Preparation method of copper hydroxide nanobelt oriented film

An oriented film and copper hydroxide technology, applied in the field of nanomaterials, can solve problems such as limiting versatility, and achieve the effects of good orientation, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

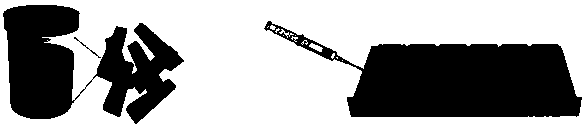

[0025] (1) Dissolve 0.005mol of cuprous nitrate trihydrate in deionized aqueous solution, add 5mL of polyethylene glycol, and after uniform dissolution, add 2g of sodium hydroxide particles into the mixed solution.

[0026] (2) The reaction was stirred at room temperature for 4h to form a blue suspension.

[0027] (3) Wash with distilled water and absolute ethanol several times in a centrifuge to remove impurities;

[0028] (4) Dissolving the substance obtained above in a high-purity ethanol solution to obtain the copper hydroxide precursor solution.

[0029] (5) Take 1 mL of the solution of (4) with a concentration of 5 mol / mL, and inject it into the aqueous solution at a rate of 200 μL / min with a syringe to form an oriented film, transfer the film to the substrate, and place it in a vacuum oven at 40 °C after the transfer drying to obtain the copper hydroxide nanoribbon oriented film.

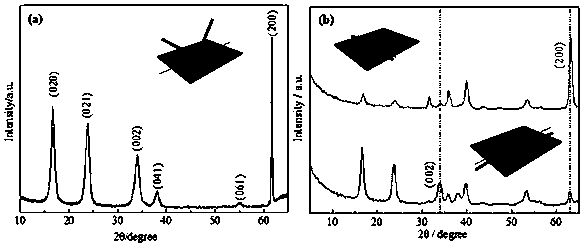

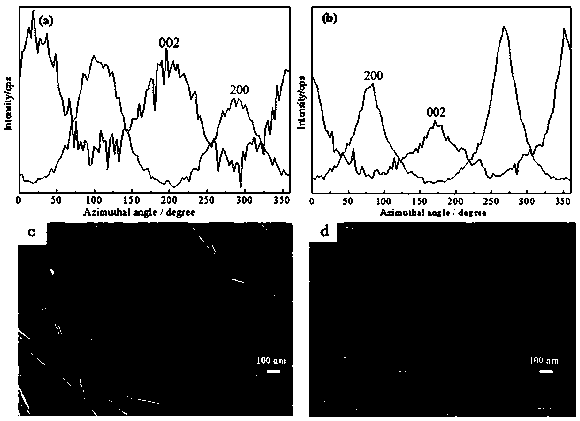

[0030] The schematic diagram of the copper hydroxide nanobelt oriented film prepared in...

Embodiment 2

[0032] (1) Dissolve 0.005mol of cuprous nitrate trihydrate in deionized aqueous solution, add 5mL of polyethylene glycol, and after uniform dissolution, add 2g of sodium hydroxide particles into the mixed solution.

[0033] (2) The reaction was stirred at room temperature for 4h to form a blue suspension.

[0034] (3) Wash with distilled water and absolute ethanol several times in a centrifuge to remove impurities;

[0035] (4) Dissolving the substance obtained above in a high-purity ethanol solution to obtain the copper hydroxide precursor solution.

[0036] (5) Take 1 mL of the solution of (4) with a concentration of 5 mol / mL, and inject it into the aqueous solution with a syringe at a speed of 600 μL / min to form an oriented film, transfer the film to the substrate, and place it in a vacuum oven at 40 °C after the transfer Drying, copper hydroxide nanoribbon oriented film.

[0037] In this example, the solution of (4) was injected into the liquid phase at a speed of 600 μL...

Embodiment 3

[0039] (1) Dissolve 0.005mol of cuprous nitrate trihydrate in deionized aqueous solution, add 5mL of polyethylene glycol, and after it is uniformly dissolved, add 2g of sodium hydroxide particles into the mixed solution.

[0040] (2) The reaction was stirred at room temperature for 4h to form a blue suspension.

[0041] (3) Wash with distilled water and absolute ethanol several times in a centrifuge to remove impurities;

[0042] (4) Dissolving the substance obtained above in a high-purity ethanol solution to obtain the copper hydroxide precursor solution.

[0043](5) Take 1 mL of the solution of (4) with a concentration of 5 mol / mL, and inject it into the aqueous solution with a syringe at a speed of 1000 μL / min to form an oriented film, transfer the film to the substrate, and place it in a vacuum oven at 40 °C after the transfer Drying, copper hydroxide nanoribbon oriented film.

[0044] In this example, the solution of (4) is injected into the liquid phase at a speed of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Orientation degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com