Manufacturing method of integrally shaped pipe having connecting part

A manufacturing method and a technology for forming pipes, which are applied in the field of pipe material manufacturing, can solve the problems of pipe joints falling off, increased working intensity, and operators' missing fastening operations, etc., so as to reduce the possibility of leakage, reduce installation workload, and enhance The effect of surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

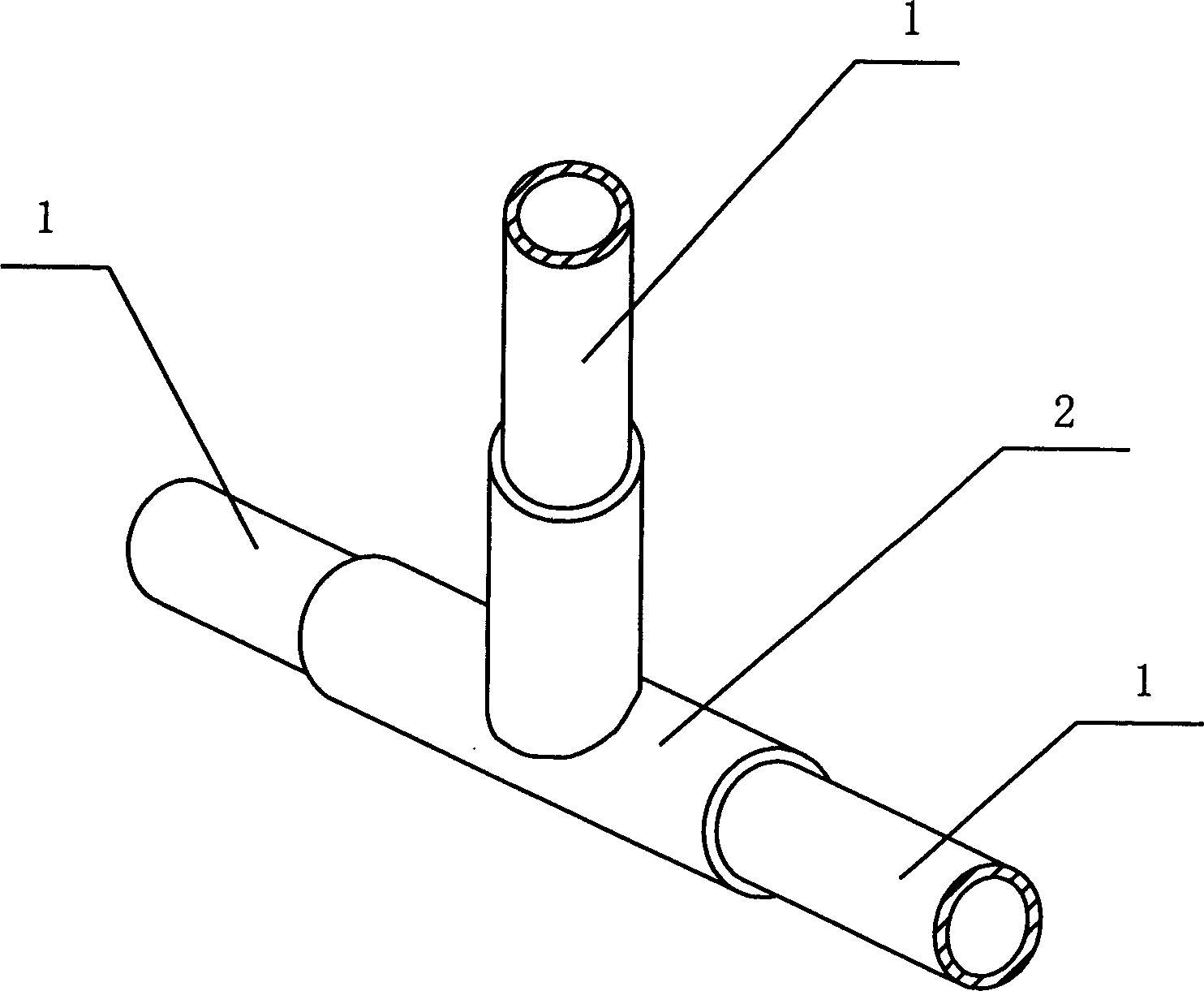

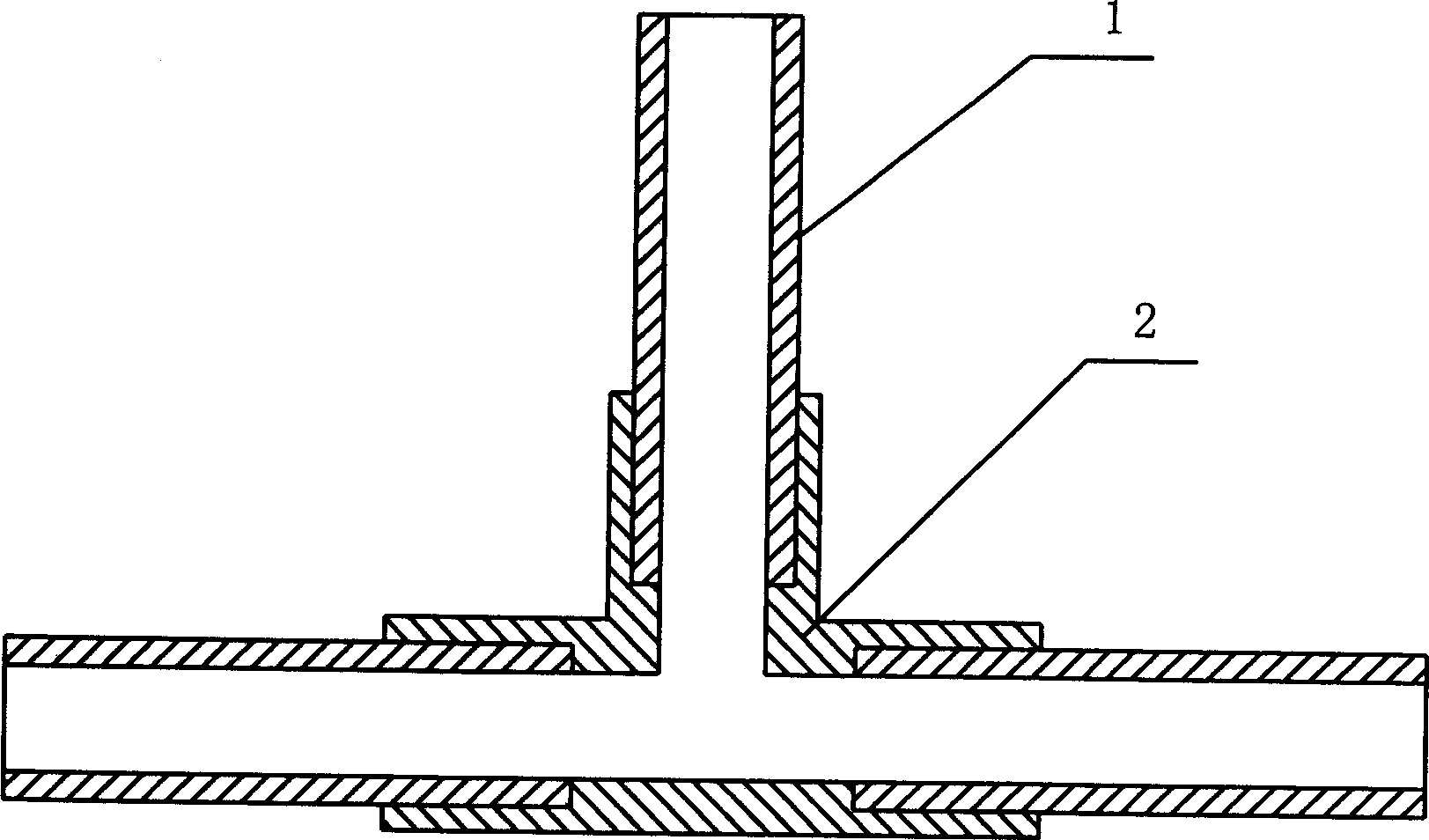

[0025] Embodiment one: see attached figure 1 and figure 2 As shown, a method for manufacturing an integrally formed pipe with a connecting portion includes the following steps:

[0026] (1) Cut and prepare 3 elastic tubes, make their length, shape, and pipe diameter meet the requirements of the integrally formed tubes to be obtained, and process their joints with methyl ethyl ketone;

[0027] (2) Insert two metal rods matching the pipe diameter into a T-shape as a forming rod, and set three elastic tubes on each branch of the forming rod respectively;

[0028] (3) Assemble the mould, so that a cavity is formed between the inner surface of the mould, the elastic tube and the forming rod;

[0029] (4) injecting thermoplastic resin into the cavity for molding;

[0030] (5) Demoulding and taking out the forming rod, the required 3-prong integral forming tube can be obtained.

[0031] The integrally formed pipe obtained in this embodiment is as attached figure 1 And attached ...

Embodiment 2

[0033] Embodiment 2: An integrally formed pipe with a connecting part, which is connected by 4 elastic pipes, one of which is a curved pipe. The manufacturing method of this embodiment is similar to that of Embodiment 1, wherein the forming The rods are composed of three metal rods in the same shape as the connecting part, and the pipes consistent with the elastic tubes can be prepared in advance.

Embodiment 3

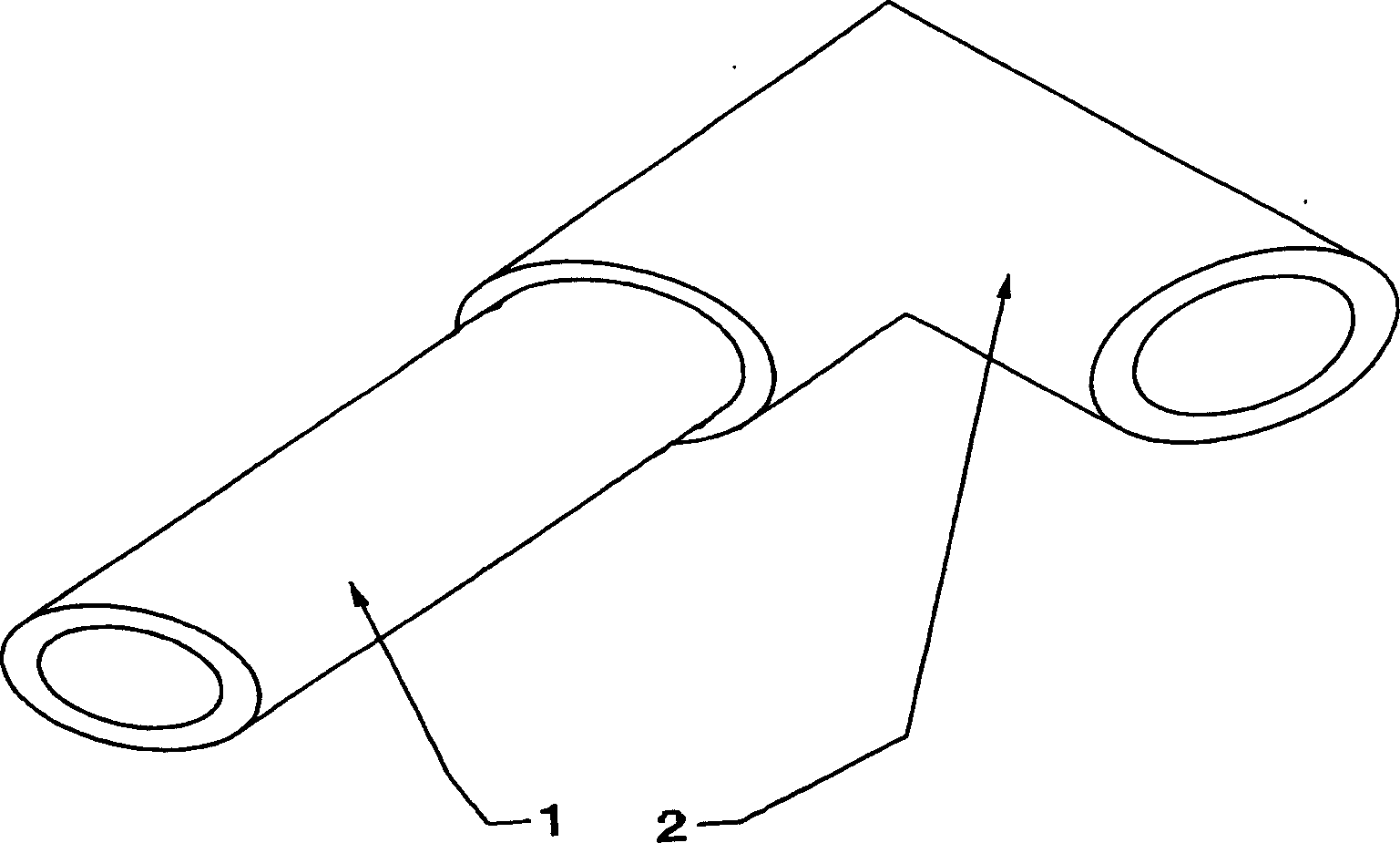

[0034] Embodiment three: see attached image 3 And attached Figure 4 As shown, an integrally formed pipe with an elbow includes an elastic pipe 1 and a connecting part 2 that acts as an elbow. The outer mold is injection molded to obtain an elbow-shaped connecting portion 2 .

[0035] This embodiment can be connected to equipment pipelines, replacing the existing connection structure of elbows and elastic tubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com