Silver halide photosensitive material

A photosensitive material, silver halide technology, applied in photosensitive materials, application of photosensitive materials, optics, etc., can solve problems such as reduction of sensitivity and deterioration of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

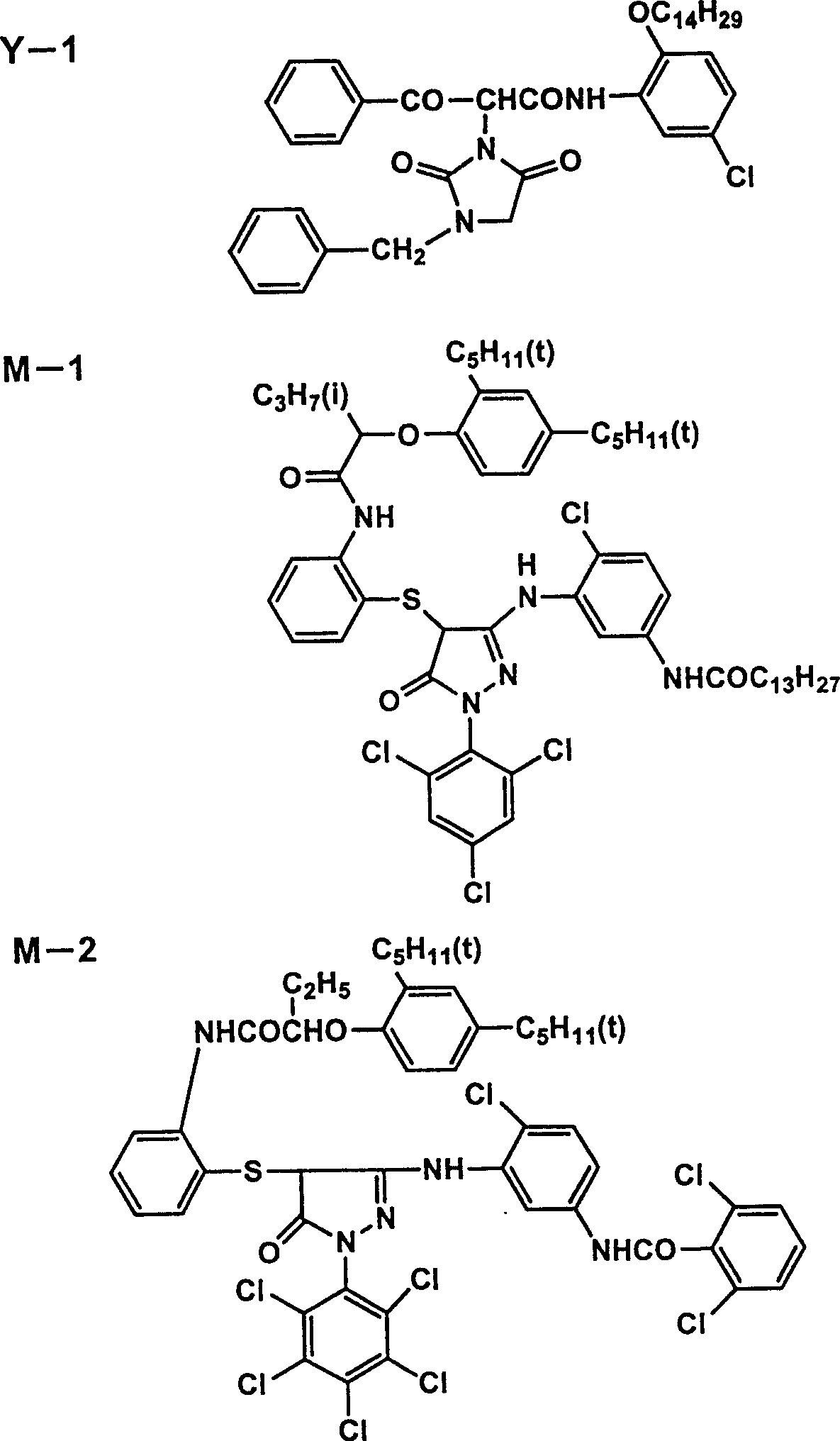

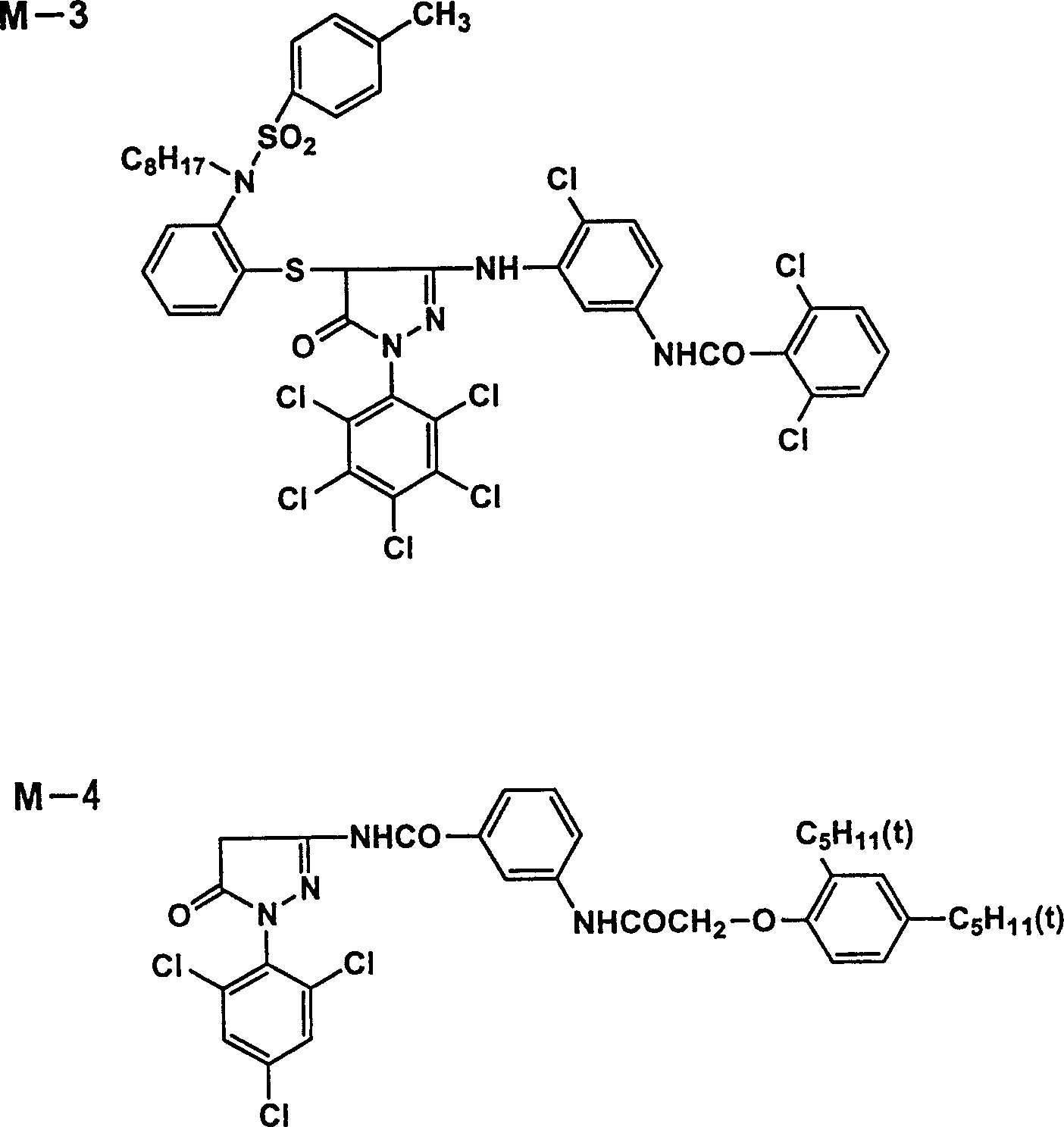

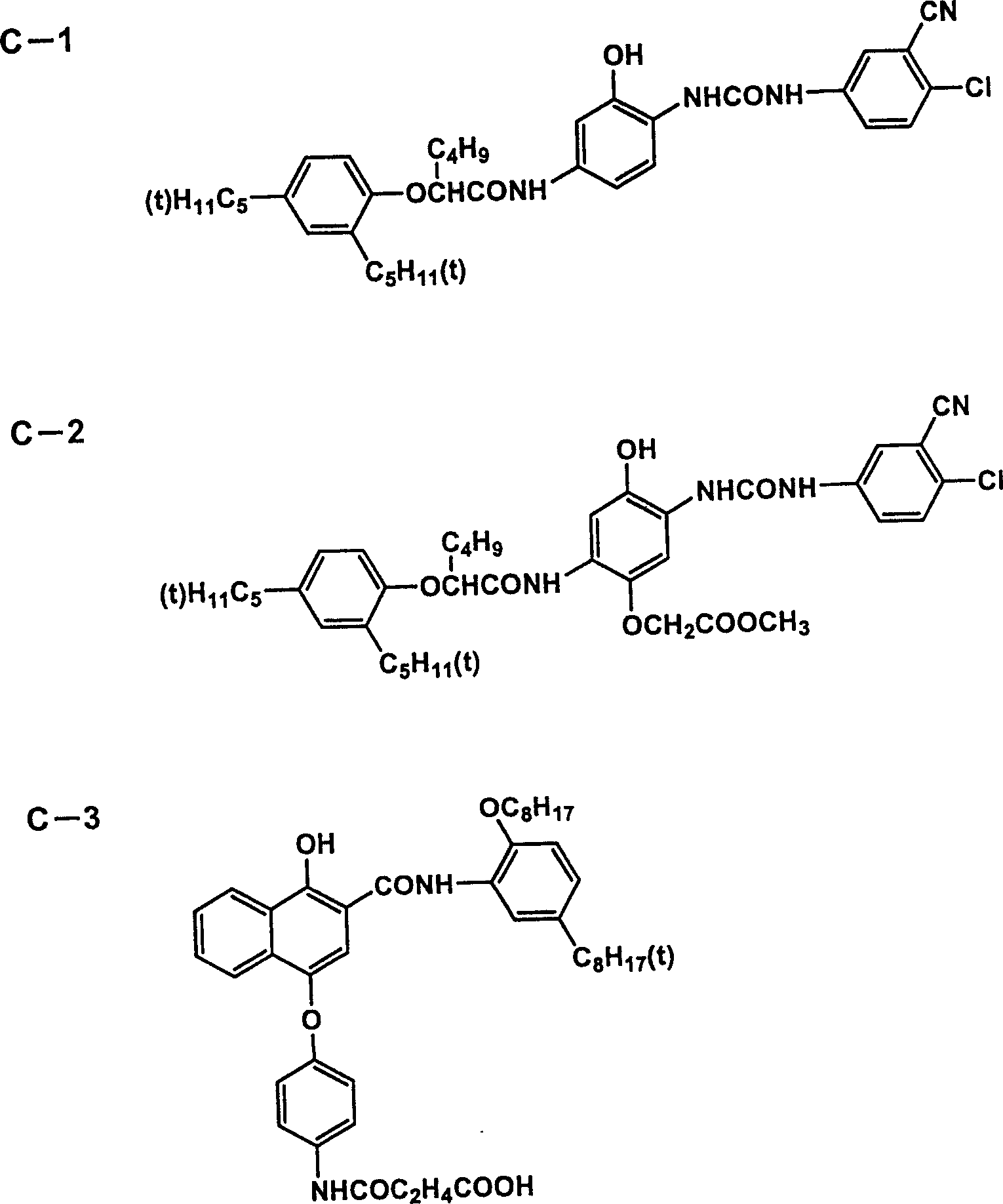

[0078] On the negative film support coated with triacetylcellulose, the following layers having the composition shown below were formed to prepare a multilayer color photographic photosensitive material sample 101. Unless otherwise stated, the amount of each compound added is in g / m 2 To represent. The amount of silver halide or colloidal silver is converted to the amount of silver, and the amount of sensitized dye (indicated by "SD") is expressed in mol / Ag mol.

[0079] Layer 1: Anti-vignetting layer

[0080] Black Colloidal Silver 0.20

[0081] UV-1 0.30

[0082] CM-1 0.040

[0083] OIL-1 0.167

[0084] Gelatin 1.33

[0085] Layer 2: Middle Layer

[0086] CM-1 0.10

[0087] OIL-1 0.06

[0088] Gelatin 0.67

[0089] Layer 3: Low speed red sensitive layer

[0090] Silver iodobromide emulsion a 0.298

[0091] Silver iodobromide emulsion b 0.160

[0092] SD-1 2.4×10 -5

[0093] SD-2 9.6×10 -5

[0094] SD-3 2.0×10 -4

[0095] SD-4 8.9×10 -5

[0096] SD-5 9.2×...

Embodiment 2

[0425] Sample 201 was prepared in accordance with sample 103 of JP-A 2000-89420.

[0426] Sample 202 was prepared similarly to sample 201, except that silver iodobromide emulsion c for the fifth layer, silver iodobromide emulsion e for the ninth layer, and Layer 12 silver iodobromide emulsion h. Sample 203 was prepared similarly to Sample 201 except that the iodide content of the silver iodobromide emulsion newly introduced into Sample 2 was changed to 2.0 mol%.

[0427] For each of Samples 201 to 203, the silver halide development rate upon exposure to neutral white light (N) or split exposure (D) was determined. In addition, as in Example 1, each sample was evaluated for graininess and radiation resistance.

[0428] The results are shown in Table 4.

[0429] Developing rate(N)

[0430] Apparently, the samples of the present invention have excellent granularity and enhanced radiation resistance.

Embodiment 3

[0432] Samples 301 and 302 were prepared in the same manner as sample 101 of Example 1 and sample 201 of Example 2. Each sample thus prepared was evaluated. Samples 301 and 302 were measured for color developer oxidation product utilization, coupler dye formation and ISO speed when exposed to neutral white light. Furthermore, similarly to Example 1 and Example 2, each sample was evaluated for dry layer thickness, graininess, and radiation resistance.

[0433] The results are shown in Table 5.

[0434] use factor

[0435] As is evident from this table, the samples of the present invention have excellent graininess and enhanced radiation resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com