Yarn humidity adjusting device and method and bobbin winder

A technology of humidity adjustment and height adjustment mechanism, which is applied in the direction of transportation and packaging, equipment configuration for processing textile materials, processing textile material carriers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

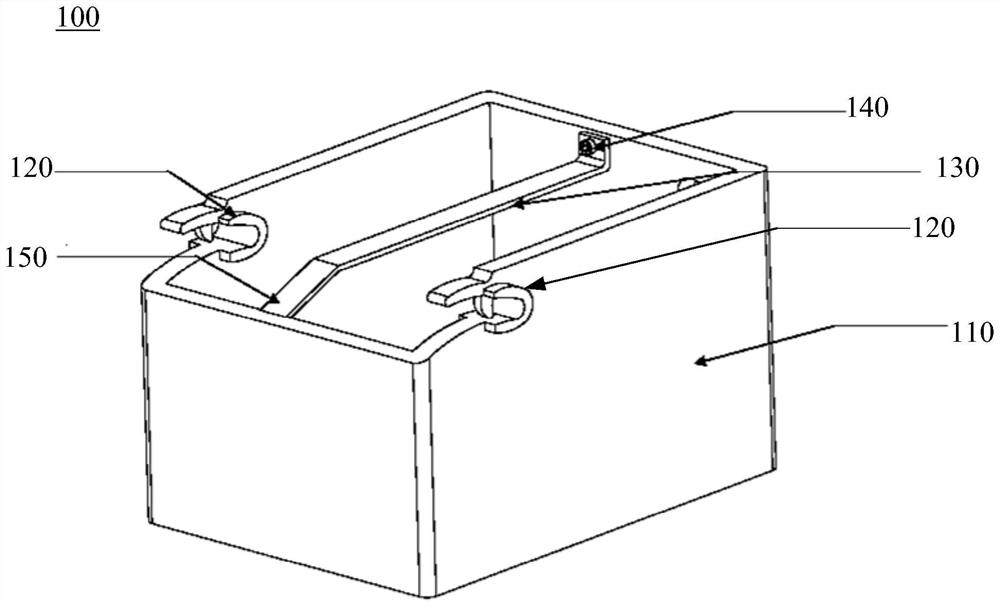

[0081] This embodiment provides a yarn humidity adjustment device 100 , which includes a liquid storage tank 110 , a yarn guide mechanism 120 , a bearing mechanism 130 , a height adjustment mechanism 140 and an elastic humidification mechanism 150 .

[0082] The liquid storage tank 110 includes a bottom plate and a plurality of side plates surrounding the bottom plate. The plurality of side plates cooperate with the bottom plate to form a groove-like structure with an upward opening for storing liquid.

[0083] The carrying mechanism 130 is a plate-like structure, one end of which is movably connected to one side wall of the liquid storage tank 110 through the height adjustment mechanism 140 , and the other end extends to the opposite side wall and straddles the liquid storage tank 110 . The height adjustment mechanism 140 is a bolt and nut assembly, and the side wall of the liquid storage tank 110 is provided with an adjustment hole matched with the height adjustment mechanism...

Embodiment 2

[0088] This embodiment provides a yarn humidity adjustment device 100 , which includes a liquid storage tank 110 , a yarn guide mechanism 120 , a bearing mechanism 130 , a height adjustment mechanism 140 and an elastic humidification mechanism 150 .

[0089] The liquid storage tank 110 includes a bottom plate and a plurality of side plates surrounding the bottom plate. The plurality of side plates cooperate with the bottom plate to form a groove-like structure with an upward opening for storing liquid.

[0090] The carrying mechanism 130 is a plate-like structure, one end of which is movably connected to one side wall of the liquid storage tank 110 through the height adjustment mechanism 140 , and the other end extends to the opposite side wall and straddles the liquid storage tank 110 . The height adjustment mechanism 140 is a bolt and nut assembly. The side wall of the liquid storage tank 110 is provided with an adjustment hole matched with the height adjustment mechanism 140...

Embodiment 3

[0096] This embodiment provides a winder. The yarn running route of the winder is as follows: a yarn guide hook, a tension disc, the yarn humidity adjustment device 100 provided in Embodiment 1, a yarn breakage sensor, a groove drum, and a wire tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com