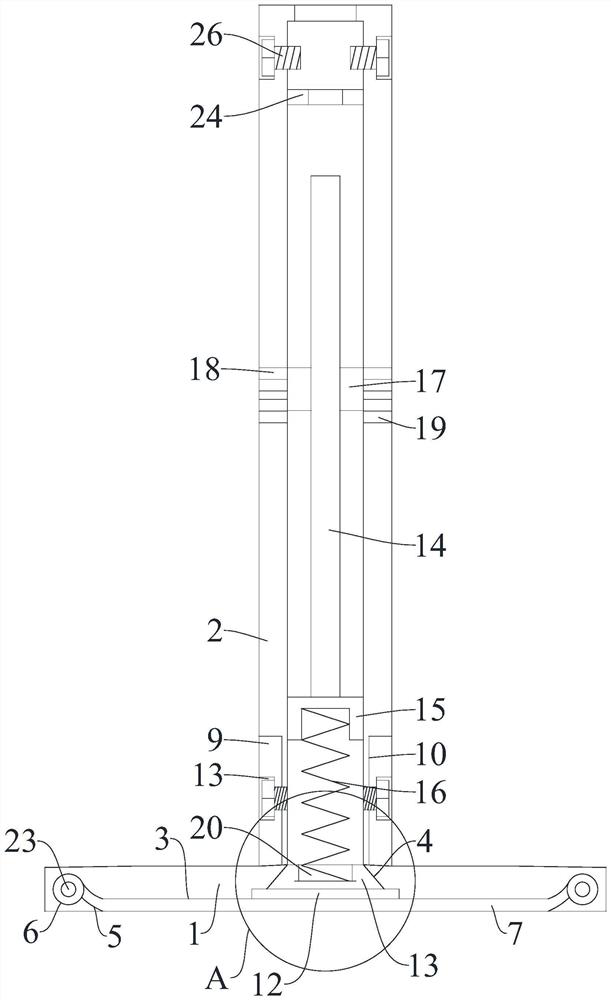

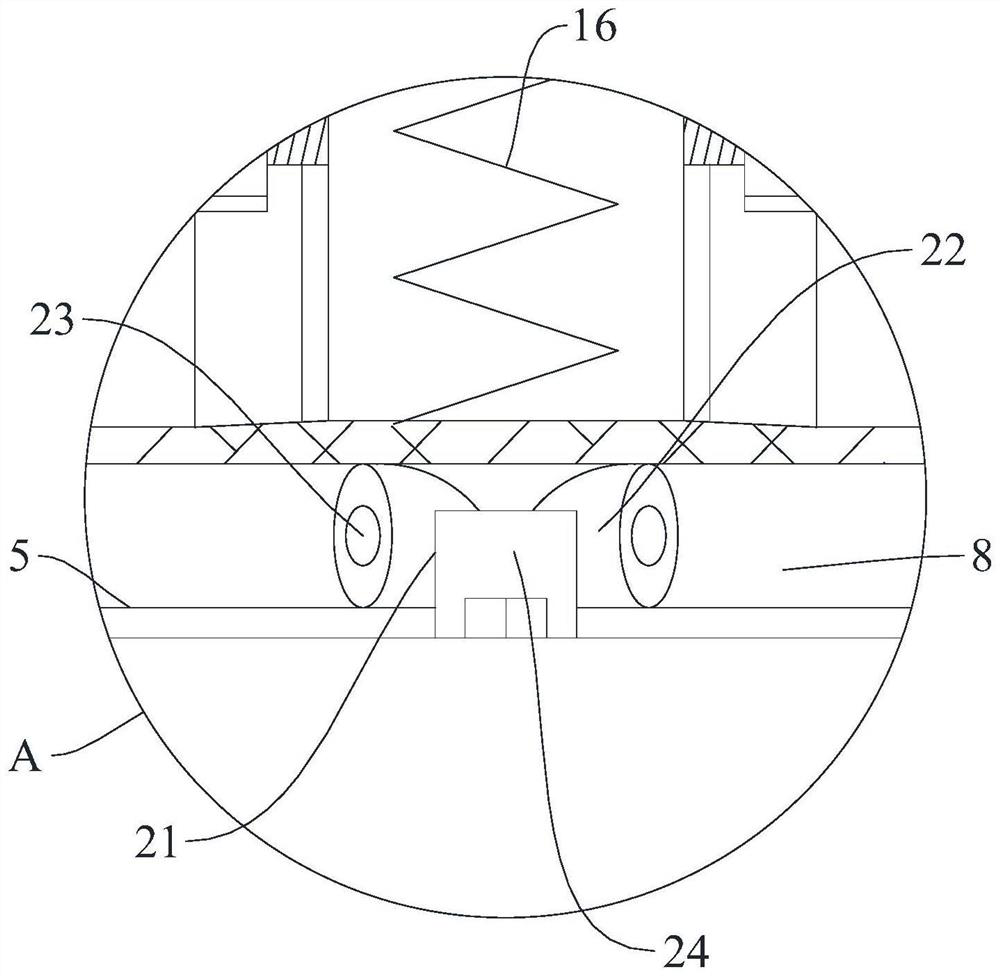

[0028] Example: When it is changed to a flexible buffer state, people translate the lateral control block 18 from the top of the lateral adjustment port 19 back to the bottom. At this time, the internal control shaft 14 drives the internal sealing cover 13 and the metal seal through the buffer spring 16 at the bottom. The shrapnel 12 is pressed downward. At this time, the middle part of the bottom rubber sealing sheet 7 is supported and deformed. At the same time, the adjustment port 4 of the circular truncated structure is opened. open;

[0029] When it is changed to a rigid state, people translate the lateral control block 18 from the bottom of the lateral adjustment port 19 back to the top. At this time, the internal control shaft 14 drives the internal sealing cover 13 and the metal sealing spring 12 to retract upward through the buffer spring 16 at the bottom. At this time, the middle part of the bottom rubber sealing sheet 7 is retracted and flat, and the adjustment port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com