Machine for adhesive strip, process for adhesive strip in order to produce heat insulation and sealed wall and heat insulation and sealed wall

A technology for adhesive tapes, machines, applied in bulk goods, outer walls of container construction, adhesives, etc., which can solve problems such as tediousness, monotony, and surface irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

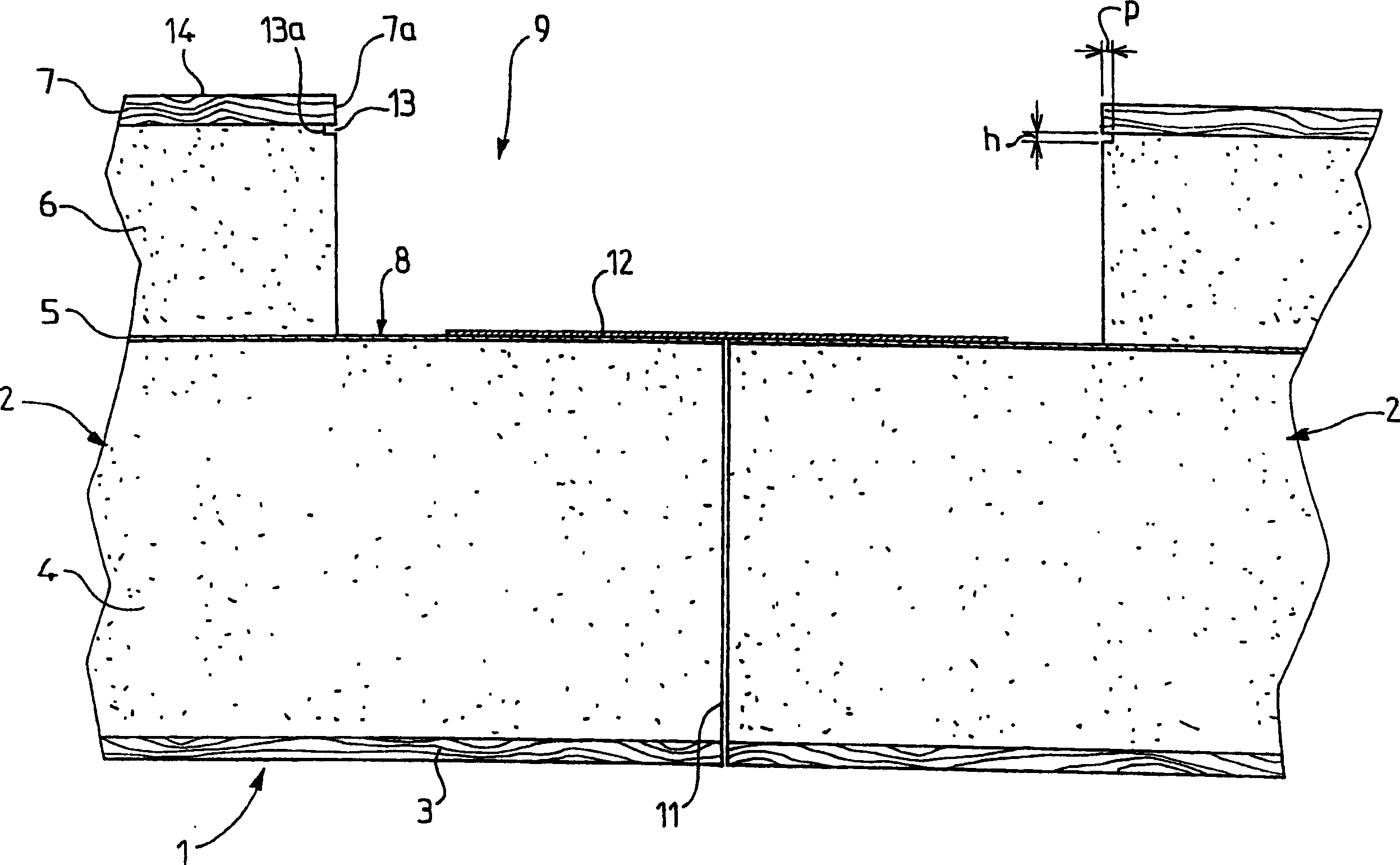

[0047] according to figure 1 , the thermally insulating and sealing wall 1 is formed by a wall panel indicated as a whole by the reference numeral 2, this wall 1 constituting a first thermally insulating barrier, a second thermally insulating barrier and a second sealing barrier. Each wall is substantially in the shape of a right-angled parallelepiped and consists of a first plywood 3 on which a first thermal insulation layer 4 is arranged, on which a layer of rigid or flexible slats 5; Subparts 6, 7 constitute a first insulating barrier part that is rectangular in plan view, with sides parallel to the sides of subparts 3, 4, 5; A rectangle with the same center, a peripheral side edge 8 of fixed length surrounds the subparts 6, 7 and is formed by the edges of the subparts 3, 4, 5. The subcomponents 3, 4 constitute a second insulating barrier part. The strip 5 covering the subcomponents 3, 4 constitutes a second sealing barrier part.

[0048] The panel 2 just described may ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com