Battery cell encapsulation control method and device

A control method and technology of a control device, which are applied in the manufacture of secondary batteries, circuits, electrical components, etc., can solve the problems of easy generation of wrinkles, unevenness, and low efficiency of cell coating, and achieve the effect of improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The present invention provides a control method and device for battery core wrapping, which has the advantages of high flatness, good quality, and good adaptability to different process requirements.

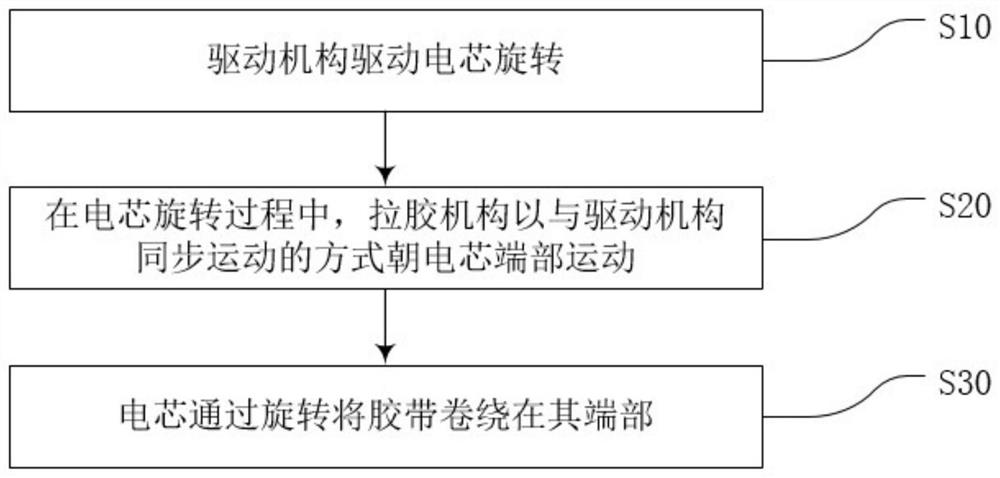

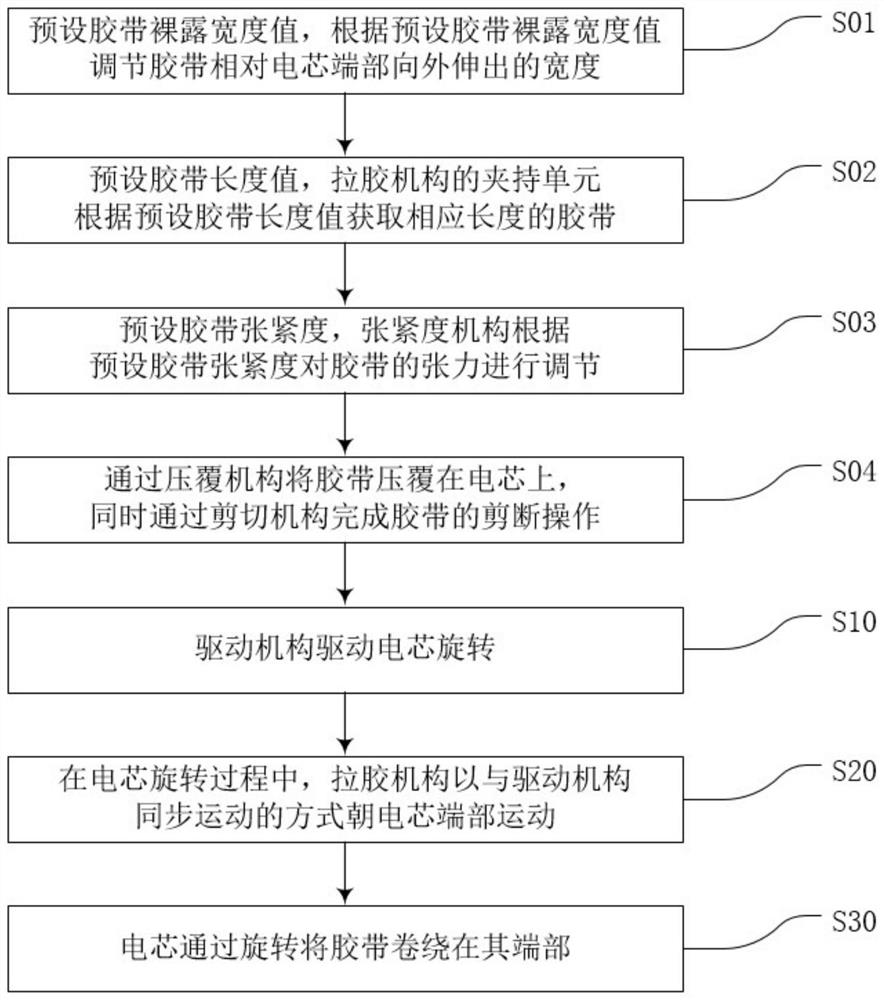

[0063] like figure 1 As shown in the figure, when the cell is covered with glue, the driving mechanism first drives the cell to rotate in step S10; then in step S20, during the rotation of the cell, the rubber-pulling mechanism moves toward the end of the cell in a synchronous motion with the driving mechanism, so that the The tape is continuously in a suitable tension state, and will not be too tight or too loose; finally, according to step S30, the battery cell is rotated to wind the tape around its end. Since the cell is in the process of encapsulating, the tape is continuously in a proper tension state, so that the flatness of the tape is better, that is, the quality of the encapsulation is higher. Wherein, the synchronous movement means that the horizontal speed of ...

Embodiment 2

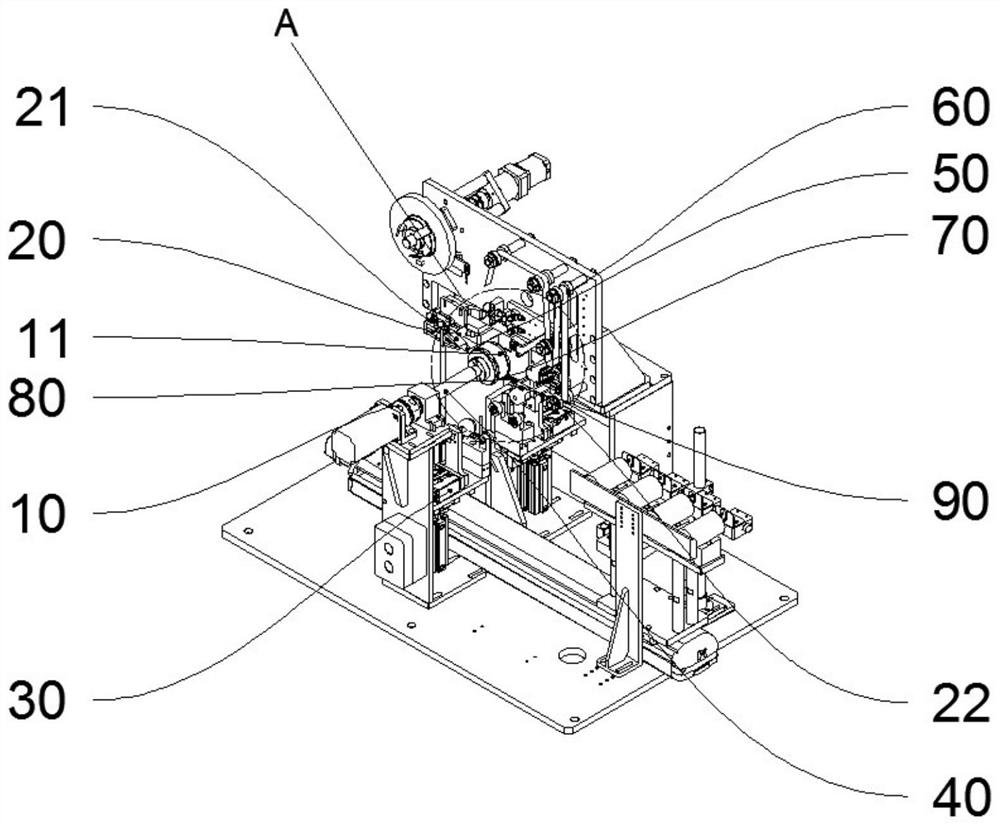

[0077] The present invention provides a control device for cell encapsulation, such as image 3 As shown, the control device for encapsulating the battery cell includes a driving mechanism 10, a rubber pulling mechanism 20 and a control unit 30. The control unit 30 obtains the rubber pulling according to the diameter of the battery cell and the linear speed of the battery core rotation. The synchronous proportional value between the driving unit of the mechanism and the driving unit of the driving mechanism, through the synchronous proportional value, the rubber pulling mechanism 10 is moved toward the end of the battery cell in a manner of synchronous movement with the driving mechanism.

[0078] Preferably, the rubber pulling mechanism and the driving unit of the driving mechanism are both high-precision servo motors. The control unit 30 is provided with a synchronous control device, and the synchronous control device is connected with two sets of high-precision servo motors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com