Handling roller

A technology for conveying rollers and rollers, which is applied in the field of conveying rollers for recording media, and can solve the problems of different conveying accuracy, uneven contact pressure, and uneven contact pressure of crimping rollers 6, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

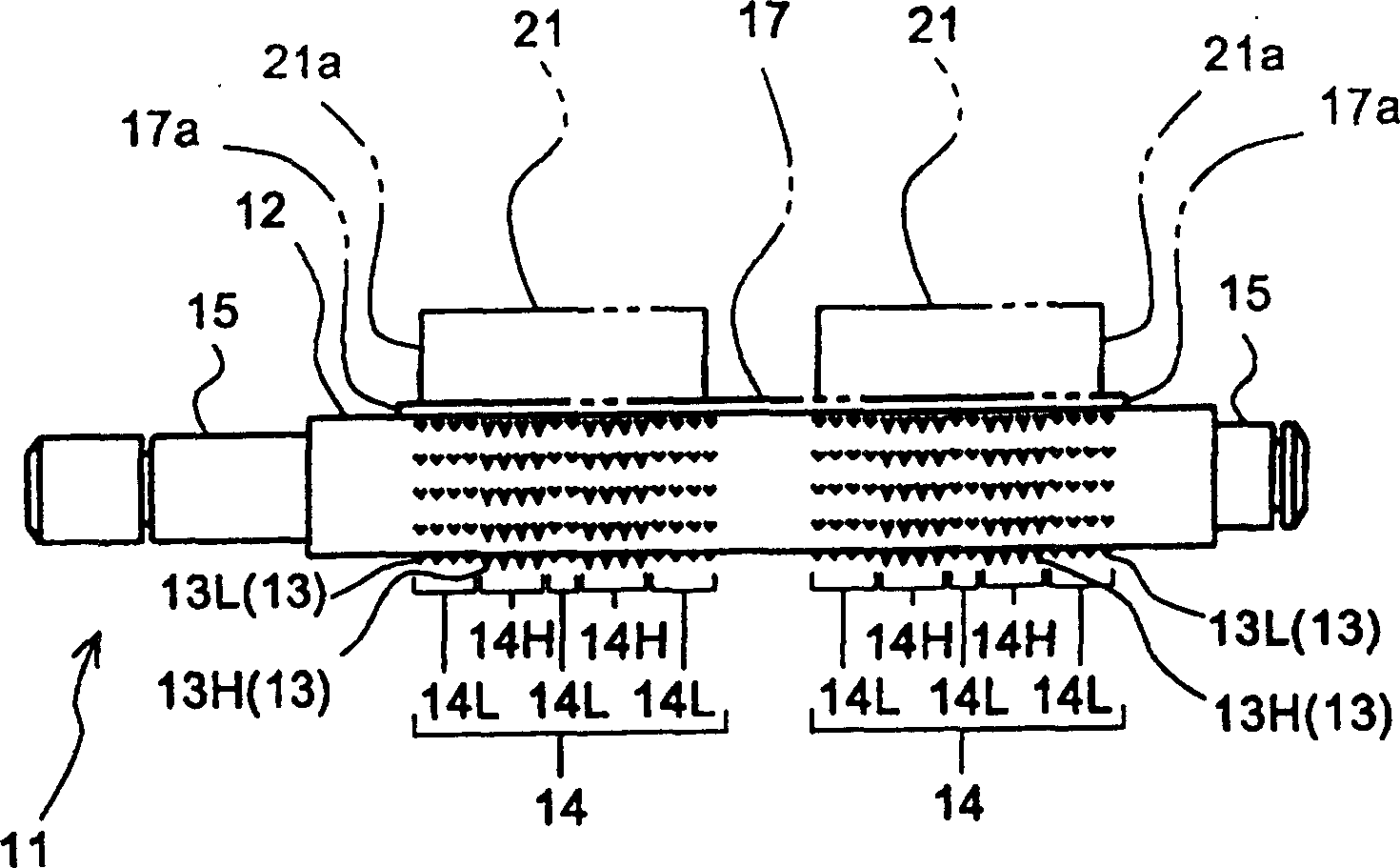

[0025] figure 1 An example in which the transport roller of the present invention is applied to a paper transport roller as a recording medium transport unit in a recording device is shown.

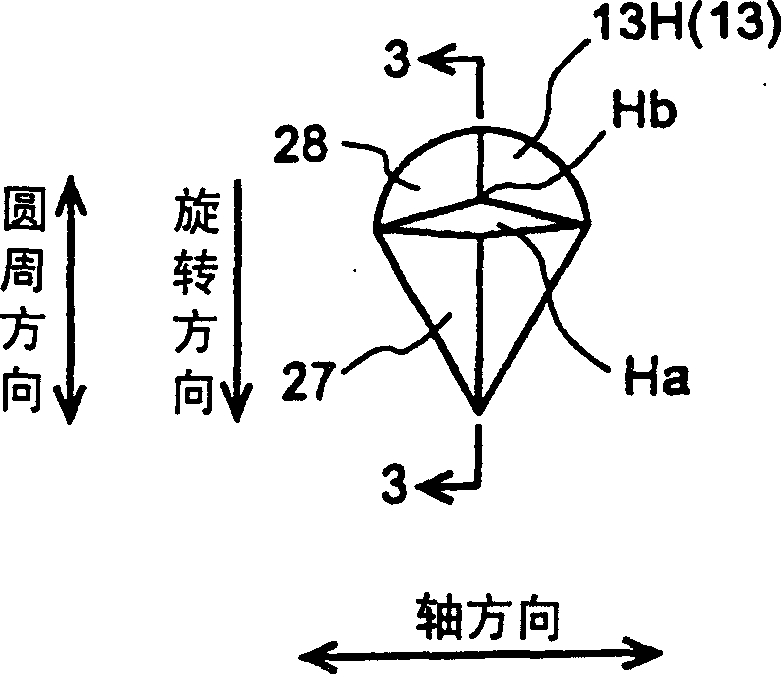

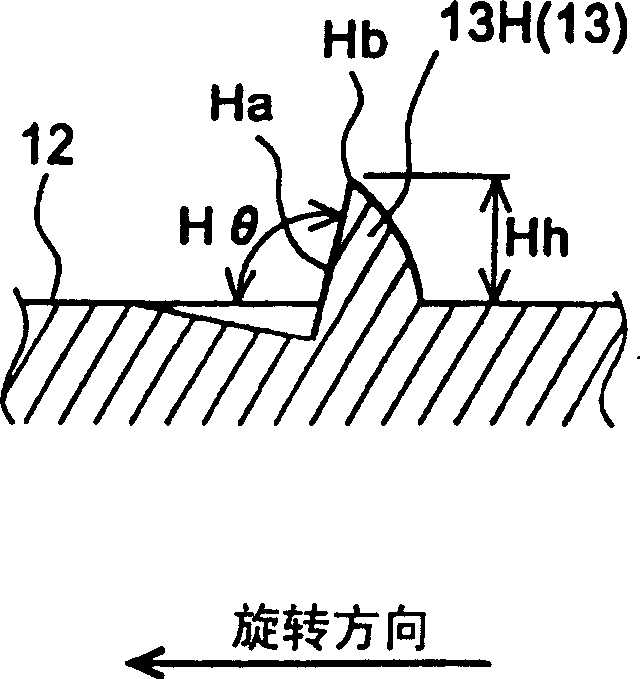

[0026] Such as figure 1 As shown, the conveying roller 11 of the present invention includes a metallic roller main body 12 formed of a metal material such as stainless steel, the two ends of which are stepped cylinders with small diameters. And at the both ends in the inner axial direction of the outer peripheral surface formed with a large diameter of the metal drum main body 12, there are respectively provided with a simplified and amplified shape shown in figure 1 The protrusion forming parts 14, 14 of a plurality of micro protrusions 13. These protrusion forming portions 14, 14 are located with figure 1 The relative positions of the crimping rollers 21 indicated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com