Carbon remover without need of disassembling engine

A dismantling-free and engine-free technology, which is applied in the direction of detergent composition fragrances, non-ionic surface active compounds, etc., can solve the problems of high cleaning cost, heavy workload, and long time, and achieve the effects of saving fuel, low cost, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

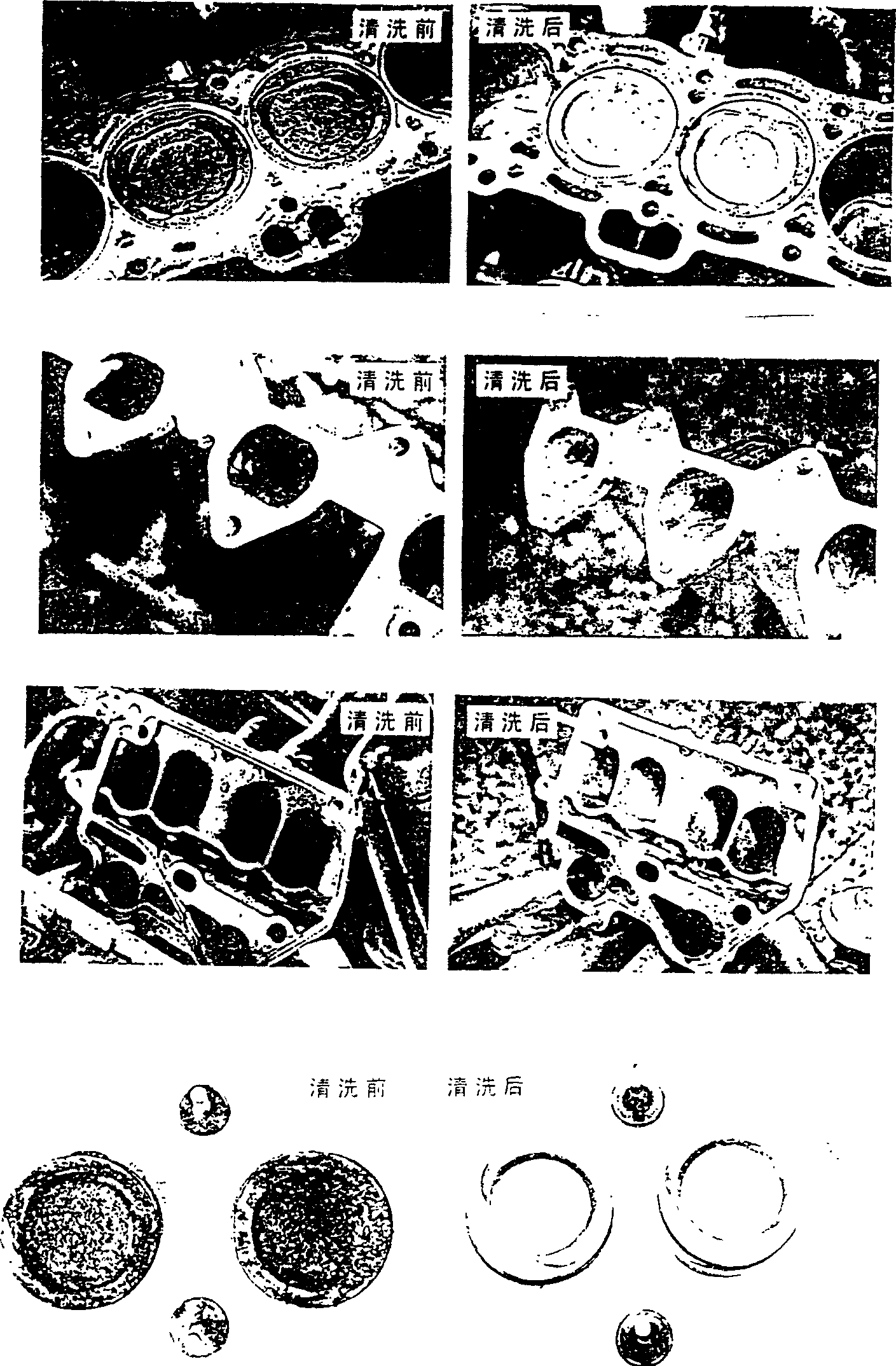

Image

Examples

Embodiment 1

[0010] 0.3 parts by weight of sodium lauryl sulfate K12, 13 parts of emulsifier alkylphenol polyoxyethylene (10) ether, 0.5 parts of spice lemon essence, and 86.2 parts of water are mixed to prepare a carbon remover.

Embodiment 2

[0012] Mix 0.8 parts by weight of sodium lauryl sulfate K12, 18 parts by weight of emulsifier alkylphenol polyoxyethylene (10) ether, 0.5 parts of spice lemon essence, and 80.7 parts of water to prepare a carbon remover.

Embodiment 3

[0014] Mix 0.5 parts by weight of sodium lauryl sulfate K12, 15 parts by weight of emulsifier alkylphenol polyoxyethylene (10) ether, 0.3 parts of spice lemon essence, and 84.2 parts of water to prepare a carbon remover.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap