Method for prolonging life of aluminum alloy preparation die

A mold life and aluminum alloy technology, which is applied in the field of improving the mold life of aluminum alloys, can solve the problems of high cost, low production efficiency, and low life, and achieve the effects of improving life, increasing service life, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

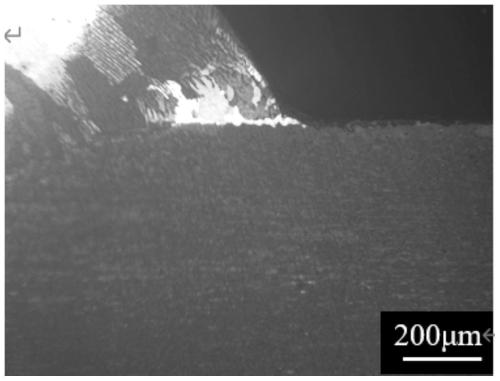

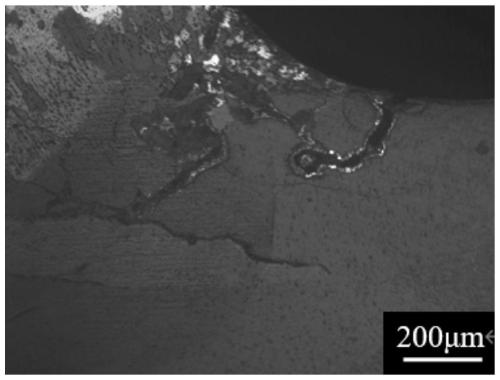

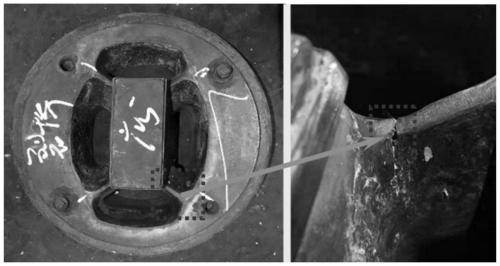

Image

Examples

Embodiment 1

[0036] In the first aspect, this embodiment provides a method for improving the life of a mold for preparing an aluminum alloy, the aluminum alloy is an aluminum alloy containing Zr, and the preparation of the aluminum alloy containing Zr includes the following steps:

[0037] S1: batching, according to production demand, be equipped with the raw material of Zr-containing aluminum alloy;

[0038] S2: smelting, adding the raw material of aluminum element in the ingredients into the smelting furnace, increasing the temperature, adding instant Zr agent after the raw material of aluminum element melts, adding other raw materials in turn after the raw material of aluminum element melts, and stirring in the smelting furnace After the raw materials are fully melted, a uniform melt A is obtained, and the composition of the furnace is detected when the melt in the melting furnace is stirred. If the composition is unqualified, the corresponding raw materials need to be supplemented until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com