Patents

Literature

48results about "Subtractive colour processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

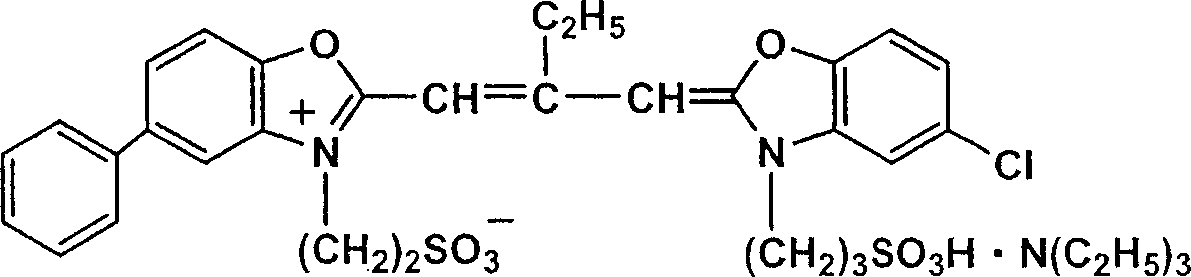

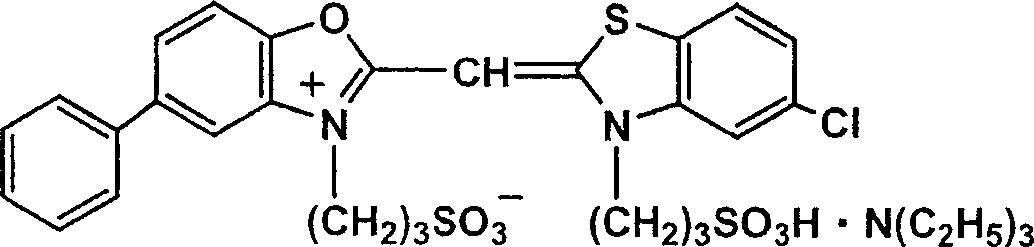

Silver halide photographic lightsensitive material

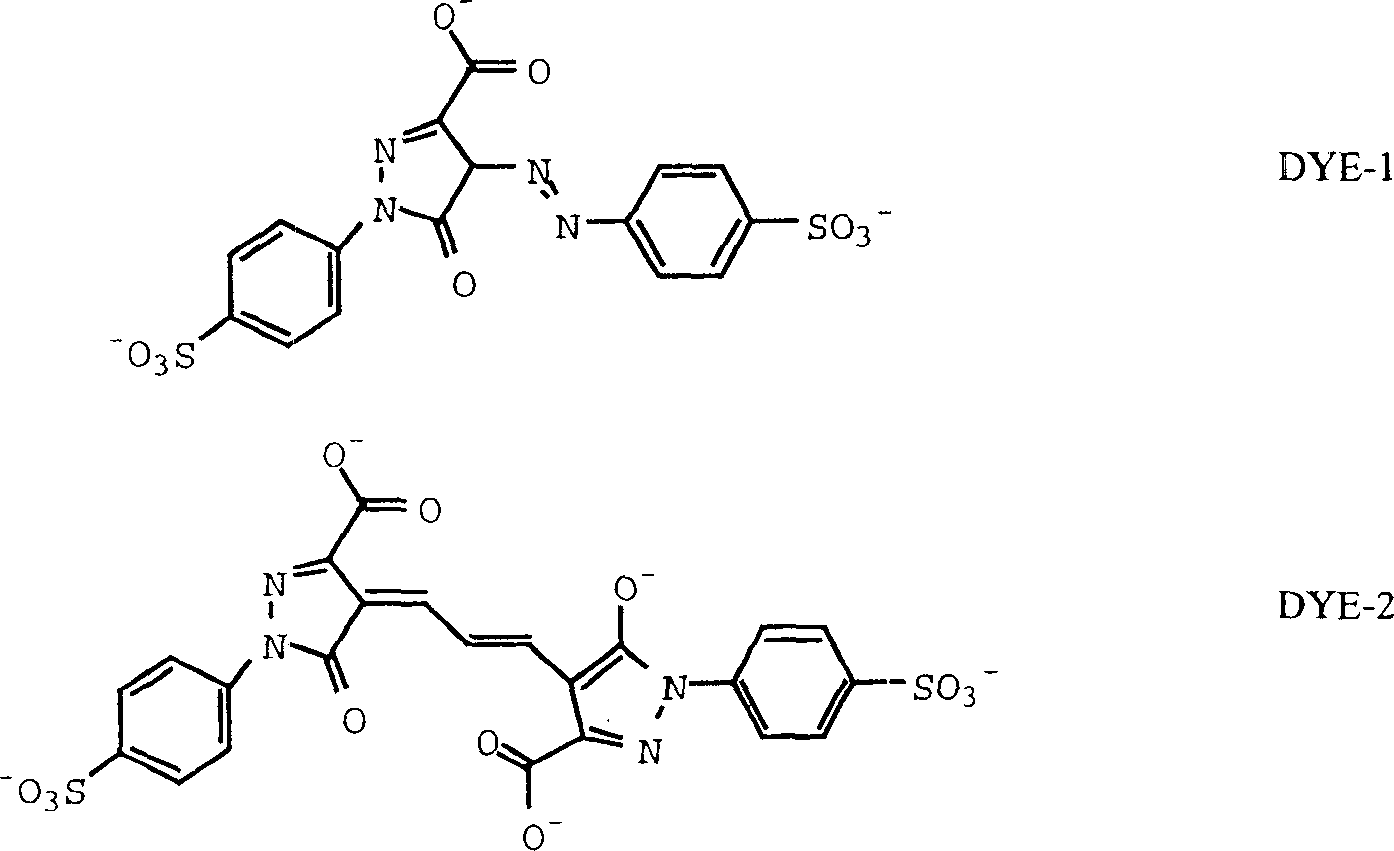

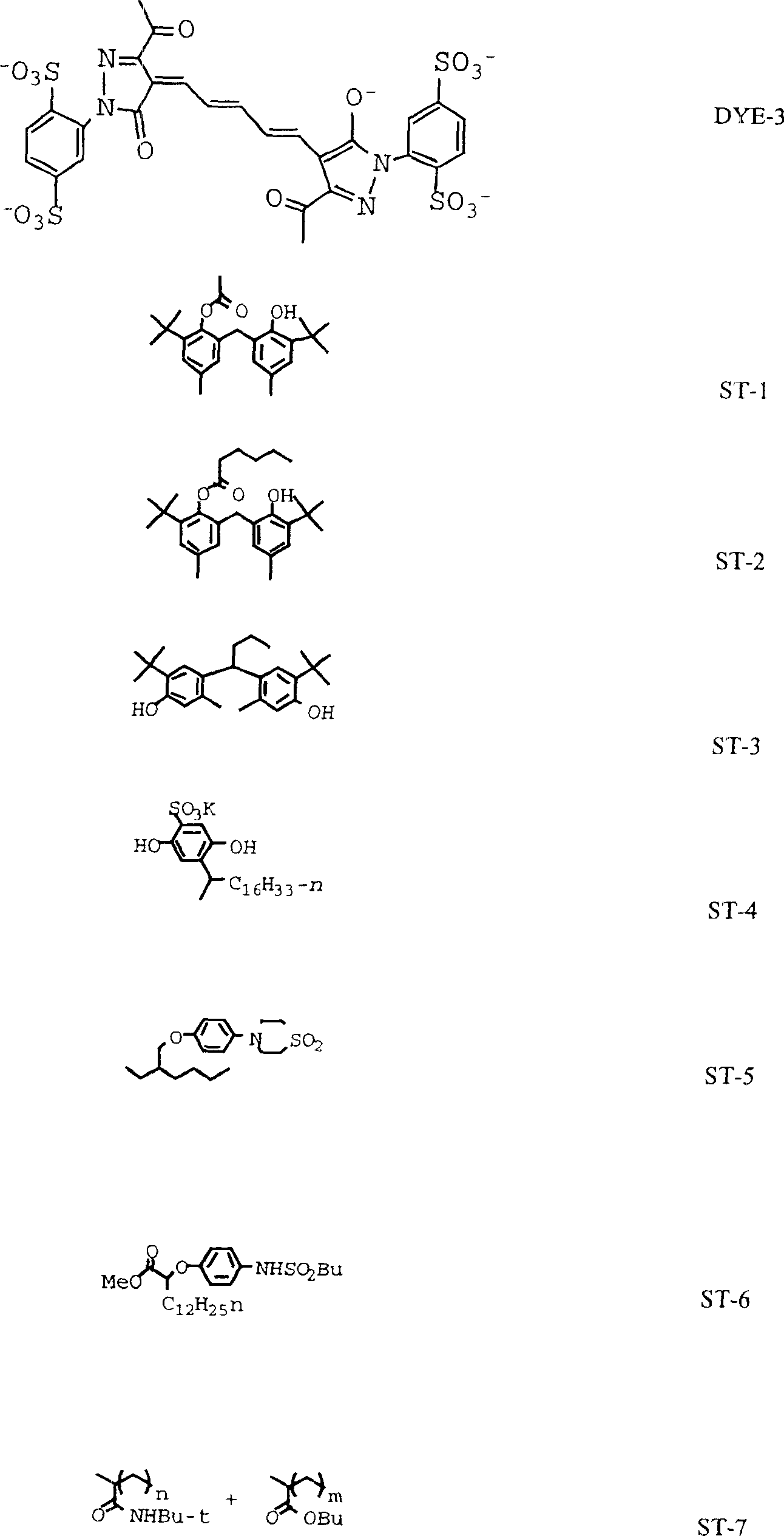

InactiveUS6610466B2Accurately determineThe right amountSubtractive colour processesSilver halide emulsionsLength wavePhotochemistry

A silver halide photographic lightsensitive material comprising at least one silver halide photographic emulsion layer containing a silver halide photographic emulsion prepared by mixing a dispersion of silver halide grains, the silver halide grains exhibiting such spectral absorption maximum wavelength and light absorption intensity that, when the spectral absorption maximum wavelength is less than 500 nm, the light absorption intensity is 60 or more, while when the spectral absorption maximum wavelength is 500 nm or more, the light absorption intensity is 100 or more, with an emulsified dispersion, wherein the silver halide photographic emulsion, when agitated at 40° C. for 30 min, exhibits a variation of absorption spectrum integrated intensity ranging from 400 nm to 700 nm of 10% or less.

Owner:FUJIFILM CORP

Combination of imaging member and functional base for new utility

InactiveUS20050112336A1Improved opticalImprove mechanical propertiesStampsPhotography auxillary processesPolymer scienceMicrometer

The invention relates to an article comprising an image member comprising a polymer sheet having an image adhered thereto permanently adhered to a functional base wherein said image member and said functional base interact to create a new image utility and wherein said polymer sheet has a thickness of less than 250 micrometers.

Owner:BOURDELAIS ROBERT P +2

Silver halide color photosensitive material

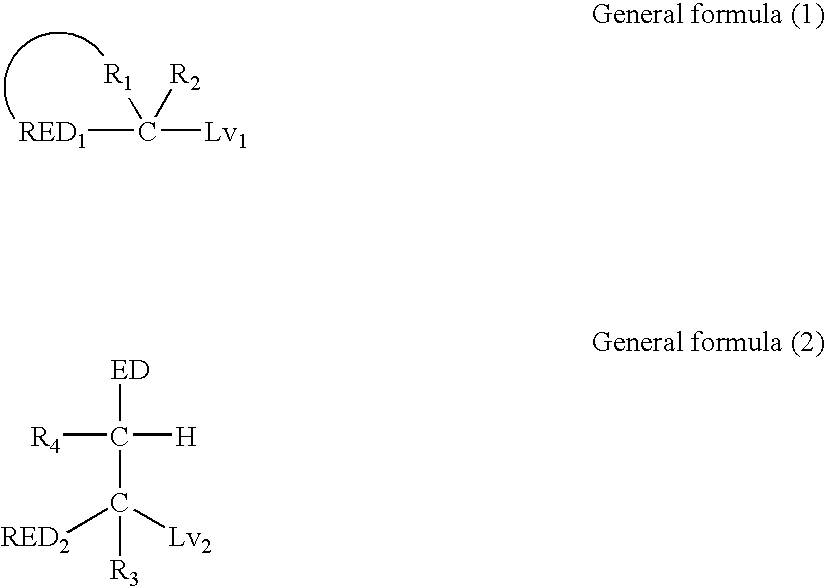

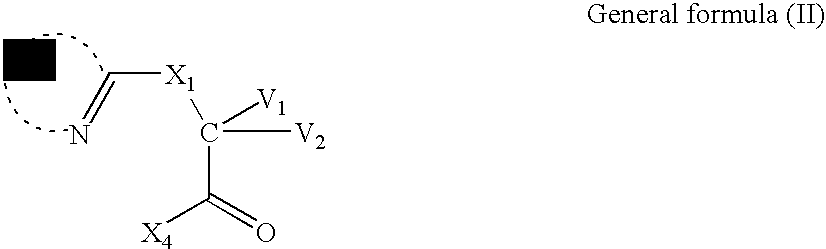

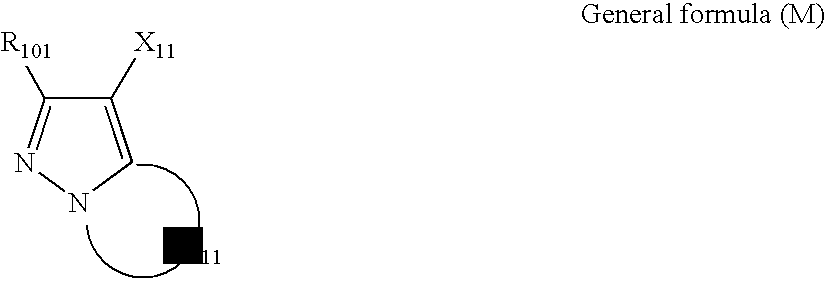

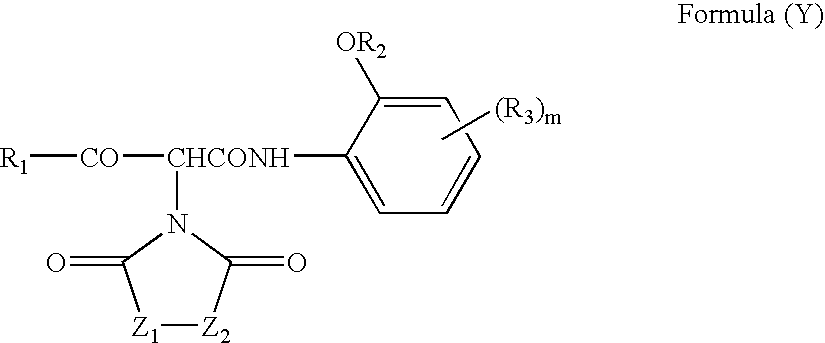

InactiveUS20050069824A1High sensitivitySuppress static-induced fogPhotosensitive material auxillary/base layersSubtractive colour processesBond cleavageLength wave

A silver halide color photosensitive material comprises a blue-sensitive layer, a green-sensitive layer, a red-sensitive layer and a non-light-sensitive layer on a support. The silver halide color photosensitive material contains a compound selected from the following type 1 and type 2 compounds, and wherein the blue-sensitive layer meets the relationship of the following formula (I): SB(370 nm) / SB(420 nm)<0.7 (I) wherein SB(λ) represents a spectral sensitivity at a wavelength of λ, (type 1) a compound capable of undergoing a one-electron oxidation to thereby form a one-electron oxidation product thereof, wherein the one-electron oxidation product is capable of releasing further one or more electrons accompanying a subsequent bond cleavage reaction, and (type 2) a compound capable of undergoing a one-electron oxidation to thereby form a one-electron oxidation product thereof, wherein the one-electron oxidation product is capable of releasing further one or more electrons accompanying a subsequent bond-forming reaction.

Owner:FUJIFILM HLDG CORP +1

Silver halide color photographic photosensitive material

InactiveUS20050214698A1High sensitivityIncrease graininessSubtractive colour processesSilver halide emulsionsDislocationAspect ratio

The present invention provides a silver halide color photographic photosensitive material that includes coupler-containing sensitive emulsion layer units on a support. Each of the photosensitive emulsion layer units are constituted of at least two photosensitive emulsion layers having sensitivities which are different from each other. An emulsion layer of the highest sensitivity among the at least two photosensitive emulsion layers contains at least one silver halide emulsion in which tabular silver halide grains with an average aspect ratio of 3 or more substantially including dislocation lines account for 50% or more of the total projected areas. Photosensitive emulsion layers other than the emulsion layer of the highest sensitivity consist of a silver halide emulsion containing silver halide grains that account for 70% or more of the total projected areas and include host grains that satisfy a specific aspect ratio condition and epitaxially joined protrusions.

Owner:FUJIFILM HLDG CORP +1

Silver halide color photosensitive material

ActiveUS7074550B2Less coatingHigh sensitivitySubtractive colour processesSilver halide emulsionsProject areaSilver halide

A silver halide color photosensitive material comprising a support and, superimposed thereon, at least one blue-sensitive silver halide emulsion layer, green-sensitive silver halide emulsion layer and red-sensitive silver halide emulsion layer, wherein(i) the specified speed of the photosensitive material is 350 or higher,(ii) the coating amount of silver in the photosensitive material is 7 g / m2 or less, and(iii) any of the color-sensitive silver halide emulsion layers is composed of two or more silver halide emulsion layers of different photographic speeds, of which the silver halide emulsion layer with the highest photographic speed contains tabular silver halide grains of 8 or greater aspect ratio in a ratio of 70% or more based on the total projected area and regular-crystal silver halide grains of 0.1 to 0.5 μm equivalent sphere diameter in a ratio of 0.5 to 5% based on the total projected area.

Owner:FUJIFILM CORP +1

Silver halide color photosensitive material

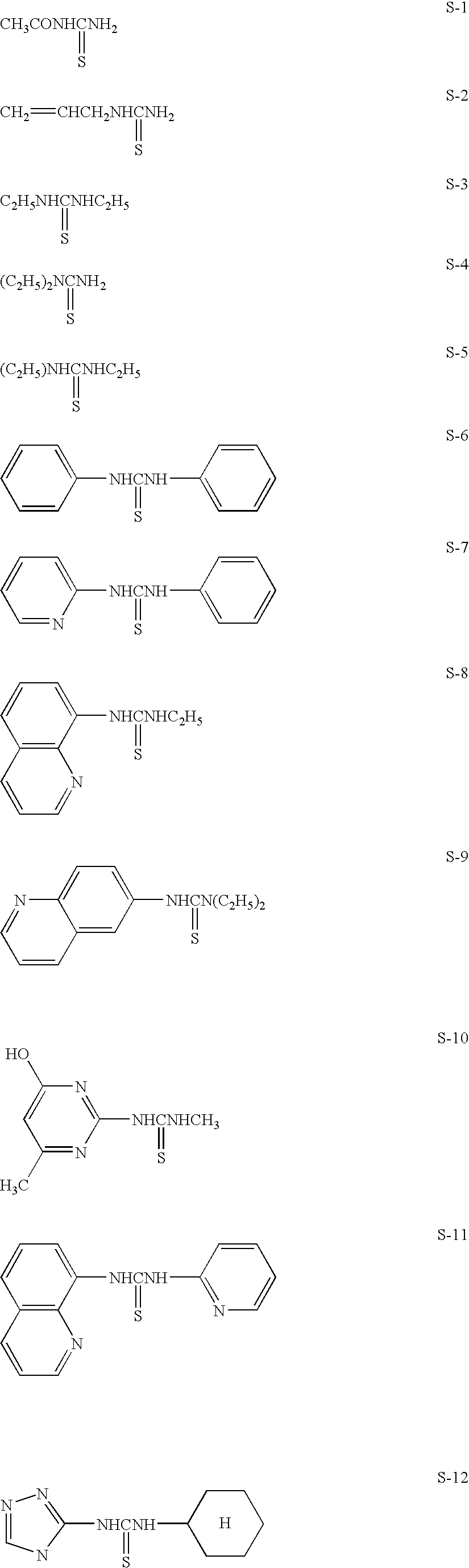

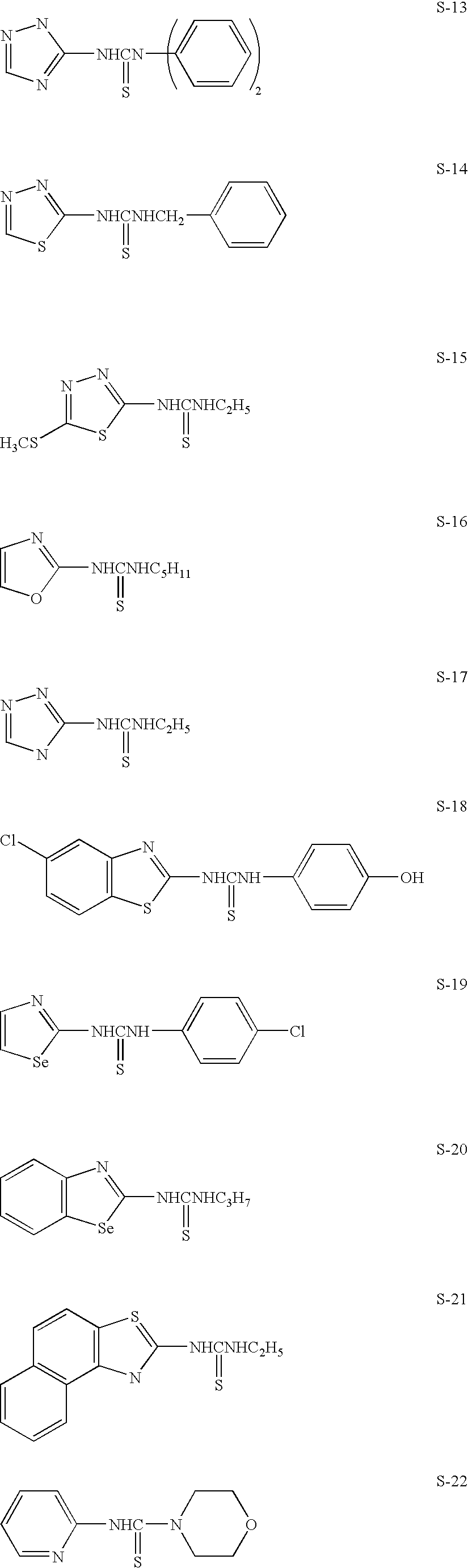

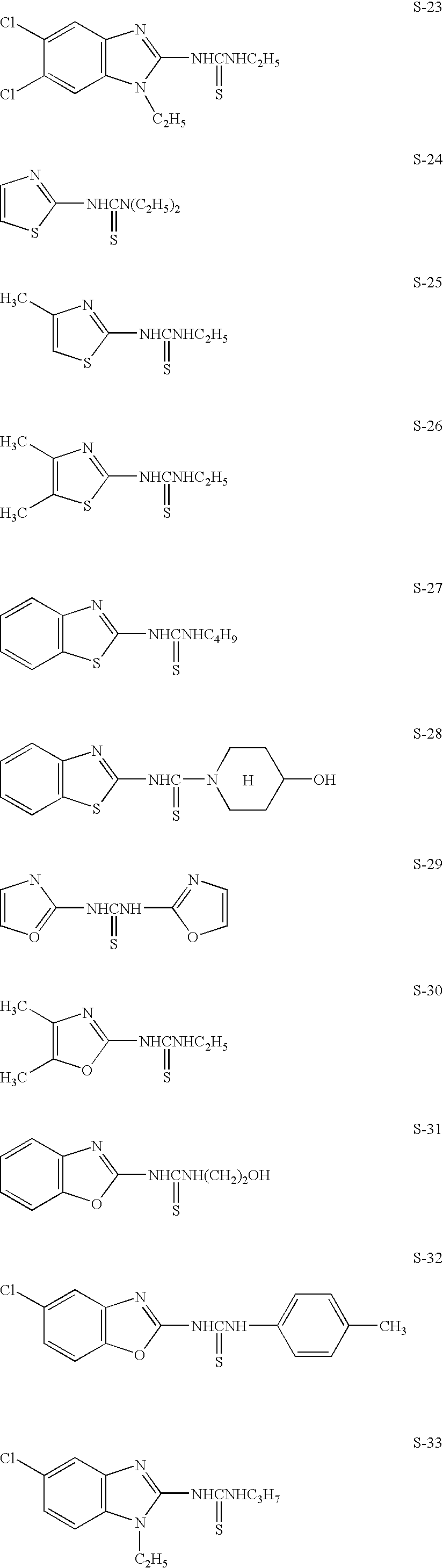

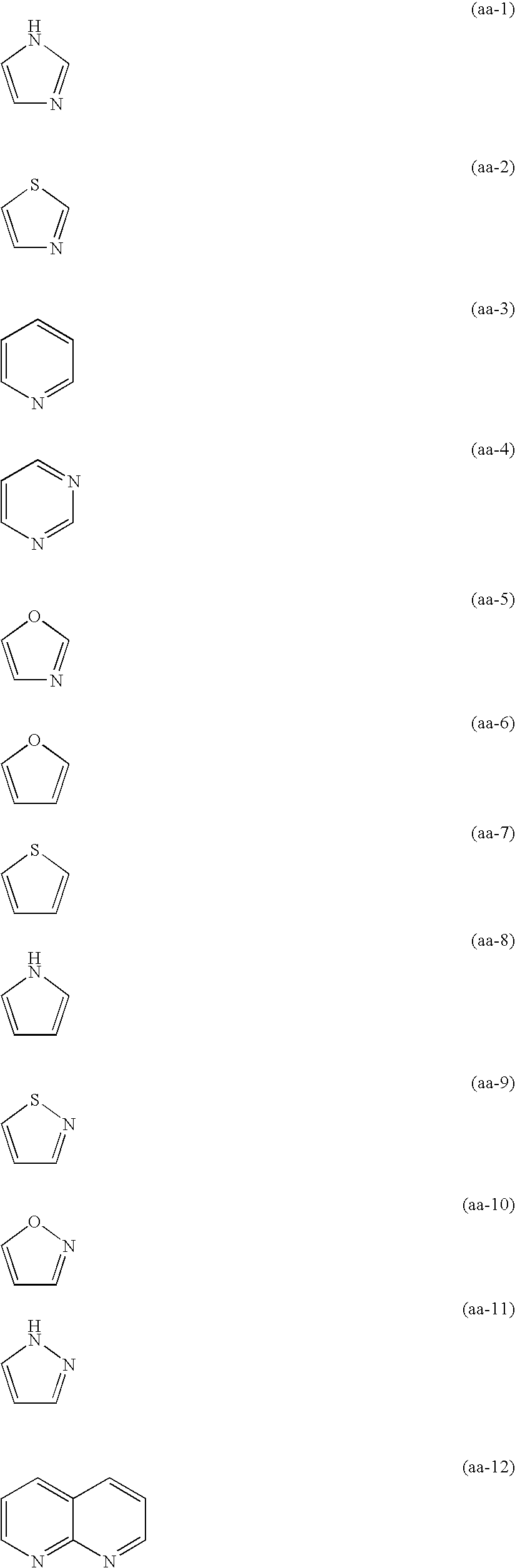

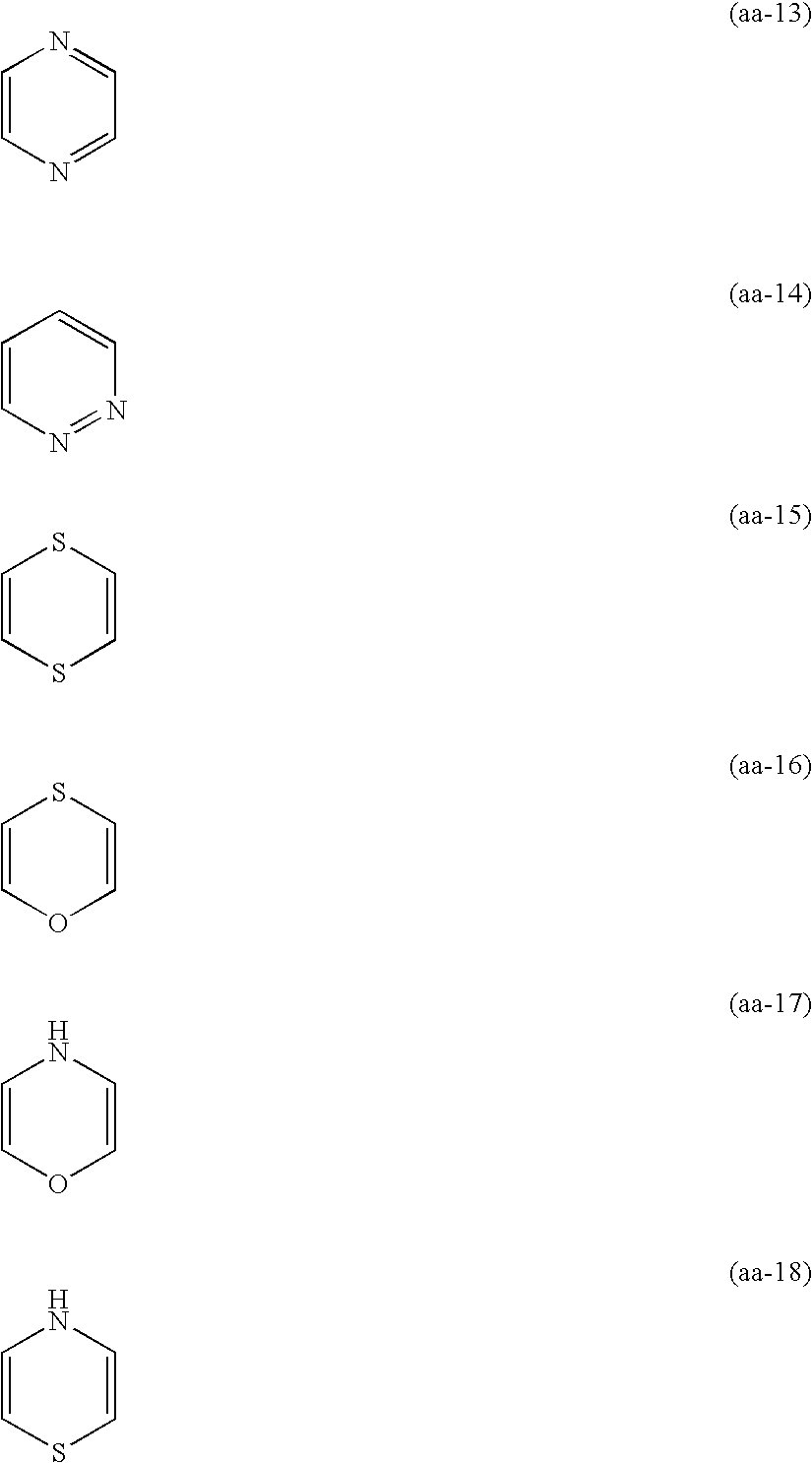

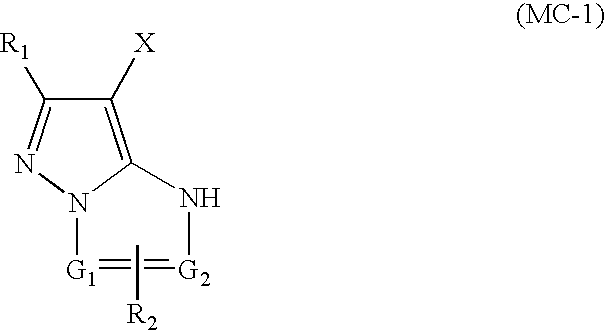

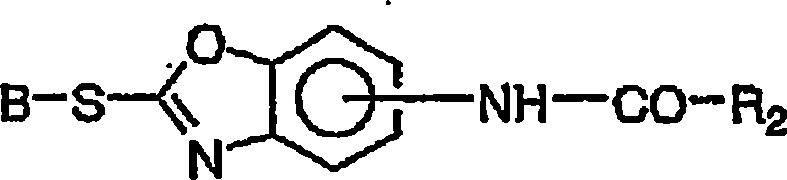

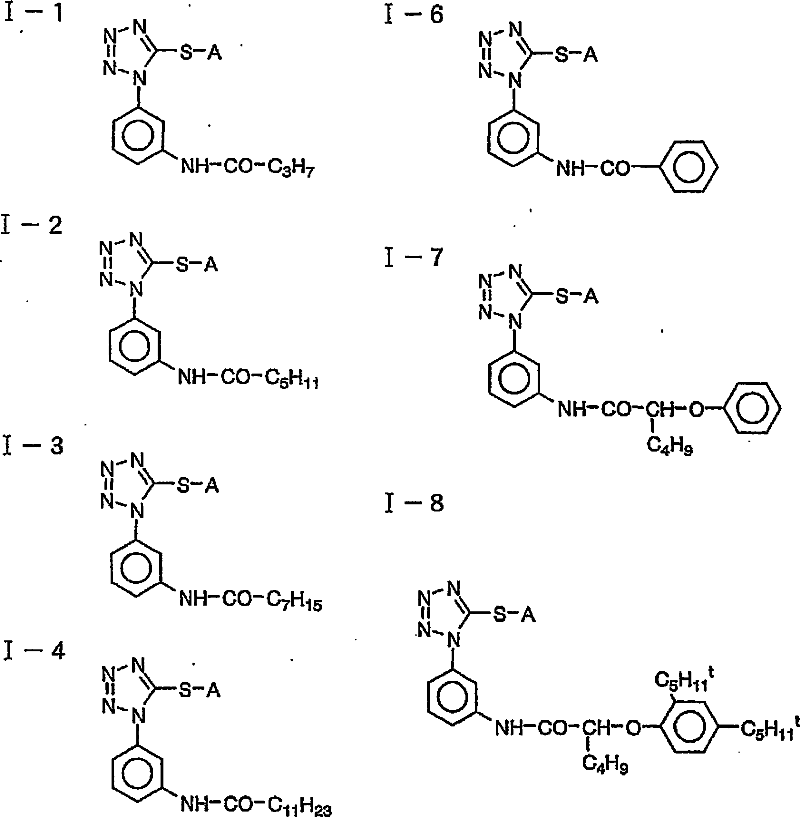

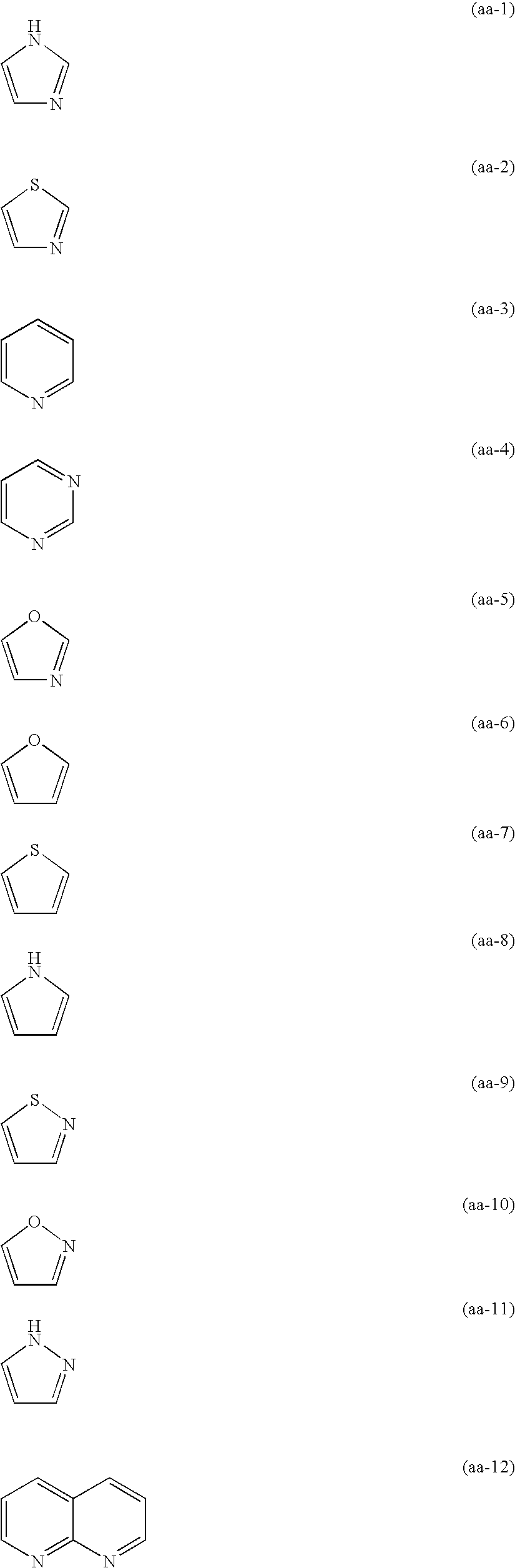

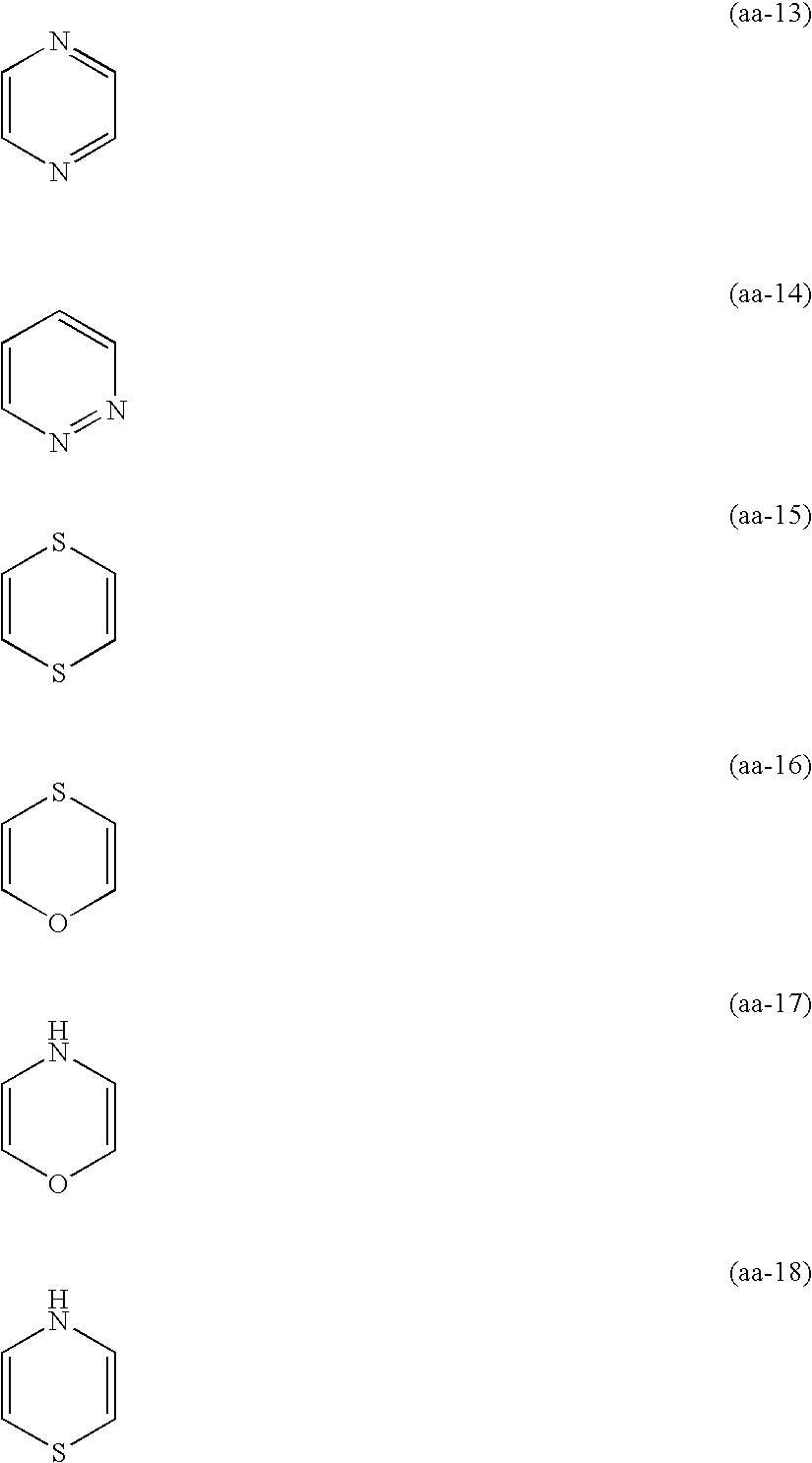

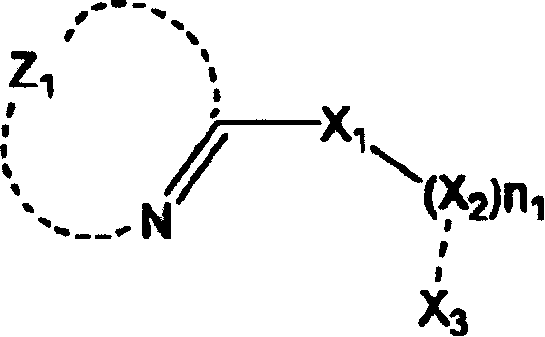

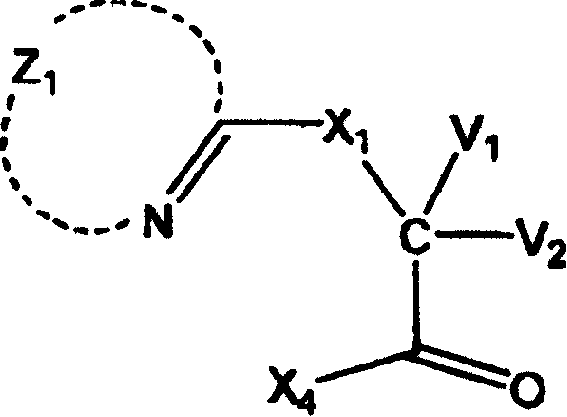

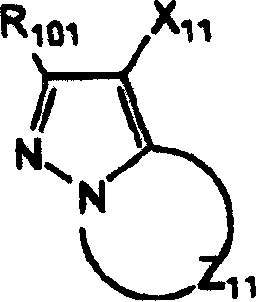

InactiveUS7115356B2Improve image qualityHigh sensitivityRadiation applicationsSubtractive colour processesHeteroatomSilver halide

A silver halide color photosensitive material of less than 320 ISO speed, comprising at least two red-sensitive emulsion layers, at least two green-sensitive emulsion layers, at least one blue-sensitive emulsion layer and at least one nonsensitive layer, wherein silver halide tabular grains of 0.15 μm or less grain thickness are contained in an amount of 50% or more in respective layers with the highest speed among the green- and red-sensitive emulsion layers; wherein the total dry film thickness of the material on the emulsion layer side thereof is 24 μm or less; and wherein the compound (A) is contained in at least one silver halide emulsion layer or the nonsensitive layer.Compound (A): heterocyclic compound having one or more heteroatoms, which heterocyclic compound is capable of substantially increasing the sensitivity of silver halide color photosensitive material by addition thereof as compared with that exhibited when the compound is not added.

Owner:FUJIFILM CORP +1

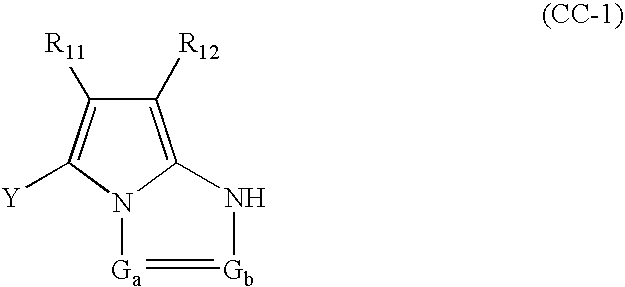

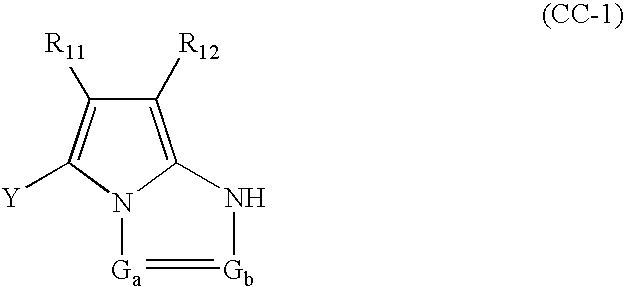

Method of forming color images

InactiveUS6936412B2High saturationPromote reproductionPhotoprinting processesPhotosensitive material auxillary/base layersColor imageHydrogen atom

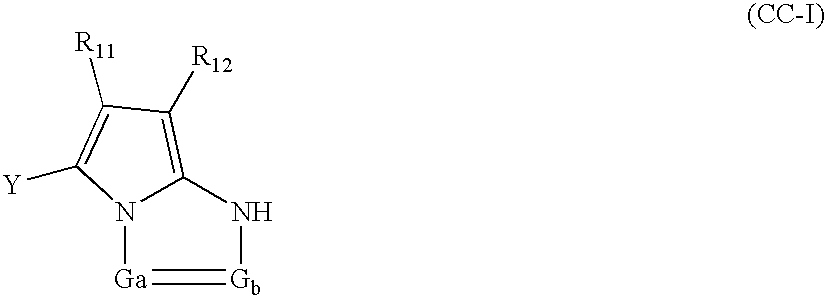

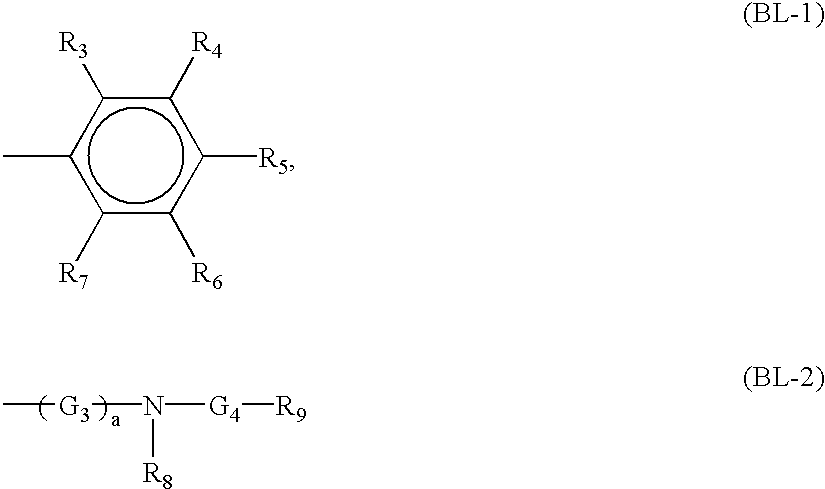

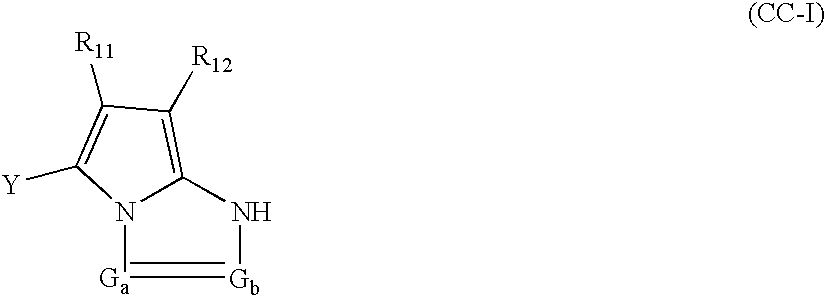

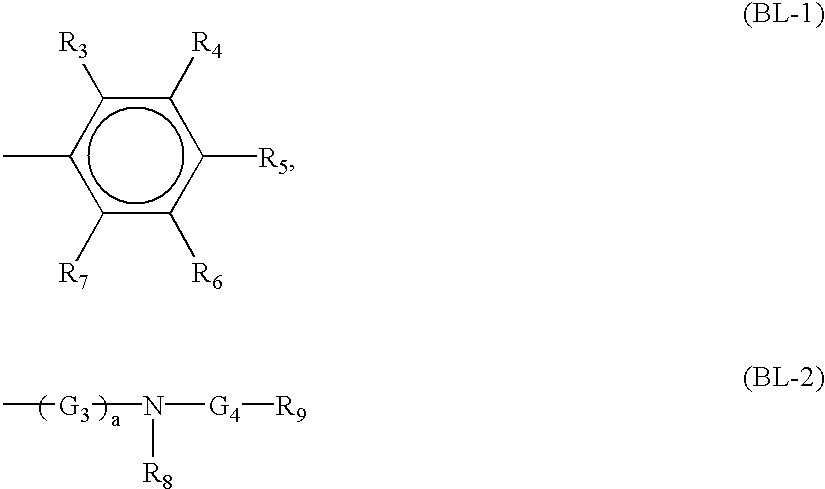

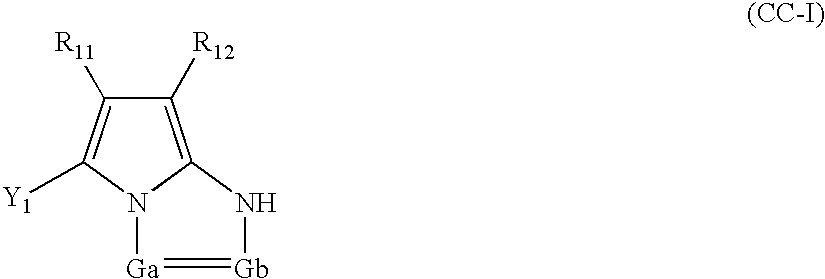

A method of forming color images comprises forming an original image and duplicating the formed original image on a color photosensitive material having blue-, green- and red-sensitive silver halide emulsion layers on a transmission or reflective support. The formed original image contains a dye formed from a cyan coupler represented by formula (CC-1): wherein Ga represents —CC(R13)═ or —N═; Gb represents —C(R13)═ when Ga represents —N═, or Gb represents —N═ when Ga represents —C(R13)═; R11 and R12 represent an electron-withdrawing group having a Hammett substituent constant σp value of 0.20 to 1.0; R13 represents a substituent; and Y represents a hydrogen atom or a group capable of splitting-off by a coupling reaction with an oxidized product of an aromatic primary amine color developing agent; andwherein the red-sensitive layer has the maximum sensitivity wavelength, λmax (D), of spectral sensitivity distribution at each density of 630 to 670 nm.

Owner:FUJIFILM CORP +1

Silver halide color photosensitive material and method of processing the same

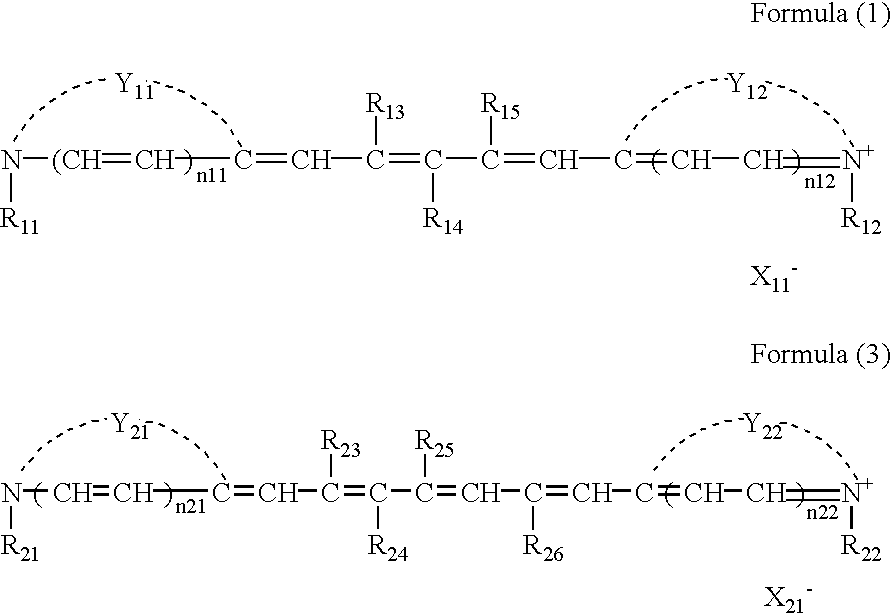

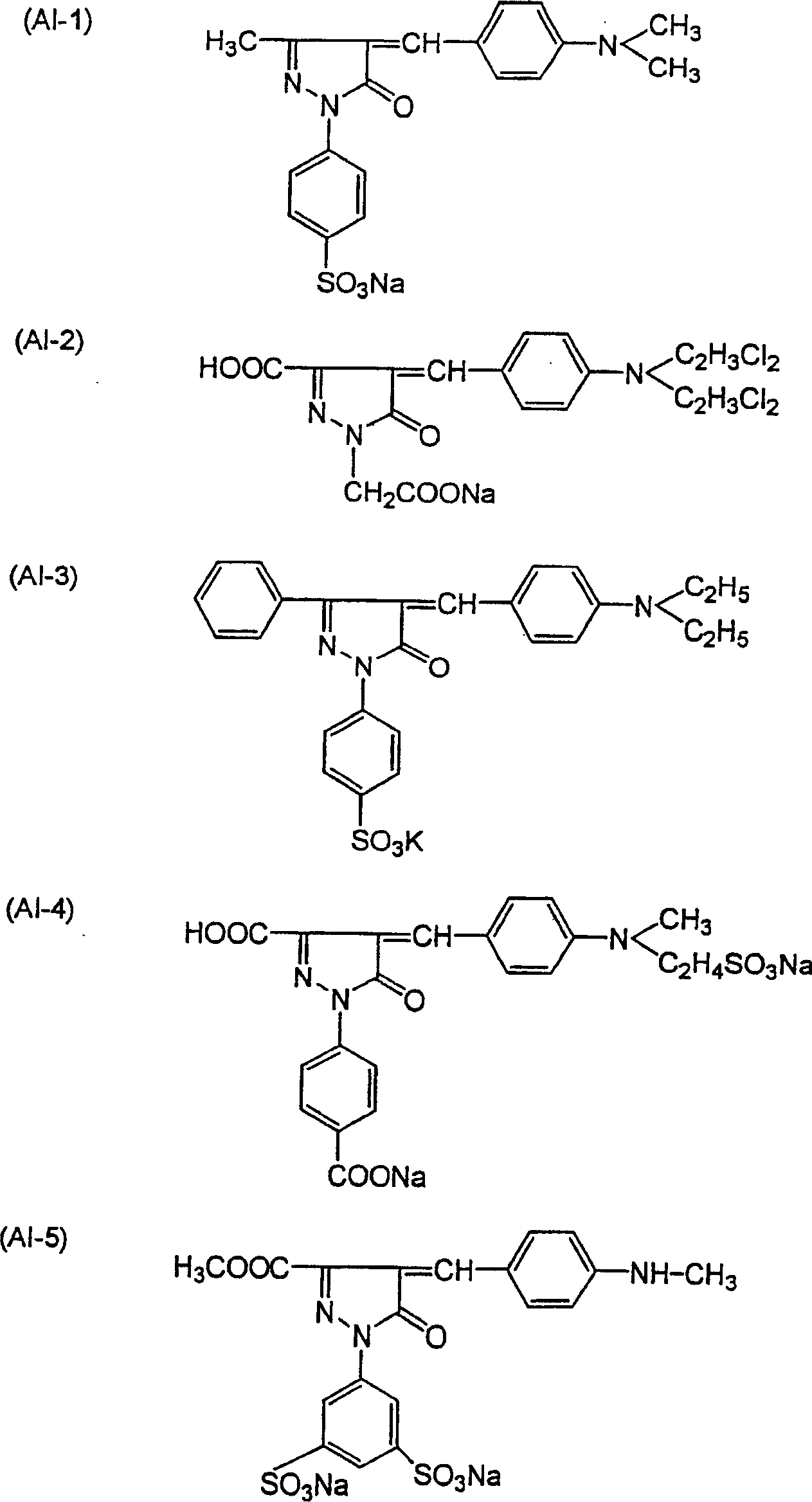

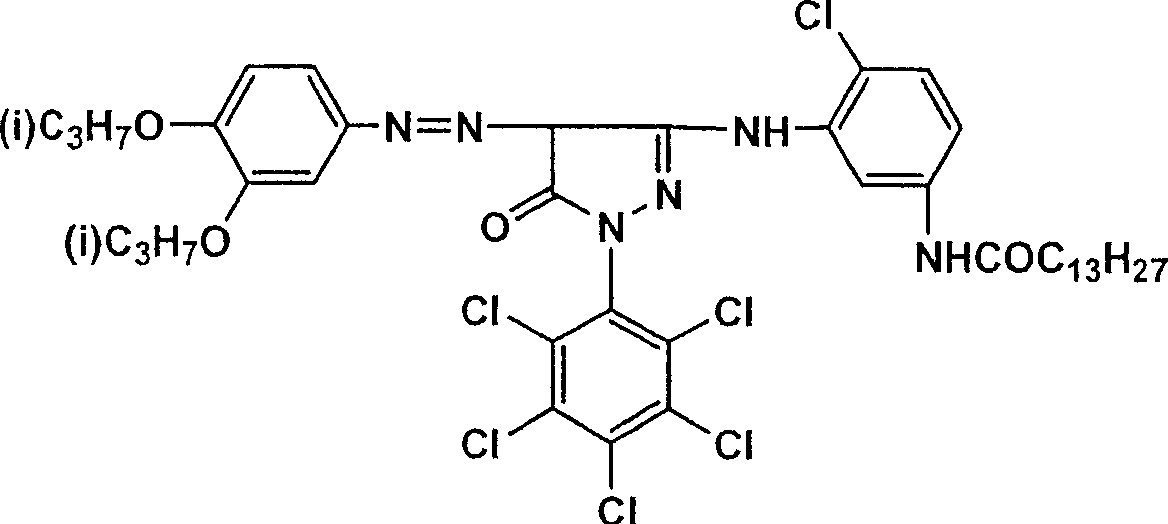

InactiveCN101044431AEasy to handleFast developing speedSubtractive colour processesSubtractive cinematographic processesWavelengthMagenta

The present invention provides a silver halide color photosensitive material, having, on a transparent support, at least one each of yellow-, cyan-, and magenta-color-forming photosensitive silver halide emulsion layers, and photosensitive silver halide emulsion layer containing a coupler that forms a dye having its absorption maximum at a wavelength longer than 730 nm upon reaction with an oxidized product of a developing agent, wherein the yellow-color-forming photosensitive silver halide emulsion layer contains photosensitive silver halide grains having an average grain size of 0.4 m or below and a silver chloride content of 95 mole% or above based on total silver in the grains, and wherein the photosensitive silver halide grains include photosensitive silver halide grains whose iodide ion concentrations have their maxima at grain surfaces and decrease gradually toward the interior of the grains; and a method of processing a silver halide color photosensitive material for use in film screening.

Owner:FUJIFILM CORP

Siliver halide color photosensitive material

ActiveUS20050069825A1Less coatingHigh sensitivitySubtractive colour processesSilver halide emulsionsSilver halidePhotochemistry

A silver halide color photosensitive material comprising a support and, superimposed thereon, at least one blue-sensitive silver halide emulsion layer, green-sensitive silver halide emulsion layer and red-sensitive silver halide emulsion layer, wherein (i) the specified speed of the photosensitive material is 350 or higher, (ii) the coating amount of silver in the photosensitive material is 7 g / m2 or less, and (iii) any of the color-sensitive silver halide emulsion layers is composed of two or more silver halide emulsion layers of different photographic speeds, of which the silver halide emulsion layer with the highest photographic speed contains tabular silver halide grains of 8 or greater aspect ratio in a ratio of 70% or more based on the total projected area and regular-crystal silver halide grains of 0.1 to 0.5 μm equivalent sphere diameter in a ratio of 0.5 to 5% based on the total projected area.

Owner:FUJIFILM CORP +1

Silver halide color reversal photographic material

InactiveUS6746834B2Subtractive colour processesSilver halide emulsionsSpectral sensitivitySilver halide

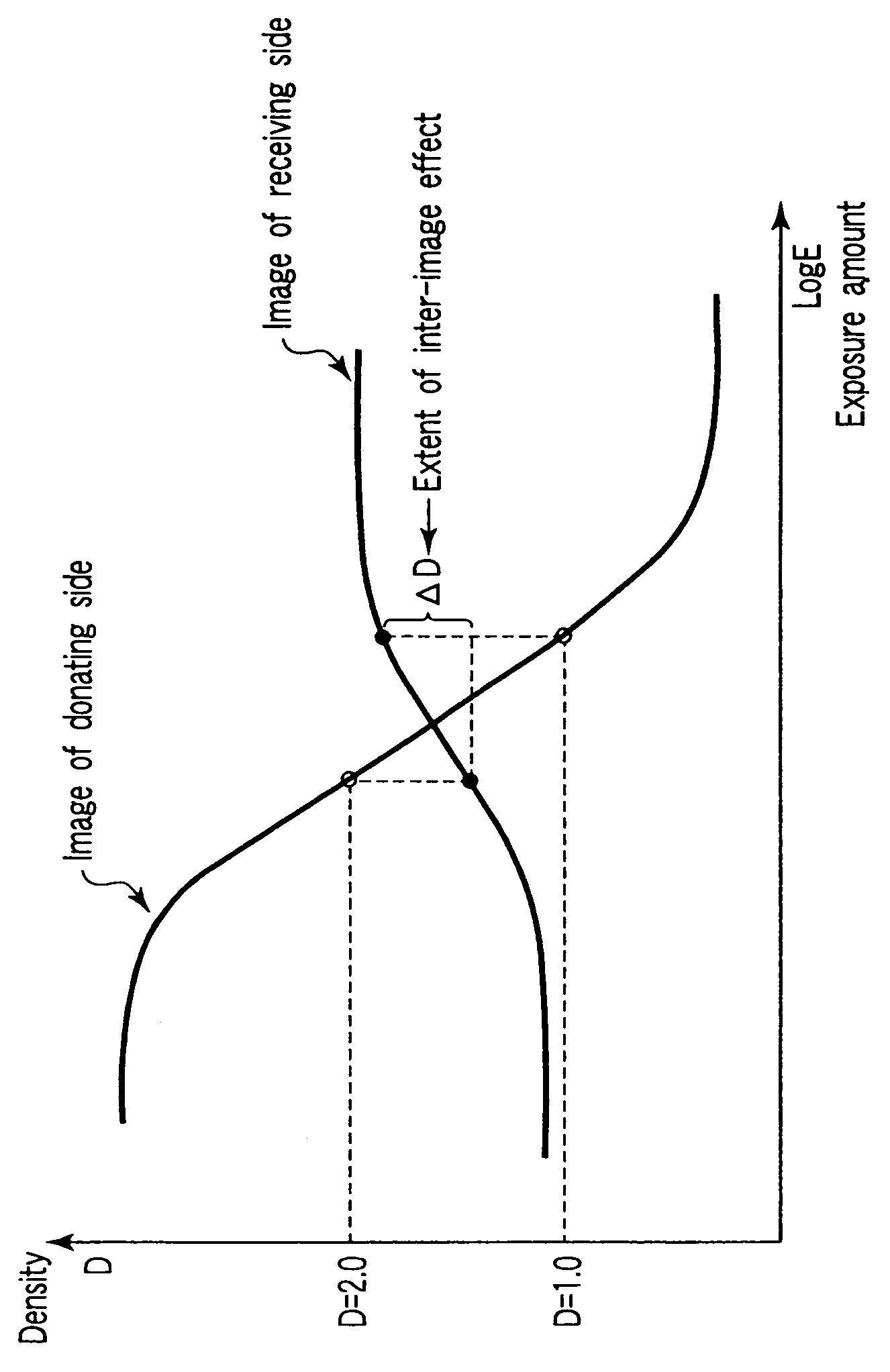

A silver halide color reversal photographic material comprises, on a transparent support, at least one each of blue-, green-, and red-sensitive emulsion layer units. The lightsensitive material further has means for regulating an interimage effect. The red-sensitive unit satisfies the relation:lambdarmax is the wavelength at which the maximum sensitivity of the spectral sensitivity distribution of the red-sensitive unit is given. The red- and green-sensitive units satisfy the relations:Sr(lambdarmax) is the maximum sensitivity of the red-sensitive unit, Sr(580) and Sg(580) are the sensitivity at 580 nm of the red- and green-sensitive unit, respectively. Magnitude of the interimage effect satisfies the relations:IIEgr is the magnitude of the interimage effect from the green- to red-sensitive units, and IIErg is that from the red- to green-sensitive units.

Owner:FUJIFILM HLDG CORP +1

Silver halide color reversal photographic material

InactiveUS20030087209A1Subtractive colour processesSilver halide emulsionsLength waveSpectral sensitivity

A silver halide color reversal photographic material comprises, on a transparent support, at least one each of blue-, green-, and red-sensitive emulsion layer units. The lightsensitive material further has means for regulating an interimage effect. The red-sensitive unit satisfies the relation:620 nm<=lambdrmax<=660 nmlambdrmax is the wavelength at which the maximum sensitivity of the spectral sensitivity distribution of the red-sensitive unit is given. The red- and green-sensitive units satisfy the relations:Sr(lambdrmax)-Sr(580)<=1.0and-0.5<=Sr(580)-Sg(580)<=0.5Sr(lambdrmax) is the maximum sensitivity of the red-sensitive unit, Sr(580) and Sg(580) are the sensitivity at 580 nm of the red- and green-sensitive unit, respectively. Magnitude of the interimage effect satisfies the relations:IIEgr<=0.15 and IIErg<=0.0IIEgr is the magnitude of the interimage effect from the green- to red-sensitive units, and IIErg is that from the red- to green-sensitive units.

Owner:FUJIFILM HLDG CORP +1

Silver halide color reversal photosensitive material

InactiveUS7115357B2High color reproductionHigh color saturationSubtractive colour processesSilver halide emulsionsLength waveMagenta

A silver halide color reversal photosensitive material comprising a blue-sensitive emulsion layer unit containing a yellow color-forming coupler, a green-sensitive emulsion layer unit containing a magenta color-forming coupler and a red-sensitive emulsion layer unit containing a cyan color-forming coupler, on a transparent support, wherein the material includes at least one interimage effect-donating layer substantially forms no image; the wavelength, λrmax, at which the maximum sensitivity of the spectral sensitivity distribution of the red-sensitive layer unit is given, satisfies the relation: 620 nm≦λrmax≦680 nm; and the sensitivities of the red-sensitive layer unit satisfy the following relationships: Sr(610) is ⅕ of Sr(λrmax) or more; Sr(680) is 1 / 10 of Sr(λrmax) or more; and / or Sr(690) is 1 / 50 of Sr(λrmax) or more wherein Sr(610), Sr(680) and Sr(690) are the sensitivities of the red-sensitive unit at 610 nm, 680 nm and 690 nm, respectively, and Sr(λrmax) is the maximum sensitivity at λrmax.

Owner:FUJIFILM HLDG CORP +1

Photographic label with copied fine printed matter

InactiveCN1432865AImprove image qualityStampsPhotography auxillary processesSilver halidePolymer chemistry

The invention relates to a photographic label comprising a pragmatic polymer sheet, at least one layer comprising at least one image forming layer comprising photosensitive silver halide grains and dye forming coupler above said pragmatic polymer sheet, wherein said at least one image forming layer has an exposure time to obtain a usable Dmax of 1.5 of less than 0.01 seconds, wherein said at least one image forming layer is substantially free of image dye stabilizers, and wherein said polymer sheet has an L* of greater than 95.

Owner:EASTMAN KODAK CO

Silver halide colour photographic light-sensitive material

InactiveCN1340740ASubtractive colour processesPhotosensitive composition applicationSilver halidePhotochemistry

A silver halide photosensitive material for color photography, comprising, on a support, a blue-sensitive silver halide emulsion layer, a green-sensitive silver halide emulsion layer, and a red-sensitive silver halide emulsion layer, each of which Both include not less than two color-sensitive layers with different sensitivities, wherein not less than 60% of tabular particles with an aspect ratio of not less than 5.0 are contained in the emulsion layer with the highest sensitivity in each color-sensitive layer The total projected area of silver halide grains, and the number of grains expressed by a specific equation does not exceed 1.00.

Owner:FUJIFILM CORP

Photographic silver halide printing medea without clearing agent

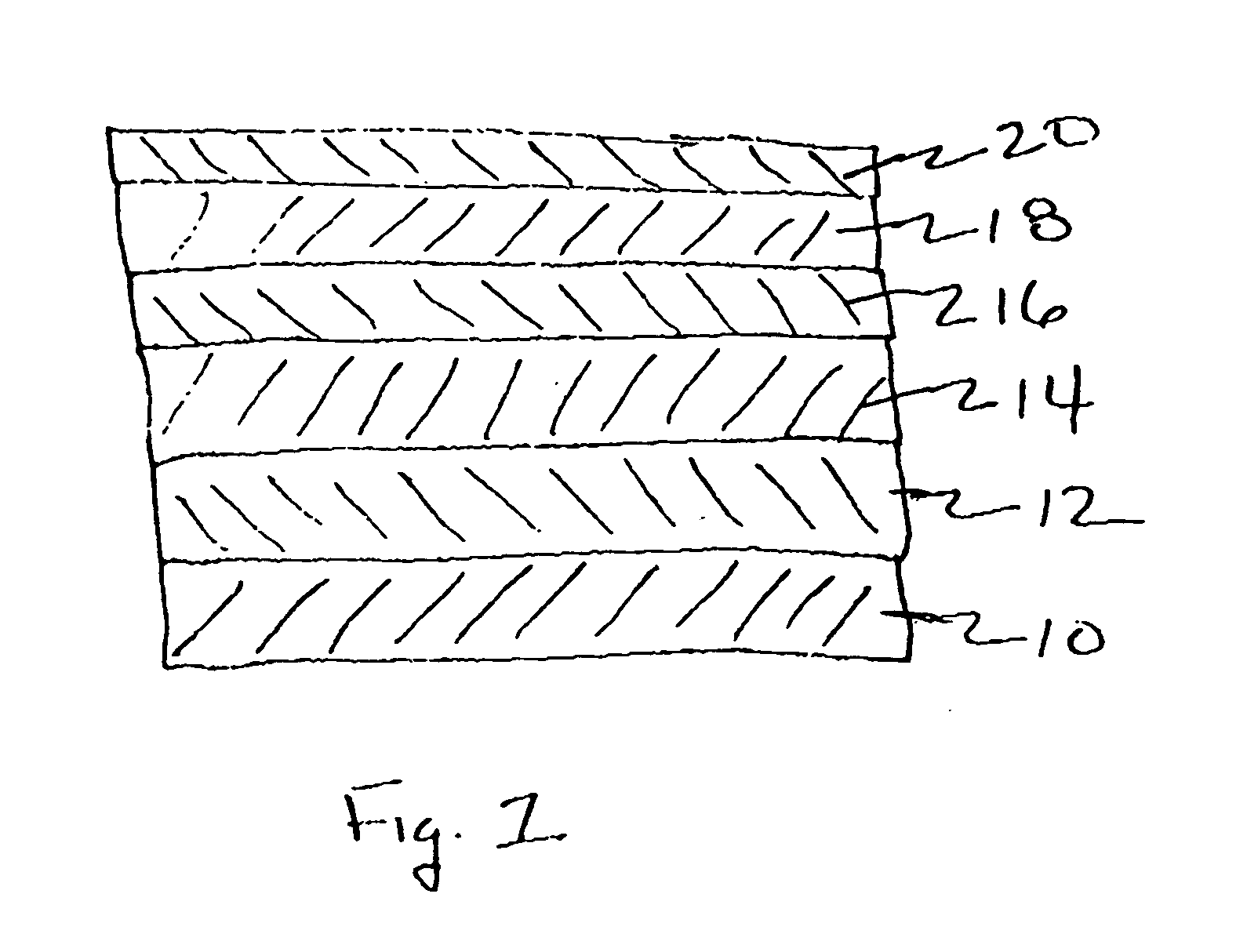

InactiveCN1301983ATake advantage ofConducive to preservationColour image correction processesSubtractive colour processesInter layerClearing Agent

The invention relates to a multilayer photographic element comprising a reflective support wherein the color record 1 adjacent to the support comprises at least one light sensitive layer and a non-light sensitive dye-forming interlayer; and wherein color record 2 above said color record 1 comprises at least one light sensitive layer and at least two non-light sensitive dye-forming interlayers and wherein color record 3 comprises at least one light sensitive layer and a non-light sensitive dye-forming interlayer; an optional UV dye containing interlayer and a top overcoat; and wherein each interlayer is completely or substantially scavenger free, silver halide grains comprising greater than 90% silver chloride, and wherein the reciprocity characteristics of the silver halide grains are such that for a separation exposure of 1 microsecond and 0.4 sec, each color record develops to a density of at least 2.0 within a log exposure range of 1.2 or less relative to the exposure point producing a density 0.04 above Dmin.

Owner:EASTMAN KODAK CO

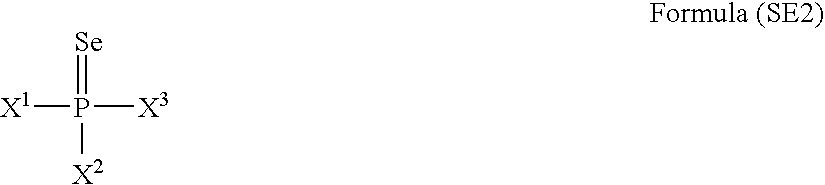

Photosensitive material for silver halide color photograph

InactiveCN101023393APhotoprinting processesPhotosensitive material auxillary/base layersSilver clusterSelenium Compound

A silver halide emulsion containing silver halide grains with a silver chloride content of at least 95 mole%, being sensitized with selenium and gold, and further containing at least two compounds each having a function of oxidizing metallic silver clusters; a silver halide photographic material containing the same; and a silver halide photographic material having red-, green, and blue-sensitive silver halide emulsion layers, wherein one of the emulsion layers contains a silver halide emulsion with a silver chloride content of at least 95 mole%, and the silver halide emulsion contains a selenium compound and a metal complex of formula (D1); formula (D1) # [M D1 X D1 n L D1 (6-n) ] m wherein M D1 represents Cr, Mo, Re, Fe, Ru, Os, Co, Rh, Pd, or Pt; X D1 represents a halogen ion; L D1 represents a ligand other than X D1 ; n represents 3, 4, 5, or 6; and m represents 4-, 3-, 2-, 1-, 0, or 1+.

Owner:FUJIFILM CORP

Silver halide color photosensitive material

InactiveUS20050112512A1Improve image qualityHigh sensitivityRadiation applicationsSubtractive colour processesHeteroatomSilver halide

A silver halide color photosensitive material of less than 320 ISO speed, comprising at least two red-sensitive emulsion layers, at least two green-sensitive emulsion layers, at least one blue-sensitive emulsion layer and at least one nonsensitive layer, wherein silver halide tabular grains of 0.15 μm or less grain thickness are contained in an amount of 50% or more in respective layers with the highest speed among the green- and red-sensitive emulsion layers; wherein the total dry film thickness of the material on the emulsion layer side thereof is 24 μm or less; and wherein the compound (A) is contained in at least one silver halide emulsion layer or the nonsensitive layer. Compound (A): heterocyclic compound having one or more heteroatoms, which heterocyclic compound is capable of substantially increasing the sensitivity of silver halide color photosensitive material by addition thereof as compared with that exhibited when the compound is not added.

Owner:FUJIFILM CORP +1

Silver halide colour photographic light-sensitive material

InactiveCN1222826CSubtractive colour processesSilver halide subtractive colour processesSilver iodideProject area

A silver halide color photographic light-sensitive material comprising, on a support, a unit blue-sensitive silver halide emulsion layer, unit green-sensitive silver halide emulsion layer, and unit red-sensitive silver halide emulsion layer, each of which includes not less than two color-sensitive layers differing in sensitivity, wherein tabular grains having an aspect ratio of not less than 5.0 account for not less than 60% of the total projected area of silver halide grains contained in an emulsion layer having the highest sensitivity in each unit color-sensitive layer, and a grain number indicated by specific equation is not more than 1.00.

Owner:FUJIFILM CORP

Silver-halide color photoelement

A silver halide color photosensitive material of less than 320 ISO speed, comprising at least two red-sensitive emulsion layers, at least two green-sensitive emulsion layers, at least one blue-sensitive emulsion layer and at least one nonsensitive layer, wherein silver halide tabular grains of 0.15 mum or less grain thickness are contained in an amount of 50% or more in respective layers with the highest speed among the green- and red-sensitive emulsion layers; wherein the total dry film thickness of the material on the emulsion layer side thereof is 24 mum or less; and wherein the compound (A) is contained in at least one silver halide emulsion layer or the nonsensitive layer. Compound (A): heterocyclic compound having one or more heteroatoms, which heterocyclic compound is capable of substantially increasing the sensitivity of silver halide color photosensitive material by addition thereof as compared with that exhibited when the compound is not added.

Owner:FUJIFILM CORP

Silver halide photographic material

InactiveUS6893808B2Improved color stabilityImprove suitabilityRadiation applicationsSubtractive colour processesImaging qualityEngineering

A silver halide photographic material which is in the form of a roll film packaged in a cartridge, and which exhibits superior print stability and is capable of providing prints with superior image quality when printed onto printing paper is disclosed, comprising on a support a red-sensitive layer, a green-sensitive layer and a blue-sensitive layer, wherein the quality value (QC) satisfies the following requirementQC≧15.982×S−0.378 (100≦S≦1600)where S is the nominal speed of the photographic speed.

Owner:KONICA CORP

Silver halide photographic lightsensitive material

InactiveUS20020177087A1Accurately determineThe right amountSubtractive colour processesSilver halide emulsionsLength wavePhotochemistry

A silver halide photographic lightsensitive material comprising at least one silver halide photographic emulsion layer containing a silver halide photographic emulsion prepared by mixing a dispersion of silver halide grains, the silver halide grains exhibiting such spectral absorption maximum wavelength and light absorption intensity that, when the spectral absorption maximum wavelength is less than 500 nm, the light absorption intensity is 60 or more, while when the spectral absorption maximum wavelength is 500 nm or more, the light absorption intensity is 100 or more, with an emulsified dispersion, wherein the silver halide photographic emulsion, when agitated at 40° C. for 30 min, exhibits a variation of absorption spectrum integrated intensity ranging from 400 nm to 700 nm of 10% or less.

Owner:FUJIFILM CORP

Silver halide color photosensitive material

InactiveUS7105285B2High sensitivitySuppress fog and fogPhotosensitive material auxillary/base layersSubtractive colour processesBond cleavageLength wave

A silver halide color photosensitive material comprises a blue-sensitive layer, a green-sensitive layer, a red-sensitive layer and a non-light-sensitive layer on a support. The silver halide color photosensitive material contains a compound selected from the following type 1 and type 2 compounds, and wherein the blue-sensitive layer meets the relationship of the following formula (I):SB(370 nm) / SB(420 nm)<0.7 (I)wherein SB(λ) represents a spectral sensitivity at a wavelength of λ,(type 1)a compound capable of undergoing a one-electron oxidation to thereby form a one-electron oxidation product thereof, wherein the one-electron oxidation product is capable of releasing further one or more electrons accompanying a subsequent bond cleavage reaction, and(type 2)a compound capable of undergoing a one-electron oxidation to thereby form a one-electron oxidation product thereof, wherein the one-electron oxidation product is capable of releasing further one or more electrons accompanying a subsequent bond-forming reaction.

Owner:FUJIFILM HLDG CORP +1

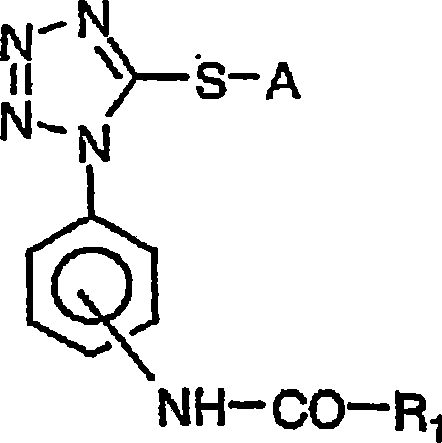

Silver halide photographic photosensitive material

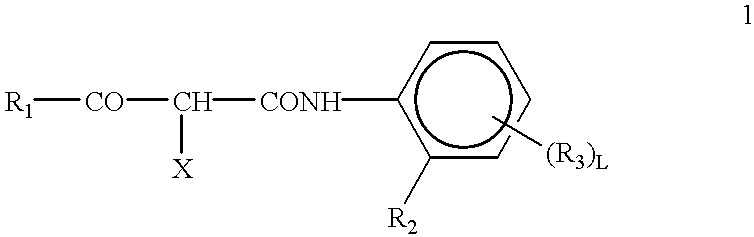

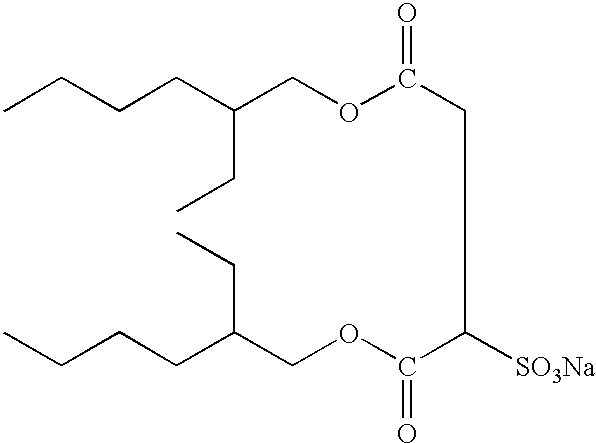

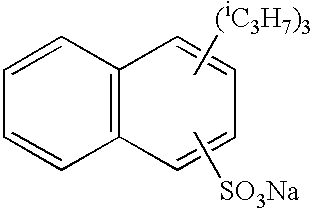

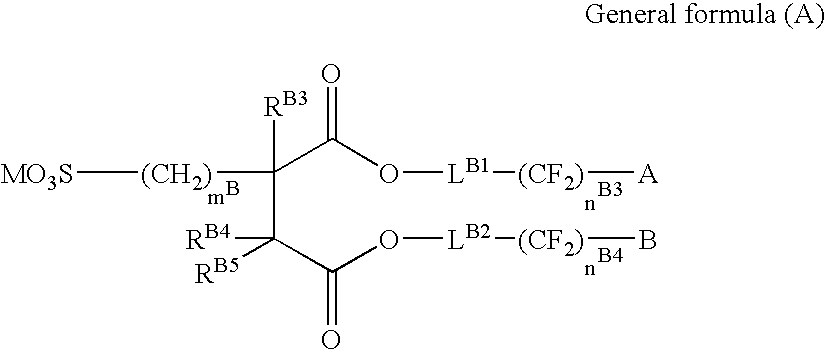

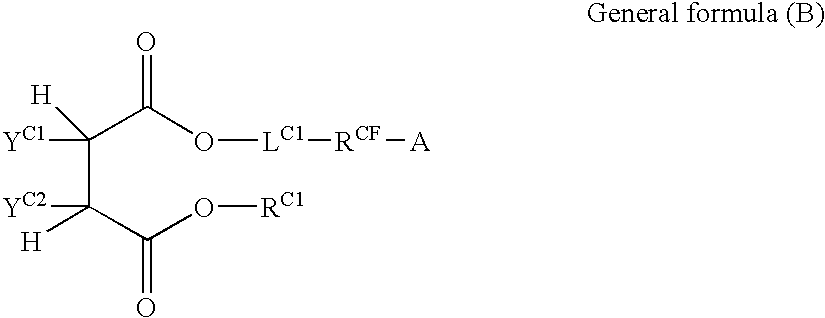

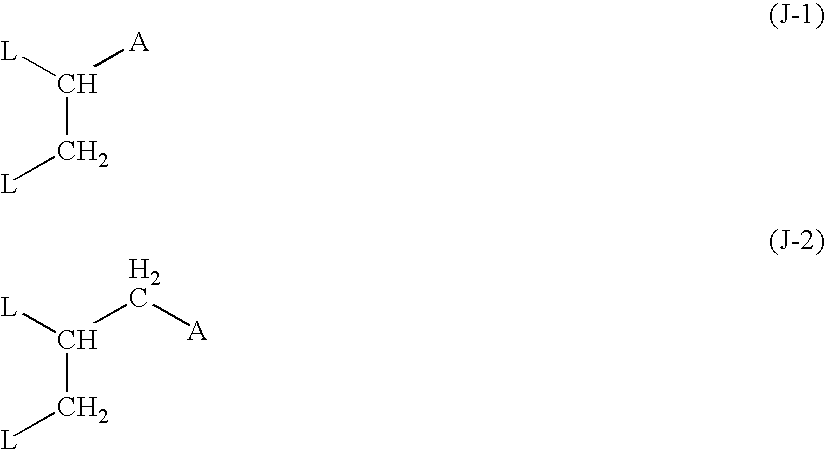

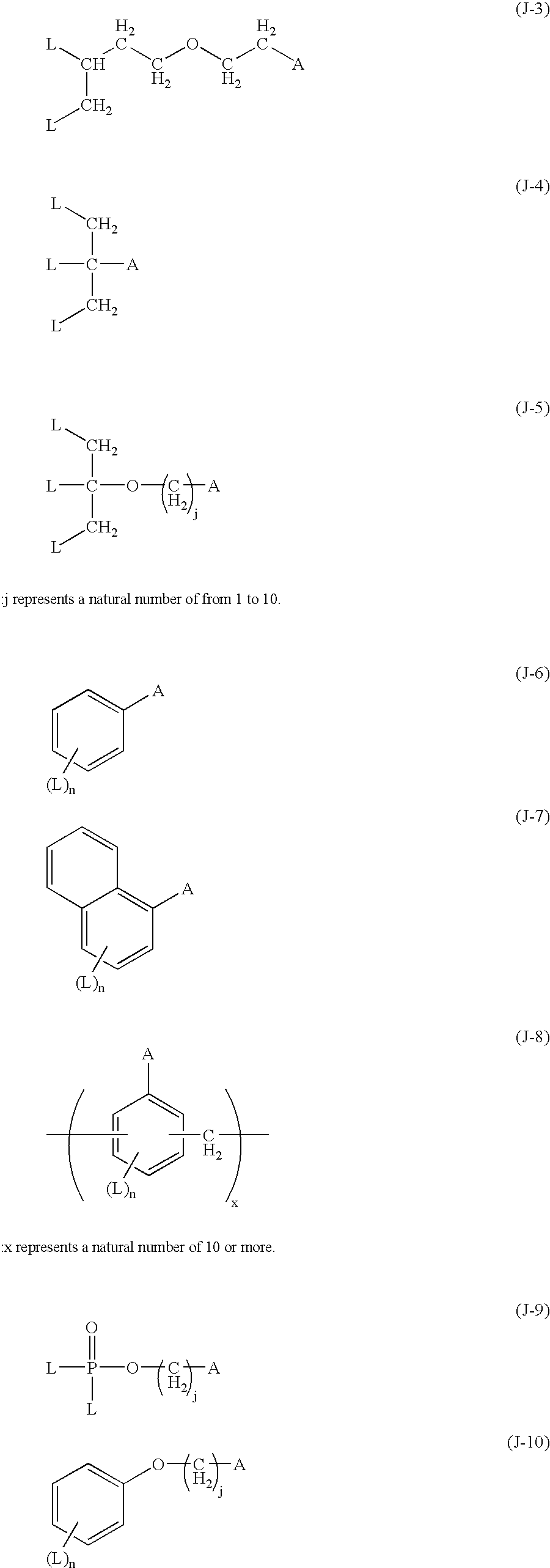

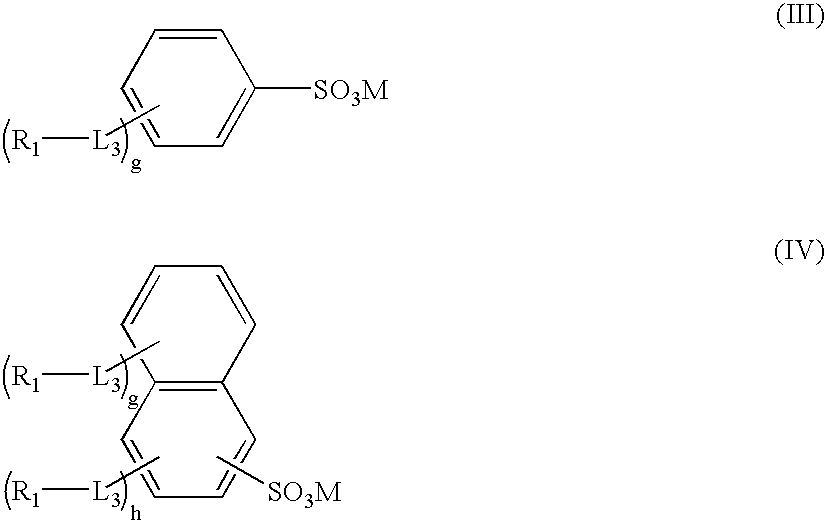

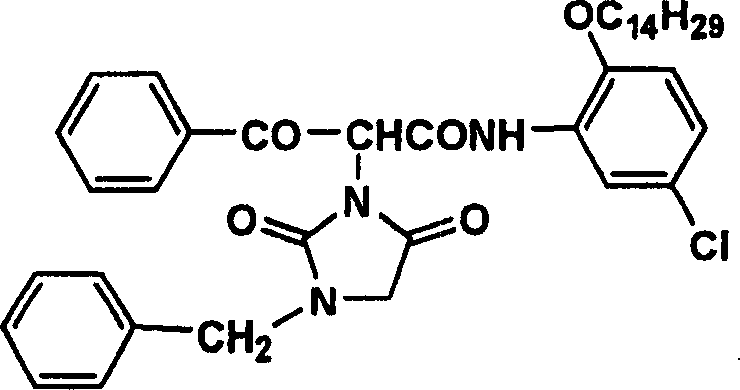

InactiveUS7122298B2High color reproductionReduce generationSubtractive colour processesSilver halide emulsionsSURFACTANT BLENDAcid group

There is provided a silver halide photographic photosensitive material, containing a support and at least one photosensitive silver halide emulsion layer on the support, the silver halide photographic photosensitive material, further including at least one layer containing an emulsion having at least one surfactant represented by the formula (I), in which the photosensitive material contains a substantially non-color-forming photosensitive emulsion layer. The formula (I) is indicated as (R1—L)n-J-(A)m. In the formula: A represents an acid group or a metal salt thereof; R1 represents an aliphatic group; L represents a divalent group; J represents a linking group, having a valence of n plus m, which links R1—L and A; n represents a natural number of from 1 to 6; and m represents a natural number of from 1 to 3.

Owner:FUJIFILM CORP +1

Silver halide color photosensitive material

A silver halide color photosensitive material exhibiting a high photosensitivity, an excellent granularity, a low humidity-dependence in photographing, and a favorable radiation fog resistance. The material is characterized in that at least one of the photosensitive layers of the material contains a silver halide emulsion made of silver halide particles, at least 50% of the total projection area of the silver halide particles contained in the silver halide emulsion includes two twin planes parallel to a major surface, the silver halide flat particles satisfies expression shown below and has an aspect ratio of 8 or more, and the content of fog particles in the unsensitized silver halide emulsion is 1 / 20 or less. Expression 1.0 <=b / a <= 1.3 [In the expression, a is the shorter one of the distance from one of the opposed major surfaces to the nearest twin plane and the distance from the other to the nearest twin plane when a line passing the center of the particle diameter is drawn vertically to the opposed major surfaces, and b is the longer one.]

Owner:KONICA MINOLTA OPTO

Color negative film element and process for developing

InactiveCN1191497CEnhance memorySubtractive colour processesFilm packagingGranularityElectronic form

A color negative photographic element especially suited for preloading in a one-time-use camera is disclosed. The element is capable of producing images that, when developed, converted to electronic form, and then converted to a viewable form, exhibit excellent color, reduced granularity, and improved sharpness. The photographic elements contain blue, green, and red recording layer units capable of forming spectrally differentiated dye images. The layer units are substantially free of colored masking coupler, and each exhibits a dye image gamma of less than 1.5. The element exhibits an exposure latitude of at least 2.7 log E. The gamma ratios of the blue, green, and red recording layer units are between 0.80 and 1.2. Chemical processing of the element is also disclosed.

Owner:EASTMAN KODAK CO

Silver halide color photographic material

InactiveUS20060040219A1Good effectSubtractive colour processesSilver halide emulsionsDigital printingExposure

The present invention provides a silver halide color photographic material having a relatively low silver content suitable for digital print, leading to print quality superior in contrast and color reproduction is attained irrespective of camera quality used for picture-taking. The silver halide color photographic material, after having been processed, satisfies the following equation (1) which is calculated for under-exposure, correct exposure and over-exposure and any one of the color-sensitive layers satisfies the following equations (2) and (3) with respect to gradients (γU, γN, γO) for under-exposure, correct exposure and over-exposure. Crm≧1045−log10S×75 (1) 0.92≦γU / γN≦1.05 (2) 0.92≦γO / γN≦1.05 (3)

Owner:KONICA MINOLTA PHOTO IMAGING

Silver halide photosensitive material

A silver halide photographic material is disclosed comprising a blue-sensitive silver halide unit containing a yellow coupler, a green-sensitive silver halide unit containing a magenta coupler, and a red-sensitive silver halide unit containing a cyan coupler, wherein a coefficient of utilization of an oxidation product of a color developing agent in a maximum density area of the blue-sensitive unit is not less than 80%, that of the green-sensitive unit is 30 to 75% and that of the red-sensitive unit is not less than 80%.

Owner:KONICA CORP

Silver halides colour negative photographic photochromic and image procesing method using the photoelectromic

InactiveCN1294453CReduce defectsImprove production stabilityColour image correction processesSubtractive colour processesSilver halideMaterials science

A silver halide color negative photographic lightsensitive material comprises, on a support, at least one blue-sensitive silver halide emulsion layer, at least one green-sensitive silver halide emulsion layer and at least one red-sensitive silver halide emulsion layer. The total coating amount of colored couplers in the lightsensitive material is less than 0.05 mMol / m2. The lightsensitive material contains at least one spectrally sensitized silver halide emulsion and a compound capable of absorbing light within the spectrally sensitizing region of the spectrally sensitized silver halide emulsion, and capable of reducing the sensitivity of the spectrally sensitized silver halide emulsion by at least 0.05 LogE.

Owner:FUJIFILM CORP

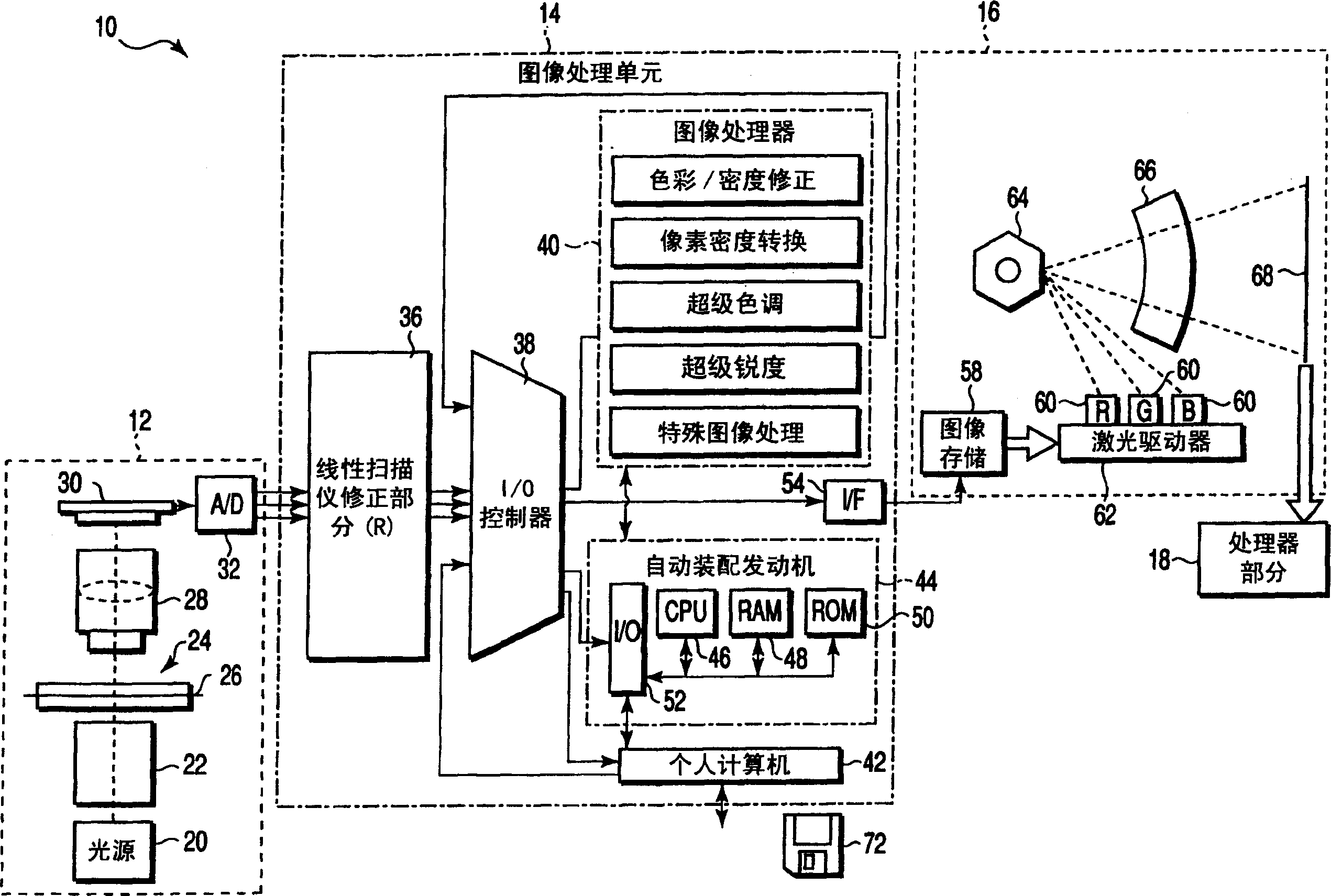

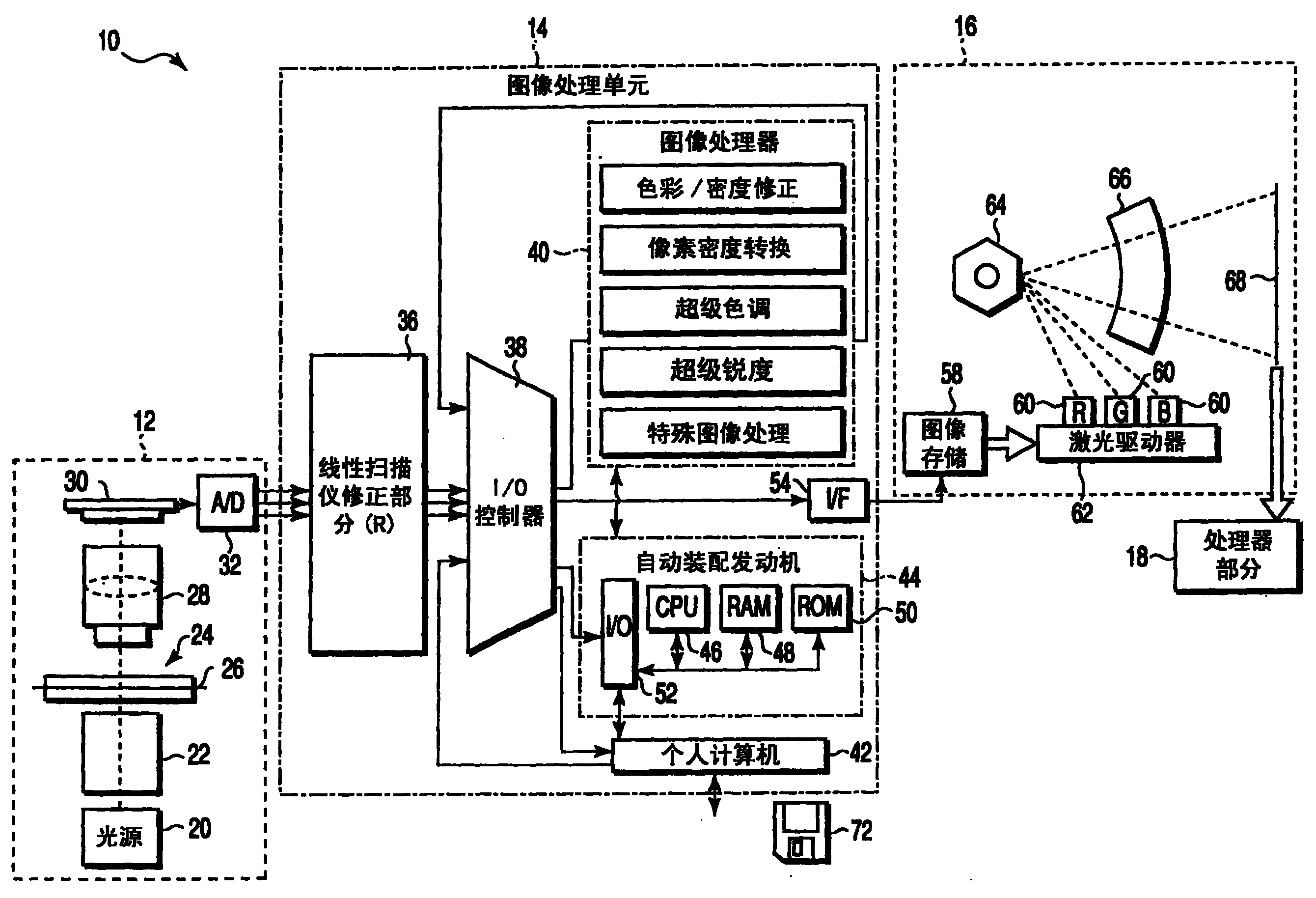

Color imaging method and digital imaging method

InactiveCN1450405AImprove processing stabilityIncreased sensitivityPhotography auxillary processesColour image correction processesColor imageMinimum density

A color image forming method is disclosed, comprising exposing a silver halide color photographic material and developing the exposed photographic material at 43 to 180 DEG C to form a color image, wherein when the photographic material is exposed so that the light-sensitive layer has a transmission density of a minimum density plus 0.1, the light-sensitive layer comprises dye-clouds having an average diameter of 3.0 to 20.0 mum. There is also disclosed a digital image forming process, wherein image recording information of the photographic material which was formed by use of the color image forming method is converted to digital image information through an image sensor.

Owner:KONICA CORP

Silver halide color photographic light-sensitive material

InactiveUS7527922B2Reduce impactProcessing damagePhotoprinting processesPhotosensitive material auxillary/base layersSelenium CompoundSilver chloride

A silver halide color photographic light-sensitive material having, on a support, at least one red-sensitive silver halide emulsion layer, at least one green-sensitive silver halide emulsion layer and at least one blue-sensitive silver halide emulsion layer, characterized in that at least one of the silver halide emulsion layers contains a silver halide emulsion having a silver chloride content of 90 mole % or above, the silver halide emulsion contains at least one kind of selenium compound, and the silver halide emulsion layer containing the silver halide emulsion has a characteristic curve satisfying the following relation (1);2.0≧γH / γL≧0.5 Relation (1)wherein γ represents a gradient of the characteristic curve, γH represents a gradient in the case of 1×10−6-second exposure and γL represents a gradient in the case of 100-second exposure.

Owner:FUJIFILM HLDG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com