Load control type exciter

A load control and exciter technology, applied in the direction of controlling mechanical energy, instruments, manufacturing tools, etc., can solve the problems of large initial load, workpiece damage, and initial load becoming larger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

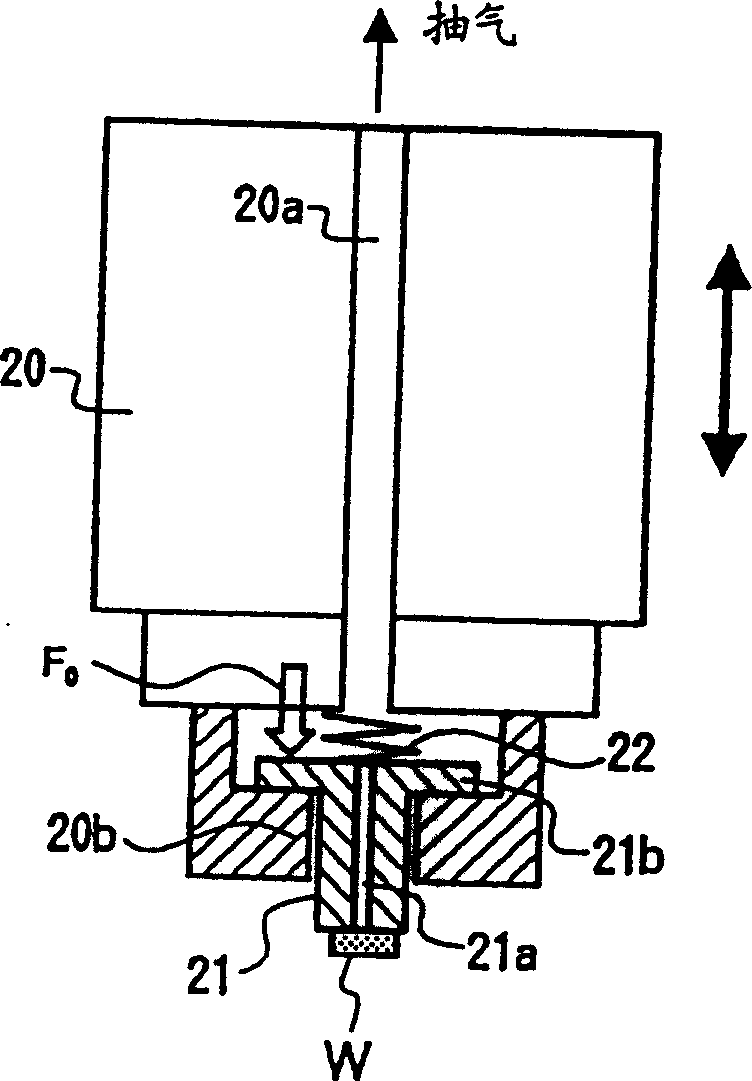

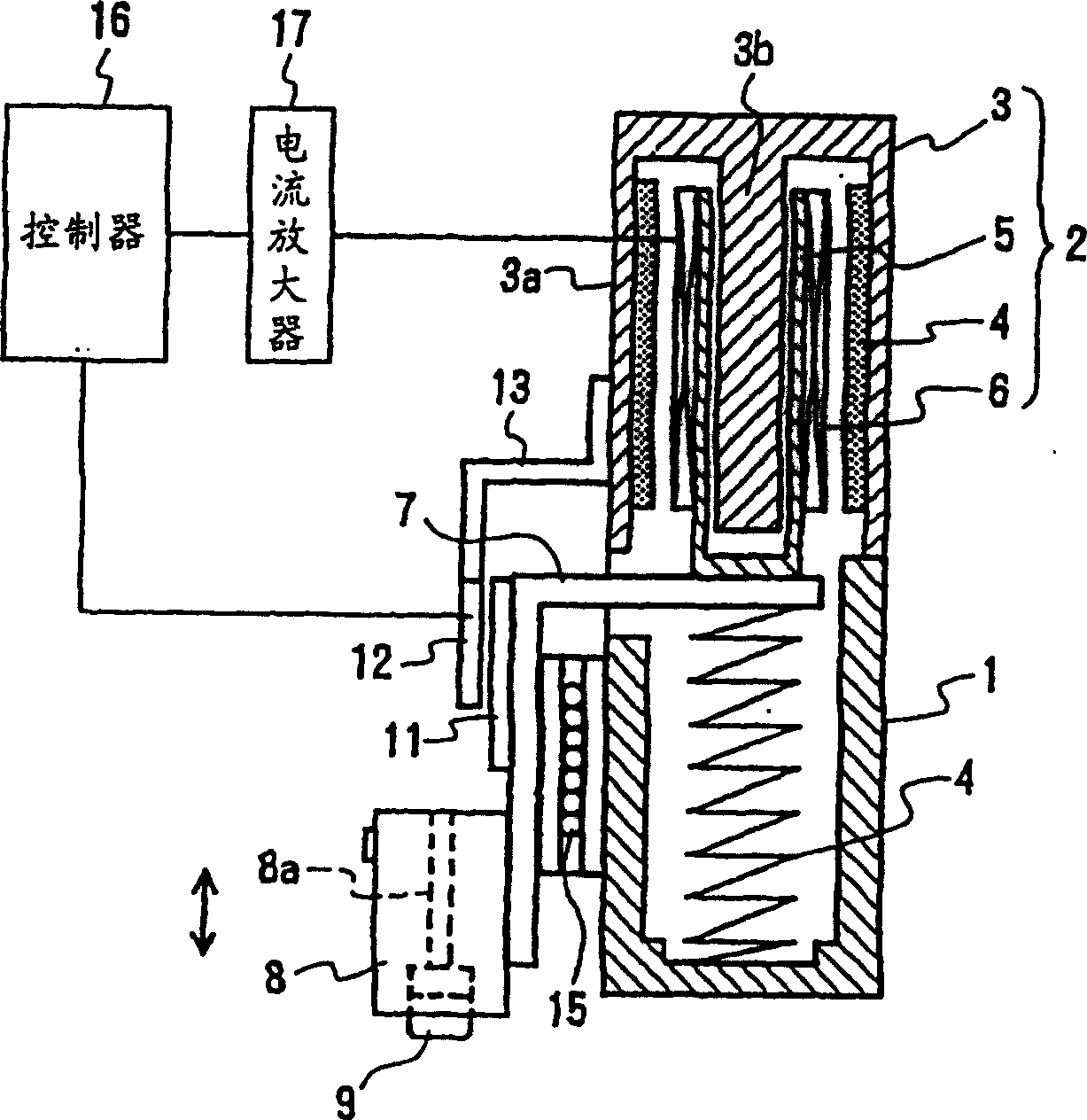

[0042]The processing device is made of non-magnetic material and mounted to the chassis 1 of the X-Y robot, and the magnetic circuit is set to the magnetic circuit of the voice coil motor. The magnetic circuit 2 includes a yoke 3 fixed to the upper portion of the chassis 1, a magnet 4 fixed to the inner surface of a cylindrical portion 3a of the yoke 3, a bobbin 5 vertically movable inserted by the center pole 3b of the yoke 3, and a winding Coil 6 of bobbin 5. The coil 6 overlaps the magnet 4 in the axial direction. In this embodiment, the magnet 4 is provided on the fixed side and the coil 6 is provided on the movable side; however, conversely, the coil 6 may be provided on the fixed side and the magnet 4 on the movable side.

[0043] On the lower end face of the bobbin 5, one end of the connecting member 7 is fixed, and the other end protrudes radially from the chassis 1 and the yoke 3, and a nozzle holder (movable member) 8 is fixed to its protruding portion 7a. Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com