Automatic glazing and spraying equipment for electric porcelain insulator and use method of automatic glazing and spraying equipment

A technology for spraying equipment and insulators, which is applied to coatings, spray booths, spraying devices, etc., can solve the problems of complex electric porcelain insulators, poor spraying quality, and difficulty in ensuring the quality of glazing, and achieve the effect of improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

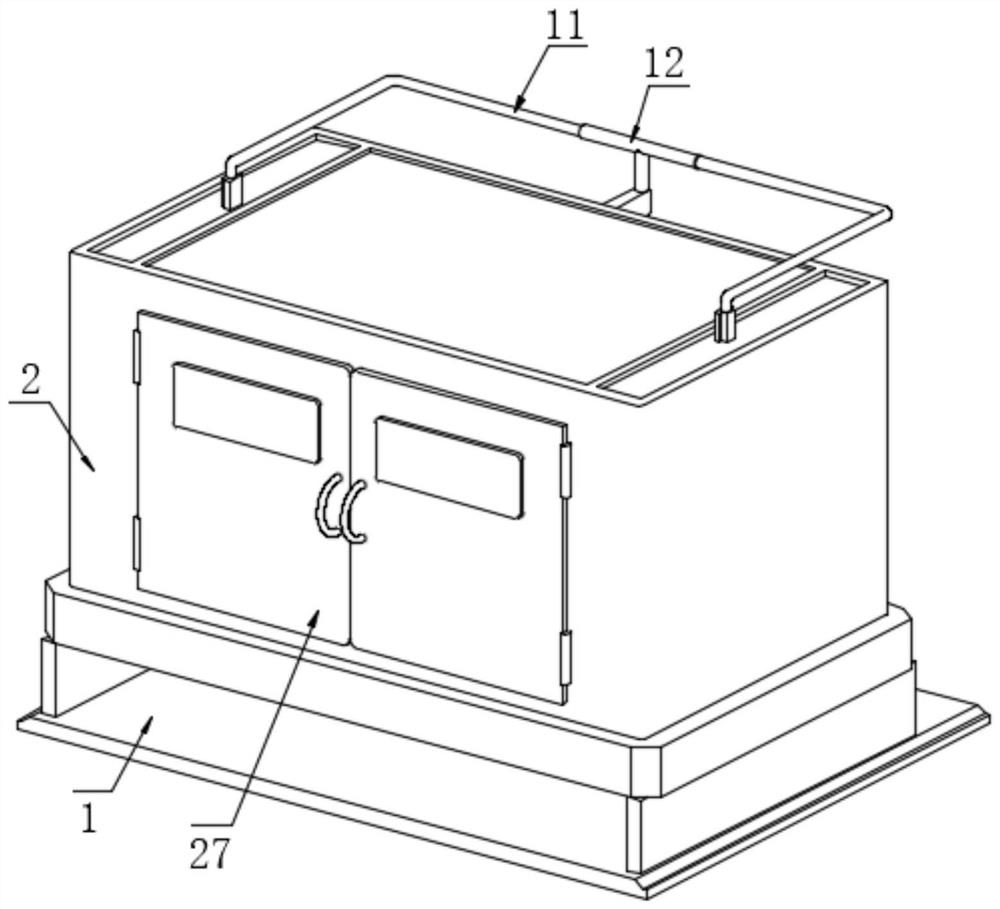

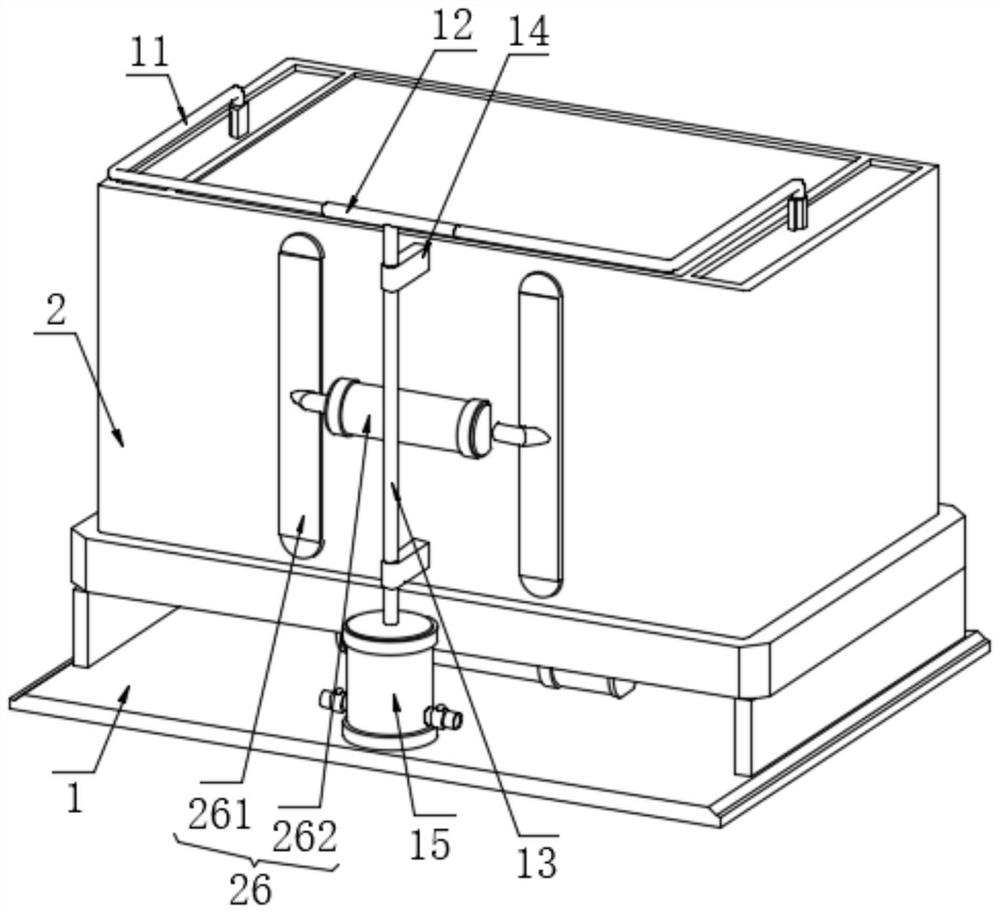

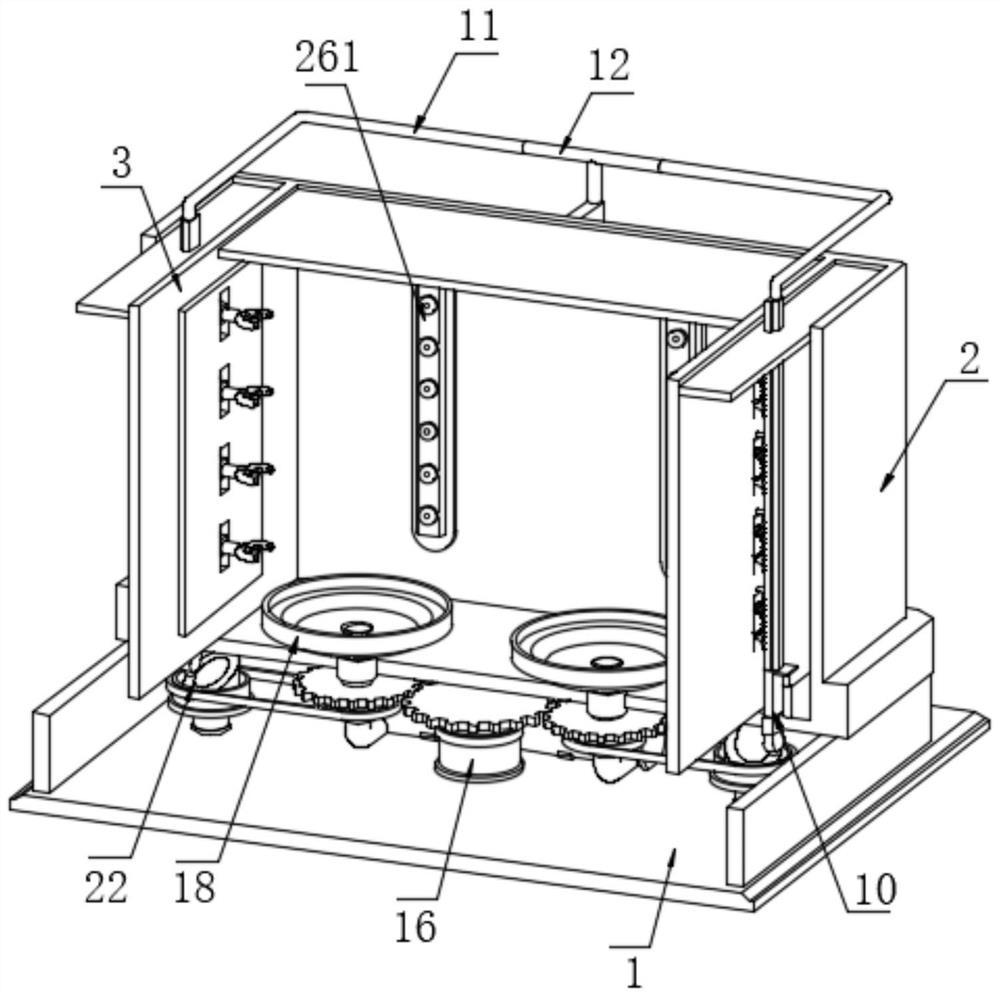

[0040] like Figure 1-6 As shown, the present invention provides a technical solution: an automatic glazing and spraying equipment for electric porcelain insulators, comprising a bottom plate 1, the upper surface of the bottom plate 1 is fixedly connected with the lower surface of the box body 2, and the box body 2 is provided with two partitions Plate 3, one side of the partition 3 is provided with four through holes 4, the through holes 4 are provided with a spraying component 5, the left side of the spraying component 5 is fixedly connected with the right side of the half toothed disc 6, and the half toothed disc 6 The middle part is set in the through hole 4 through the connecting shaft 7, and the four half toothed discs 6 are all engaged with the right side of the glaze filling assembly 9. The bottom end of the glaze filling assembly 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com