Low-coupling fiber grating three-dimensional force sensor

A fiber grating and three-dimensional force technology, applied in instruments, force/torque/power measuring instruments, measuring devices, etc., can solve the problems of large coupling interference, achieve the effects of reducing coupling interference, light and compact structure, and solving complicated and difficult wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

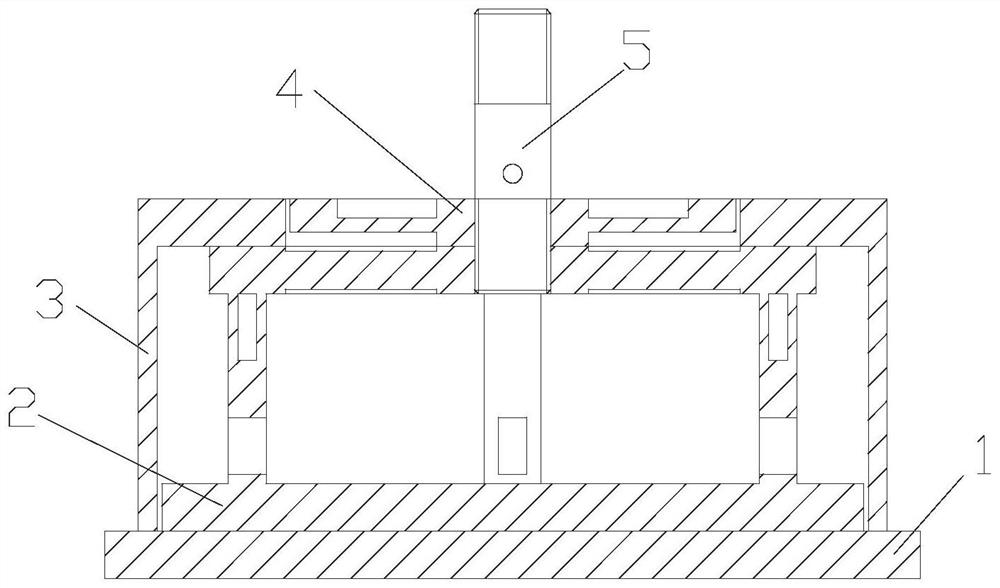

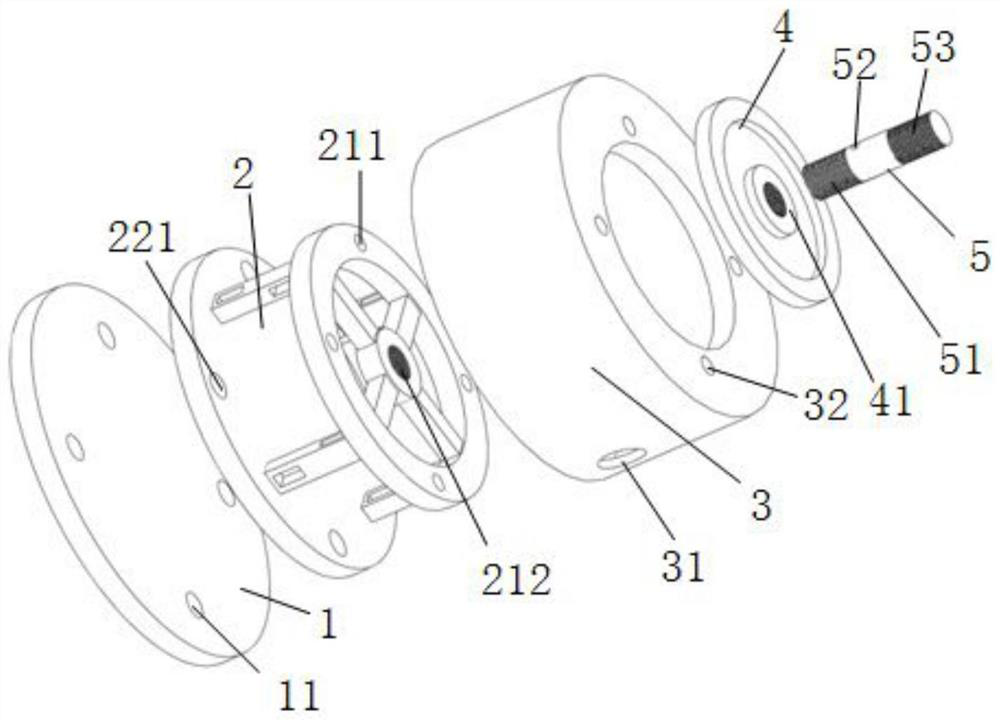

[0036] like Figure 1 to Figure 5 Shown: This embodiment provides a low-coupling fiber grating three-dimensional force sensor, including a sensor body 2 and a force transmission column 5, the force transmission column 5 is an elastic column structure that can be bent in the radial direction and stretched in the axial direction .

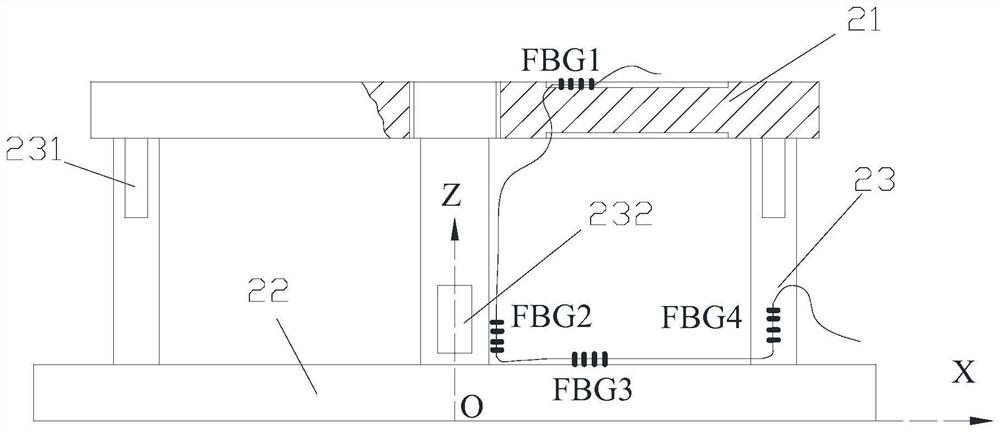

[0037] The sensor body 2 includes a horizontal elastic disk 21 , a chassis 22 , an elastic vertical beam 23 and a fiber grating assembly.

[0038] The horizontal elastic disk 21 is made of elastic material and includes a disk body 213 with a cavity and a plane strain beam 215 located in the cavity 214. The plane strain beam 215 is a cross beam structure and has four in the same plane. The outer ends of the four described branch beams (one end away from the connection center) are all connected to the inner wall of the disk body 213, and the center of the plane strain beam 215 is connected to the lower end of the force transmission column 5; the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com