Device for transporting hollow bodies

A transmission device, hollow technology, applied in the direction of conveyor control devices, packaging, conveyors, etc., can solve the problems of unproposed protective coating, breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

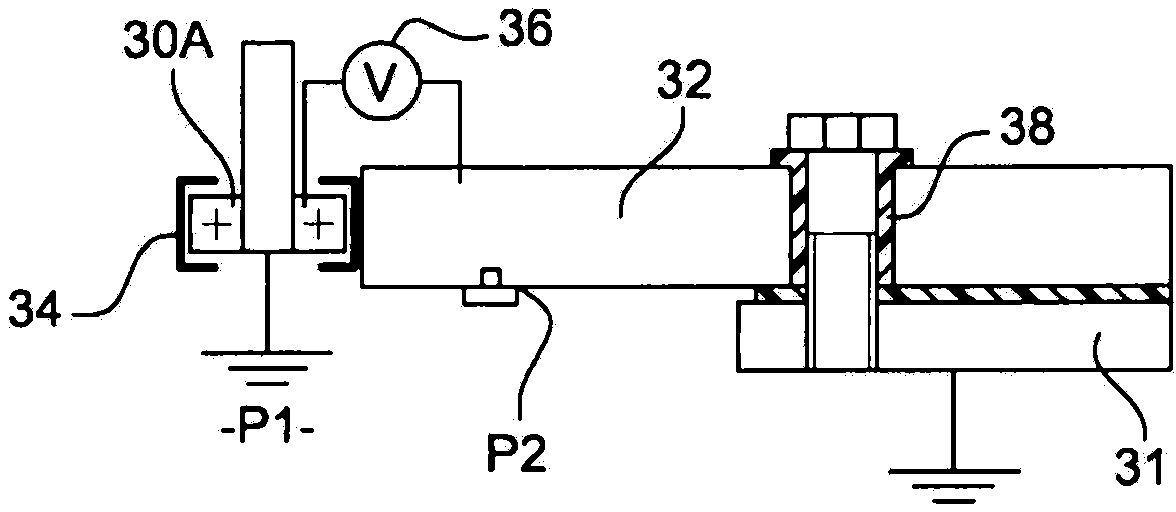

[0064] According to the first embodiment of the present invention, the detection mechanism 36 is formed by a measuring instrument for measuring potential differences, such as a voltmeter, one terminal of which is electrically connected to the cam 32 and the other terminal of which is electrically connected to the cam follower 30A. , 30B. A second terminal of the detection mechanism 36 may, for example, be electrically connected to the arm 18 .

[0065] When the cam 32 is properly insulated from each cam follower 30A, 30B by the insulating layer 34, the detection mechanism 36 formed by a voltmeter thus measures a potential difference equal to P2-P1.

[0066] When a voltage dip is observed, this implies electrical contact between at least one of the cam followers 30A, 30B and the cam 32 . A fracture of the contact layer 34 is concluded from this. The appropriate action is thereby initiated.

[0067] The detection means 36 are connected, for example, to acoustic or visual warn...

Embodiment approach

[0069] According to Figure 5 In the second embodiment of the invention shown above, the detection mechanism 36 is formed by an electric dipole, such as a lamp or LED, capable of detecting the flow of current and interposed between the source of the second electric signal "P2" and the cam 32 in the circuit. Thus, when the contact layer 34 is damaged or broken, the electrical contact between the cam 32 and at least one of the cam followers 30A, 30B causes current to flow inside the electric dipole.

[0070] According to a variant of the invention not shown, the opening and closing of the jaws of the gripping part can be controlled by means of a cam follower supported by the gripping part cooperating with a fixed cam. The invention described above can thus be applied to this type of control means.

[0071] This type of device 10 thus allows rapid detection of breaks in the contact layer 34 .

[0072] Furthermore, the return spring 28 is also made of conductive material and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com