Conic perforator

A piercing machine and cone-shaped technology, applied in the direction of metal rolling, etc., can solve the problems of insufficient overall rigidity, difficult to compress the roll, and reduce volume, so as to achieve no stress concentration point, uniform radial force, and force reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

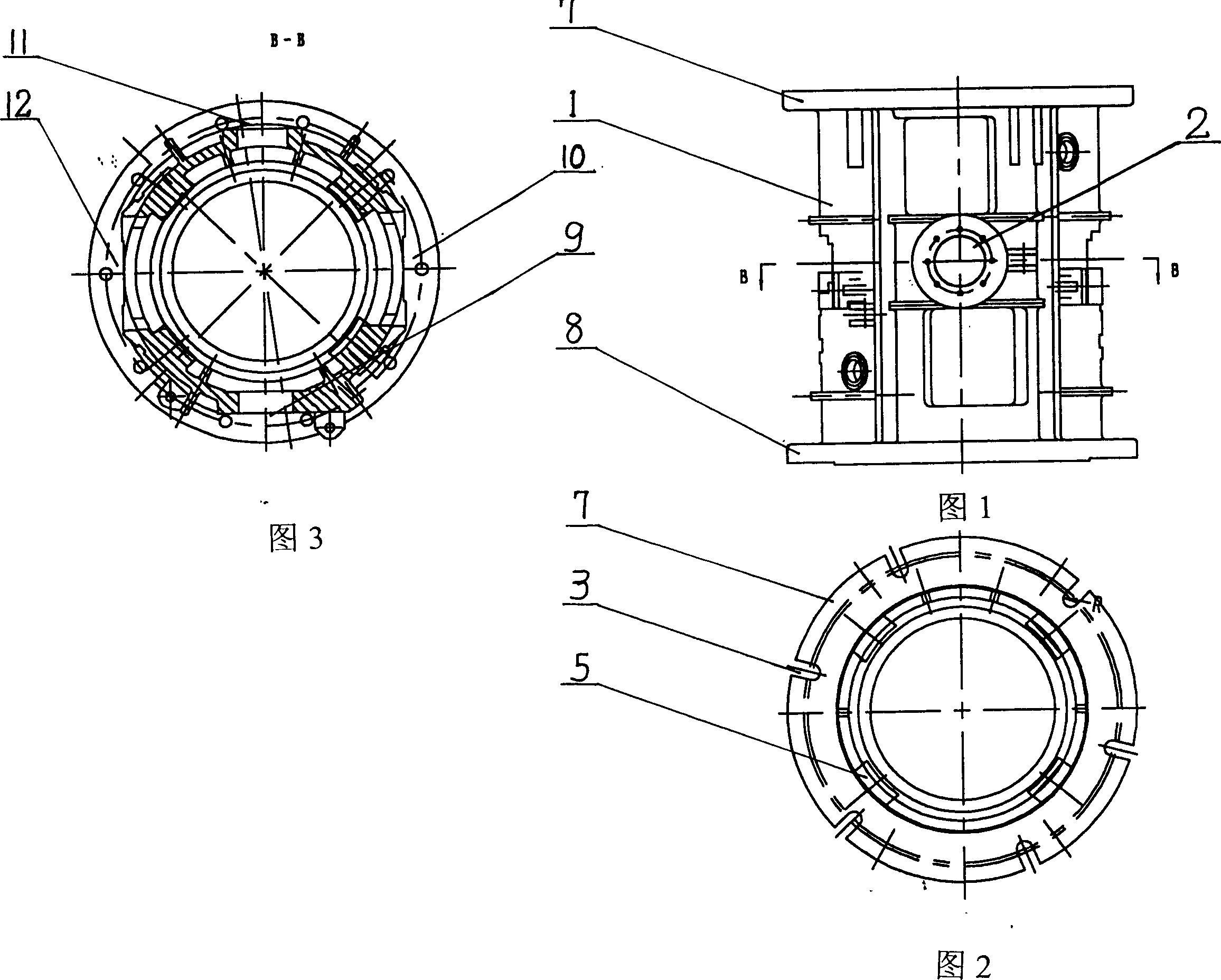

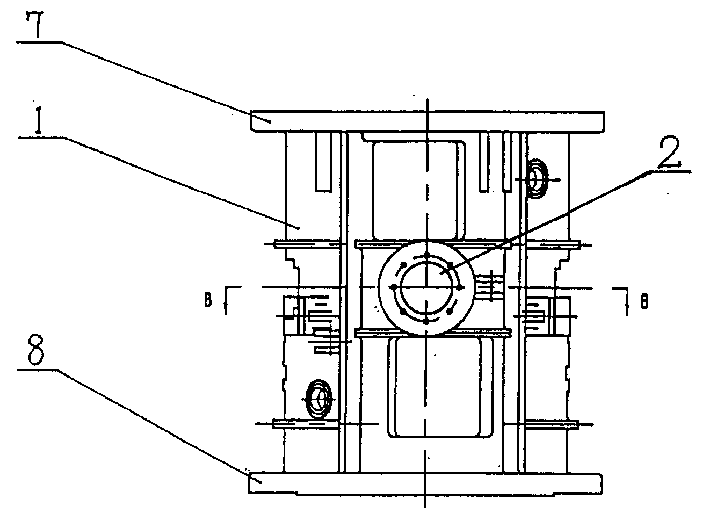

[0021] Referring to FIGS. 1-3, the frame 1 of the tapered piercer of the present invention is a cylindrical shape, which is integrally cast from low-expansion metal such as cast steel 35 or similar materials. The upper and lower outer edges 7 and 8 of the frame 1 are provided with wedge locking openings 3 for fixing with the upper cover 4 and the base 6 . There are reinforcing ribs 5 on the inner wall of the cylindrical frame, and various functional openings are arranged on different parts of the side of the cylindrical frame 1, such as the entrance 9 of the universal joint shaft that provides power for the rolls, the left guide plate opening 10, and the right guide plate opening 12 , 11 entrances of rolled blanks, 2 exits of waste pipes, etc.

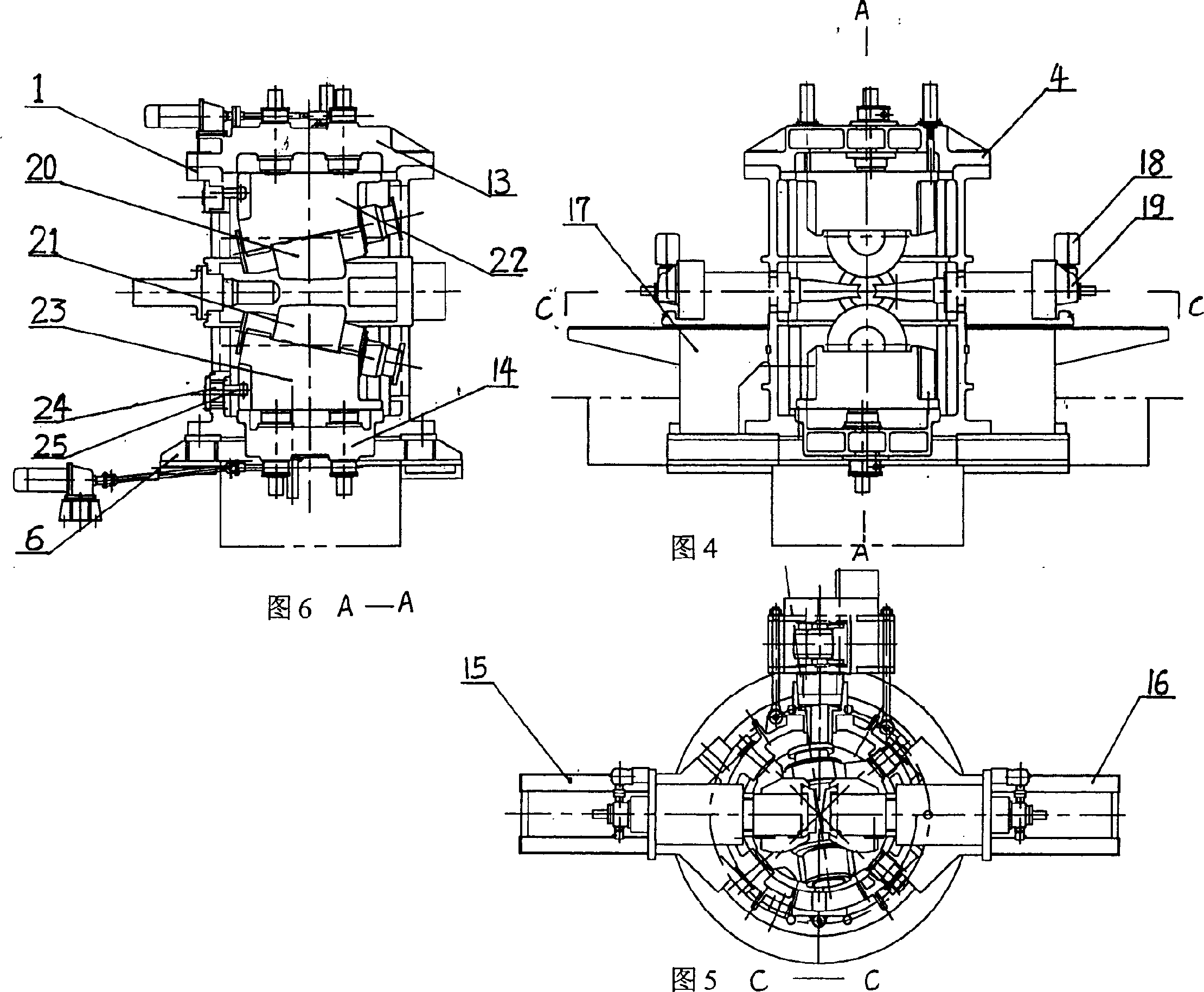

[0022] Figure 4-6 is an assembly drawing of the frame of the tapered piercing machine. There is a cover 4 on the upper part of the cylindrical frame 1 shown in the figure, and the two are locked with the wedge locking port 3 on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com