Flexible composite sheet for disposable dressing article

A composite sheet, disposable technology, applied in applications, layered products, textiles and paper, which can solve the problems of difficult absorption, blocking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

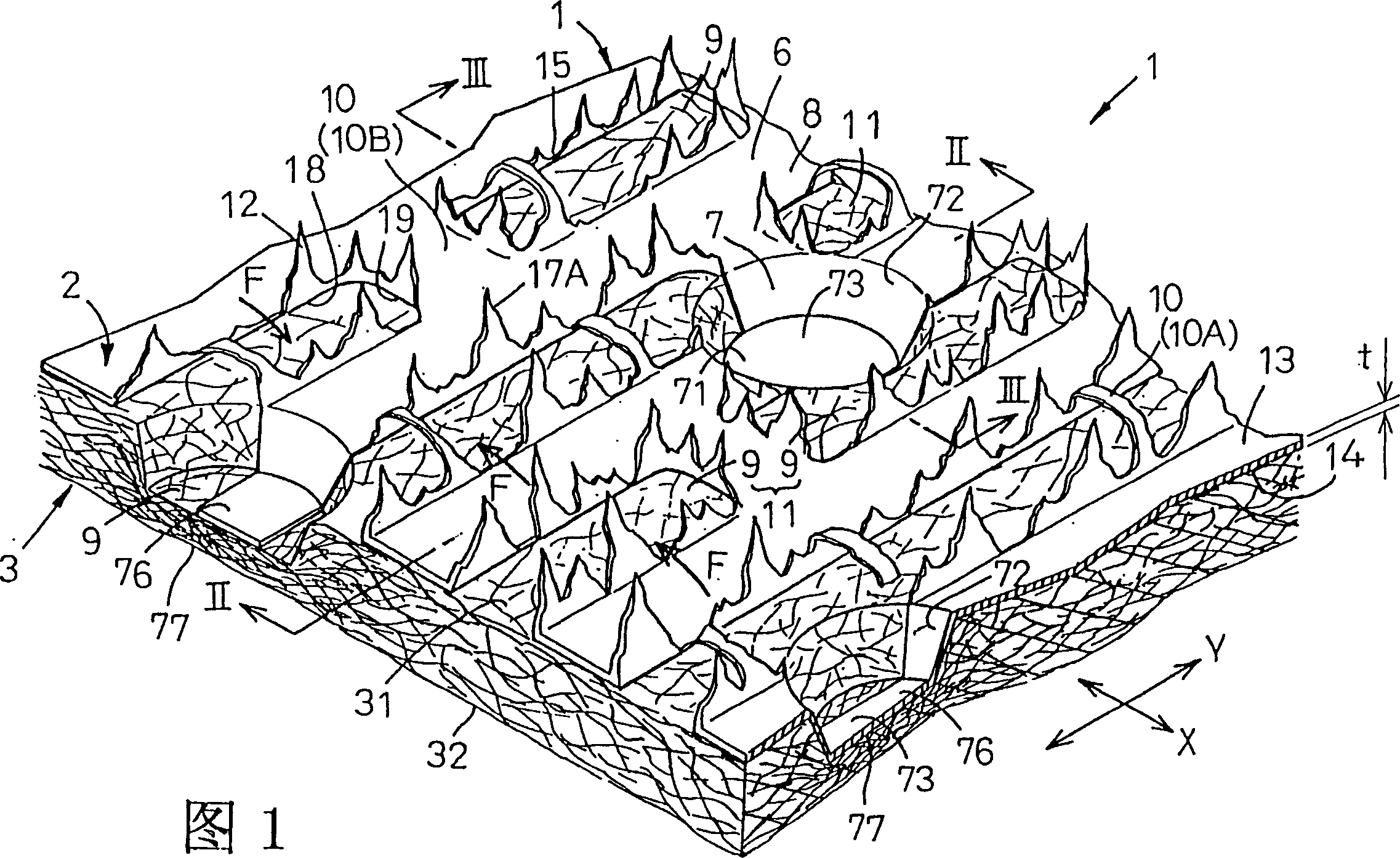

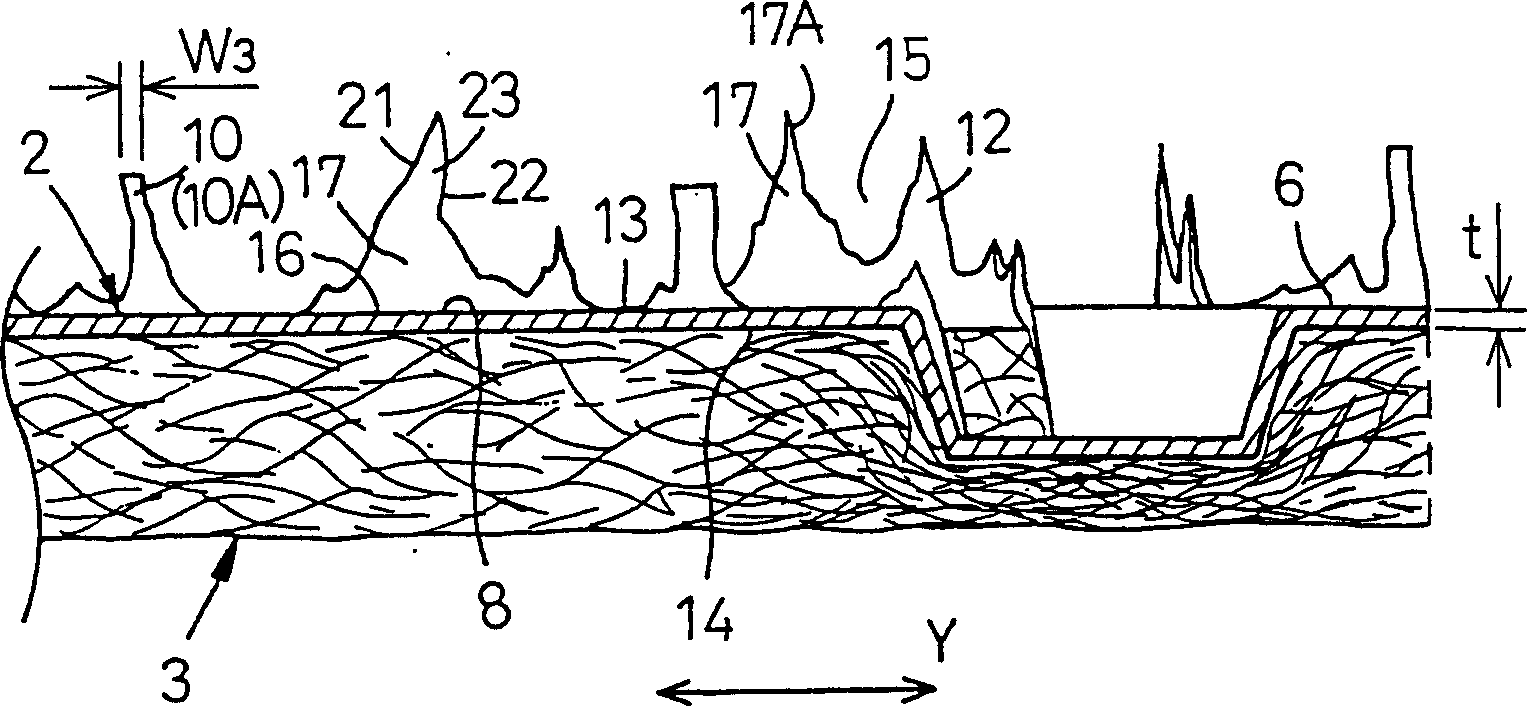

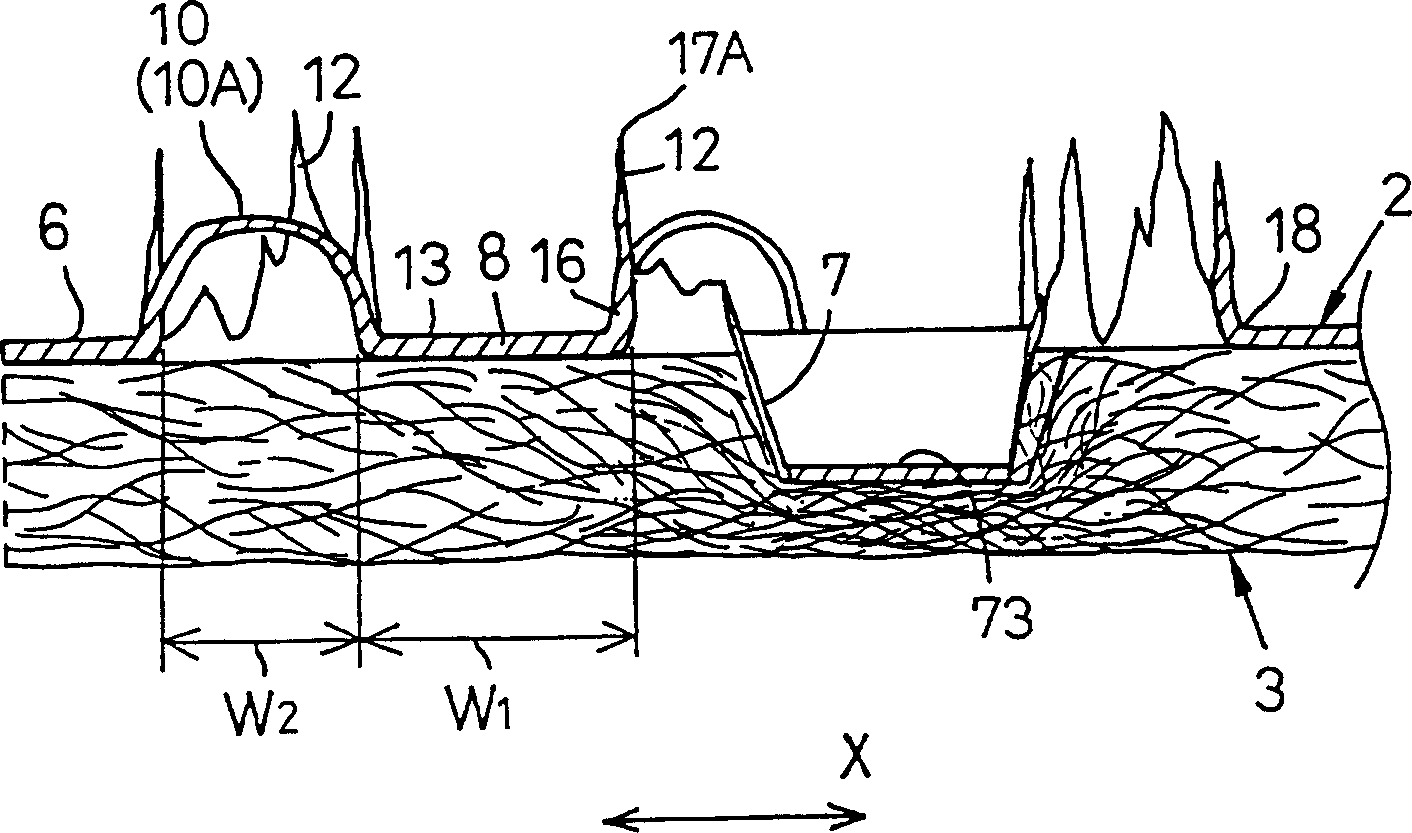

[0022] Next, the flexible composite sheet used in disposable wearing articles related to the present invention will be described in detail with reference to the drawings.

[0023] A composite sheet 1 shown in a perspective view in FIG. 1 is composed of an upper layer 2 and a lower layer 3 .

[0024] The upper layer 2 is manufactured from a thermoplastic synthetic resin film and has a first surface region 6 and a second surface region 7 . The first surface region 6 has a plurality of flat portions 8 extending parallel to each other in the direction of the double-headed arrow Y, and a plurality of opening rows 11 formed by extending the plurality of openings 9 in parallel to each other in the direction of the arrow Y.

[0025] The flat portion 8 has an upper face 13 and a lower face 14, and the opening 9 is located between the flat portions 8 and 8 adjacent in the arrow X direction perpendicular to the arrow Y direction. A crosslinking portion 10 connecting the flat portions 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com