Silver-halide color photoelement

一种感光材料、卤化银的技术,应用在感光材料、感光材料的应用、乳化银乳剂等方向,达到高图像质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0528] Referring to the preparation method of the emulsions Em-A to Em-O described in Example 1 in JP-A-2001-281815, the silver halide emulsions Em-A to Em-O listed in Table 1 were prepared.

[0529] emulsion name

[0530] In the tabular grains of Table 1, dislocation lines were observed by a high-voltage electron microscope as described in JP-A-3-237450.

[0531] 1) Superposition of photosensitive layer (preparation sample 001)

[0532] A cellulose triacetate support was multilayer coated with the following composition to obtain a color negative film (Sample 001). (Composition of photosensitive layer)

[0533] The main raw materials used in the monolayer are classified as follows.

[0534] ExC: Cyan coupler UV: Ultraviolet absorber

[0535] ExM: magenta coupler HBS: high boiling point organic solvent

[0536] ExY: Yellow coupler H: Gelatin hardener

[0537] (In the following description, actual compounds have numbers appended to their symbols. The general formu...

Embodiment 2

[0846] The supports of samples 101, 102, 105, 110, and 112 were changed to a triacetyl cellulose sheet with a 7 μm thick bottom layer composed of a hydrophilic colloid layer, and samples 201, 202, 205, 210, and 212 were prepared. The sample was made into a Brownie format, used for the same photography as in Example 1, and developed with an automatic processor FP-232B manufactured by Fuji Photo Film Co., Ltd. Thereafter, the same evaluation as in Example 1 was performed. As shown in Example 1, the photosensitive material of the present invention produced favorable results.

[0847] The samples were observed after treatment and although slight wear was observed on samples 201 and 202, the other samples showed no wear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| coating mass | aaaaa | aaaaa |

| coating mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

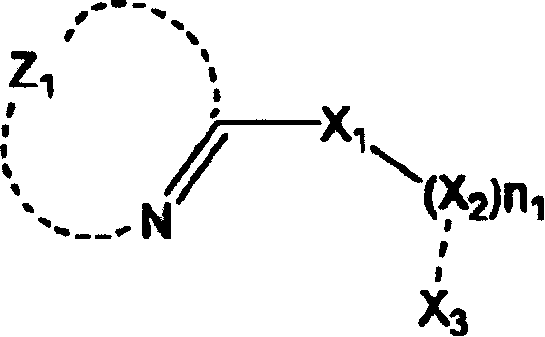

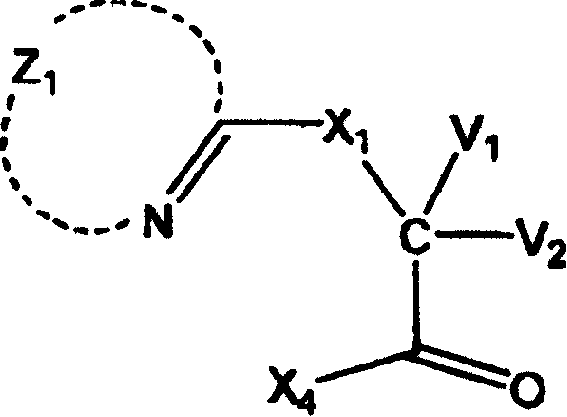

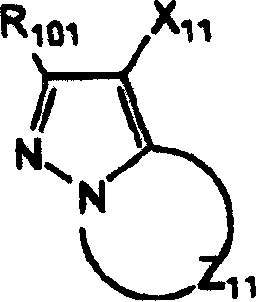

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com