Silencer of rotary compressor

A technology of rotary compressor and muffler, which is applied in machine/engine, rotary piston/oscillating piston pump components, mechanical equipment, etc., can solve the problem of the overall performance degradation of the compressor, and it is difficult to effectively reduce noise in specific bands, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

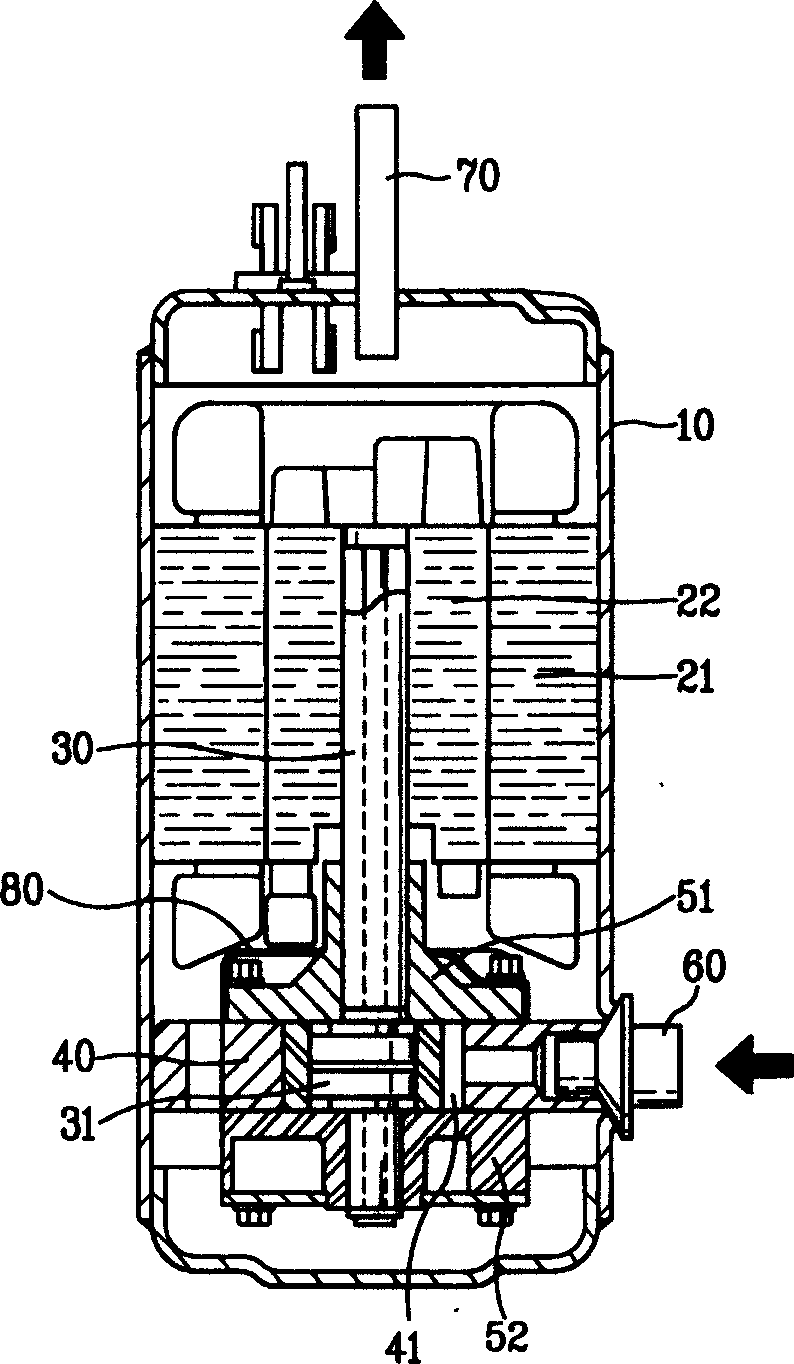

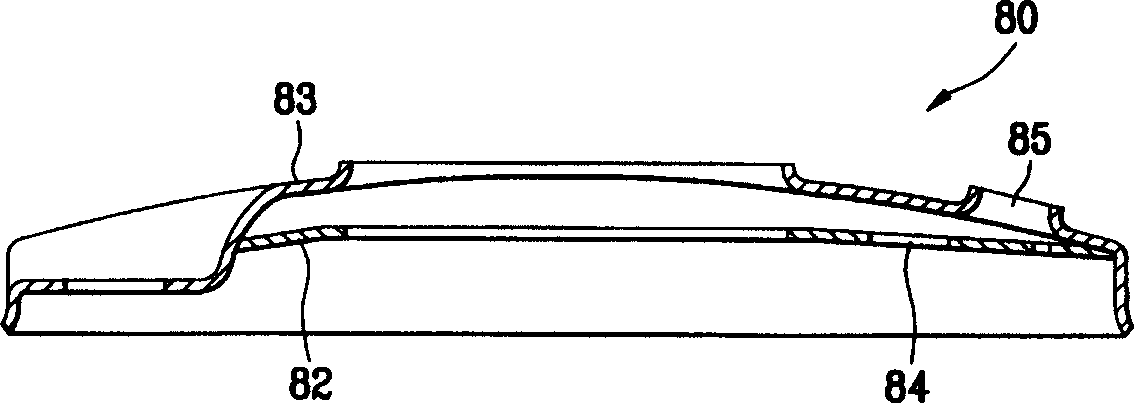

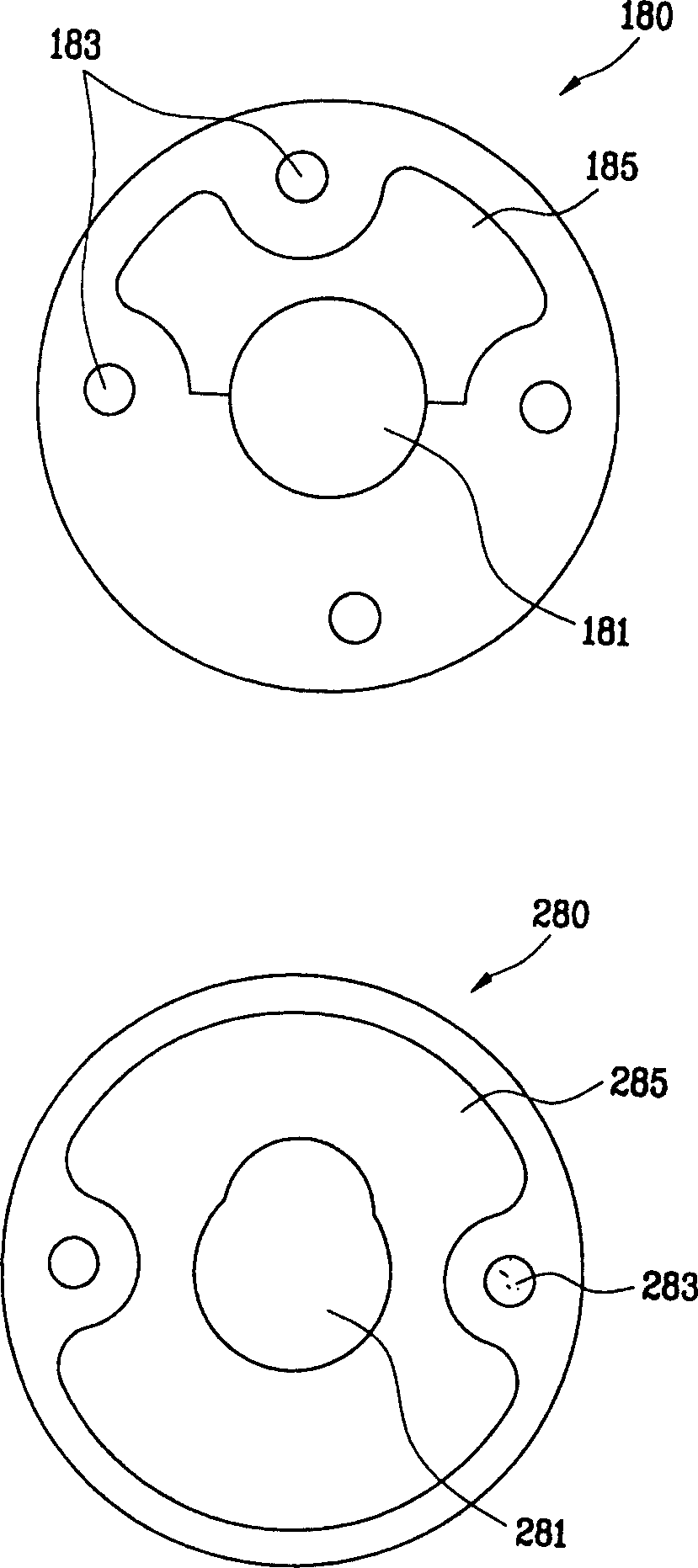

[0017] refer to figure 1 , image 3 , Figure 4 As shown, the rotary compressor muffler of the present invention includes an inner muffler 180 installed on the upper part of the main bearing 51 and an outer muffler 280 installed on the upper end of the inner muffler 180, thus having two functions of reducing noise.

[0018] The inner muffler 180 is formed by the crankshaft insertion space 181 through which the central crankshaft 30 is inserted, and an assembly groove 183 for fixing the inner muffler 180 on the main bearing 51 is formed at its edge position. In this embodiment, the assembly grooves 183 are respectively They are provided at four places in the front, back, left, and right of the edge portion of the internal muffler 180 . The middle part of one side of the internal muffler 180 is the compression chamber 41 refrigerant gas discharge space 185 formed on the top of the main bearing 51 and the outer surface of the crankshaft 30, and this discharge space 185 is open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com