Real-time acquisition system of low-temp metallographer for computer

A real-time acquisition, computer technology, used in tabulation machines, preparation of test samples, computers with plug-in boards, etc., can solve problems such as the inability to observe the dynamic change process of metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

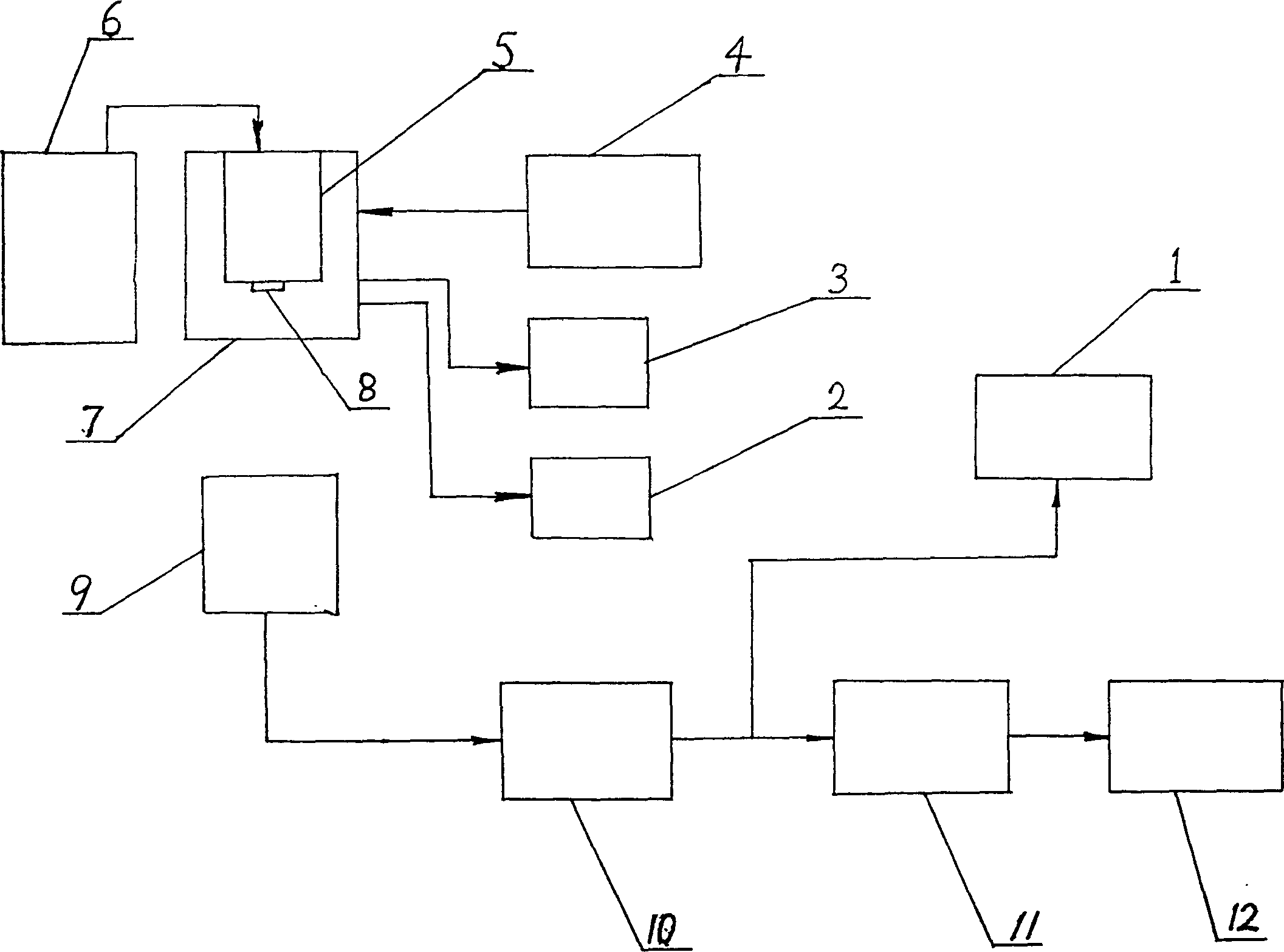

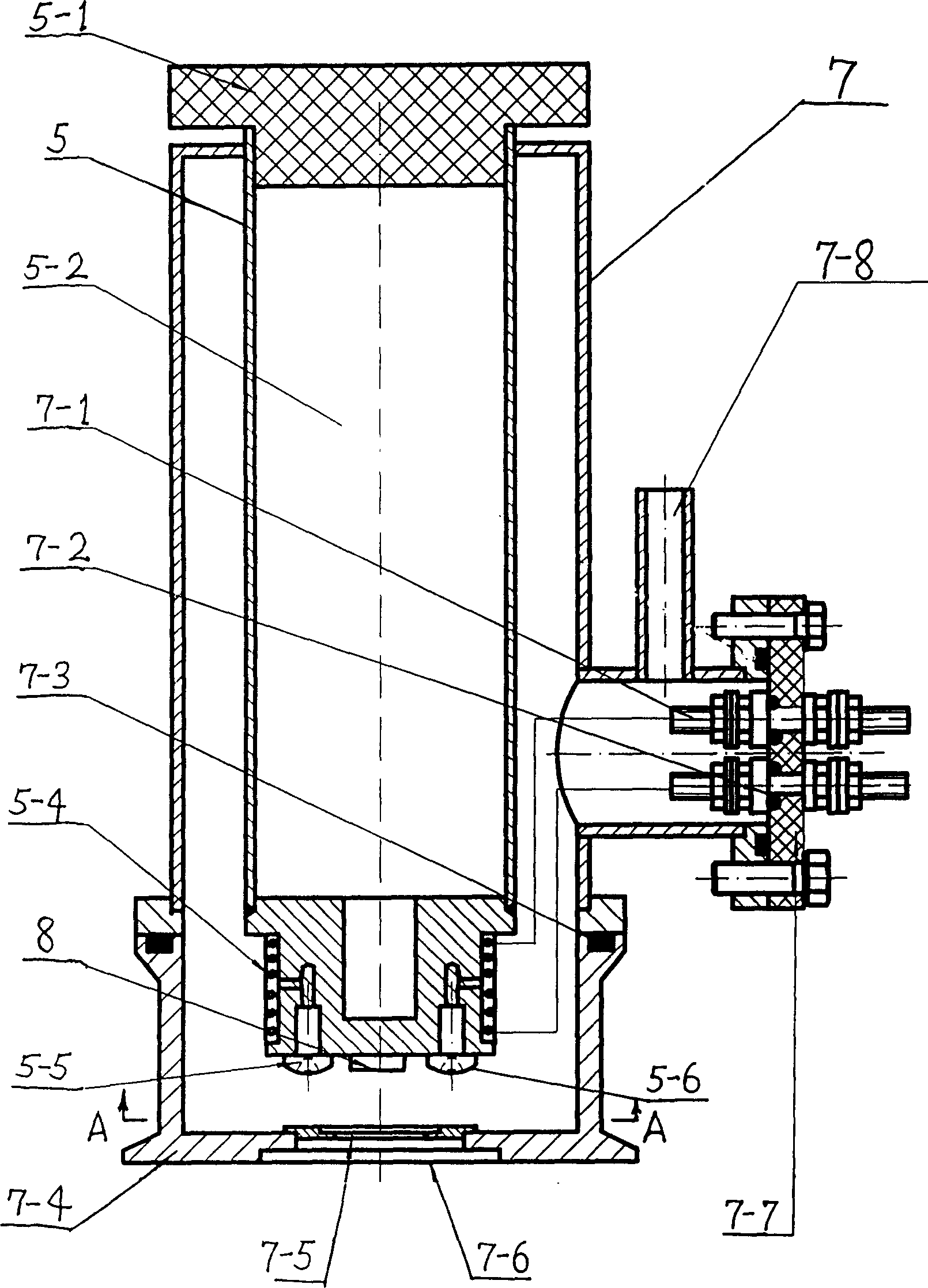

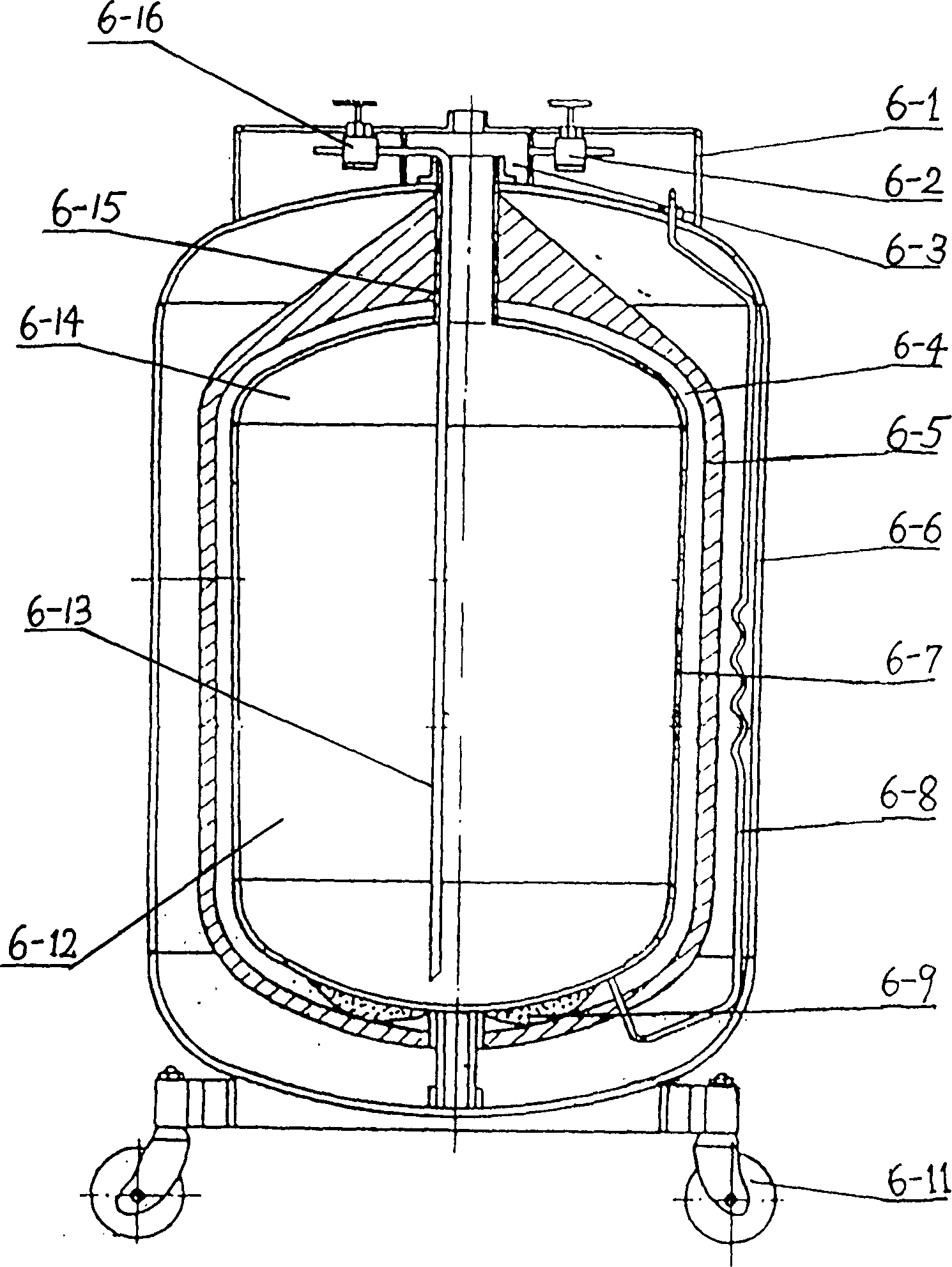

[0010] Such as figure 1, figure 2, Figure 4 As shown, the liquid nitrogen tank 5 is set on the vacuum tank 7, the high-vacuum low-temperature insulation device is placed on the stage of the metallographic microscope 9, and the vacuum pump 4 draws out the air in the vacuum tank 7 through the air extraction interface 7-8 to automatically increase The pressing and discharging device 6 supplies liquid nitrogen 5-2 to the liquid nitrogen tank 5. The junction of the thermocouple 5-5 is set near the metallographic sample 8, and the other end passes through the electrode column 7-1 (two groups of 4) The 2 electrode columns are connected with the thermometer 3. Thermometer 3 is a universal secondary temperature measurement instrument. At the lower end of the liquid nitrogen tank 5 is an electric heating coil 5-4 for heating the metallographic sample 8, and the resistance heating device 5-4 is connected to the adjustable heating power source 2 through the two electrode columns of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com