Photosensitive material for silver halide color photograph

A photosensitive material, color photography technology, applied in the direction of photosensitive material, photosensitive material application, photosensitive material substrate/auxiliary layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

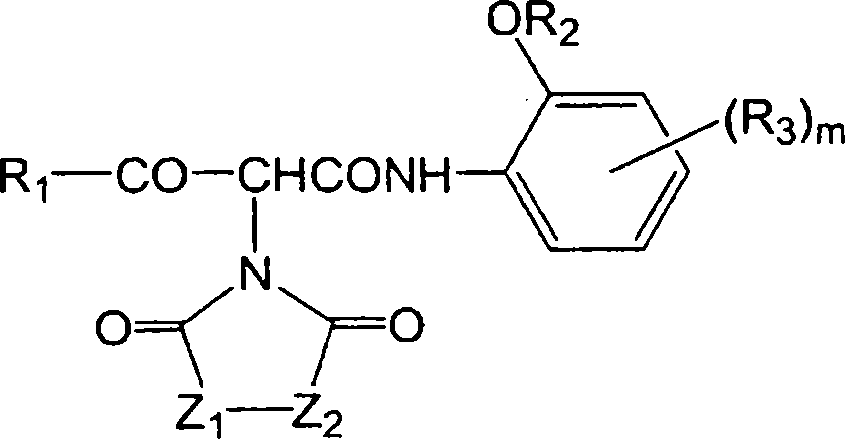

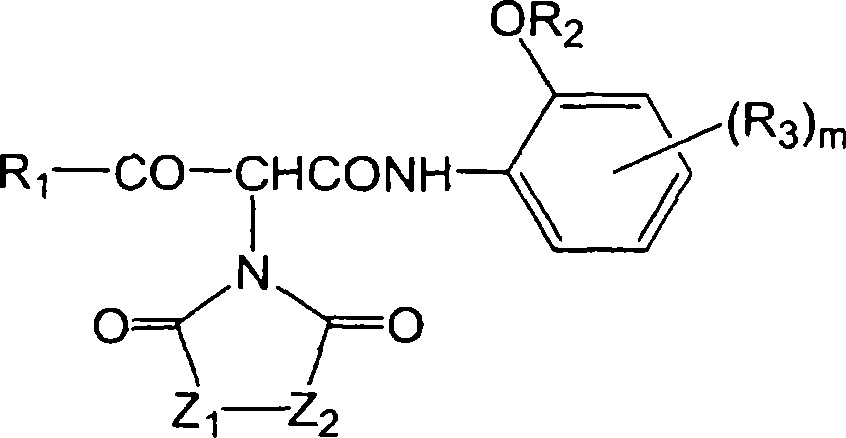

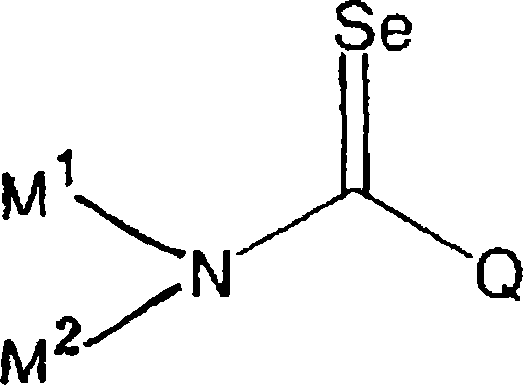

Method used

Image

Examples

Embodiment 1-1

[0710] (Preparation of Emulsion B-1)

[0711]High silver chloride cubic particles were prepared by simultaneously adding and mixing aqueous silver nitrate and sodium chloride solutions to agitated deionized, distilled water containing deionized gelatin. During the preparation process, the time at which the addition of 3% silver nitrate was completed was the time for the nucleation part. The rate of addition of the aqueous silver nitrate and sodium chloride solutions increases as a linear function of time during the addition phase of 3% to 80% of the total amount of silver nitrate. Potassium bromide (4.0 mole % per mole of final silver halide) was added during the addition phase of 80% to 100% of the total silver nitrate. After 90% of the total silver nitrate addition was complete, potassium iodide (0.3 mole % per mole of final silver halide) was added with vigorous stirring. In the addition stage of 92% to 97% of the total silver nitrate, add K 4 [Ru(CN) 6 ]. The thus obt...

Embodiment -2

[1043] (Preparation of Emulsion B-15)

[1044] In the preparation of Emulsion B-15, the addition rate of the nucleating moiety was changed. K 4 [RuCl 5 (NO)] was doubled. Emulsion B-15 was prepared in the same manner as Emulsion B-8 except as mentioned above. The emulsion grains thus obtained were monodisperse cubic silver iodobromochloride having side lengths of 0.40 µm and a coefficient of variation of 9.5% as observed by transmission electron micrographs and measured by (direct method). After the precipitation desalination process, the following were added to the resulting emulsion: deionized water, compounds Ab-1, Ab-2 and Ab-3, and calcium nitrate, and then the emulsion was dispersed.

[1045] (Preparation of Emulsion B-16)

[1046] Emulsion B-16 was prepared in the same way as Emulsion B-15, except that K 2 [IrCl 5 (H 2 O)] (2.0×10 -7 mol% / mole final silver halide) and K[IrCl 4 (H 2 O) 2 ](2.0×10 -8 mol % / mol final silver halide).

[1047] (Preparation of E...

Embodiment 1-3

[1094] The evaluation was carried out in the same evaluation method according to Example 1-2, except that Process A in Example 1-2 was replaced with Process B described below. The results of the obtained yellow image are shown in Table 6.

[1095] A standard photographic image was formed on a film sample of EVER-BEAUTY PAPER TYPEII (trade name, produced by Fuji Photo Film Co., Ltd.) for laser light in a width of 127 mm by the exposure method described below. Thereafter, the exposed sample was continuously processed (running the test) with a Digita Minilab Frontier 340 (trade name, produced by Fuji Photo Film Co., Ltd) with the following process steps until the amount of the accumulated replenishing liquid of the color developing solution reached the color 2 times the volume of the developing tank. The process using the process solution being used here is designated Process B. In addition, in order to obtain the processing time described below in the processing machine, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com