Liquid container

A liquid container, container technology, applied in the field of flexible containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

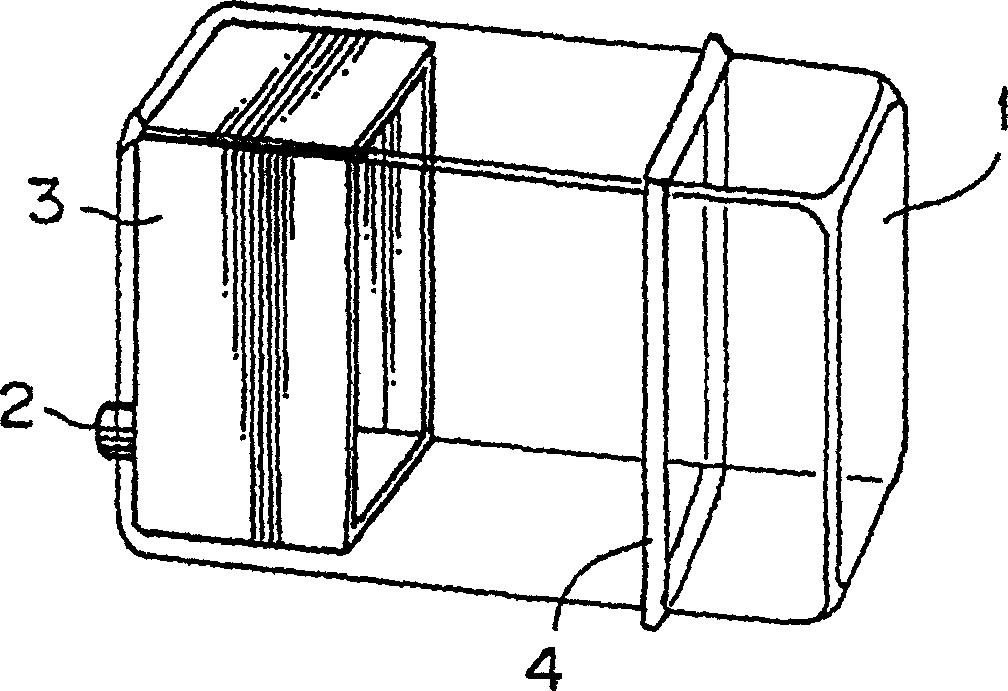

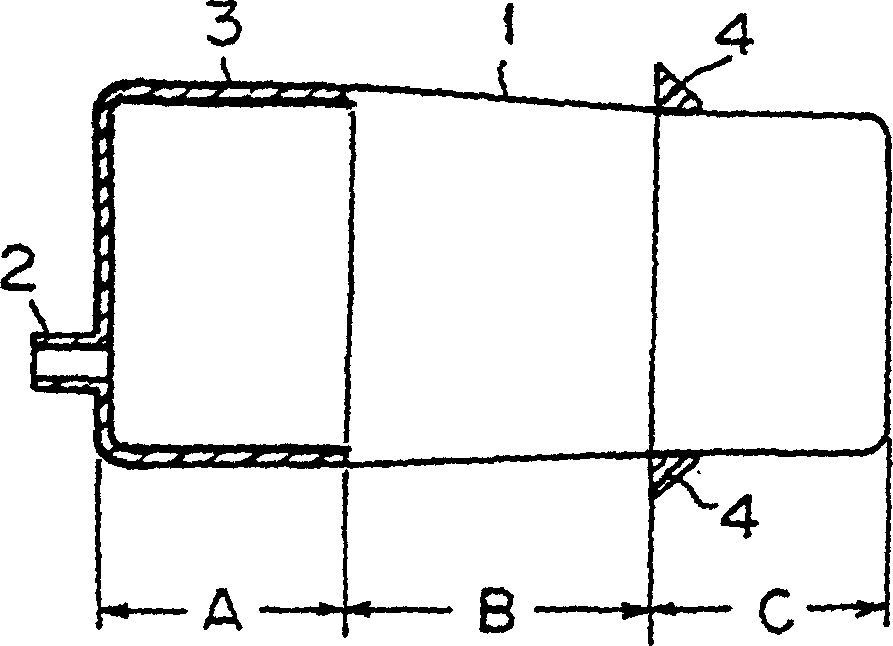

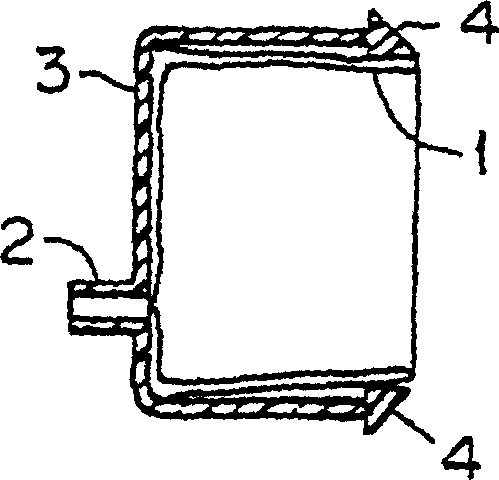

[0024] figure 1 The container has a container body 1 arranged in the form of a flexible bag made of plastic film. The container body 1 may be formed in an almost quadrangular prism shape when filled with a liquid. The container body 1 is provided with a pouring outlet 2 on the lower part of a closed end surface, and the outlet 2 is formed to communicate with the inner side of the container body 1 and protrude outward from the container body 1 . Furthermore, the container body 1 is internally provided with a support 3 adjacent to the end face provided with the pouring spout 2 . The support 3 has a box shape and is composed of a rectangular hard end wall adjacent to the end face and side walls extending vertically from the four sides of the end wall along the four sides of the container body 1, and the pouring outlet 2 passes through the support 3 and connected to the end wall to keep the support 3 at a predetermined position in the container body. The end wall and the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com