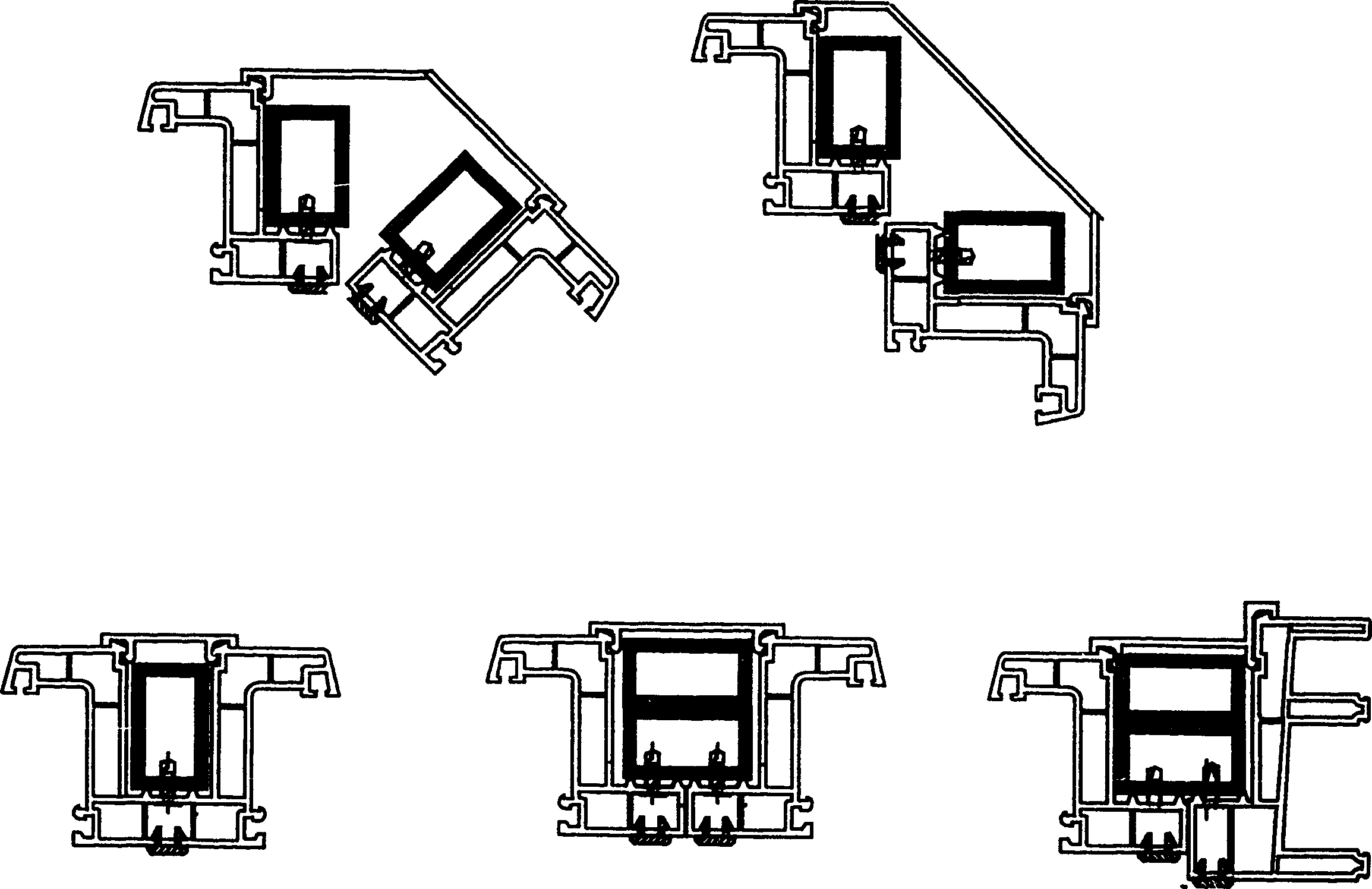

Frame steel-lined welded plastic door and window and their manufacture and mounting method

A technology of plastic steel doors and windows and lining steel, applied in the direction of wing fan frame, etc., can solve the problems of difficult doors and windows, increase construction period, low strength and rigidity, etc., and achieve the effect of improving sealing reliability, improving mechanical performance and uniform gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

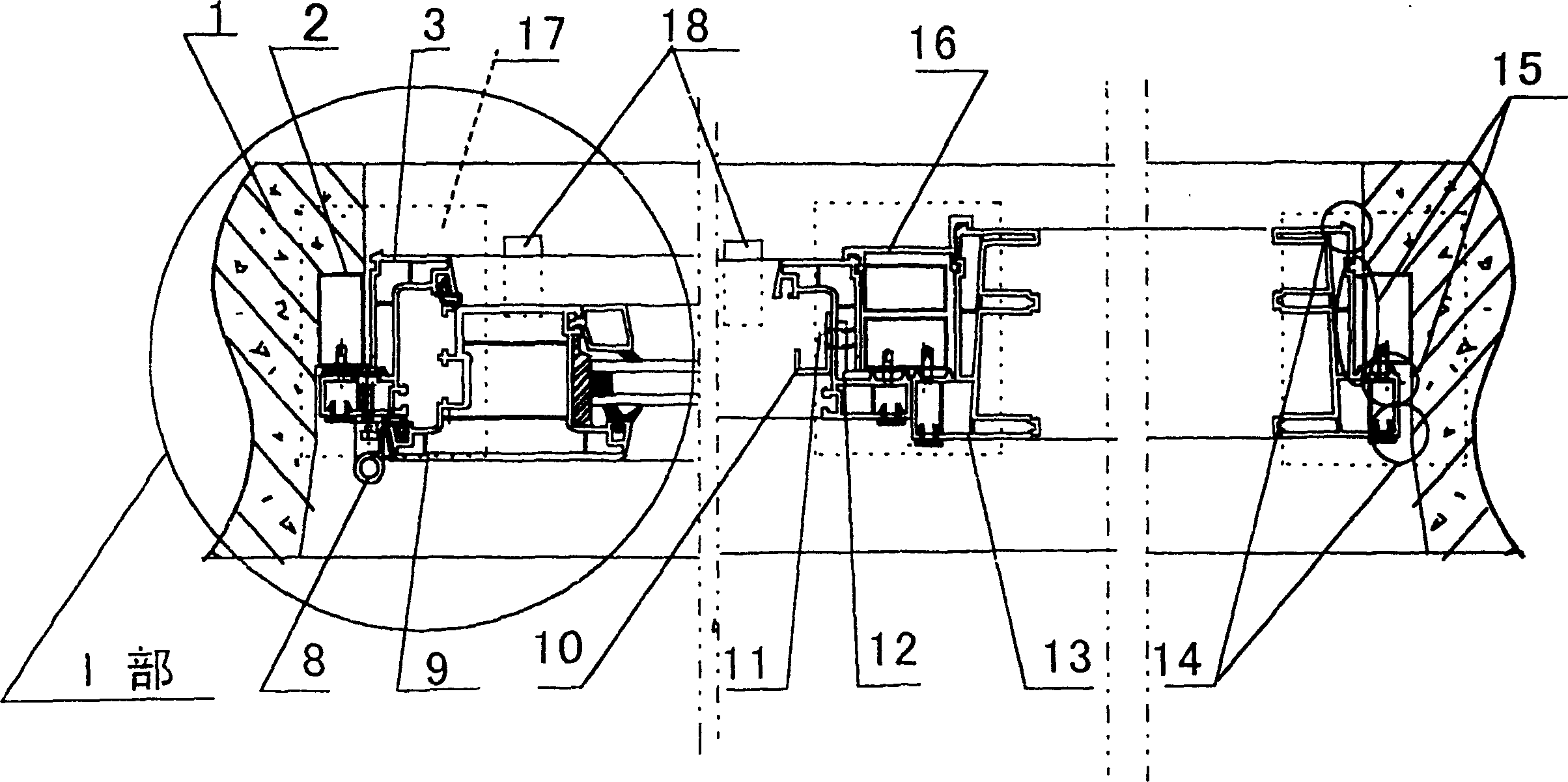

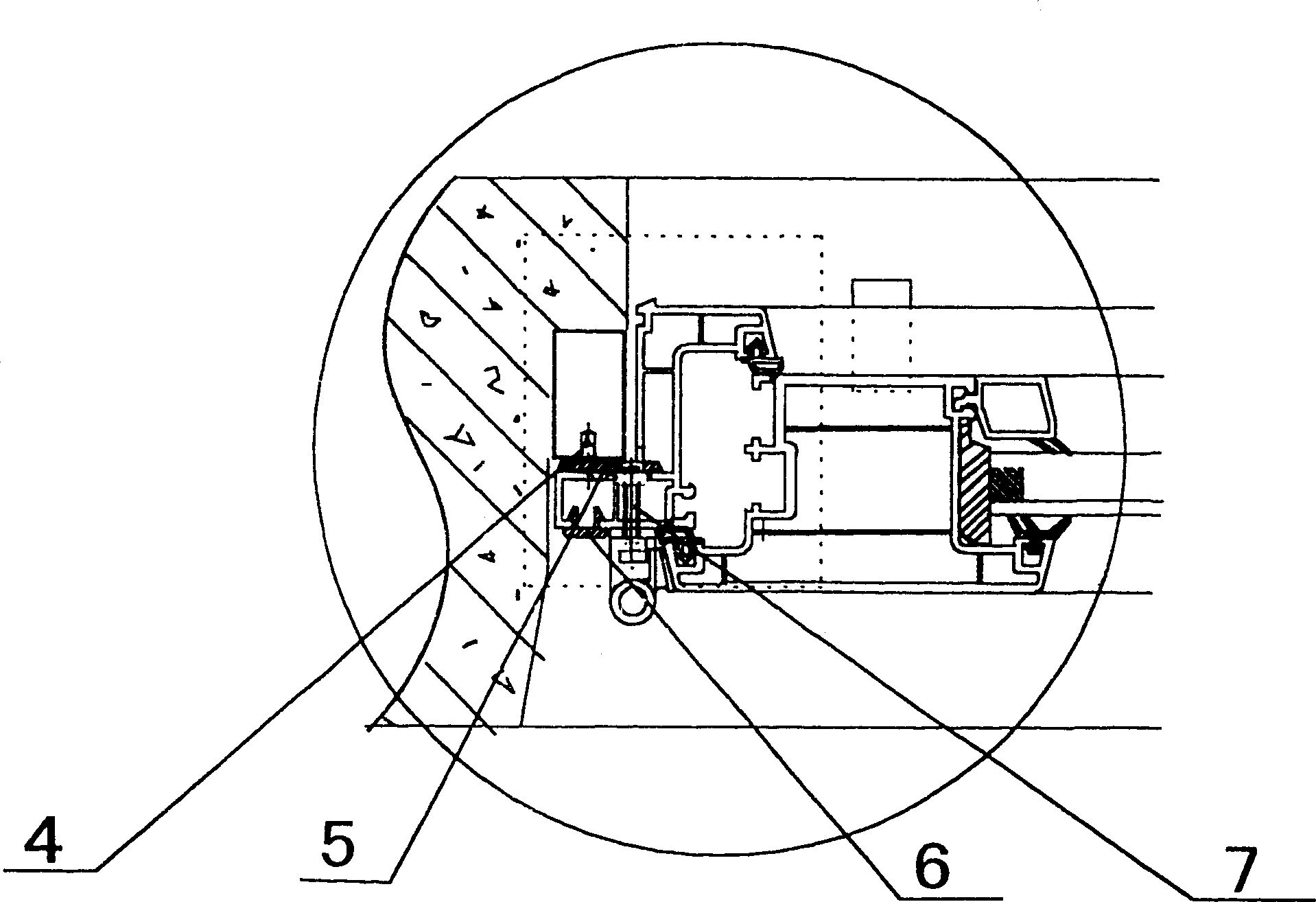

[0011] The steel-lined cavity of the plastic frame is open, and a snap-in structure for easy sealing is designed at the opening. The lining steel is welded into a steel frame and pre-embedded ( Figure 2-2 , 17); the plastic frame profile is processed and assembled to form a window. Place the crafting block ( diagram 2-1 8), play the foaming agent in the groove of the window frame ( diagram 2-1 5), insert the finished window into the steel frame, apply glass glue to the groove of the sealing cover plate and snap it in ( diagram 2-1 6), the lining steel nail is fixed by the side ( figure 2 -4), plug the process hole cover ( figure 2 -6), pull out the craft block ( diagram 2-1 8), apply glass glue on both sides ( diagram 2-1 4). When the window is installed, the plastic frame is reinforced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com