A detection and remanufacturing equipment for a failed guide sleeve for an oil cylinder

A guide sleeve and remanufacturing technology, applied in welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of guide sleeve processing and use limitations, rust pit guide sleeve, etc., and achieve the effect of improving conveying accuracy and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

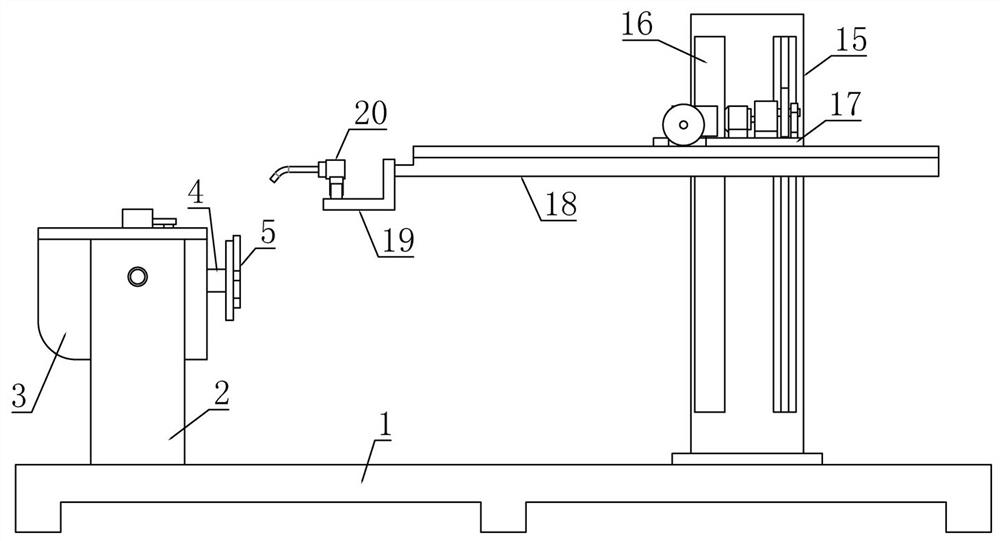

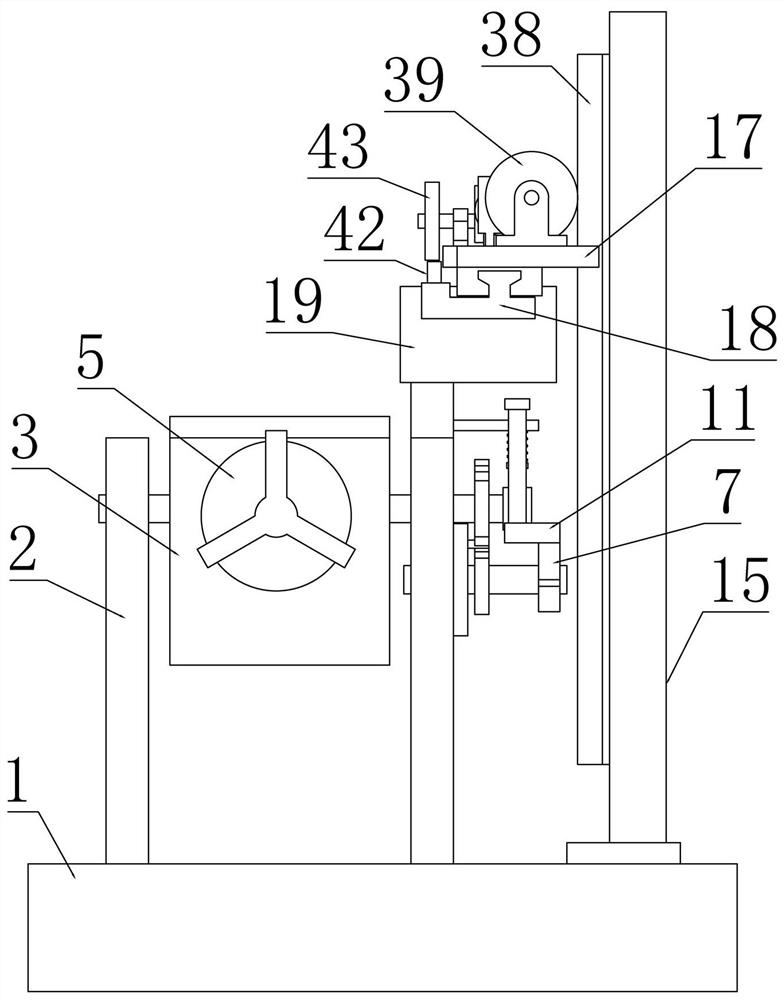

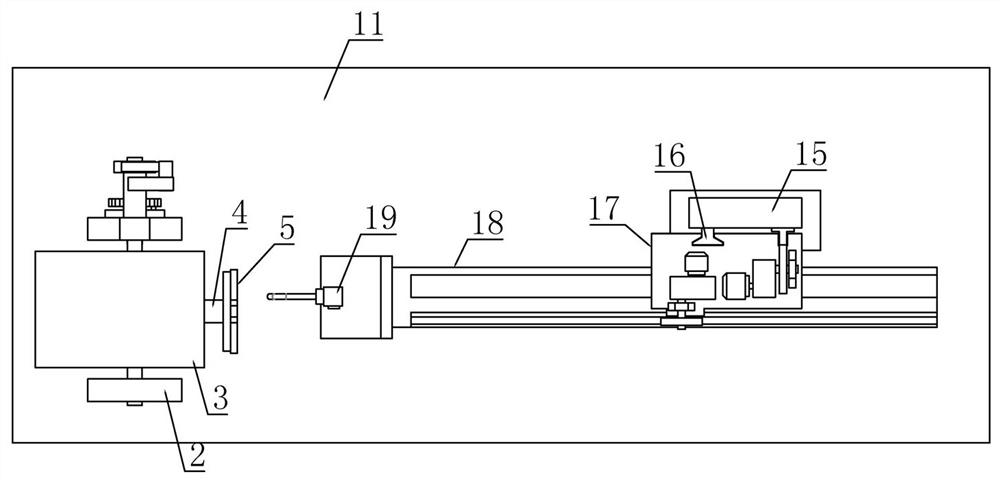

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Depend on Figure 1 to Figure 8 Provided is a detection and remanufacturing equipment for a failed guide sleeve for an oil cylinder, which includes a base 1 and a motor bracket 2 installed on one side of the base 1. The motor bracket 2 is connected to a motor box 3 through a rotating shaft, and the inside of the motor box 3 is An electric spindle 4 is provided, and the electric spindle 4 protrudes out of the motor box 3 and is coaxially connected with a clamping structure 5. It is characterized in that the clamping structure adopts a three-jaw chuck, and the three-jaw chuck is coaxially fixedly connected with the electric spindle. A sheave 6 with four grooves is installed on the rotating shaft, and a drive shaft 7 is connected in rotation on the motor support 2. A dial 47 cooperating with the sheave 6 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com