Fuel box fixing structure for small ships

A technology for fuel tanks and boats, which is applied in the field of fixed structure of fuel tanks, and can solve problems such as inability to position and fix in a stable state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

[0028] Embodiments of the present invention will be described below with reference to the drawings.

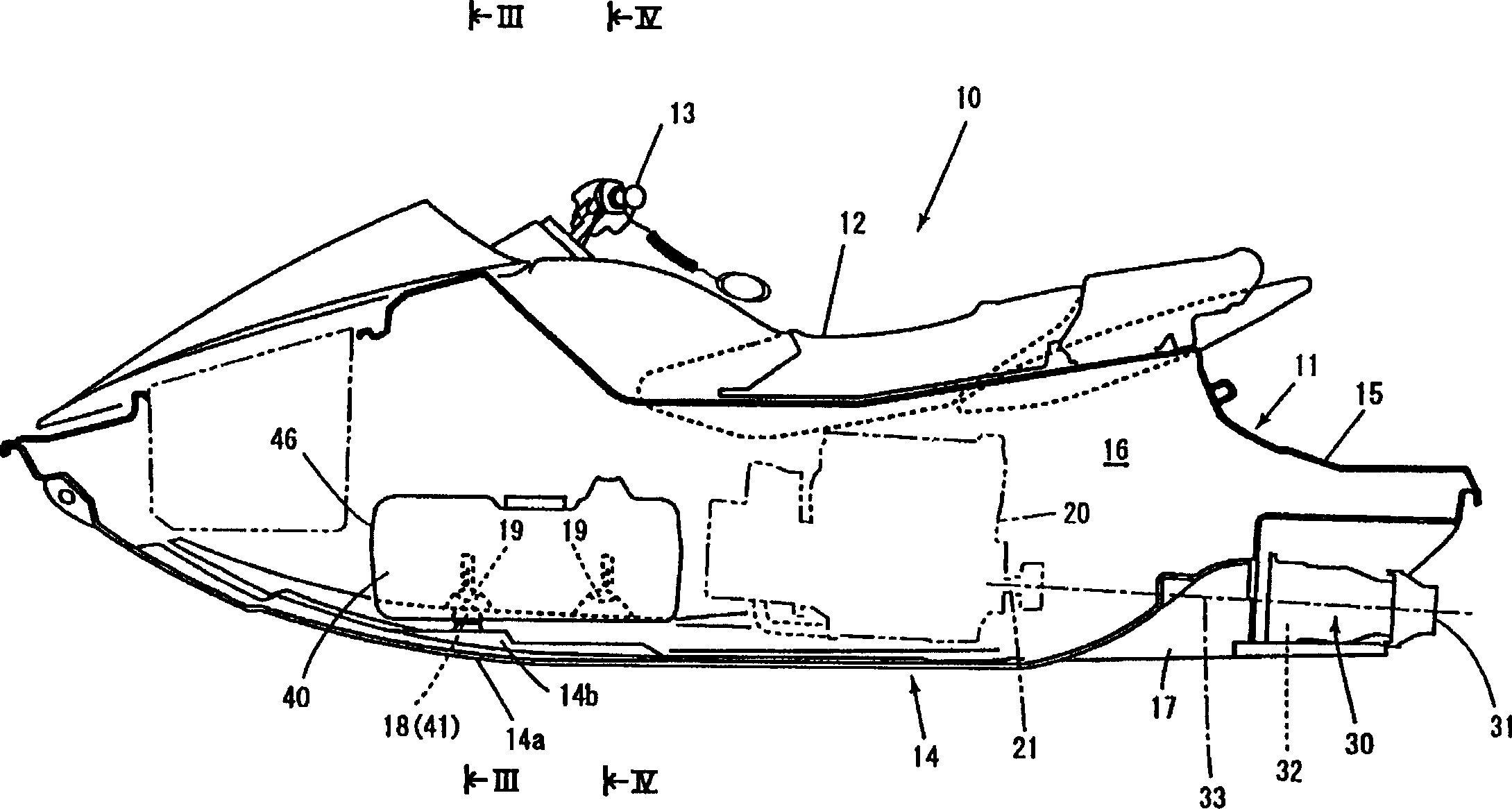

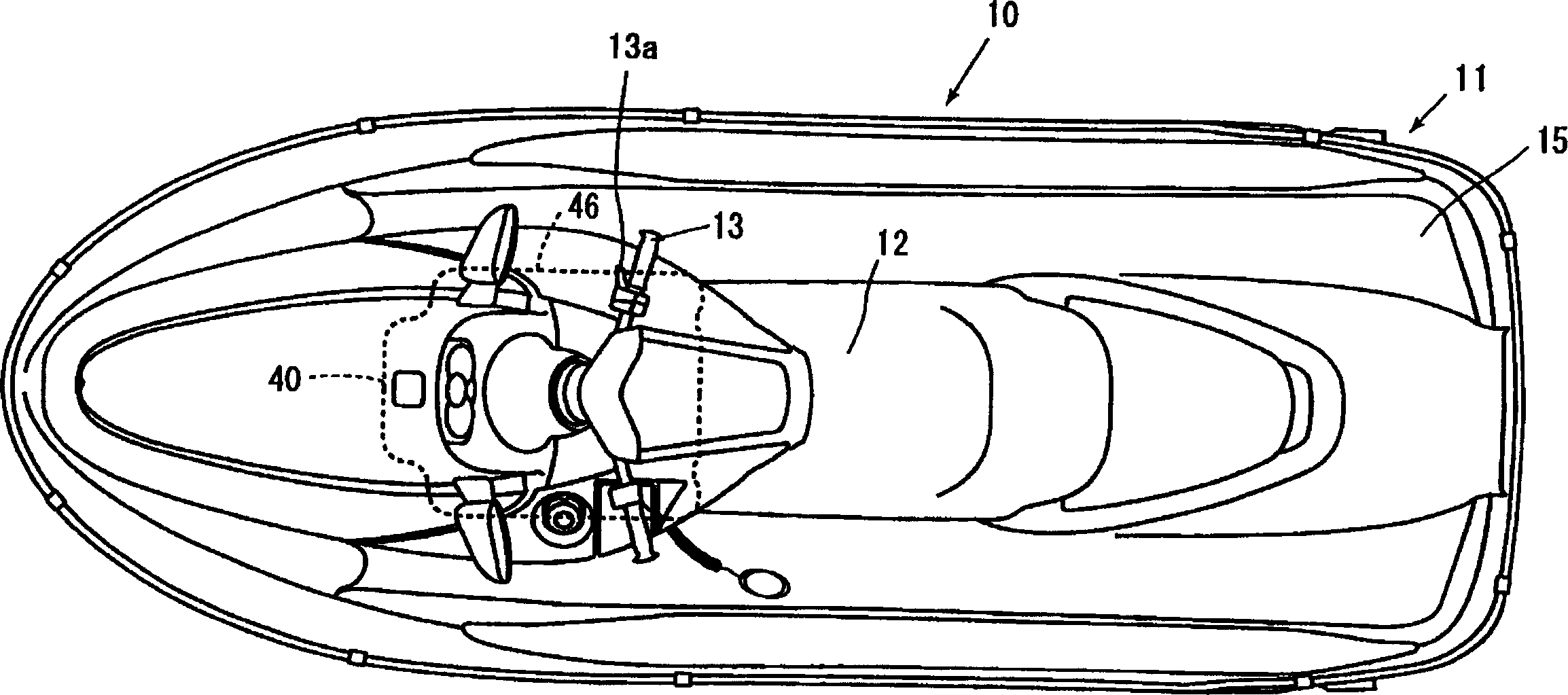

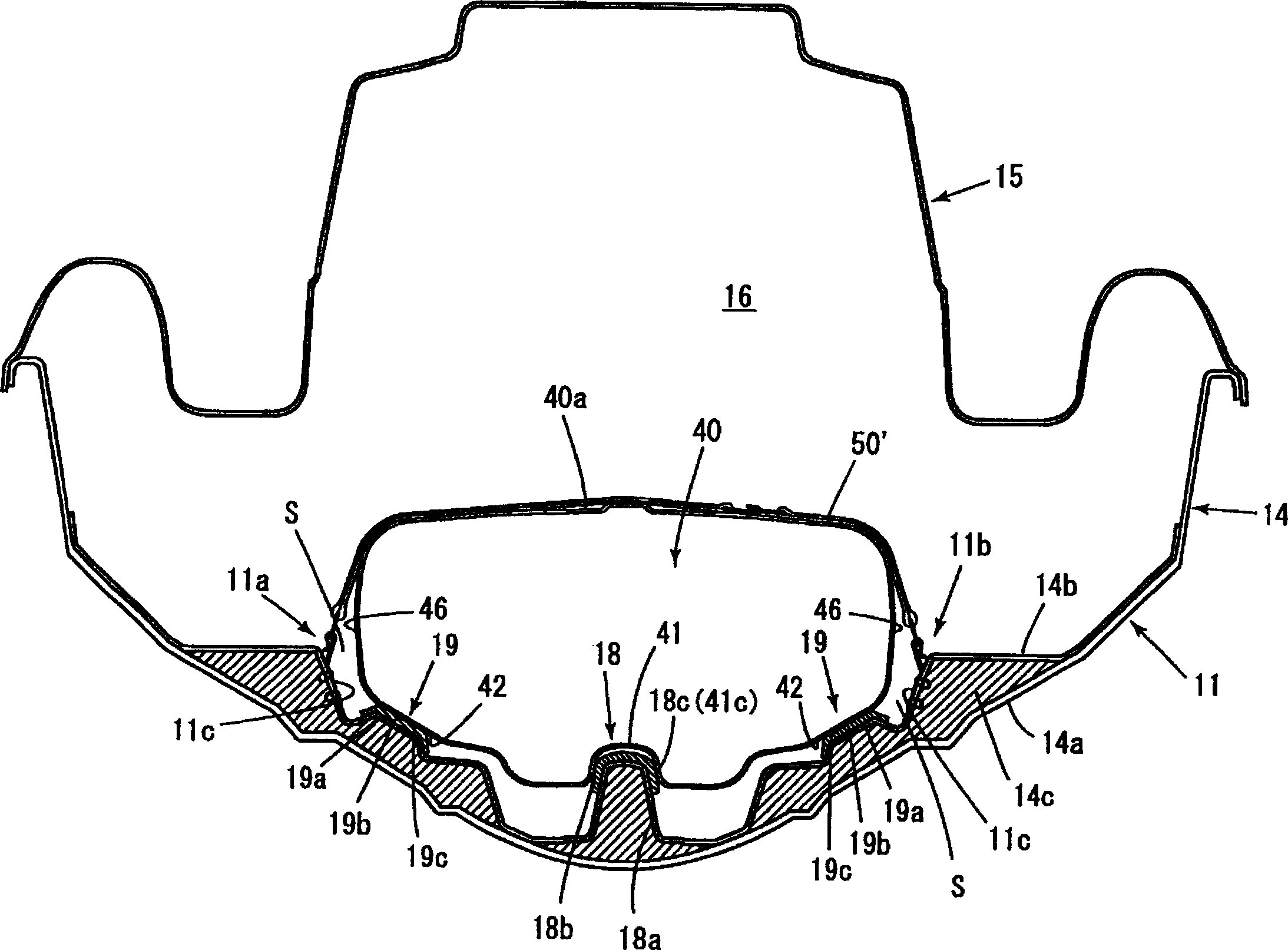

[0029] figure 1 It is a partially omitted side view showing an example of a small watercraft employing an embodiment of the fuel tank fixing structure of the present invention; figure 2 is the same figure 1 floor plan. image 3 yes figure 1 Part III-III cross-sectional view is omitted; Figure 4 yes figure 1 Part IV-IV sectional view is omitted; Figure 5 It is a schematic perspective view of the fuel tank mounted part at the bottom of the inner wall of the hull; Figure 6 is the bottom view of the fuel tank.

[0030] As shown in these figures (mainly figure 1 ), the small boat 10 of this embodiment is a saddle type small boat, and the occupant sits on the seat 12 on the hull 11 and can hold the belt adjustment rod 13a (refer to figure 2 ) of the steering handle 13 to operate.

[0031] The hull 11 is a floating body struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com