Guide device of semiconductor packaging frame and metal filing removal method

A guiding device, semiconductor technology, applied in cleaning methods and utensils, chemical instruments and methods, transportation and packaging, etc., can solve problems such as product quality problems, machine short-circuits, easy to slip out of the track, etc. The effect of stable operation and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described in detail below through the embodiments and the accompanying drawings.

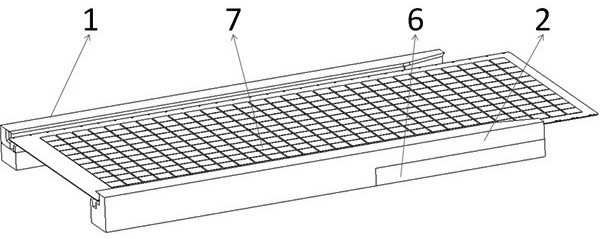

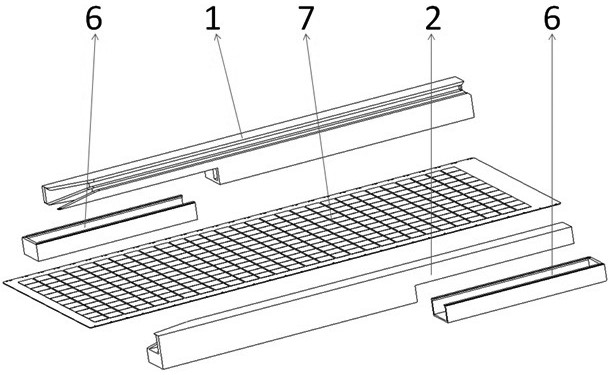

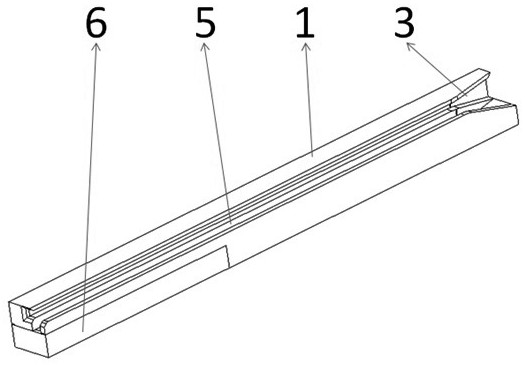

[0026] like Figure 1-Figure 11 As shown in the figure, a guide device for a semiconductor packaging frame of the present invention includes a left flow channel 1 and a right flow channel 2 laid on the left and right sides of the frame 7 in the running direction. The upper part of the left flow channel 1 and the right flow channel 2 U-shaped grooves 3 along the running direction of the frame 7 are respectively provided, and the U-shaped grooves 3 on the upper part of the left runner 1 and the U-shaped grooves 3 on the upper part of the right runner 2 are opposite to each other; the left runner 1 and the right runner The lower part of 2 is respectively provided with a collection groove 5 with the opening facing upward and along the running direction of the frame 7; , the collection tank 5 is located at one end of the left fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com