Wedge base electric light bulb

A wedge-shaped base and light bulb technology, applied to discharge lamps, gas discharge lamps, gas discharge lamp parts, etc., can solve discoloration or peeling off, unbearable paint, difficult to prevent glass bubble coating spots or pores, etc. achieve low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

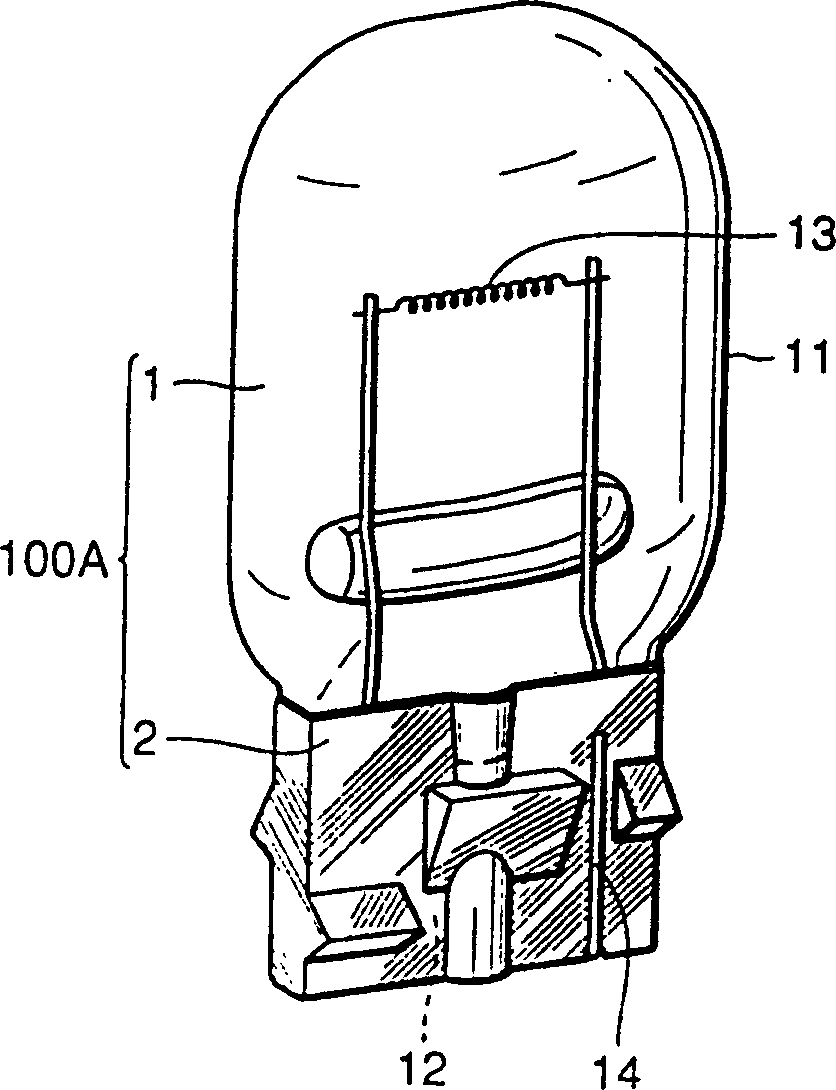

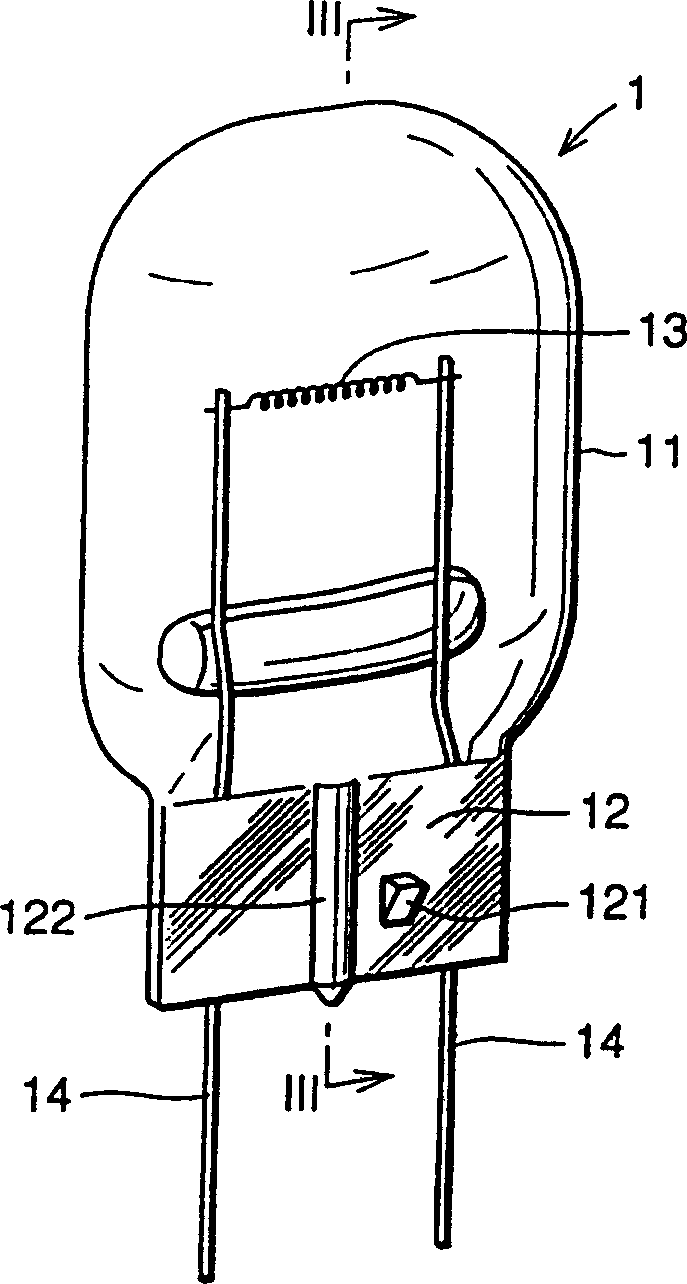

[0025] Hereinafter, a wedge-shaped light bulb according to an embodiment of the present invention, a manufacturing method thereof, and an insulating collar using the wedge-shaped light bulb will be described with reference to the accompanying drawings.

[0026] The structure of the wedge-shaped base light bulb will now be described.

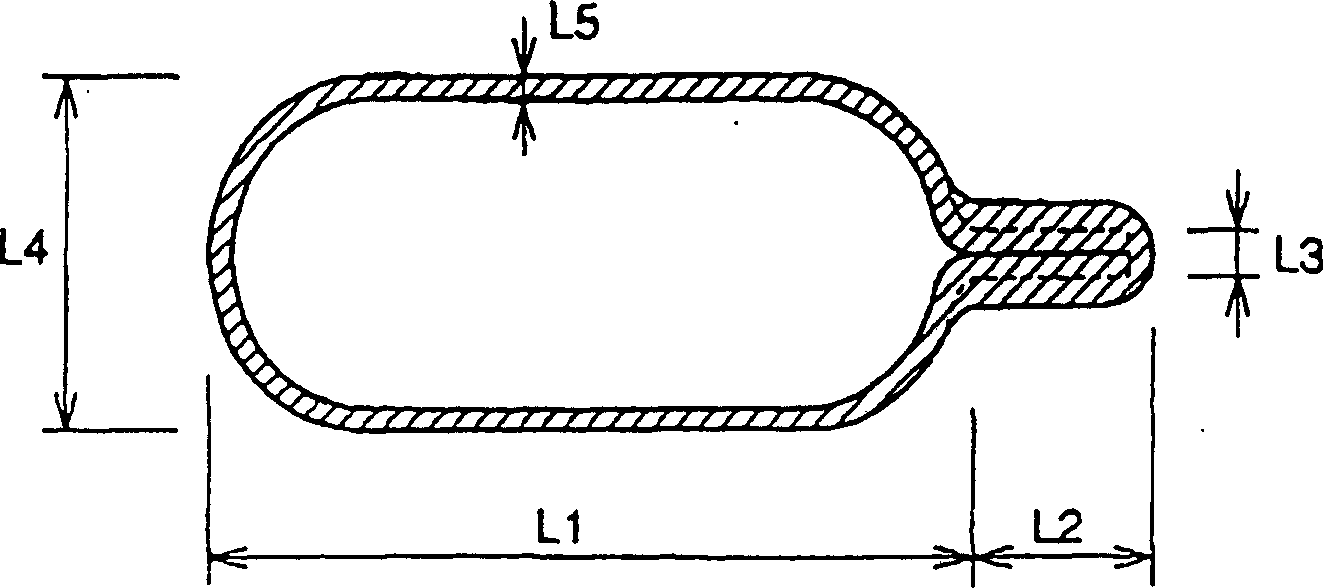

[0027] refer to figure 1 and figure 2 , the structure of the wedge base light bulb 100A in this embodiment will be described. This wedge base light bulb 100A has a light bulb body 1 and an insulating collar 2 . The head of the light bulb body 1 is hemispherical, and the body has a substantially cylindrical colored glass bulb 11 and a pressurized sealing portion 12 . A filament 13 is housed in the colored glass bulb 11 . The filament 13 is connected to a lead wire 14 whose distal end side is connected to the filament 13 and whose proximal end side is exposed from the pressure sealing part 12 .

[0028] The base end side of the lead wire 14 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com