Fully mechanized coal mining face real-time three-dimensional imaging method and system based on multiple laser radars

A fully mechanized mining face, laser radar technology, applied in radio wave measurement systems, instruments, measurement devices, etc., can solve the problems of poor real-time imaging results, high cost, and complicated installation process of imaging systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

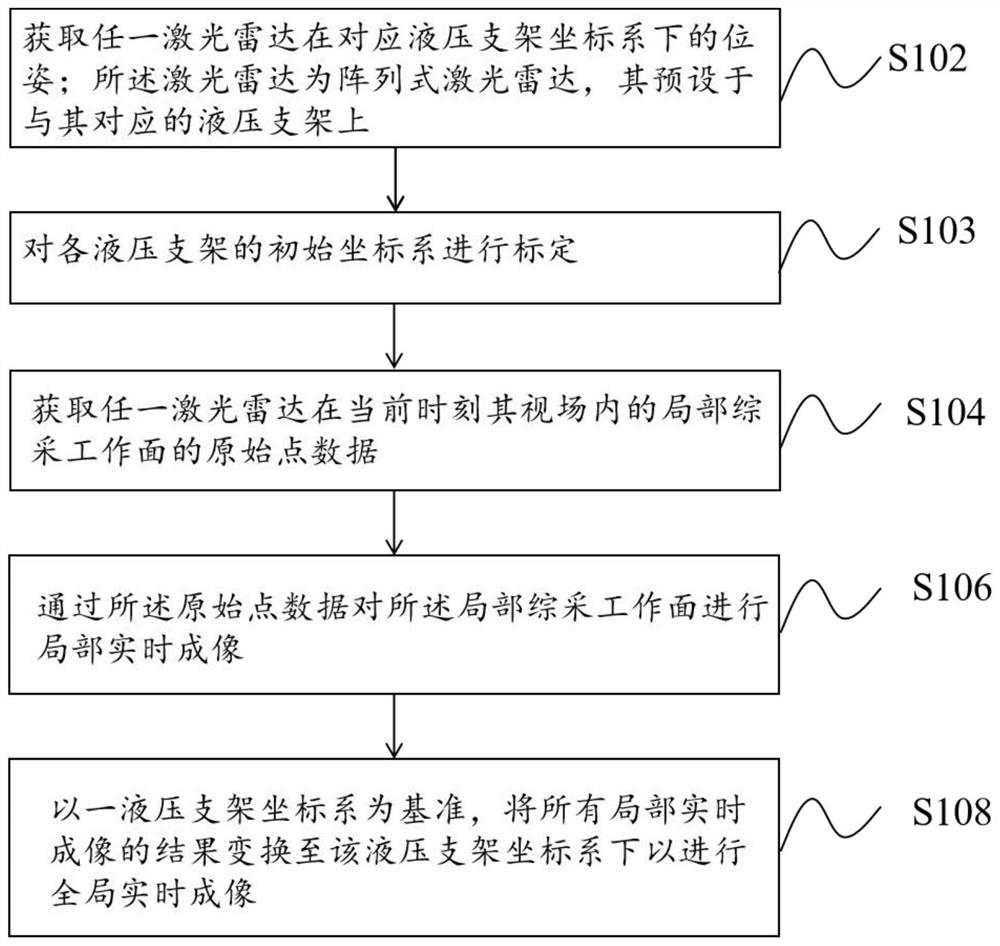

[0056] like figure 1 As shown, the imaging method includes:

[0057] Step S102 , obtaining the pose of any laser radar in the coordinate system corresponding to the hydraulic support; the laser radar is an array laser radar, which is preset on the corresponding hydraulic support.

[0058] Since the hydraulic supports are the supporting equipment of the fully mechanized mining face, they are separately arranged in the entire fully mechanized mining face, and are pushed forward synchronously with the advancement of the fully mechanized mining face. In this step, the lidar is set on the hydraulic support, and the pose of the lidar is converted to the coordinate system corresponding to the hydraulic support. Therefore, in the later stage, whether local imaging or global imaging is performed, at any time, the original point data obtained relatively statically in the field of view of the lidar will correspond to the local three-dimensional structure of the fully mechanized mining f...

Embodiment 2

[0097] like Figure 4 As shown, the imaging system is constructed based on the imaging method, and includes several lidars, several hydraulic supports, several sub-processors, a general processor and software.

[0098] The laser radar is an array-type laser radar, which is hoisted on the hydraulic support at intervals and used to obtain the original point data of the local fully mechanized mining face in its field of view.

[0099] The sub-processors are connected to the lidars in one-to-one correspondence, and are used to process the original point data of the corresponding lidars to perform local real-time imaging; the general processor is connected to each of the sub-processors for Perform global live imaging. The software is loaded on the sub-processor and the main processor for executing the imaging method described in Embodiment 1.

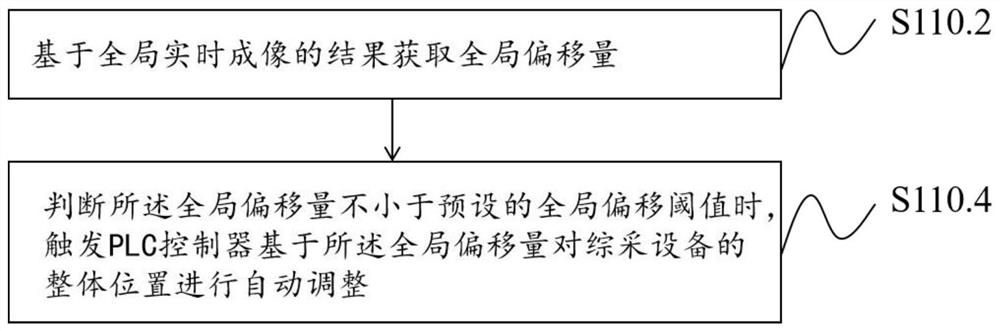

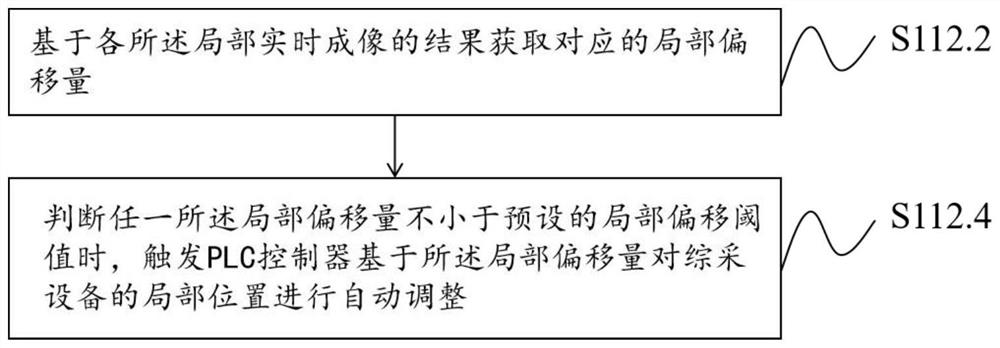

[0100] And when the global real-time imaging is performed by the general processor, it can be performed based on the result of the local ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com