Biological chip with minimized reactor isolation structure height and its preparation method

A technology of isolation structures and biochips, applied in biochemical equipment and methods, biological testing, microbial measurement/inspection, etc., can solve problems such as inability to minimize thickness and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: Multi-reactor biochip

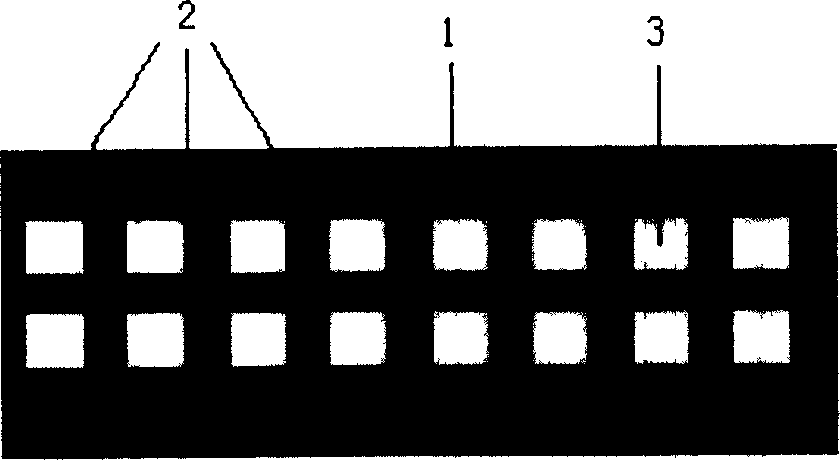

[0071] The basic structure of the biochip in this example is as follows figure 1 shown.

[0072] In this example, the substrate used is a glass substrate, and the highly hydrophobic materials used are all liquid materials, which are "super-hydrophobic latex paint" (provided by Chenguang Chemical Design Institute, China), "organic silicon waterproof coating" (China Chengdu Chenguang Chemical Design Institute) and "Polyacrylate Coating" (provided by Chengdu Chenguang Chemical Design Institute, China).

[0073] In this embodiment, the size of the substrate 1 is 75 × 25 × 1mm (length × width × height), and the highly hydrophobic material is evenly applied in the isolation area on the substrate, and cured after drying at room temperature according to the instructions of the supplier. ,form figure 1 The coating isolation structure 2 shown in , forms 16 reaction cells 3 with the substrate, and the size of the reaction cells is 3mm×3mm. ...

Embodiment 2

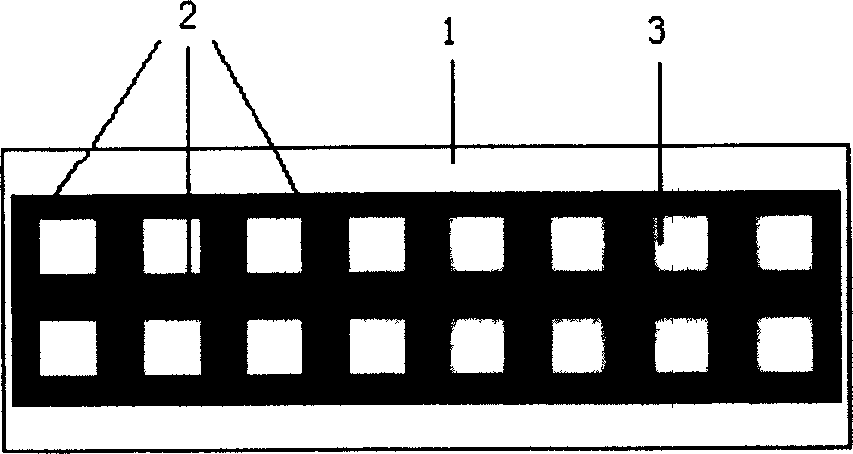

[0090] Embodiment 2: Multi-reactor biochip

[0091] The basic structure of the biochip in this example is as follows figure 2 shown.

[0092] In this example, the substrate used is a glass substrate, and the highly hydrophobic materials used are all solid-phase materials, which are respectively "polytetrafluoroethylene adhesive tape" (provided by Chenguang Chemical Design Institute, Chengdu, China, with a static water contact degree of 117 degrees) ) and "nano textiles" (provided by China Zhoushan Tomorrow Nanomaterials Company, static water contact degree of 155 degrees).

[0093] In this embodiment, the size of the substrate 1 is 75×25×1mm (length×width×height). The highly hydrophobic material is perforated and bonded to the isolation area on the substrate. After drying at room temperature, a figure 2 The highly hydrophobic isolation structure 2 shown in , forms 16 reaction cells 3 with the substrate 1, and the size of the reaction cells is 4.5mm×4.5mm. The thickness of...

Embodiment 3

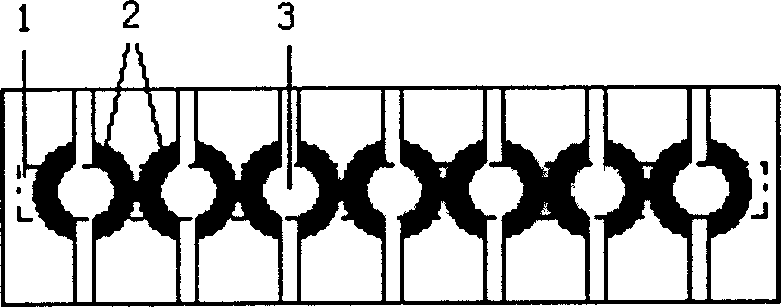

[0096] Example 3: Multi-reactor open flow biochip

[0097] The basic structure of the biochip in this example is as follows image 3 shown. The left side of the figure is a top view, and the right side is a cross-sectional view of a-a. The dotted line in the middle is the activated glass slide substrate 1. The size of the substrate is 75mm×5mm×1mm (length×width×height). The substrate is fixed on a liquid-feeding structure and The plastic forming plate of the liquid outlet structure, the shape size of the forming plate is 80mm×25mm×1mm (length×width×height), the liquid feeding structure and the liquid outlet structure on it are grooves with a width of 2mm, and there are guides in the grooves. Fluid hydrophilic material. The periphery of the reaction pool on the substrate is a super-hydrophobic isolation structure 2 formed by coating a layer of super-hydrophobic "nano-silicon oxide CDS7" (provided by China Zhoushan Mingri Nanomaterials Co., Ltd.). According to the requirement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com