Six-bar mechanism knee joint with knee moment controller

A technology of a six-bar mechanism and a control device, which is applied to artificial legs and other directions, can solve the problems of the movement law of the upper and lower legs, the limitation of the trajectory of the ankle joint, and the large volume of the structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

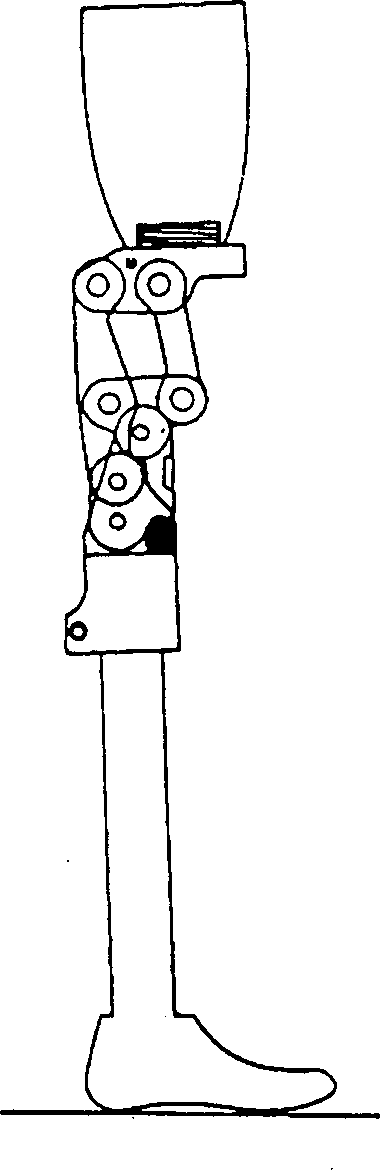

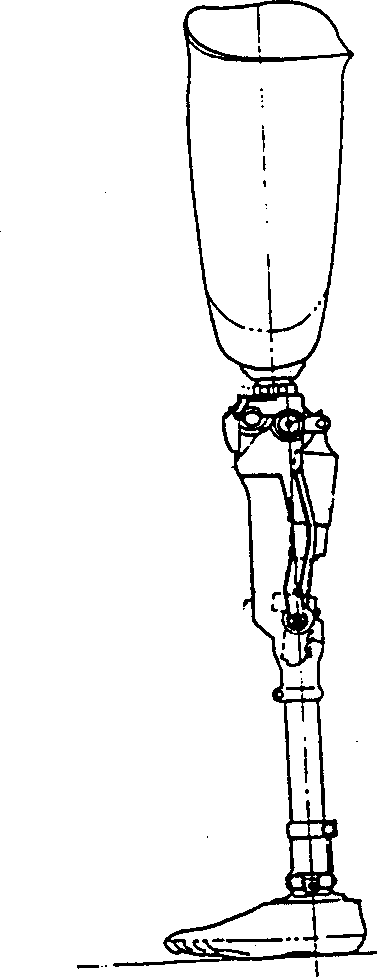

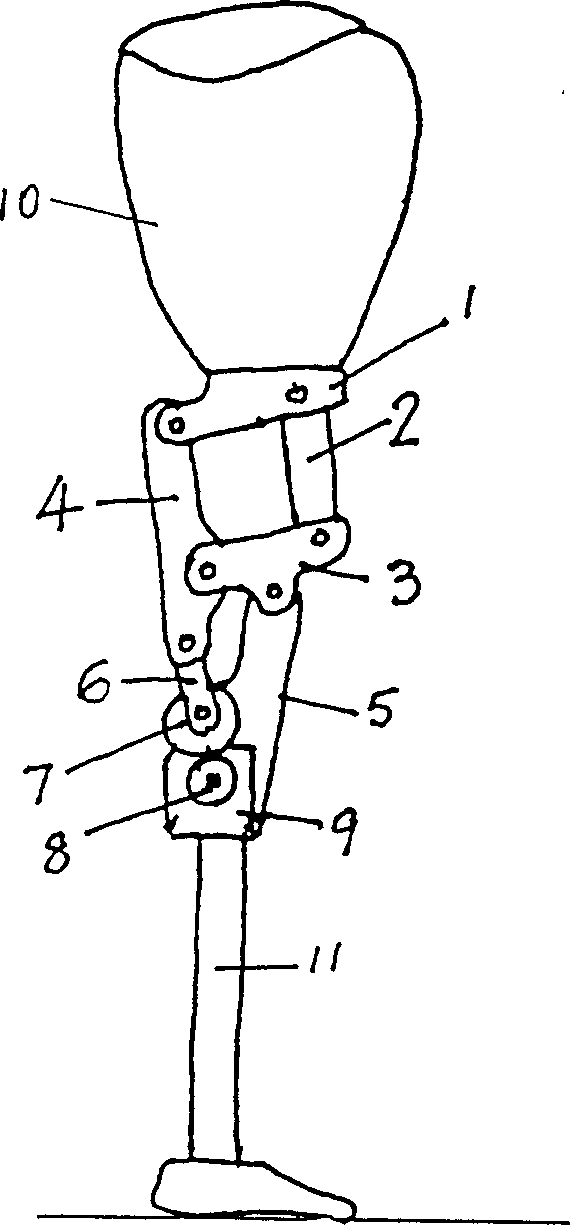

[0024] The specific structure and best implementation mode of the present invention will be described in detail below in conjunction with the accompanying drawings. image 3 , Figure 4 They are respectively the position of the knee joint mechanism of the present invention in the lower limb prosthesis and the variable schematic diagrams when the mechanism is optimally designed. The six-bar mechanism consists of component 1 (AB), component 2 (BD), component 3, (CDG), component 4 (ACE), component 5 (GF) and component 6 (EF). A~G are the seven hinge axes of the six-bar mechanism.

[0025] The thigh bar 10 is fixedly connected to the member 1, and the calf bar 11 is fixedly connected to the member 5. When the big and small legs are parallel ( image 3 ), the mechanism can be self-locking and has reliable stability.

[0026] l 1 ~ l 10 Respectively represent the rod length of the six-bar mechanism.

[0027] l 11 : The distance between the consolidation point I of thigh bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com