Method for controlling transverse crystal orientation of metal monocrystal

A technology of crystal orientation and control method, which is applied in the direction of crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of lateral orientation that few people discuss, and achieve the effect of simple method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

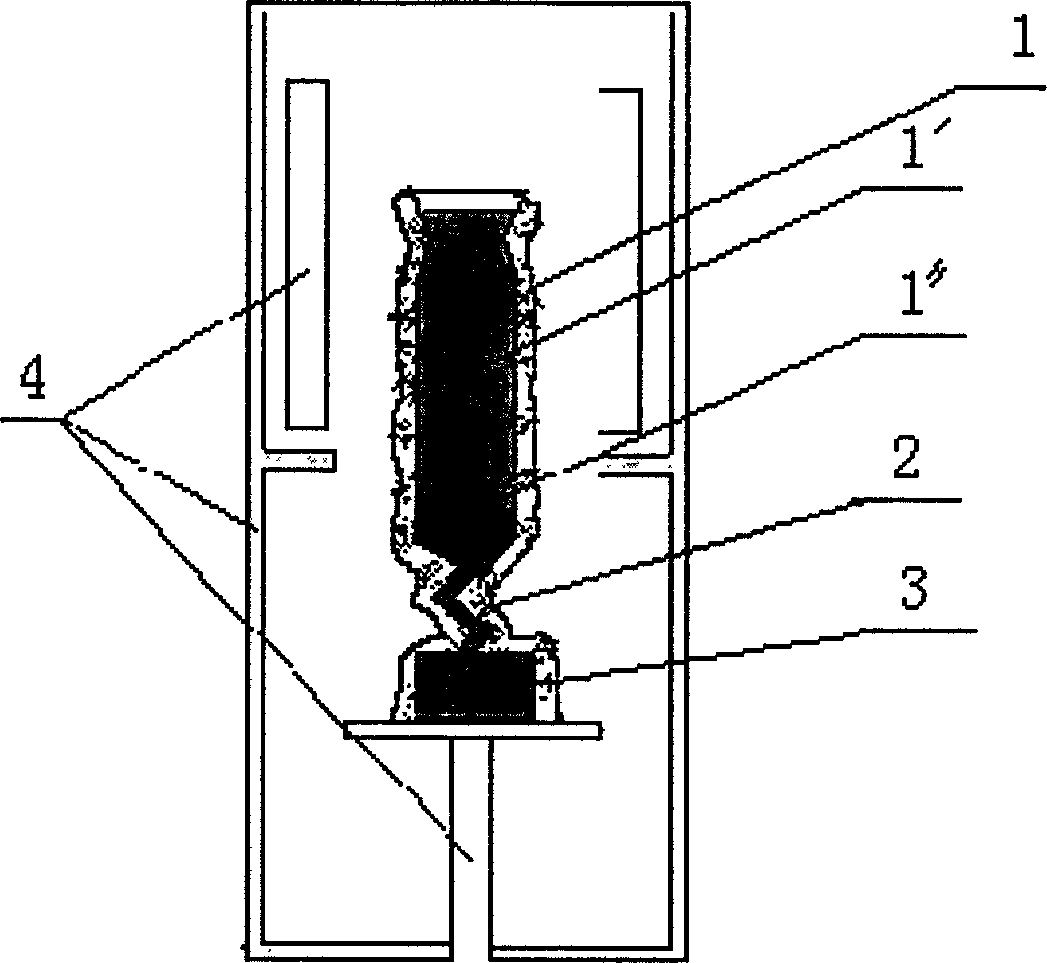

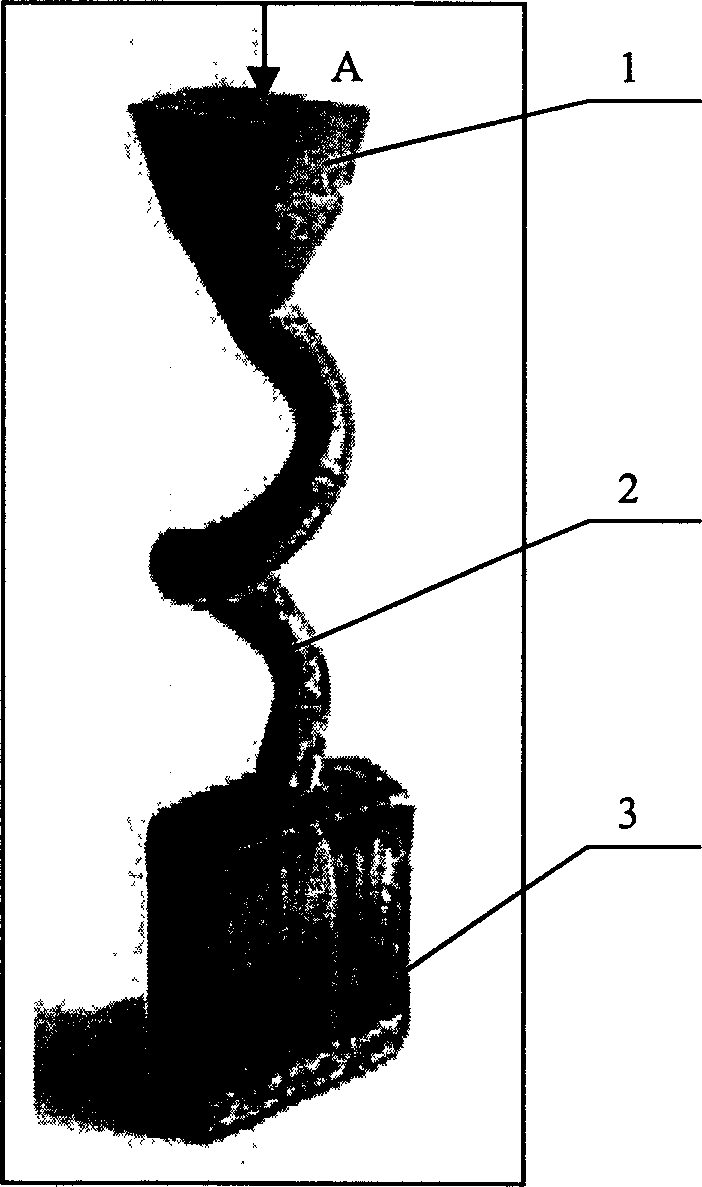

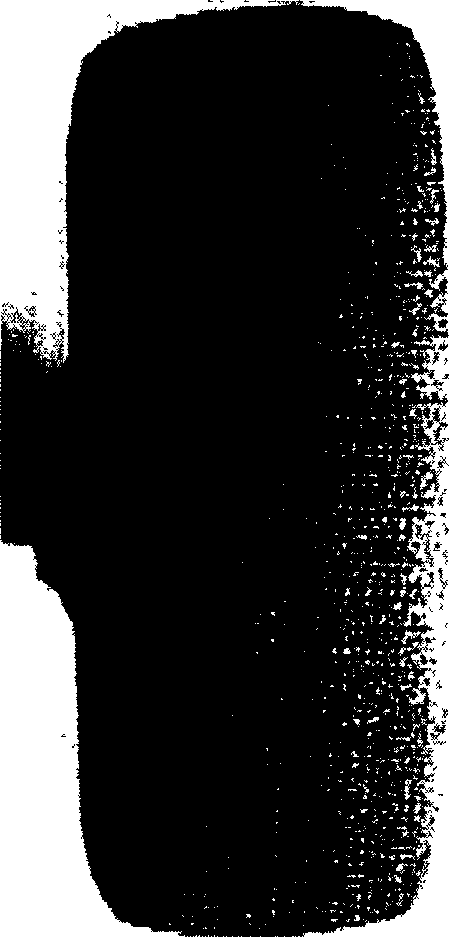

Embodiment 1

[0022] Such as Figure 1b As shown, the TMS64 single crystal superalloy sample is used as the single crystal casting 1, the cross section of the crystal lifter 3 is rectangular, 30mm long and 8mm wide, and the crystal lifter 3 is 30mm high to introduce an additional directional transverse thermal field; the crystal selector 2 is a spiral The structure adopts investment precision casting ceramic shell technology, grows single crystal in ZGD-2 gradient furnace, melt temperature is 1600 ℃, and pulling speed is 3mm / min; the result of single crystal lateral crystal orientation during crystal growth is as follows: Figure 1c As shown, the single crystal sample takes a rectangular cross-section, the long axis direction is the predetermined direction of the transverse [001] orientation, and a single crystal with the transverse orientation consistent with the predetermined direction is obtained, and the deviation is less than 15°;

[0023] In the figure, 1' is liquid metal, and 1" is c...

Embodiment 2

[0032] Difference with embodiment 1 is: the inventive method is applied to DD8 single crystal superalloy, and single crystal sample section is circular, and crystal riser 3 section is still rectangular, long 20mm, wide 4mm, its height 40mm; But melting The body temperature was 1550°C, and the pulling speed was 4mm / min; the basic process was the same as in Example 1, and the transverse [001] orientation of the obtained single crystal sample was consistent with the long axis direction of the crystal riser 3, and the deviation was less than 15°.

Embodiment 3

[0034] Difference with embodiment 1 is: the inventive method is applied to DD98 single crystal superalloy, and its cross-section is circular; Crystal riser 3 cross-sections are rectangular, long 50mm, wide 20mm, its height 50mm; Other and embodiment 1 Similarly, the transverse [001] orientation of the obtained single crystal sample is consistent with the long axis direction of the crystal riser 3, and the deviation is less than 15°.

[0035] The cross-section of the crystal riser 3 in the present invention can also be in a shape similar to a rectangle, such as one of polygonal, waist-shaped, square, etc., with a pair of relatively long, relatively parallel opposite sides as a principle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com