Pipe cutter

A technology for cutting knives, pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

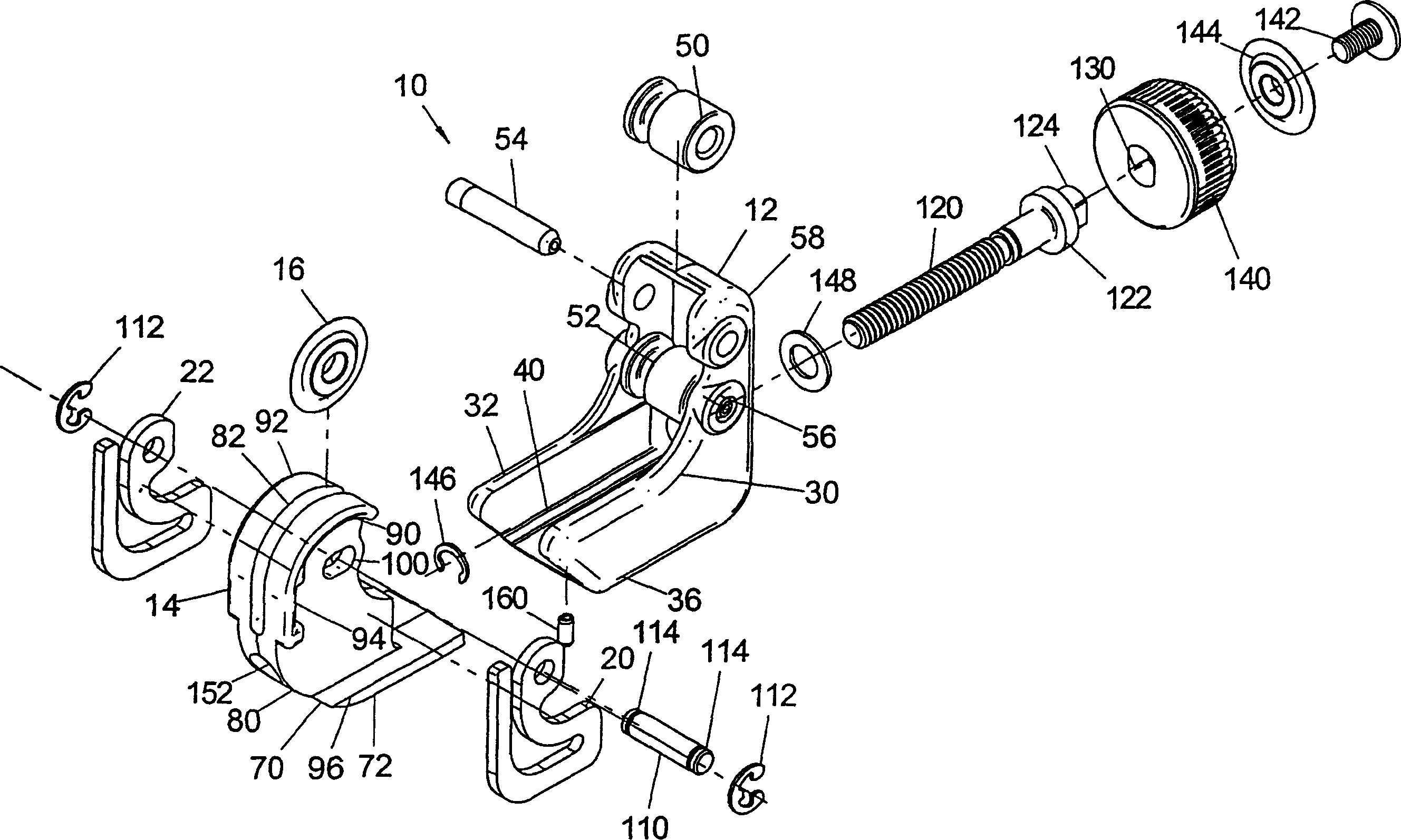

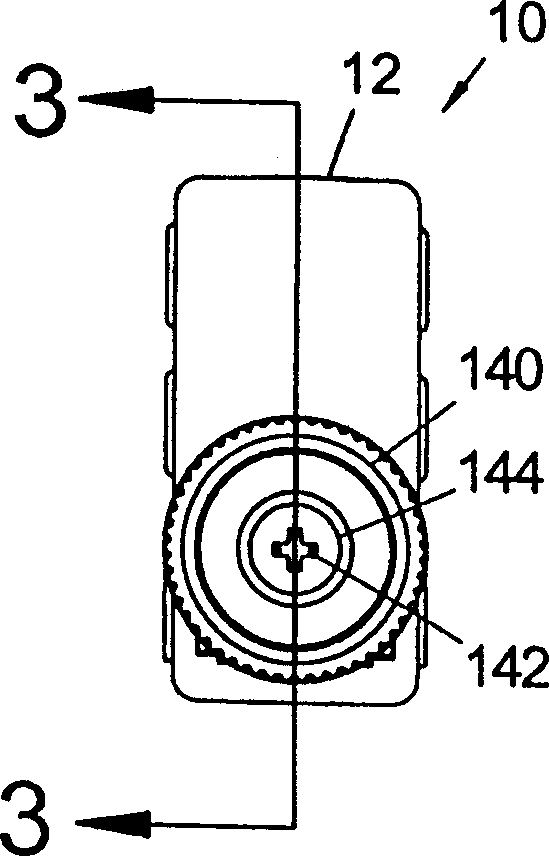

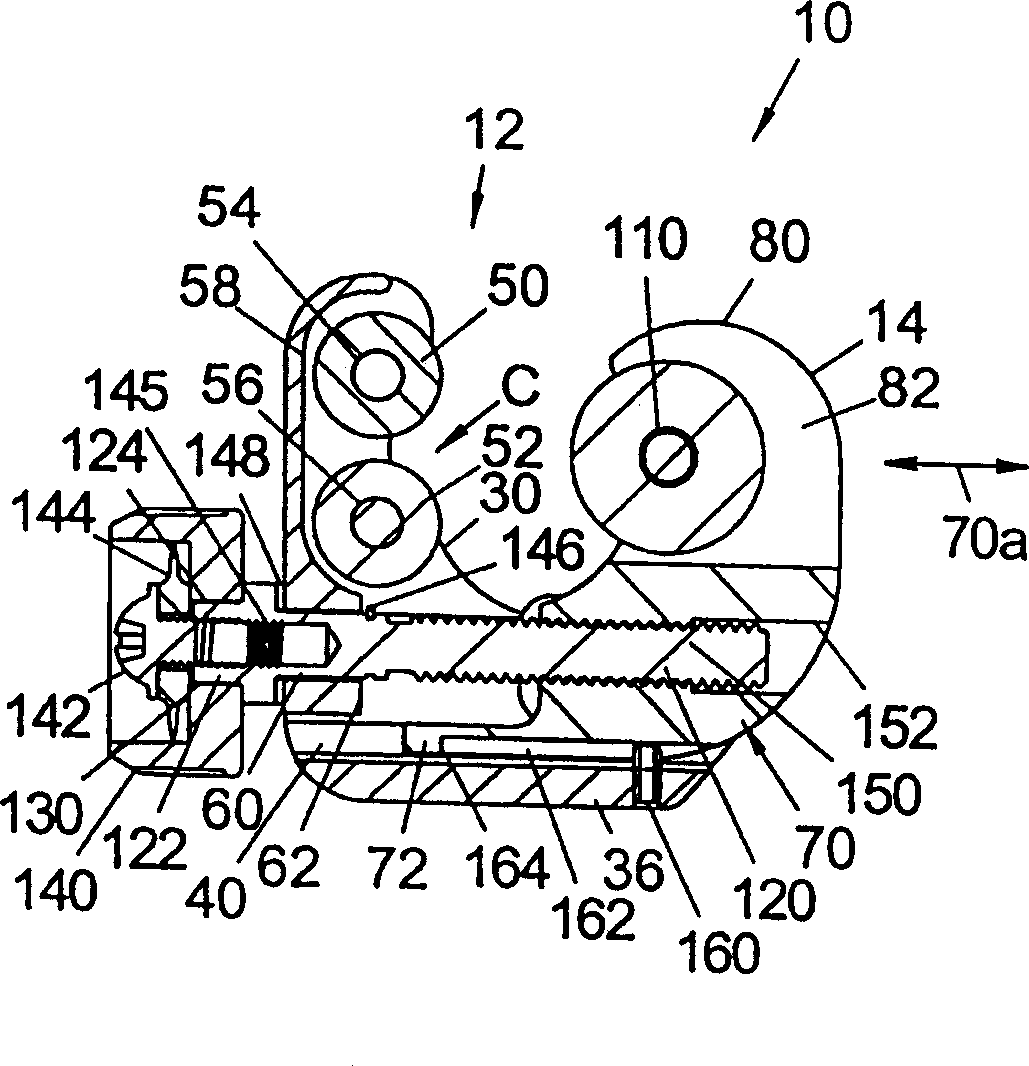

[0027] Referring now to the accompanying drawings, the contents shown in the drawings are only for illustrating the embodiments of the present invention, but not for limiting the present invention. Figure 1 to Figure 5 Represents a pipe cutting tool 10 having a first seat or bracket 12, and a second seat or head 14, such as Figure 4 and Figure 5 As clearly shown, a cutter head 16 for cutting the tube T is rotatably mounted on the cutter head 14 . During the cutting operation, the cutter 10 is loaded and rotated on the pipe either manually or by an electrically driven handle. During rotation, if Figure 6 Two spaced apart resilient elements 20, 22 in the form of leaf springs are shown to automatically advance the cutter head 16 towards the pipe. In operation, the second seat slides relative to the first seat until the cutter head 16 bears against the tube T. As shown in FIG. Further movement of the second support then deforms the springs 20, 22 until the springs are full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com