Naked shoe and production process thereof

A production process and bare-feeling technology, which is applied to shoe uppers, shoes, soles, etc., can solve problems that are not conducive to production safety, long residual time, and affect wearing comfort, and achieve the effect of improving the adhesion of shoes and improving the three-dimensional shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the specific drawings.

[0018] if Figure 1 to Figure 3 shown:

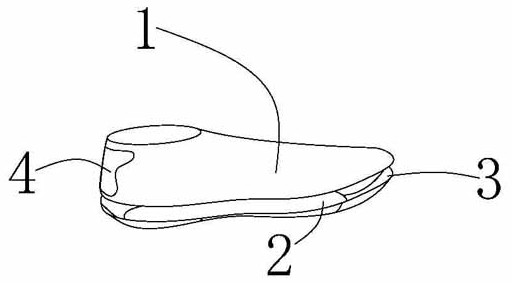

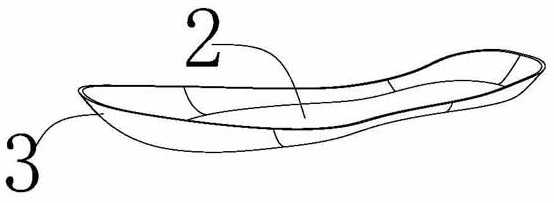

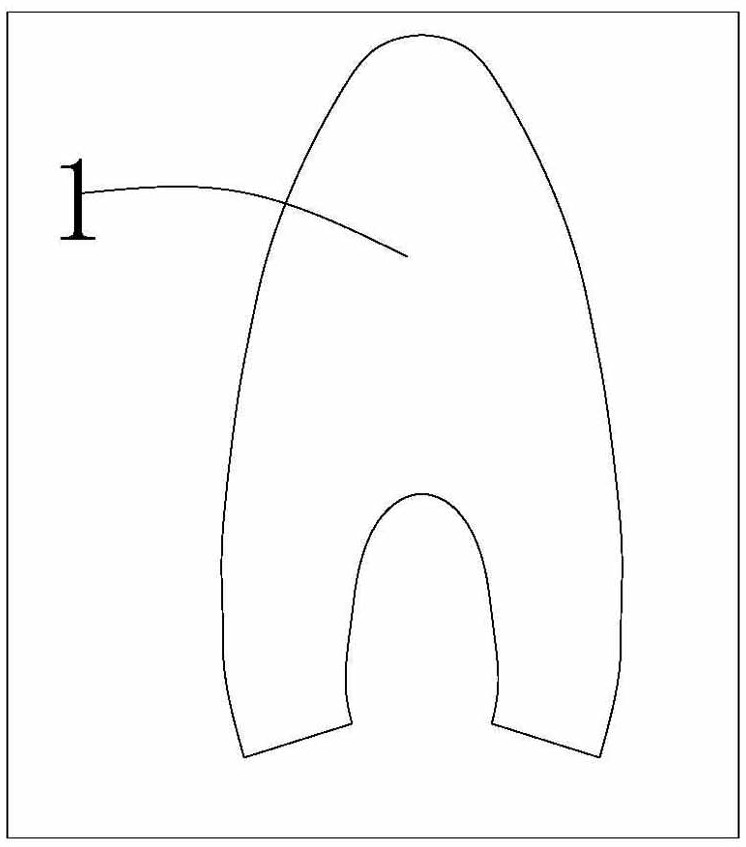

[0019] The preferred embodiment of the present invention is: a kind of nude shoes, comprising an upper 1 and a sole 2, the edge of the sole 2 is provided with an upwardly curved arc edge 3, and the upper 1 and the sole 2 are connected by four needles and six threads, The vamp 1 is fixed with the arc edge 3 by four needles and six threads, so that the vamp 1 forms a three-dimensional shape. In this embodiment, the arc length of the arc edge 3 of the head of the sole 2 extends to be almost perpendicular to the plane.

[0020] like Figure 4 Shown: The shape of the sole 2 fits the arc at the front end of the toe, and the connection between the upper 1 and the sole 2 is set on the foot surface at the end of the arc, which perfectly fits the foot.

[0021] In this embodiment, the arc length of the arc edge 3 gradually shortens from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com