Degradable and absorbable polymer nano fibrous membrane materials and preparation process and use thereof

A nanofiber membrane and biodegradation technology, which is applied in the field of polymer nanofiber membrane materials and their preparation, can solve problems such as being unsuitable for electrospinning, and achieve the effects of good uniformity, high porosity, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

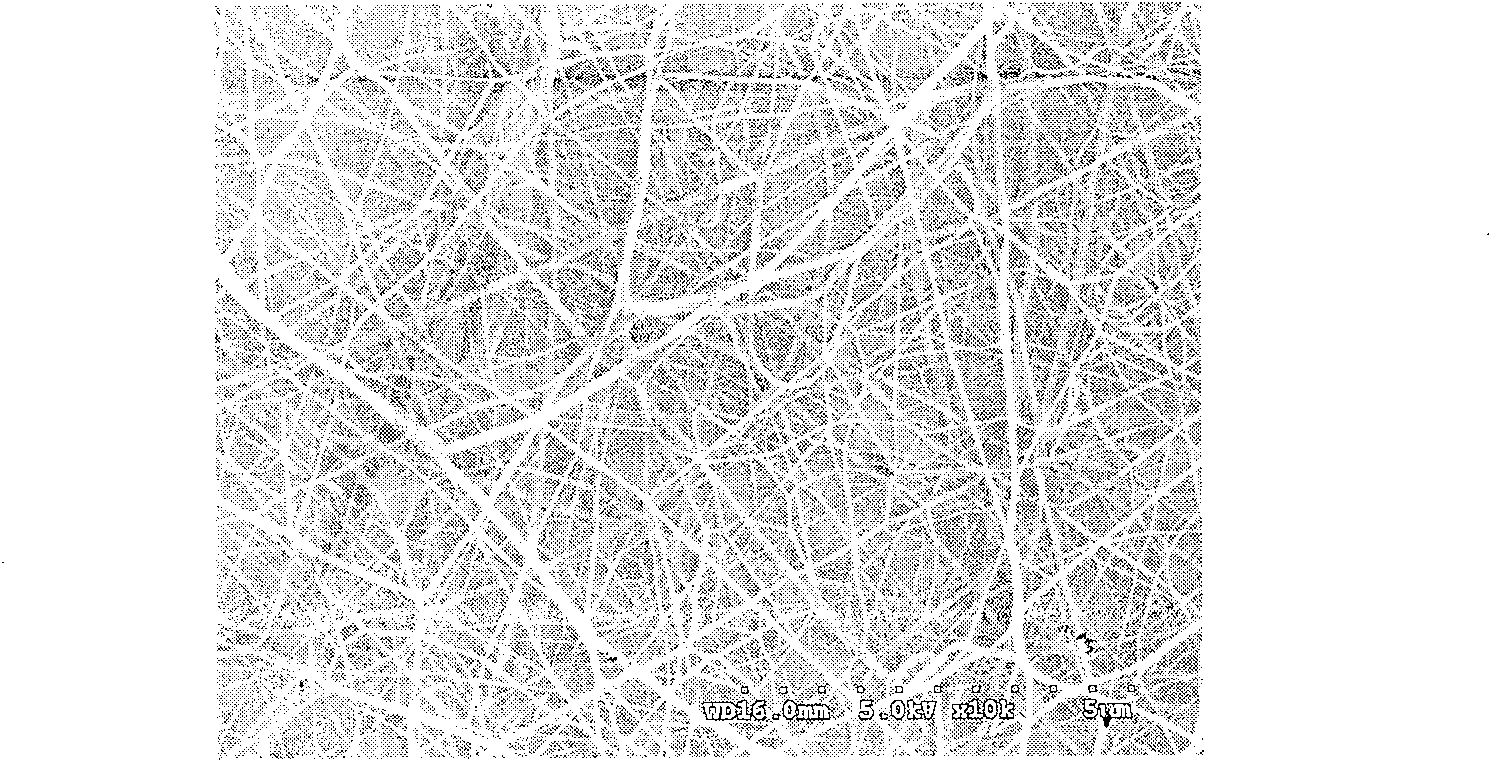

Image

Examples

Embodiment 1

[0059] 1) Prepare 5ml of HA / GE water / ethanol solution with a mass volume percentage concentration of 1.8wt / v, wherein the mass ratio of HA / GE is 5:1, and the volume ratio of water / ethanol is 90:10, and put it in the stock solution device.

[0060] 2) Install a metal plate as a collector, and the temperature of the collector is 40 degrees.

[0061] 3) Adjust the distance between the spinneret and the collecting plate to be 8cm.

[0062] 4) The ambient temperature of spinning is 50 degrees, including the temperature of the solution in the liquid storage device and the temperature of the collecting plate are both 50 degrees.

[0063] 5) Turn on the high-voltage power supply, adjust the voltage to 18KV, and the air velocity of the environment is 6m 3 / hr, the feed rate of the solution is 100ul / min, spinning, and then the polymer fiber film on the receiving plate is vacuum-dried at 40 degrees for 2 days.

[0064] 6) Place the vacuum-dried polymer fiber membrane in 20 ml of a mix...

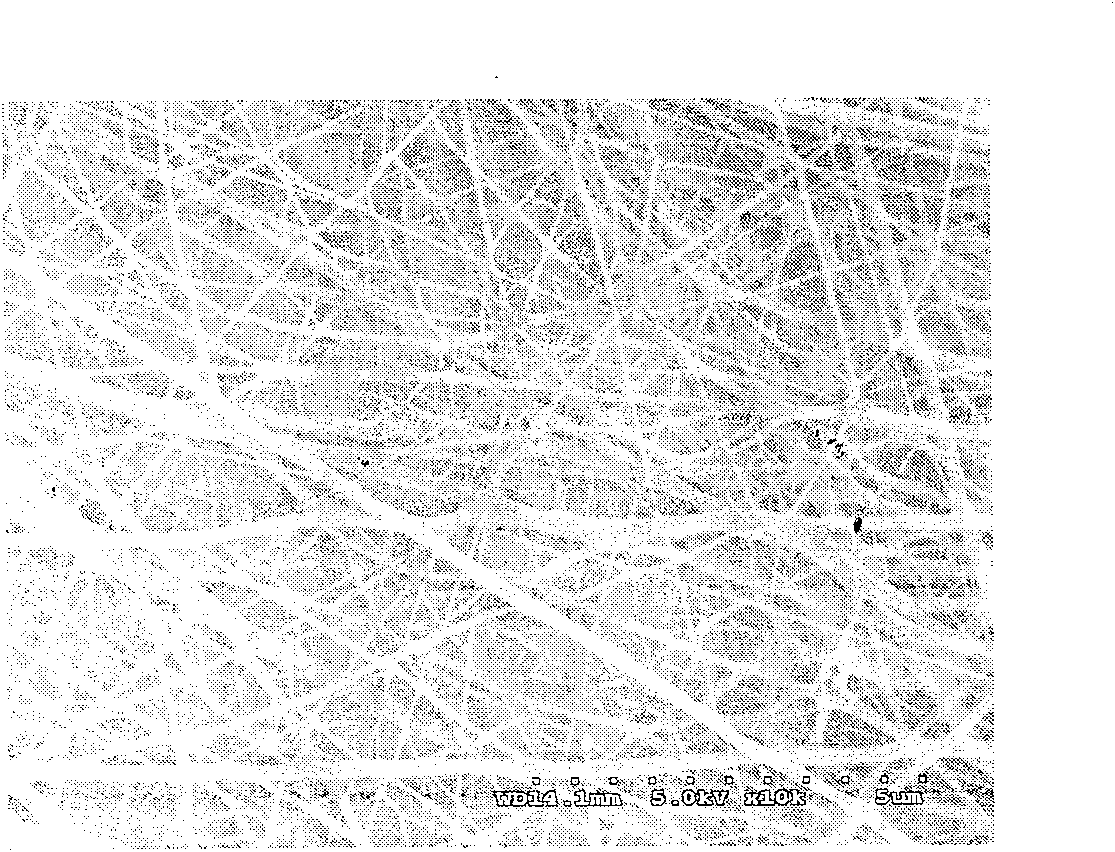

Embodiment 2

[0066] 1) Prepare 10ml of water / ethanol solution of HA / GE with a mass volume percentage concentration of 2wt / v, wherein the mass ratio of HA / GE is 3:1, the volume ratio of water / ethanol is 90:10, and the polymer solution contains 0.02 g of growth factor, polymer solution was placed in the reservoir.

[0067] 2) Install a metal plate as a collector.

[0068] 3) Adjust the distance between the spinneret and the collecting plate to be 8cm.

[0069] 4) The ambient temperature of spinning is 50 degrees, including the temperature of the solution in the liquid storage device and the temperature of the collecting plate are both 50 degrees.

[0070] 5) Turn on the high-voltage power supply, adjust the voltage to 18KV, and the air velocity of the environment is 5m 3 / hr, the moving speed of the spinneret is 0.1m / min, the feeding speed of the solution is 120ul / min, spinning, the moving speed of the collecting plate is 0.01m / min, and then the polymer fiber film on the receiving plate is...

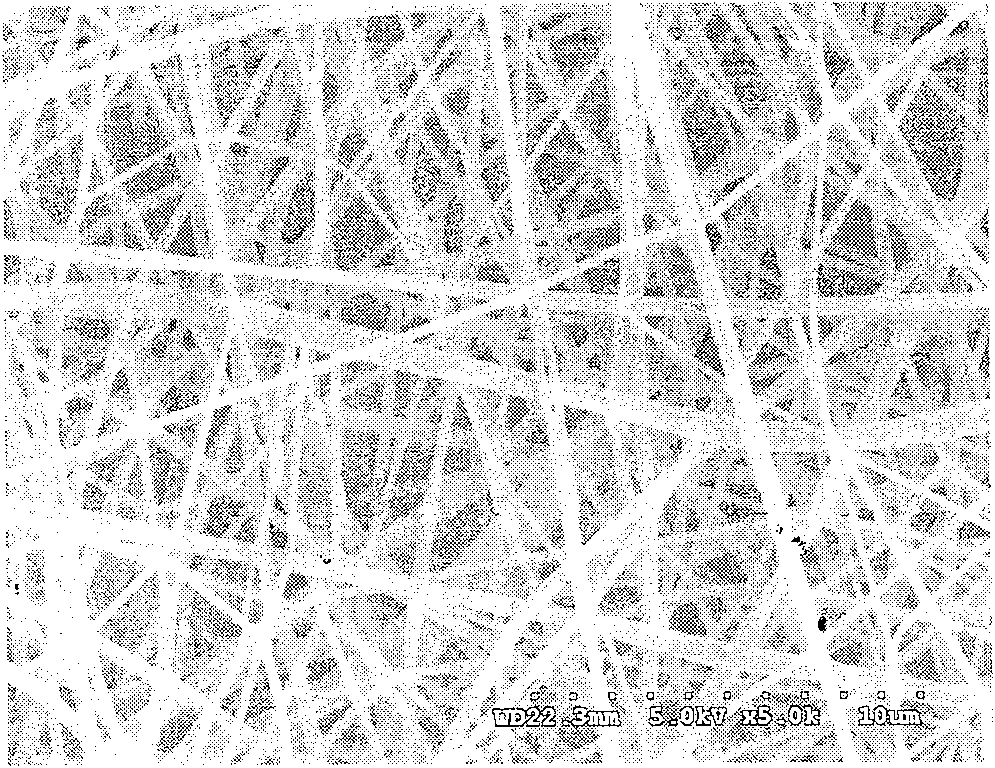

Embodiment 3

[0073]1) Prepare 5ml of HA / GE water / ethanol solution with a mass volume percentage concentration of 3wt / v, wherein the mass ratio of HA / GE is 1:1, and the volume ratio of water / ethanol is 90:10, and place it in the liquid storage device middle.

[0074] 2) Install a metal drum as a collector.

[0075] 3) Adjust the distance between the spinneret and the collector to be 8cm.

[0076] 4) The ambient temperature of spinning is 50 degrees, including the temperature of the solution in the liquid storage device and the temperature of the collecting plate are both 50 degrees.

[0077] 5) Turn on the high-voltage power supply, adjust the voltage to 18KV, and the air velocity of the environment is 4m 3 / hr, the feeding speed of the solution is 130ul / min, the moving speed of the spinneret is 0.5m / min, the rotating speed of the collector is 300r / min, spinning, and then the polymer fiber film on the receiving drum is at 40 Dry under vacuum for 2 days.

[0078] 6) Place the vacuum-drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com