Restricted scanning gas atomizing system

A gas atomization and restrictive technology, which is applied in the field of restrictive scanning gas atomization systems, can solve the problems that the nozzle cannot scan and swing, cannot perform scanning atomization, and is not suitable for metal slabs, etc., and achieves good atomization effect. Small average size and savings in usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

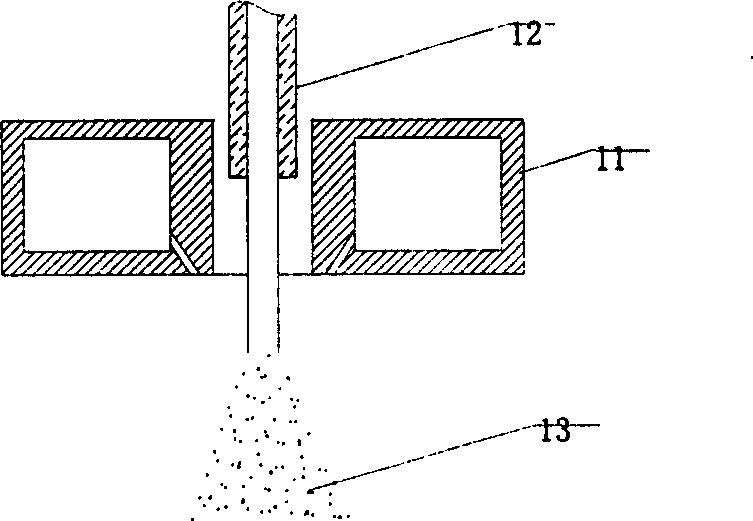

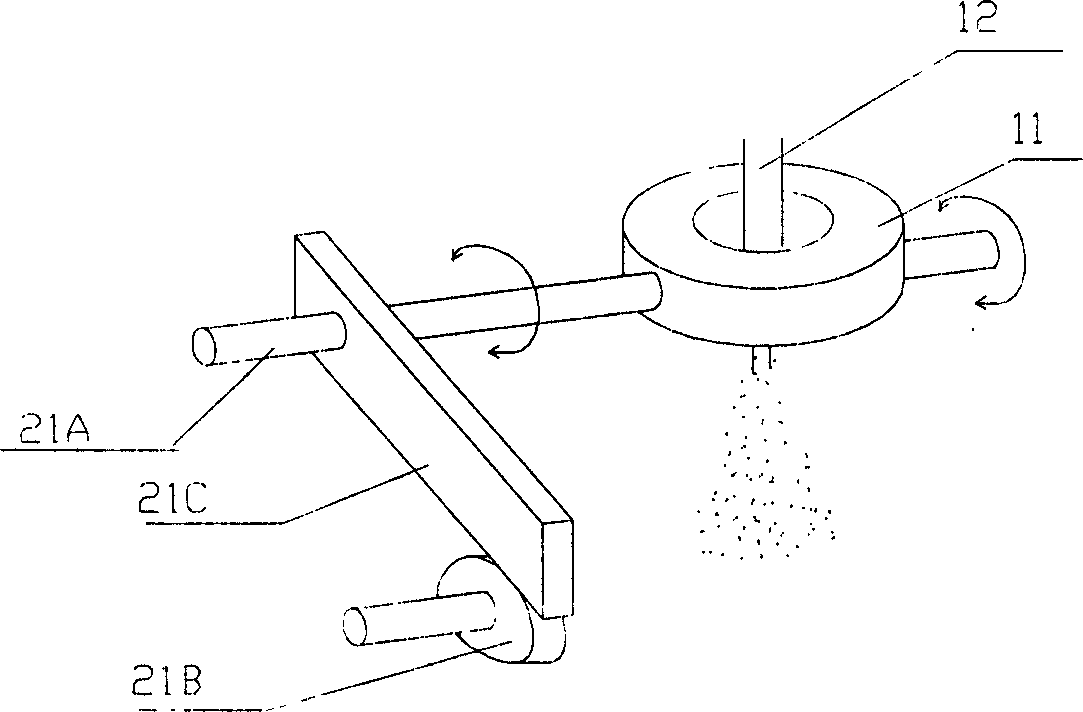

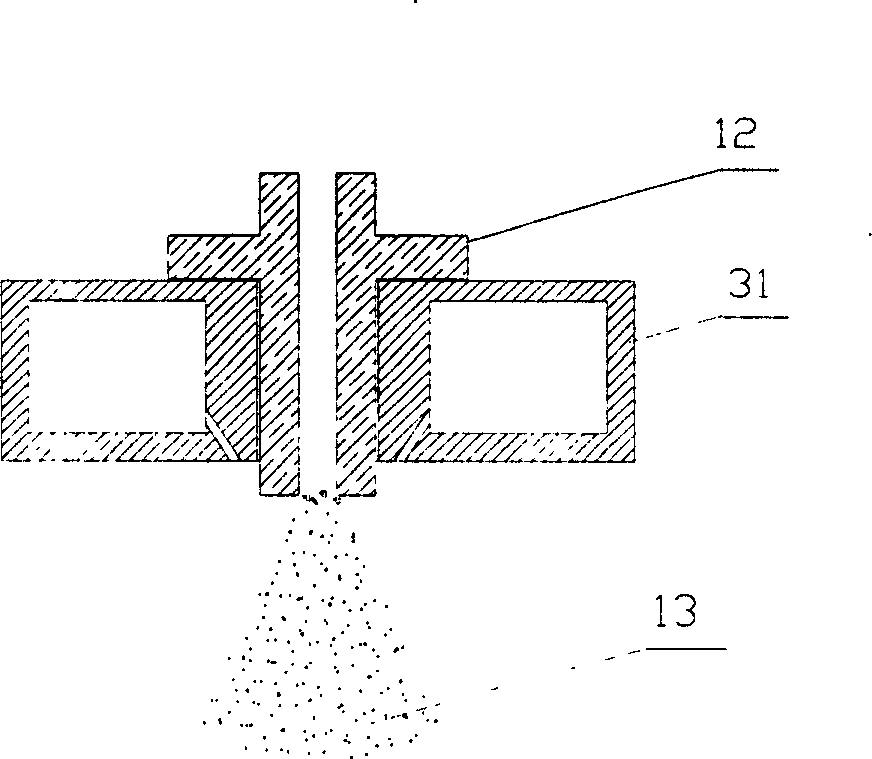

[0018] Such as Figure 4 As shown, the restrictive scanning gas atomization system of the present invention is composed of a restrictive atomizing nozzle 31, a flow guiding mechanism 41 and a scanning swing mechanism 21. The flow guiding mechanism 41 is located in the middle of the restrictive atomizing nozzle 31, and the restrictive atomizing nozzle 31 is a non-restricted atomizing nozzle structure, which is connected with the scanning swing mechanism 21 through a connecting piece to realize the swing scanning of the restrictive atomizing nozzle 31 in the atomization process; The central axis coincides.

[0019] The lower end of the restrictive atomizing nozzle 31 has 36 vent holes 31A (the vent holes 31A in this embodiment are ring hole structures) evenly distributed on the circumference of its lower end, and the outer wall of the restrictive atomizing nozzle 31 has atomizing gas introduction holes 31B; The introduction hole 31B is connected to the atomizing gas pipeline th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com