Centrifugal pressurized separators and methods of controlling same

A separator and pressure sensor technology, applied in separation methods, centrifugal separation water/sewage treatment, chemical instruments and methods, etc., can solve problems such as difficulty in separation, and achieve the effect of reducing the amount of liquid and preventing the phenomenon of vortex transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

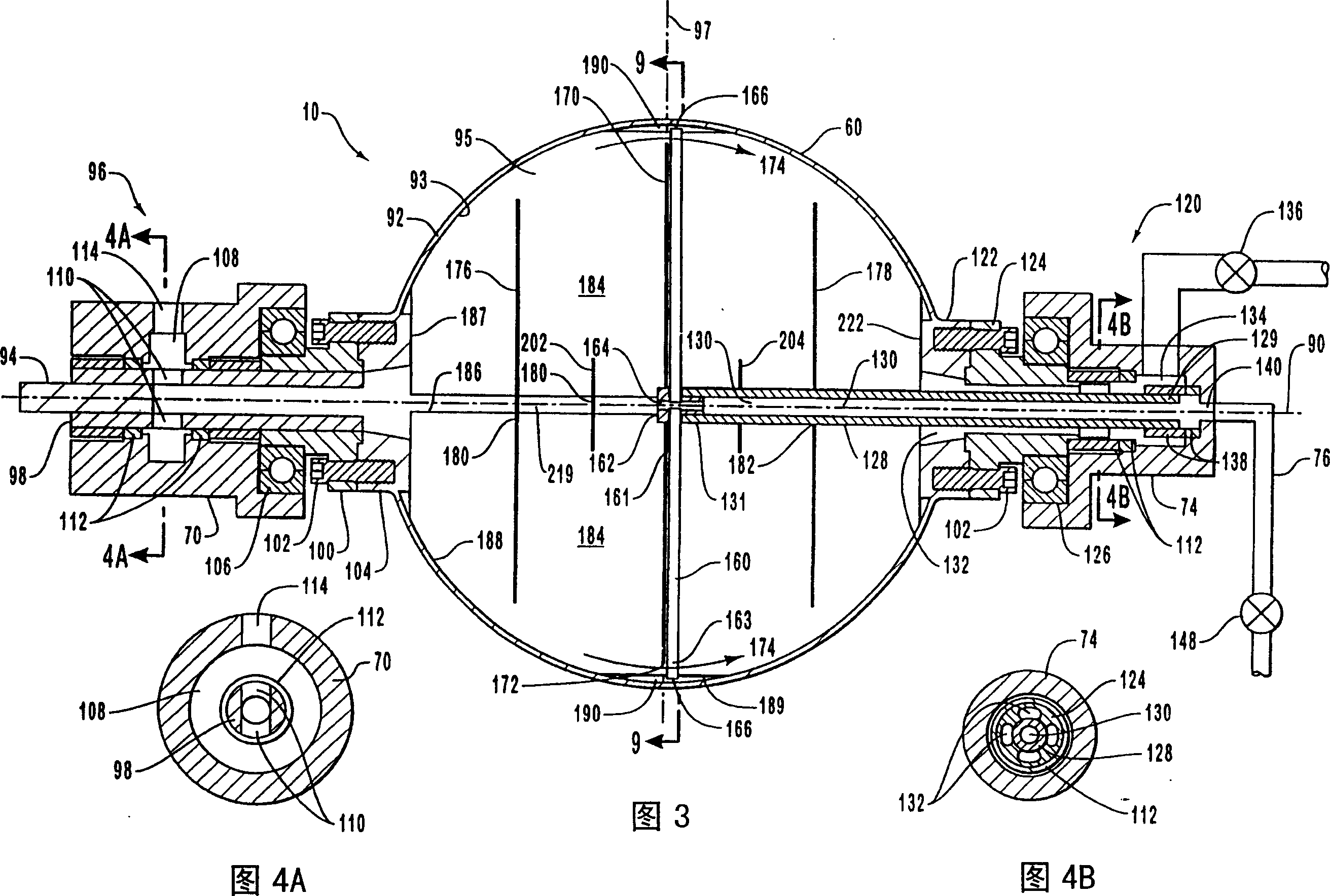

[0046] The present invention relates to a system for purifying water contaminated with particulate matter, both organic and non-organic.

[0047] The invention also relates to a system for separating immiscible liquid (for example separating an oil / water) mixture. Referring now to the drawings, in which like reference numerals indicate like parts, operations or structures. The figures should be regarded as schematic and / or schematic and not necessarily drawn to scale, nor do they limit the spirit and scope of the present invention.

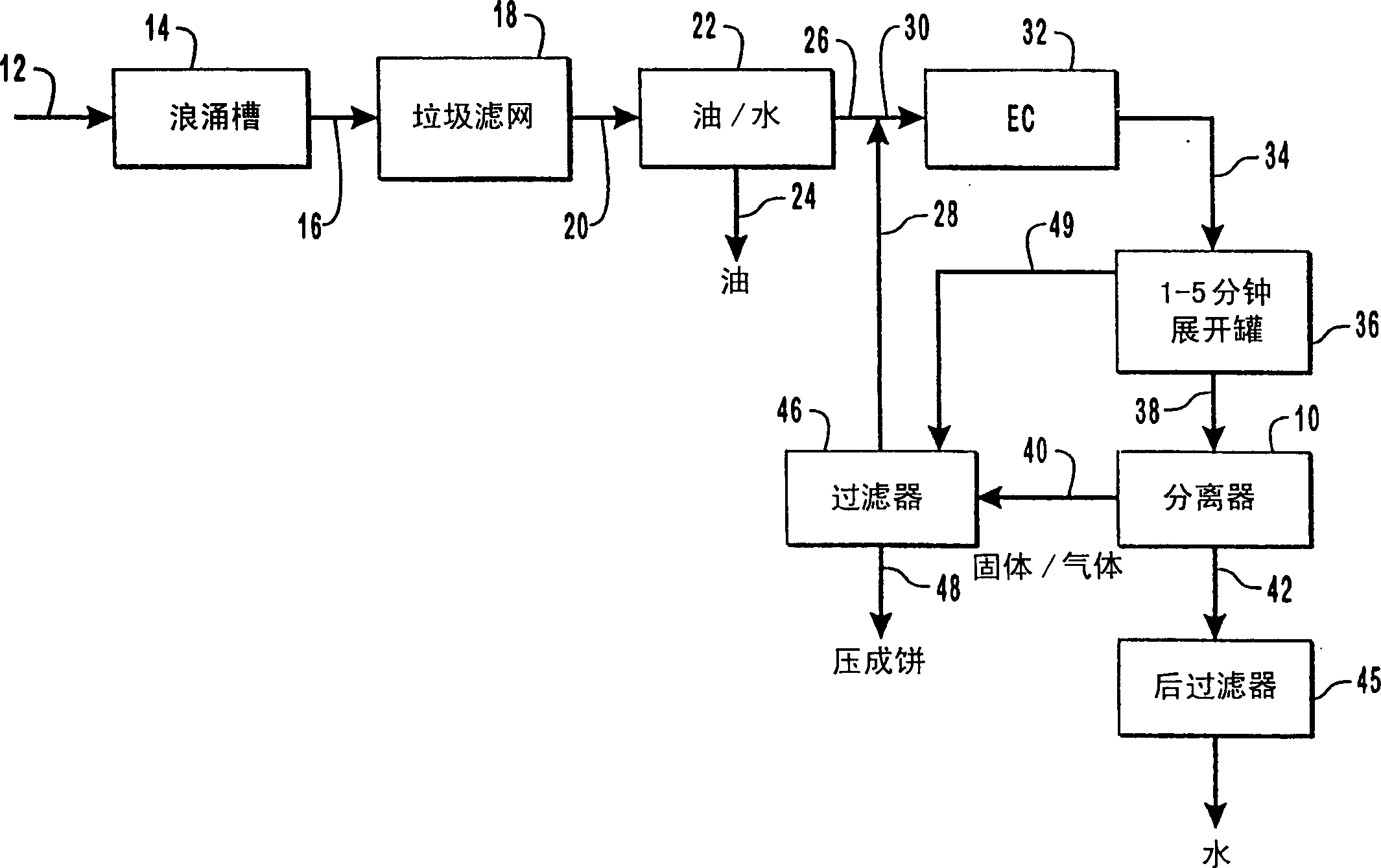

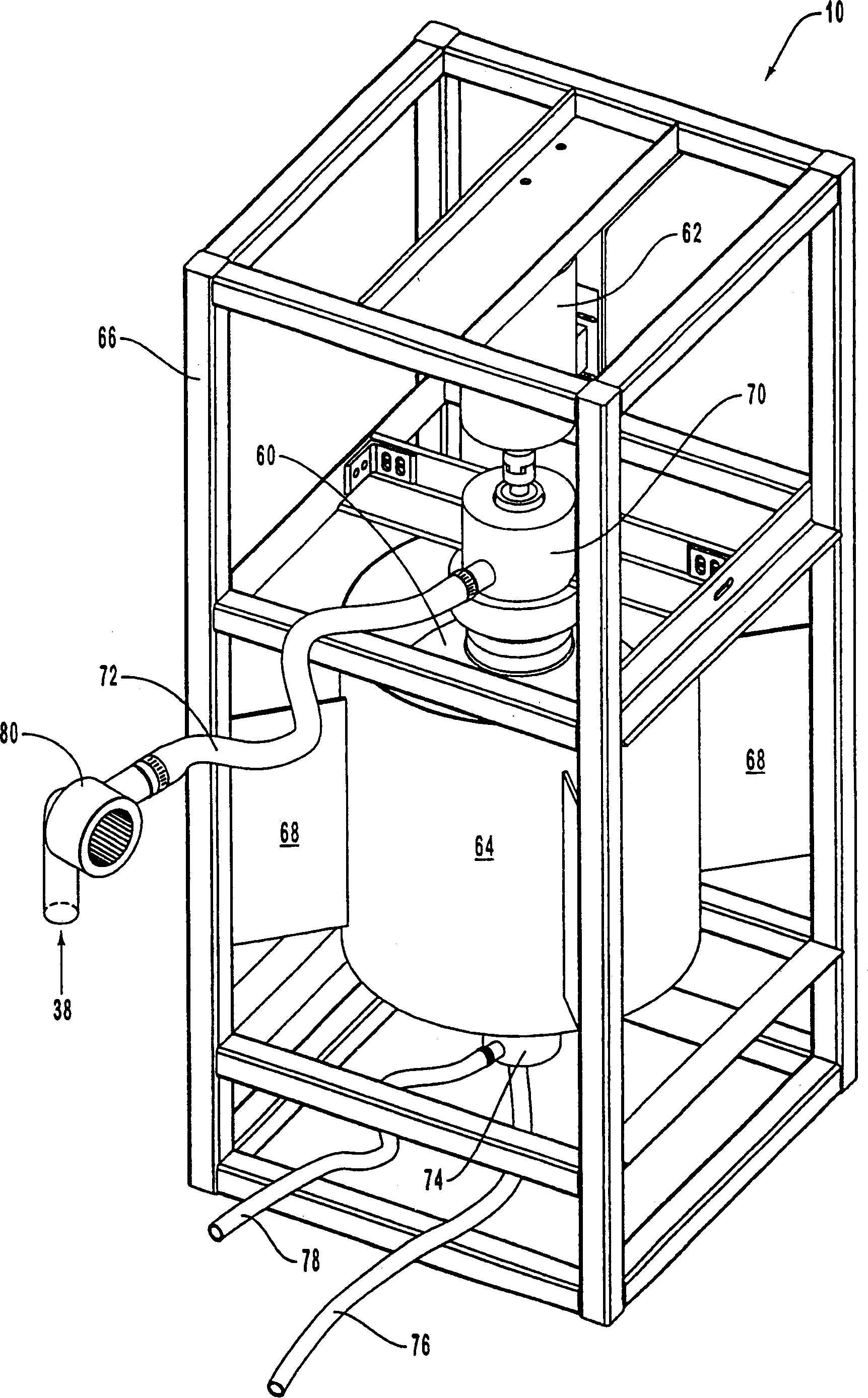

[0048] figure 1 is a general structure diagram of a process using the solid-liquid separator of the present invention; as figure 1 As illustrated in , a solid-liquid separator 10 is connected to a series of other process components. A configuration may include a source stream 12 comprising a stream of material to be processed. Feed stream 12 may include a wide variety of components, such as water including contaminants such as oils, bacterial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com