Printed matter adhesion detection equipment

A detection equipment and adhesion technology, applied in measuring devices, instruments, mechanical devices, etc., can solve problems such as poor effect and low detection efficiency, and achieve the effect of ensuring detection quality, increasing moving time, and improving detection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

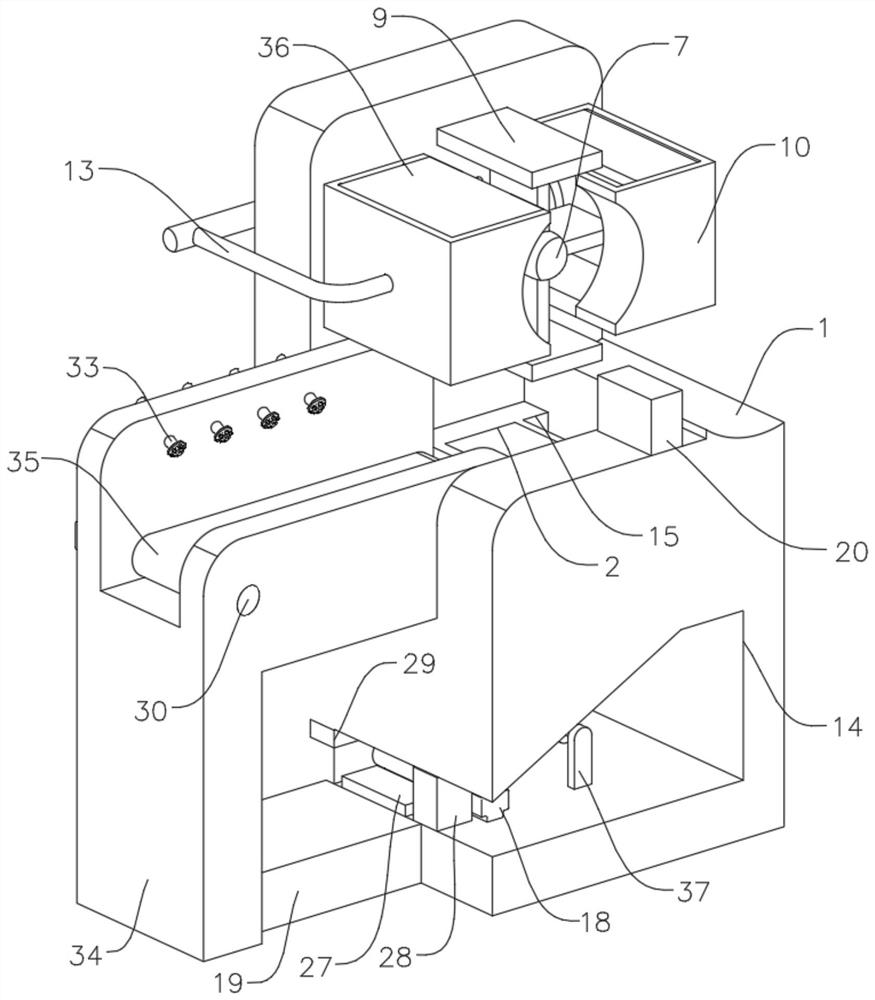

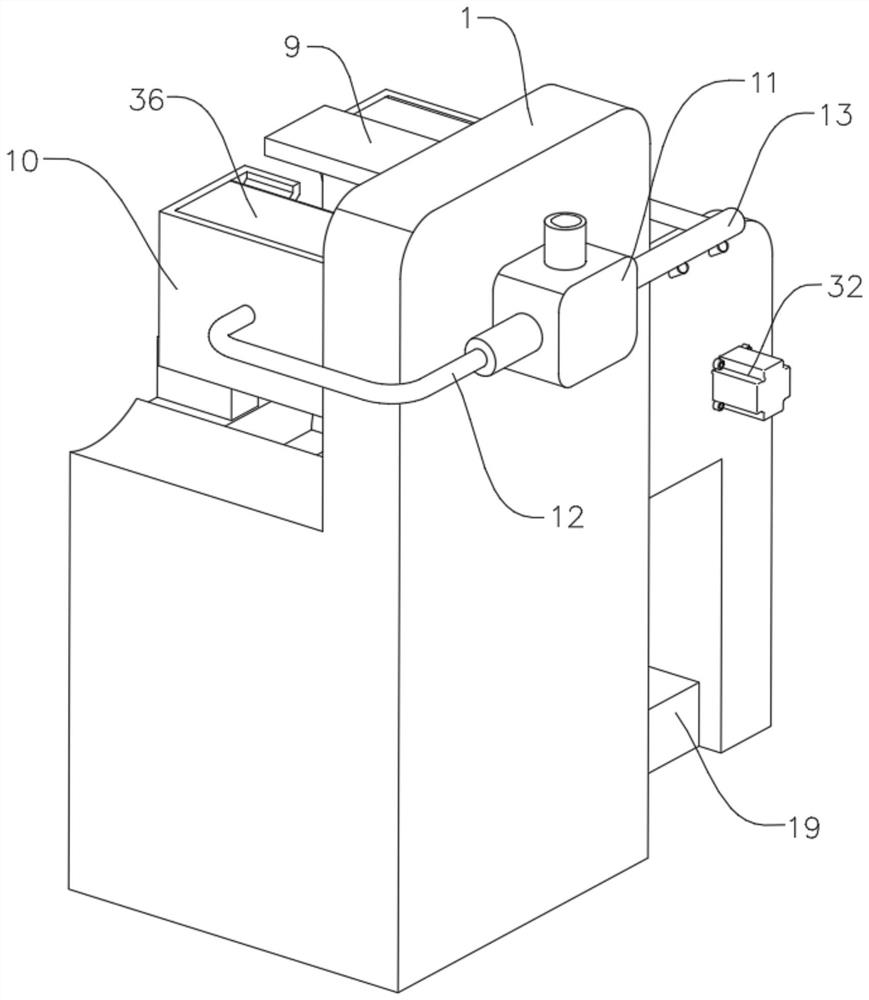

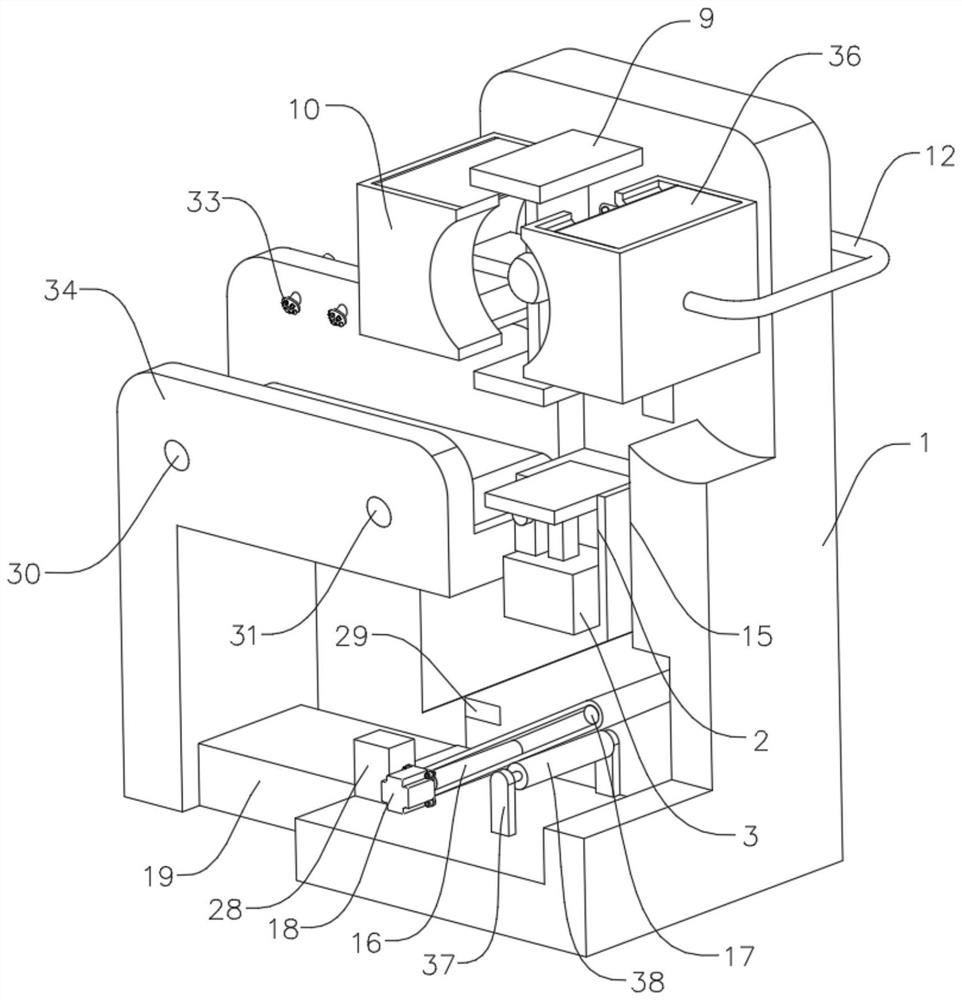

[0025] refer to Figure 1-7 , a printed matter adhesion detection equipment, including a detection table 1, the upper end of the detection table 1 is provided with a lifting groove 2, the inner wall of the lifting groove 2 is fixed with a lifting rod 3, and the upper end of the lifting rod 3 is rotatably connected with a support plate 4, the lifting rod The side wall of 3 is fixed with a turning box 5, and the inside of turning box 5 is provided with a turning transfer mechanism for pushing the support plate 4 to turn over. There is a transposition shaft 7, a plurality of connection plates 8 are fixed on the circumferential side wall of the transposition shaft 7, a pressure plate 9 is fixed on the side wall of each connection plate 8, and two temperature control boxes are fixed on the side wall of the detection table 1 10. The vortex tube 11 is fixed on the back of the testing table 1. The vortex tube 11 is connected to the external air compressor, and after starting, the cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com