Metal mold device, electronic device and casing of electronic device making method

A metal mold and shell technology, which is applied in the direction of manufacturing tools, metal processing equipment, casting and molding equipment, etc., can solve the problems of large unfilled parts and inability to form holes 7, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

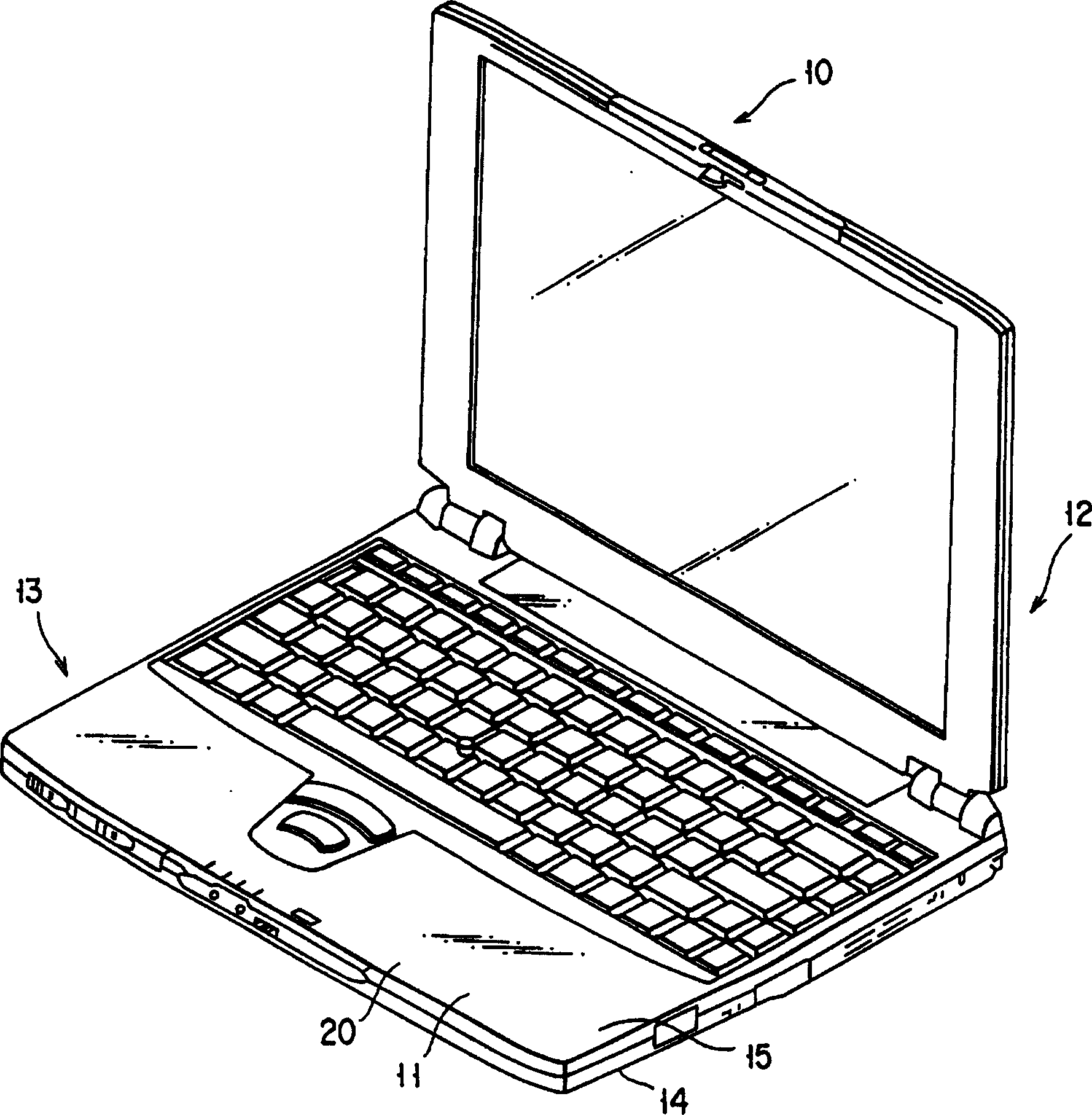

[0023] Below, refer to image 3 Turning to FIG. 8, an embodiment of the present invention is described.

[0024] image 3 It is an external view showing the shape of a portable computer 10 such as a notebook computer. In this figure, a portable computer 10 includes a computer body 11 and a display 12 rotatably supported by the computer body 11 . The computer body 11 is provided with a casing 13 . The case 13 is formed by connecting the lower case 14 and the upper case 15 with screws, for example. However, the joint structure of the lower case 14 and the upper case is not limited to this, and other joint structures may be used.

[0025] In the following description, a housing suitable for electronic equipment such as the portable computer 10 will be described as the housing 20 for electronic equipment. Below, refer to Figure 4 to Figure 8 for illustration.

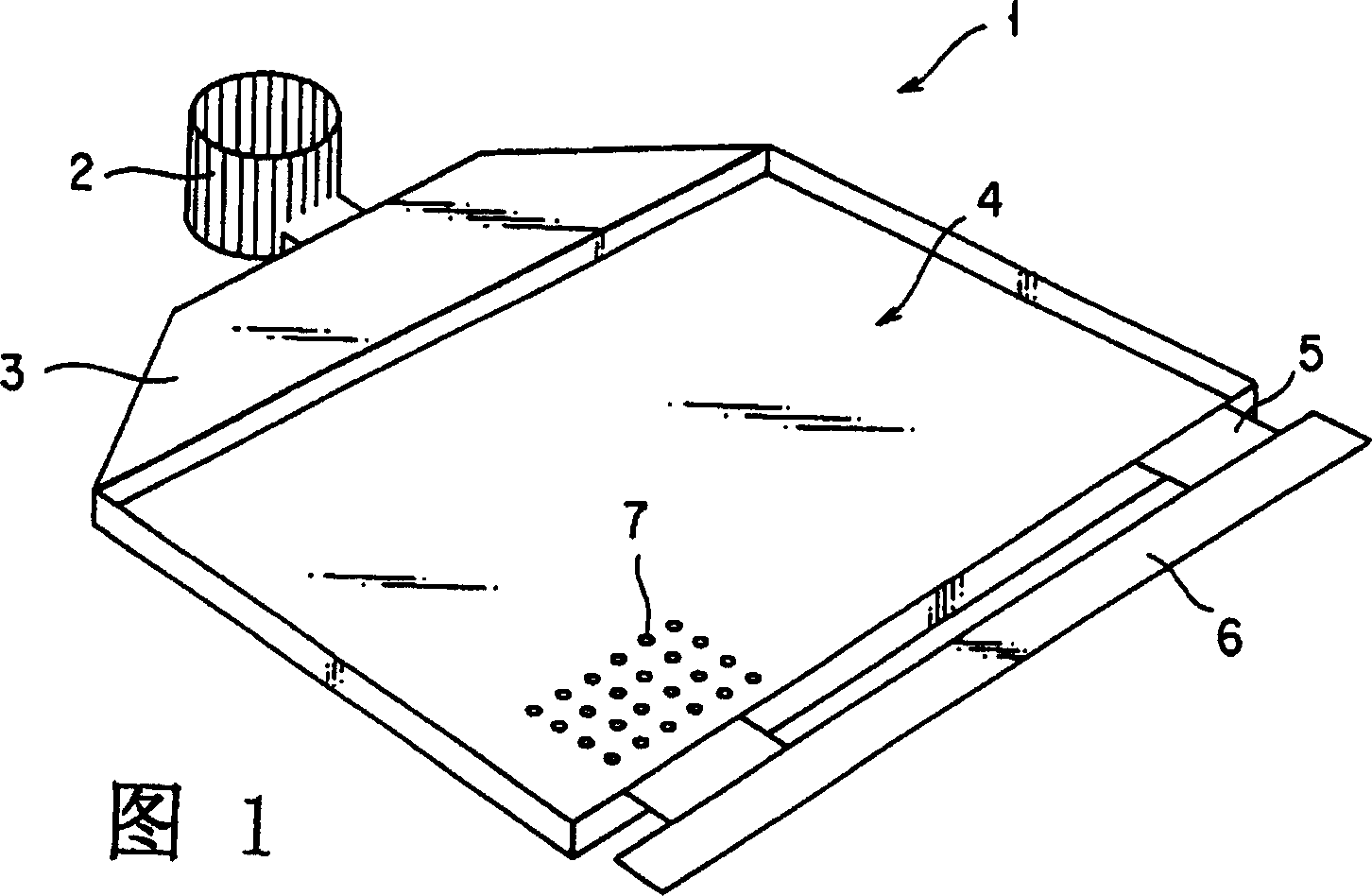

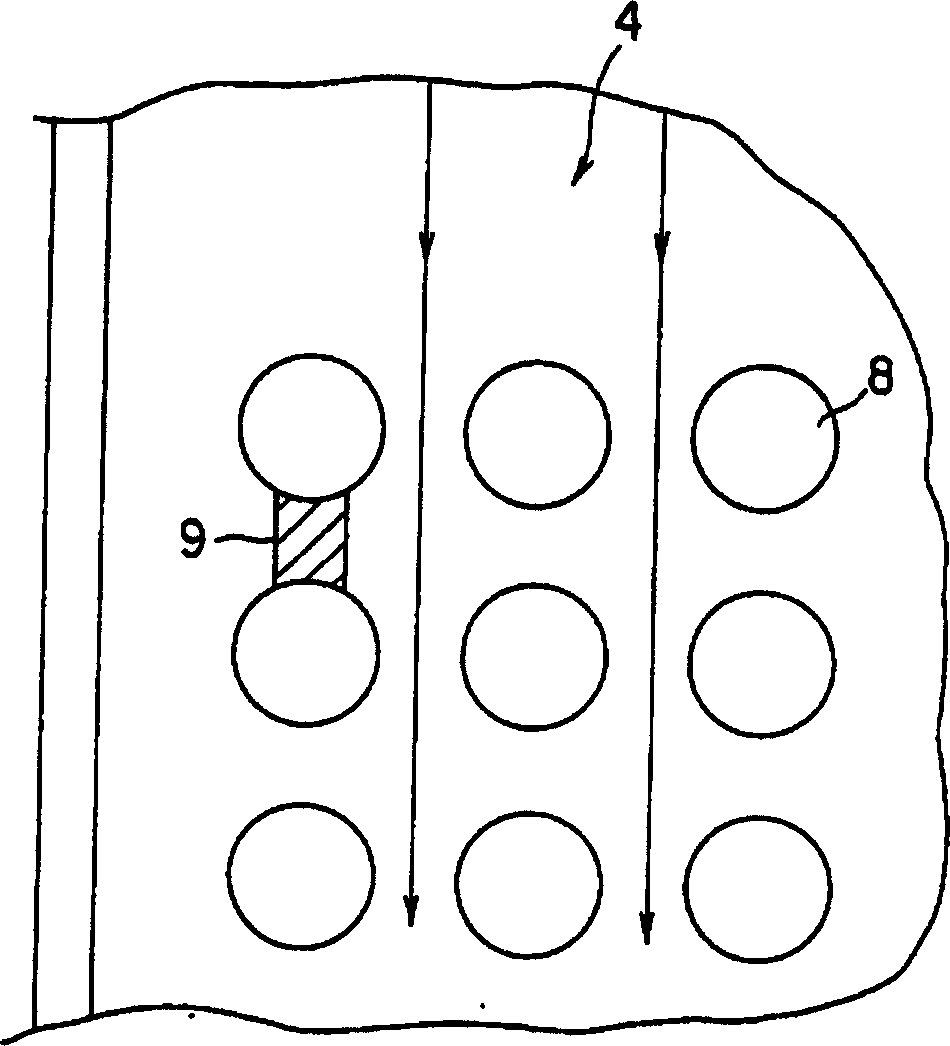

[0026] For example, a case 20 for an electronic device such as a computer made of a light metal made of a magnesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com