Ultrasonic probe and manufacturing mehtod thereof

An ultrasonic probe and ultrasonic technology, which is used in ultrasonic/sonic/infrasonic diagnosis, sonic diagnosis, material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of destroying the accuracy of the ultrasonic probe unit and the bulky volume of the ultrasonic probe unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

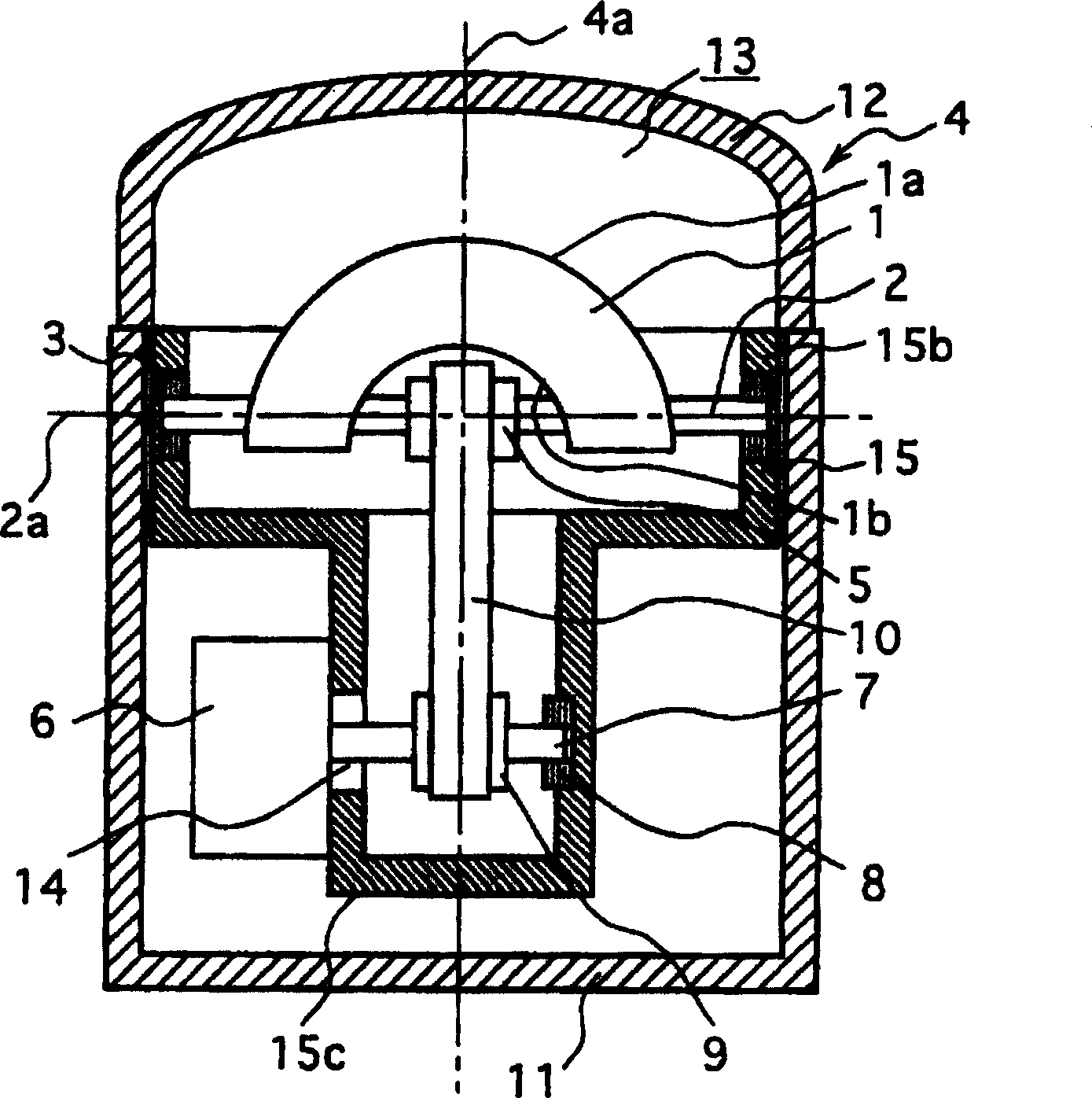

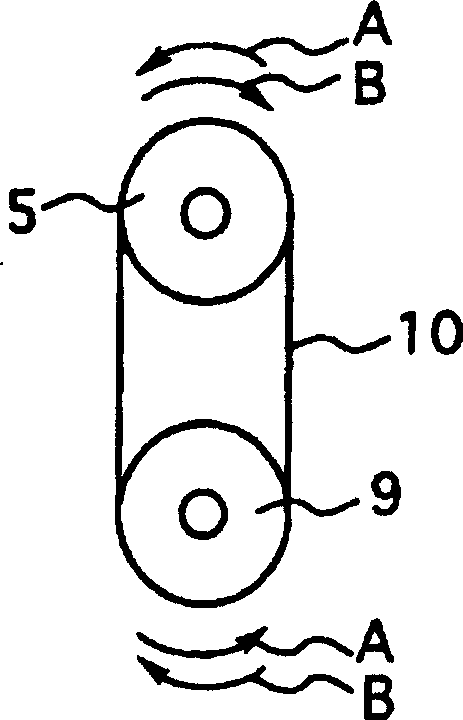

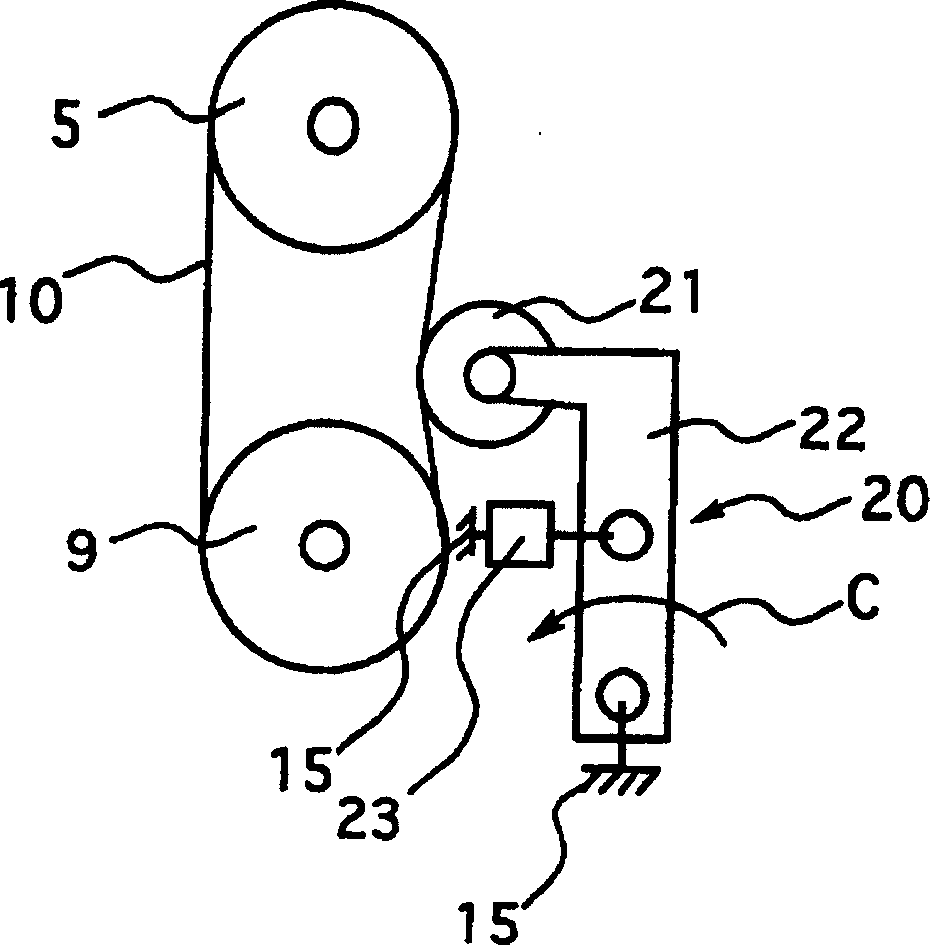

[0046] Refer to attached Figure 1A and 1B , shows the first embodiment of the ultrasonic probe of the present invention. thus Figure 1A and 1B The indicated ultrasonic probe includes a converter 1 , a driven shaft 2 , a pair of bearings 3 , a probe cover 4 , a driven driving wheel 5 , a driving motor 6 , and a driving shaft 7 . The probe cover 4 has a central axis 4 a and includes an outer cover 11 , an inner cover 15 adapted to the outer cover 11 and maintaining a fixed relationship with the outer cover 11 . The inner cover 15 is cup-shaped, the upper part 15b is connected to the outer cover 11, and the bottom 15c is integrally formed with the upper part 15b. The cross-sectional area of the bottom portion 15 c measured perpendicular to the central axis 4 a of the probe cover 4 is smaller than the cross-sectional area of the upper portion 15 b also measured perpendicular to the central axis 4 a of the probe cover 4 . The window 12 is made of a material suitable for ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com