Oil pipe flaw detection method and device for well drilling/repairing operation

A flaw detection and oil pipe technology, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the fluid's acceleration and deceleration rate, etc. good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

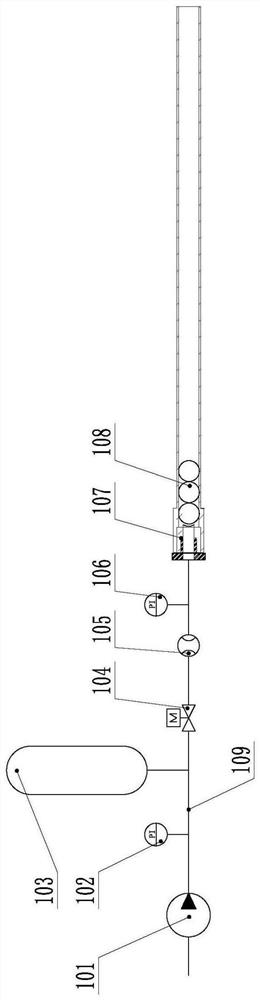

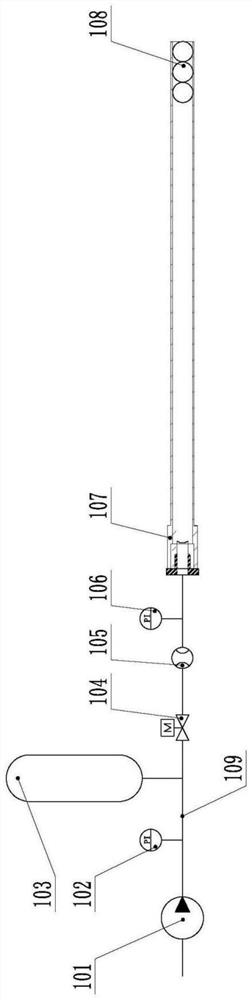

[0034] The present invention provides a method for inspection and detection of oil pipe flaws in drilling / workover operations. The steps of a specific embodiment are as follows:

[0035] 1) Drive the balls into the oil pipe to be tested with a water flow; 1-3 small balls are driven into the oil pipe to be tested with a water flow at a time; the diameter of the balls is the same as the inner diameter of the oil pipe to be tested.

[0036] 2) Measure the water flow pressure P1 entering the oil pipe and the water flow volume V1 entering the oil pipe;

[0037] 3) Measure the water flow pressure P2 in the oil pipe and the water flow volume V2 in the oil pipe;

[0038] 4) According to Boyle's law:

[0039] P1*V1=P2*V2

[0040] On the premise that the input water flow pressure P1 into the oil pipe and the water flow volume V1 into the oil pipe are fixed parameters, ensure that the water flow volume V2 in the oil pipe is a constant parameter, and by observing the pressure change of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com