A workpiece positioning device

A technology for positioning devices and workpieces, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve problems such as increasing labor intensity of workers, increasing costs, and difficulty in unloading workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

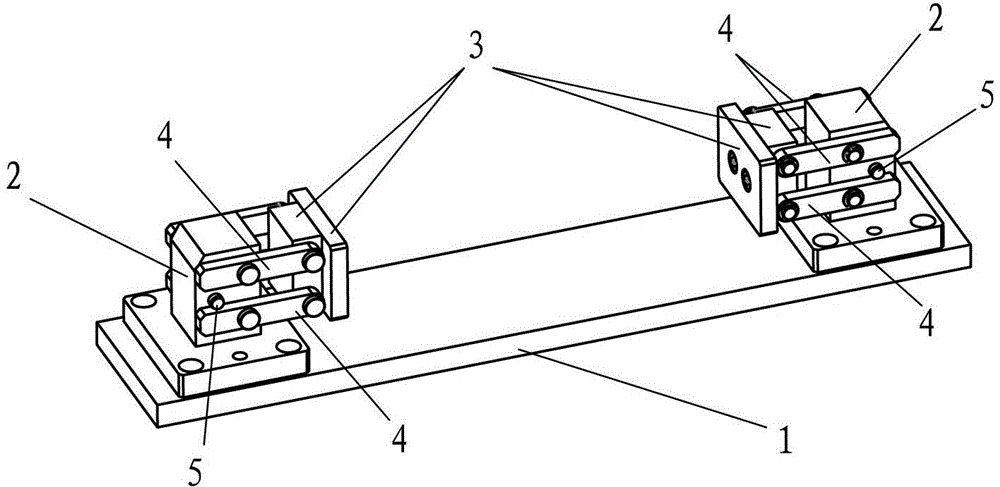

[0016] A workpiece positioning device, comprising a base 1 and two bases 2, the two bases 2 are fixed on the base 1 by bolts, the distance between the two bases 2 can be adjusted to the workpiece to be processed Fixed when matching the length. A positioning baffle 3 is respectively arranged on the opposite sides of the two bases 2, and the working surfaces of the two positioning baffles 3 are arranged oppositely;

[0017] Each of the left and right sides of each positioning baffle 3 is connected to the base 2 through two rocking arms 4 arranged in parallel up and down, and the rocking arms 4 are connected to the base 2 and the positioning baffle 3 respectively. Rotatably pivoted, the center distances of the two ends of the two rocker arms 4 are equal to each other, the distance between the centers of the two shafts on the positioning baffle 3 and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com