Wire box automatic unloading device

A technology of automatic blanking and wire boxes, applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of time-consuming and labor-intensive, and achieve the effect of good conveying accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

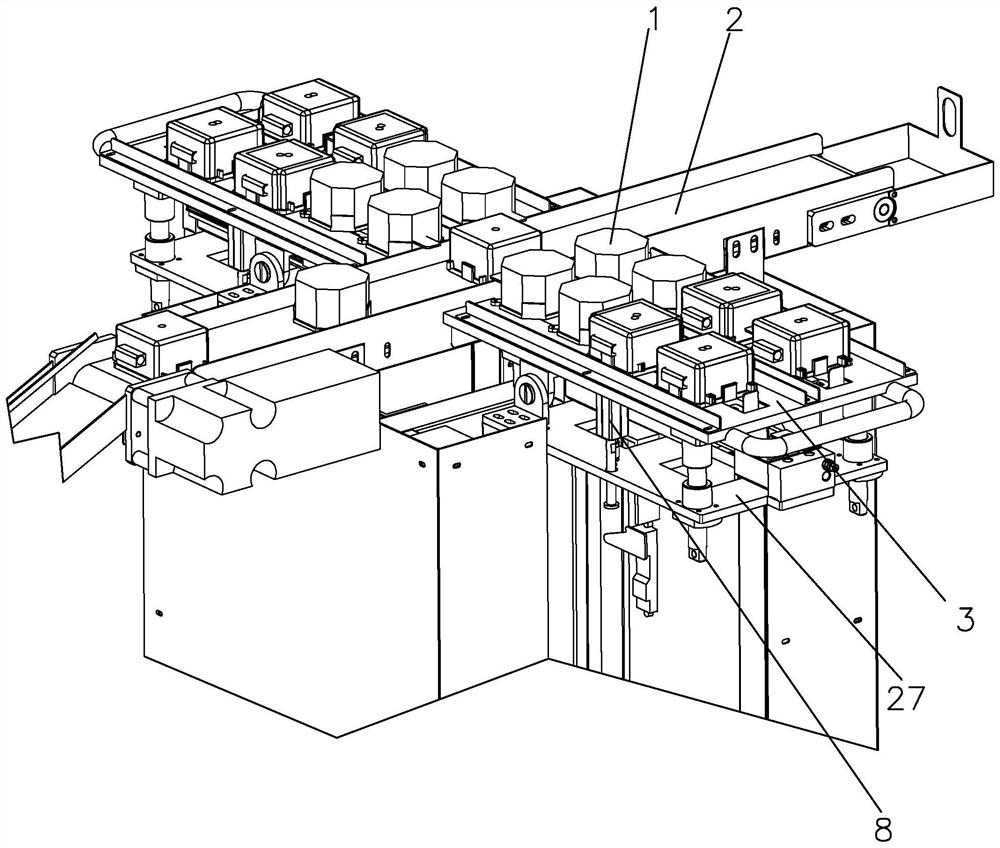

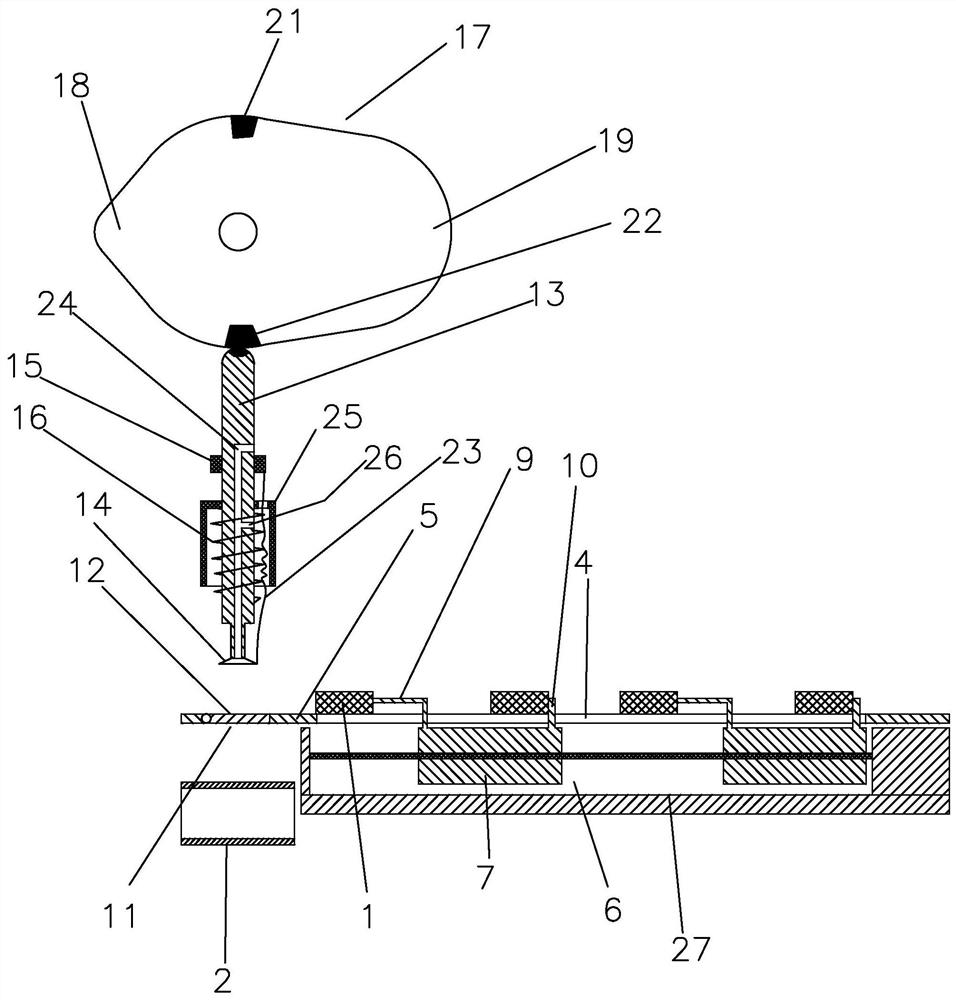

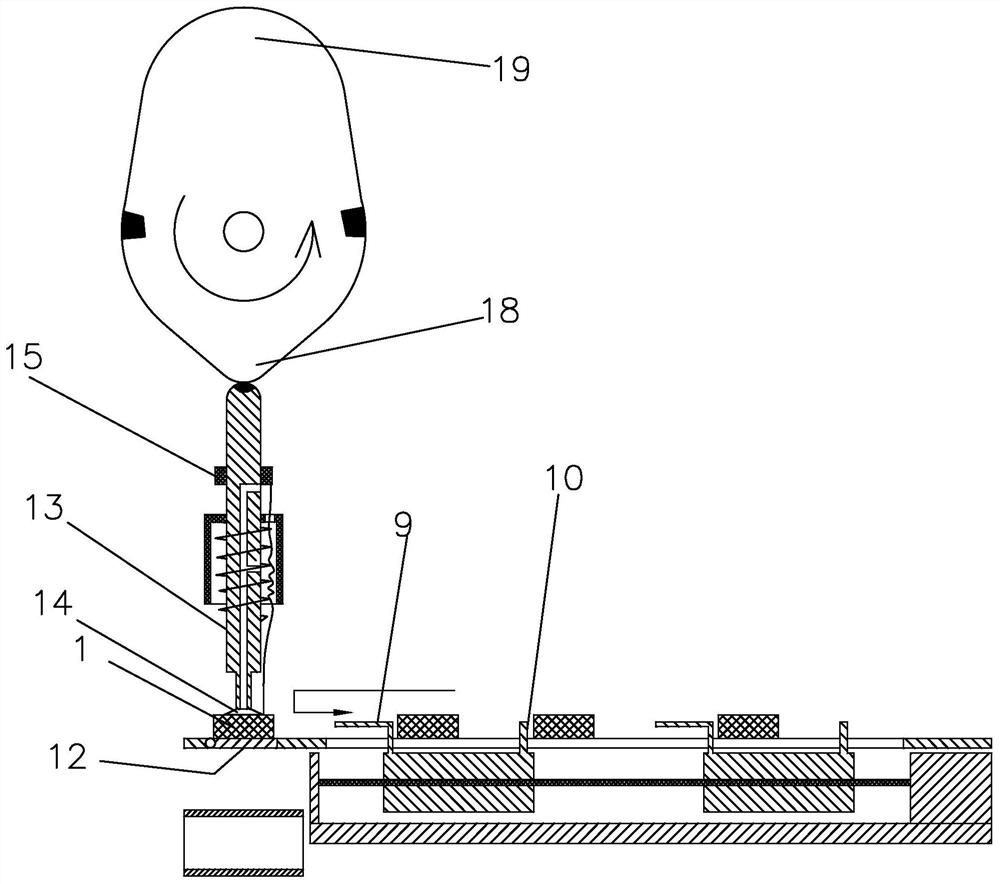

[0025] see Figure 1 to Figure 7 , an automatic wire box unloading device, comprising a conveyor belt 2 for delivering the wire box 1 to a stamping system, and a conveying mechanism for delivering the wire box 1 to the conveyor belt 2 .

[0026] The conveying mechanism includes a slide plate 3 that slides for the wire box 1 and one end is located above the conveying mechanism, a discharge port 11 located at the end of the slide block 5 close to the conveyor belt 2, a material blocking plate 12 that is connected to the discharge port 11 side in rotation, and is used for rotating The motor of the baffle plate 12, the long hole 4 arranged along the direction of the slide plate 3 on the slide plate 3, the servo module 6 including the slide block 7 under the slide block 5, and the lifting cylinder for lifting the servo module 6 8. The first push plate 9 fixed on the slider 5 is used to push the wire box 1 towards the baffle plate 12, and the first push plate fixed on the slider 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com