Heat treatment method of nodular iron casting and nodular iron casting obtained by heat treatment method

A heat treatment method and technology of ductile iron, applied in heat treatment equipment, quenching agent, manufacturing tools, etc., can solve problems such as uneven structure of ductile iron castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Non-standard ductile iron casting QT830-2, the product is a box body, the thickest wall thickness is 56mm. The technical scheme adopted is as follows:

[0047] (1) Critical temperature point and phase transition point temperature of QT830-2: Mf is 66°C; Bs is 429°C; Ac1 is 789°C; Ac3 is 845°C; the best dissolution point of carbide is 965°C.

[0048] (2) Heating and high temperature homogenization process: Put the ductile iron castings into the furnace at 30°C, heat for 8h, heat to 450°C and keep it for 2h, continue heating for 6h, heat to 800°C and keep it for 75min, continue heating for 1.5h, and heat to 980°C, keep warm for 42 minutes.

[0049] (3) In the uniform cooling stage, the ductile iron castings are cooled with the furnace for 2 hours, cooled to 880°C and kept for 60 minutes. Then immerse the ductile iron casting in a cooling tank for cooling for 89 seconds, wherein the temperature of the cooling water in the cooling tank is 85°C. Then enter the 600 ° C hea...

Embodiment 2

[0051] Non-standard ductile iron casting QT700-3, the product is a shaft, the maximum wall thickness is 81mm. The technical scheme adopted is as follows:

[0052] (1) Critical temperature point and phase transition point temperature of QT700-3: Mf is 280°C; Bs is 539°C; Ac1 is 791°C; Ac3 is 815°C; the best dissolution point of carbide is 879°C.

[0053] (2) Heating and high temperature homogenization process: Put the ductile iron castings into the furnace at 25°C, heat for 10h, heat to 600°C and keep it for 2h, continue heating for 4h, heat it to 810°C and keep it for 90min, continue heating for 1h, and heat it to 930 ℃, keep warm for 60min.

[0054] (3) In the uniform cooling stage, the ductile iron castings are cooled with the furnace for 3 hours, cooled to 840°C and kept for 90 minutes. Then immerse the ductile iron casting in a cooling tank for cooling for 210 seconds, wherein the temperature of the cooling water in the cooling tank is 90°C. Then enter the 650 ° C heati...

Embodiment 3

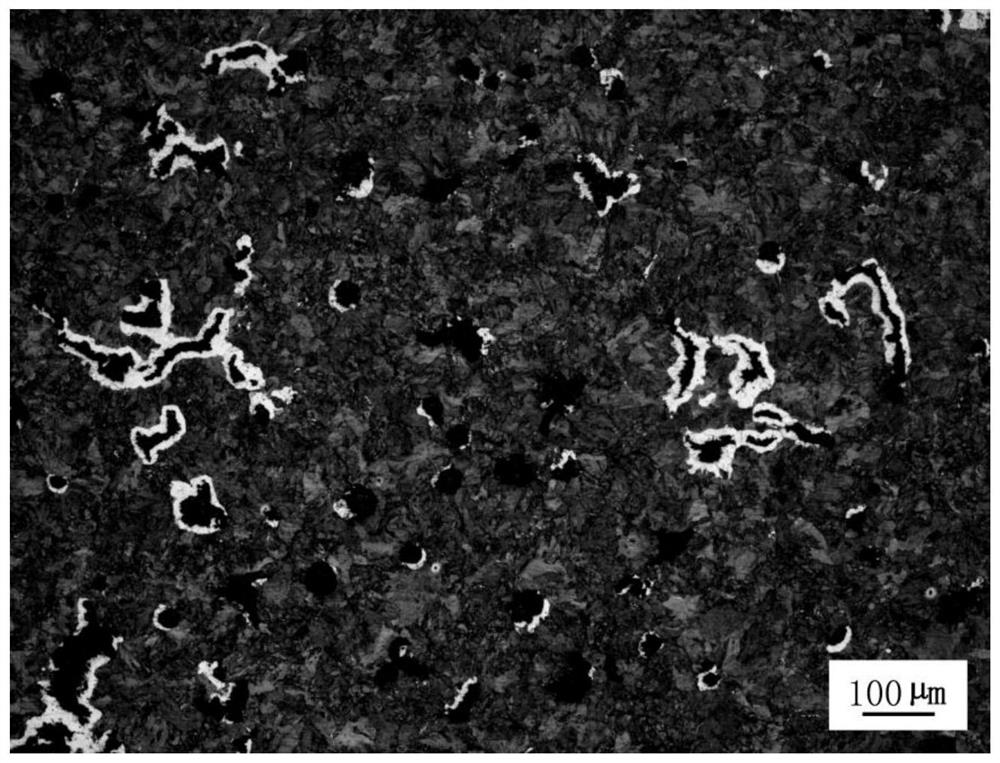

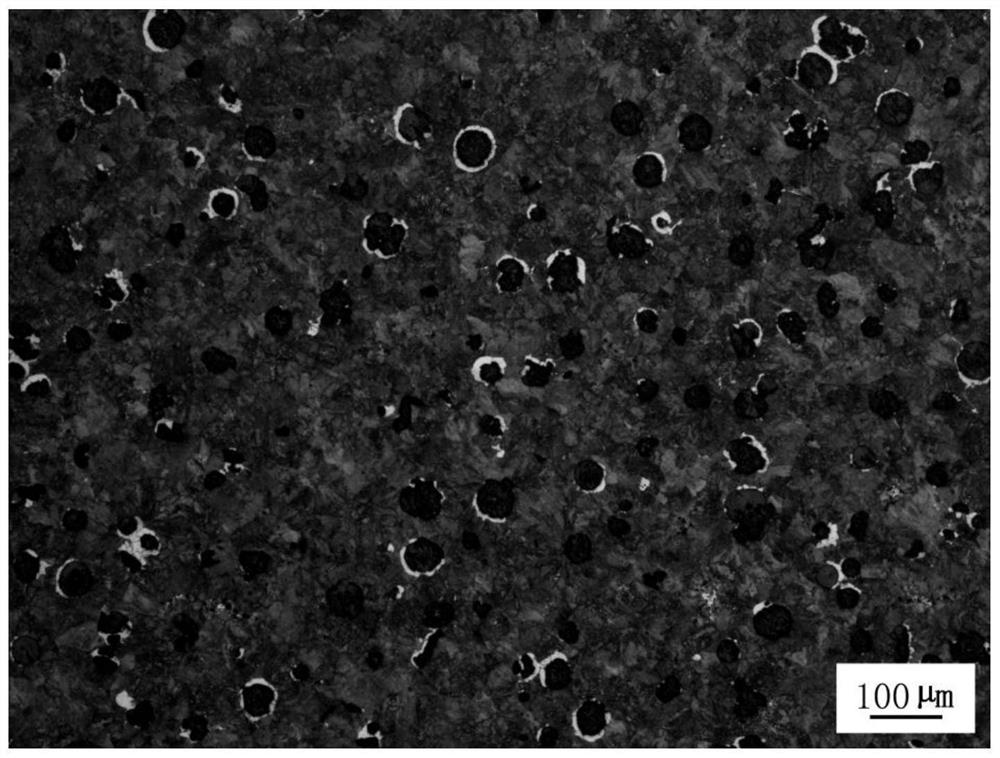

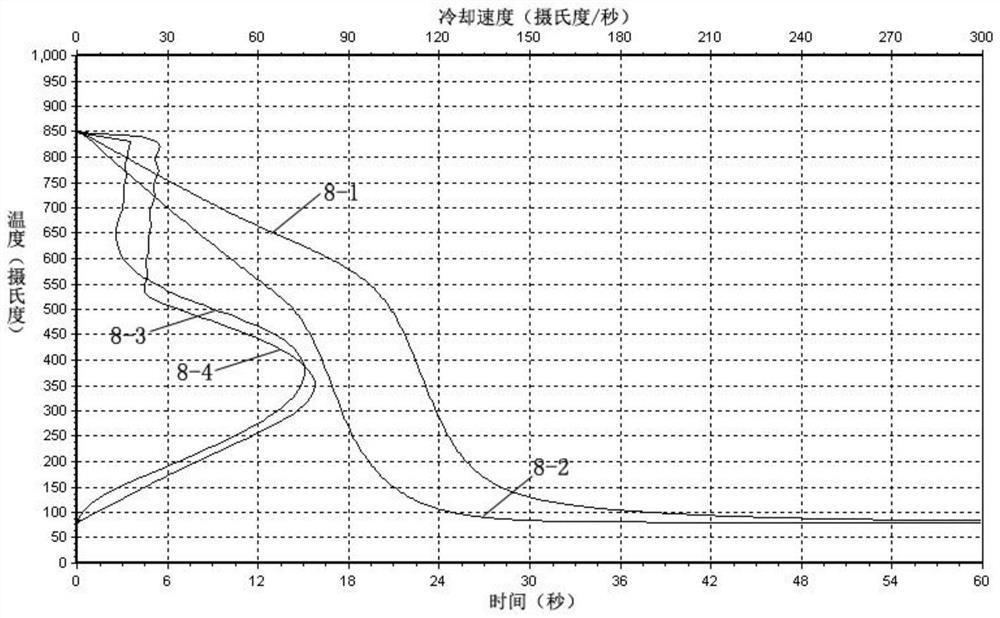

[0056] The difference between embodiment 3 and embodiment 1 is that the temperature of water in embodiment 3 is 80°C, and when the ductile iron casting is cooled in a water bath in a static state and a water bath in a stirring state at 80°C, the cooling curve of the cooling water is as follows image 3 ,from image 3 It can be seen from the figure that in the temperature range of 550-850 °C, the cooling rate of 80 °C water at rest is 13-17 °C / s, and the cooling rate of stirring state is 25-29 °C / s. In this temperature range, due to The cooling rate of water is uniform, which is beneficial to the uniform cooling of ductile iron castings, thereby improving the uniformity of hardness, uniformity of structure and regularity of deformation of ductile iron castings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com