Color imaging method and digital imaging method

A color image and imaging technology, applied in the direction of color image correction process, color reduction processing process, multi-color photography process, etc., can solve the problems of affecting the stability of photographic materials, ineffective realization, low recycling rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

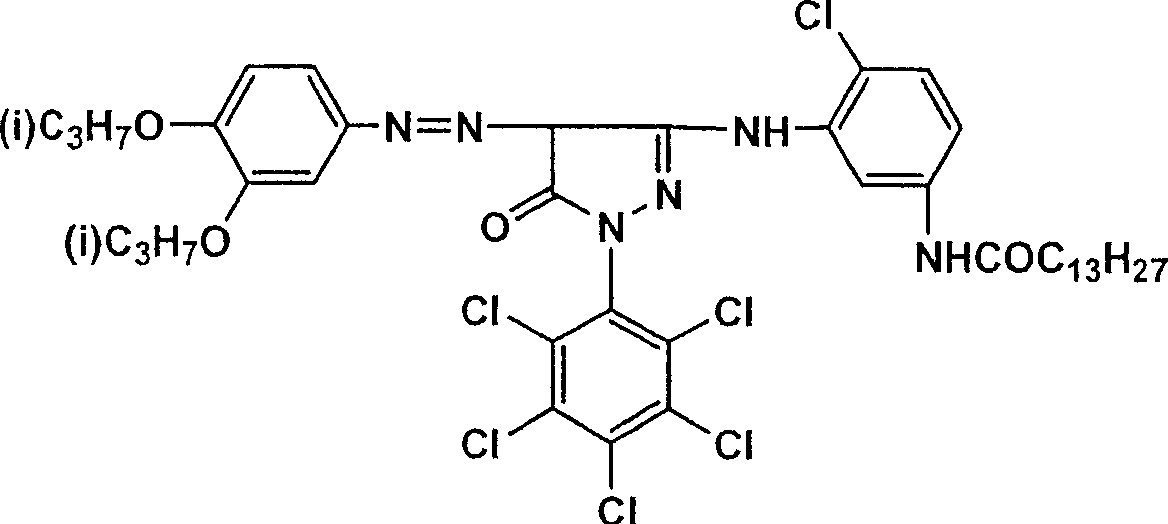

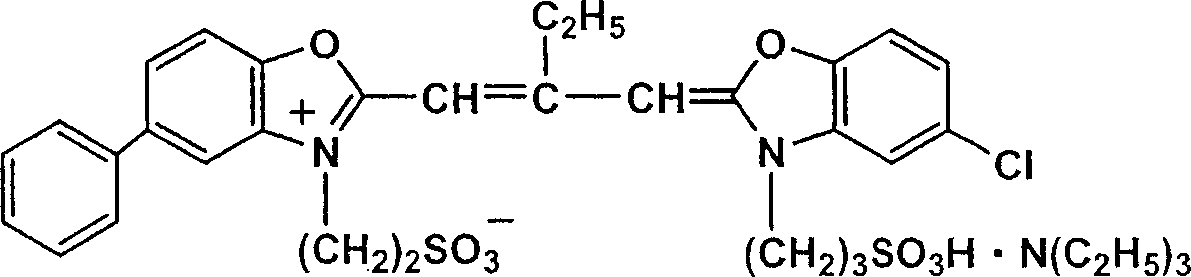

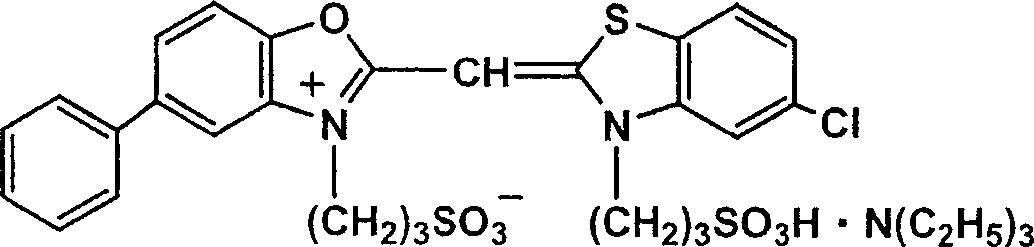

Image

Examples

Embodiment 1

[0246] Preparation of Silver Halide Color Photographic Materials

[0247] Preparation of Sample 101

[0248] black colloidal silver

0.16

UV-1

0.30

CM-1

0.12

oil-1

0.24

1.33

Silver iodobromide emulsion i

0.06

AS-1

0.12

oil-1

0.15

0.67

Silver iodobromide emulsion h

0.19

Silver iodobromide emulsion e

0.17

SD-1

2.22×10 -4

SD-2

3.72×10 -5

SD-3

1.56×10 -4

SD-4

3.41×10 -4

C-1

0.77

CC-1

0.006

oil-2

0.47

AS-2

0.002

1.82

Silver iodobromide emulsion b

0.41

Silver iodobromide emulsion h

0.19

SD-1

3.46×10 -4

SD-2

2.44×10 -5

SD-4

3.69×10 -4

C-1

0.42

CC-1

0.072

DI-1

0.046 ...

Embodiment 2

[0320] Preparation of Silver Halide Color Photographic Material

[0321] Preparation of sample 201

[0322] black colloidal silver

0.16

UV-1

0.30

CM-1

0.12

oil-1

0.24

AP-1

0.65

gelatin

1.33

Silver iodobromide emulsion i

0.06

AS-1

0.12

oil-1

0.15

DP-1

0.50

gelatin

0.67

Silver iodobromide emulsion h

0.39

Silver iodobromide emulsion e

0.32

SD-1

2.22×10 -4

SD-2

3.72×10 -5

SD-3

1.56×10 -4

SD-4

3.41×10 -4

C-1

0.77

CC-1

0.006

oil-2

0.47

AS-2

0.002

Hot Solvent TS-1

0.23

silver behenate

1.82

gelatin

1.82

Silver iodobromide emulsion b

0.83

Silver iodobromide emulsion h

0.36

SD-1

3.46×10 -4

S...

Embodiment 3

[0350] The photographic samples made in Examples 1 and 2 were individually converted and packaged in cassettes according to the 135 size film standard. Using these film samples and a single-lens reflex camera equipped with a 35mm focal length and F: 2 lens (F4, product of Nikon Corp.), 5 scenes including people, flowers, green plants, distant mountains and blue sky A photograph was taken with the ISO speed set to 800. The exposed film samples were then color developed according to the methods described in Examples 1 and 2 without further bleaching, fixing and stabilization processes to obtain developed samples with developed silver and silver halide remaining therein.

[0351] From the film thus developed, a 2048×2048 pixel monochrome CCD camera (KX4, obtained from Eastman Kodak Co.) was used to obtain R, G and B separated negative images, wherein the red separation filter (gelatin filter W26, obtained From Eastman Kodak Co.), a green separation filter (W99) or a blue separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com