Patents

Literature

45results about How to "Avoid backsplash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

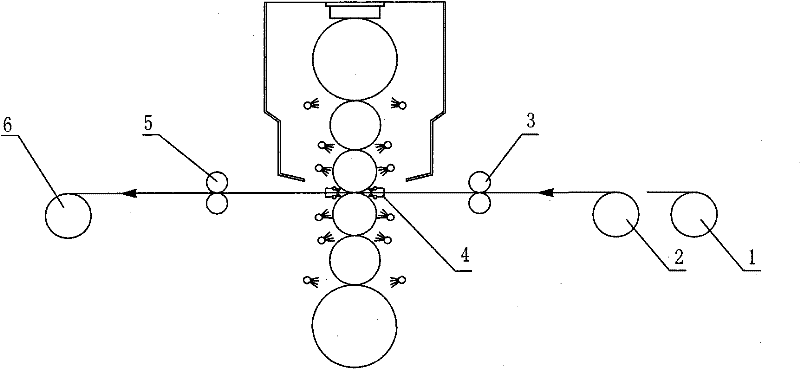

Blowing-free emulsion residue removal method

ActiveCN101829693AImprove surface qualityReduce noise pollutionRollsWork cleaning devicesEmulsionRolling mill

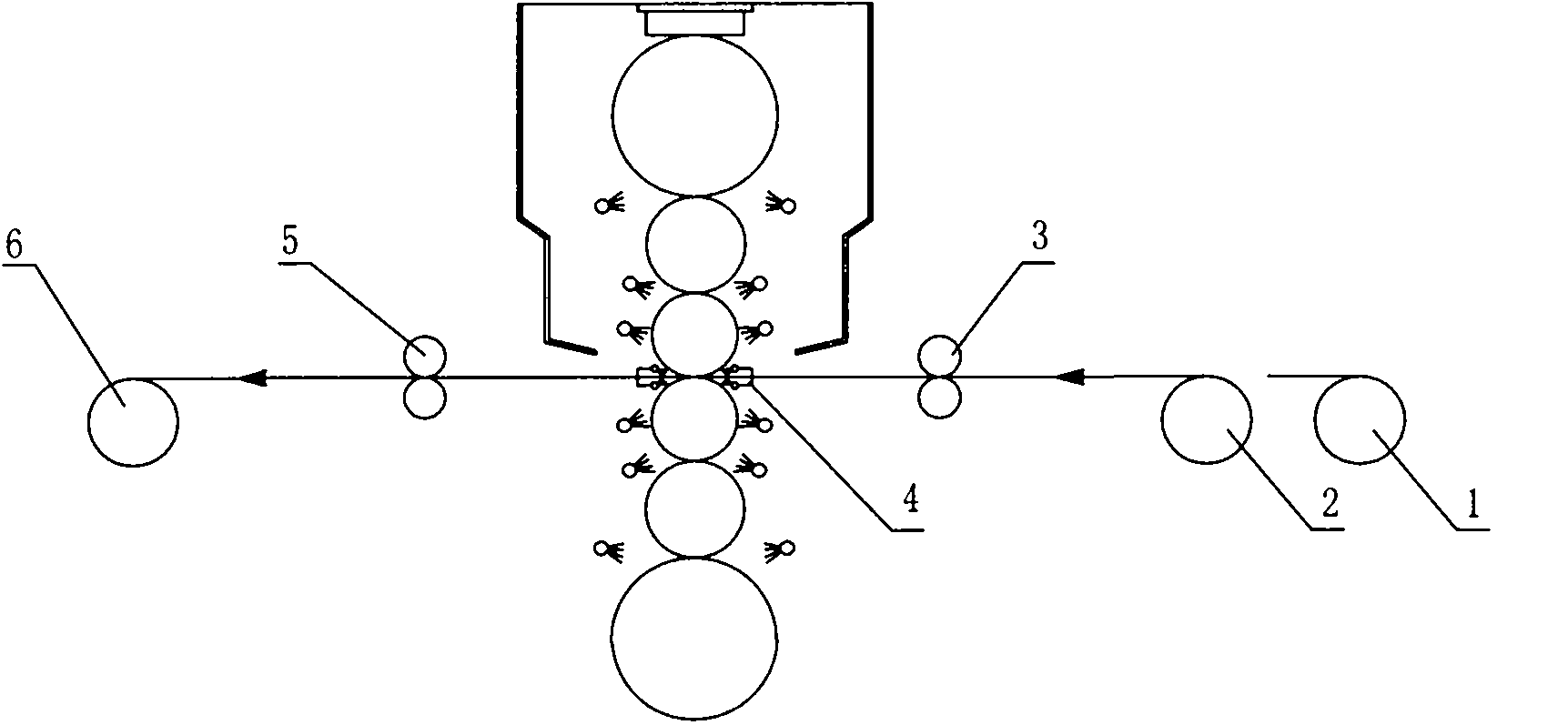

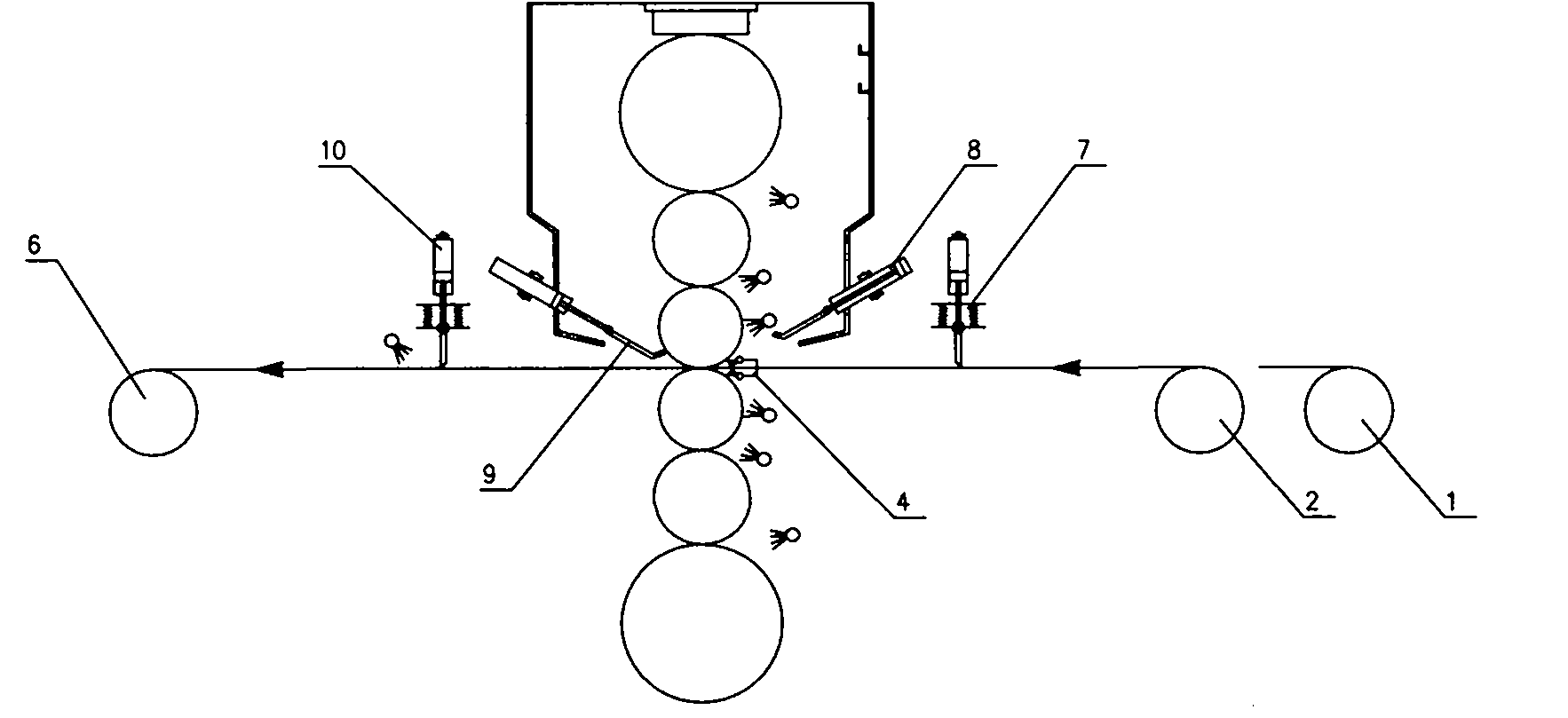

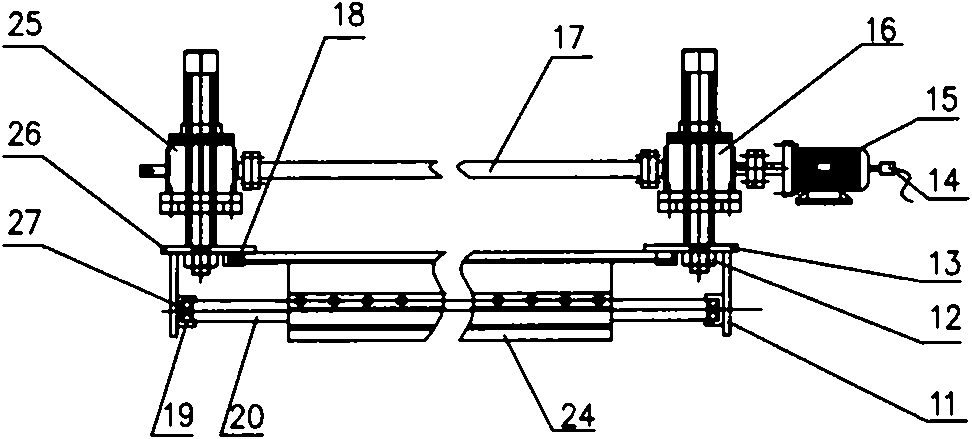

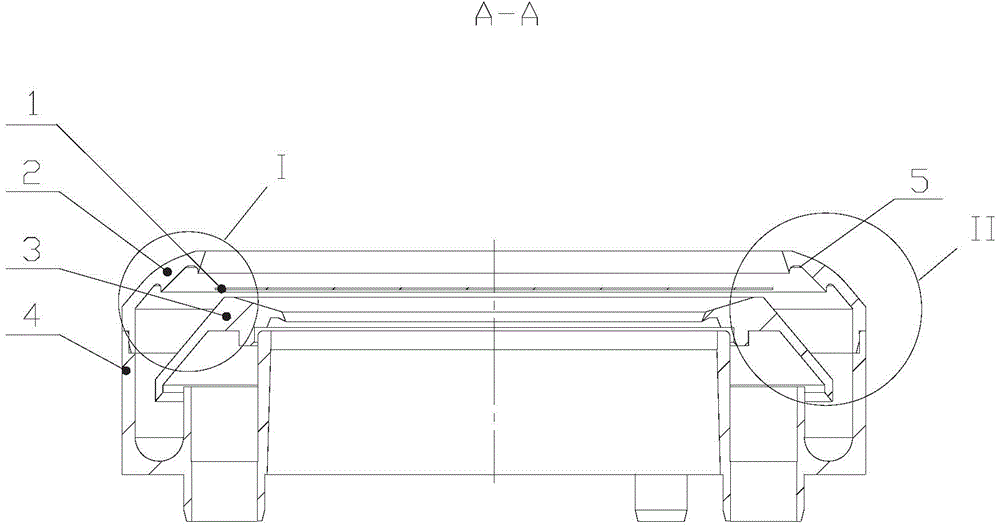

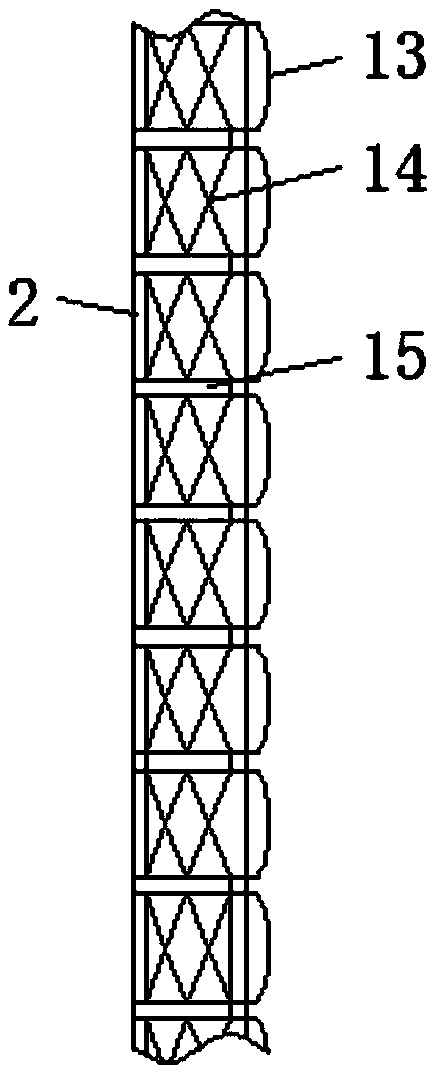

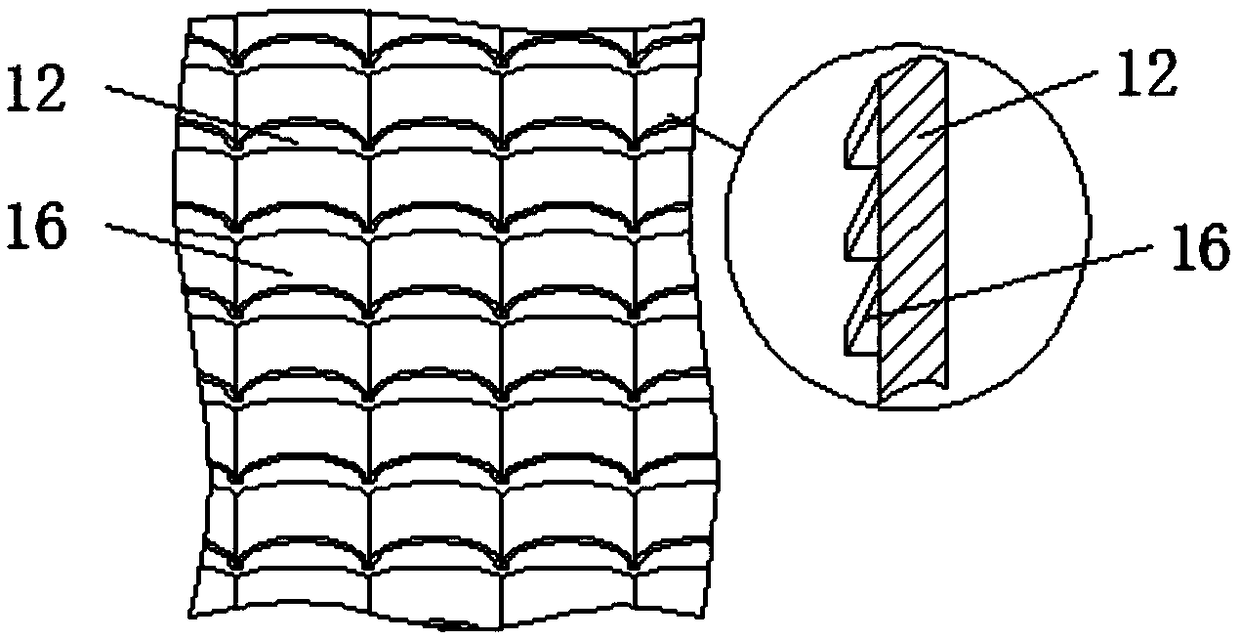

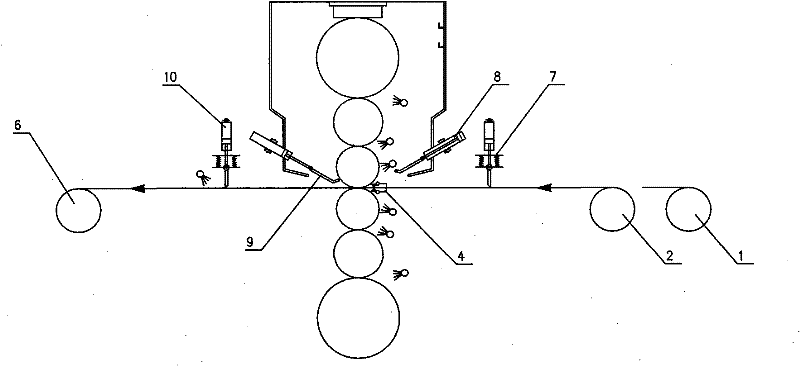

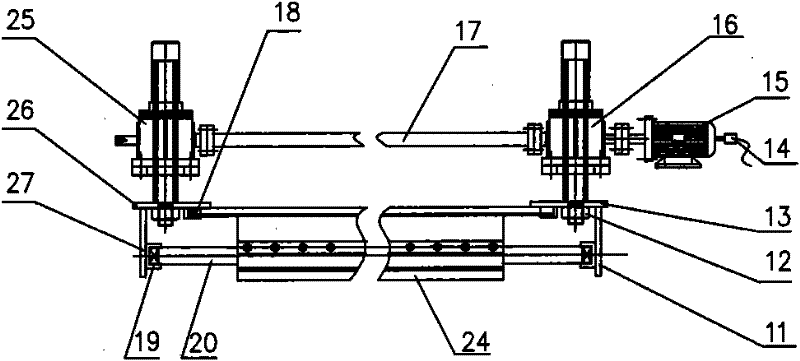

The invention belongs to the technical field of cold-rolled emulsion spot treatment, and in particular relates to a blowing-free emulsion residue removal method, which is applied to various cold-rolling mills. The blowing-free emulsion residue removal method is characterized by comprising the following steps of: 1) blocking low inertia force return of the emulsion; 2) blocking side fluid channeling of the emulsion; 3) blocking fluid channeling of intermediate roll shifting empty emulsion; 4) blocking the condensate of the emulsion; 5) rapidly draining the injection beam of the emulsion; and 6) preventing splashing. The blowing-free emulsion residue removal method has the advantages of simpleness and excellent treatment efficiency.

Owner:WISDRI ENG & RES INC LTD

Trash can cleaning lid

A trash can lid has incorporated in it an apparatus for coupling to and receiving water from a hose and conveying the water to a spray-head mechanism, wherein the water is pressurized and from whence the pressurized water is directed against the angled blades of rotary water-deflector, such that a rotary spray of pressurized water is directed against the interior walls of the trash can, thereby flushing wastes from the walls to the bottom of the trash can.

Owner:VETTER DOUGLAS J +1

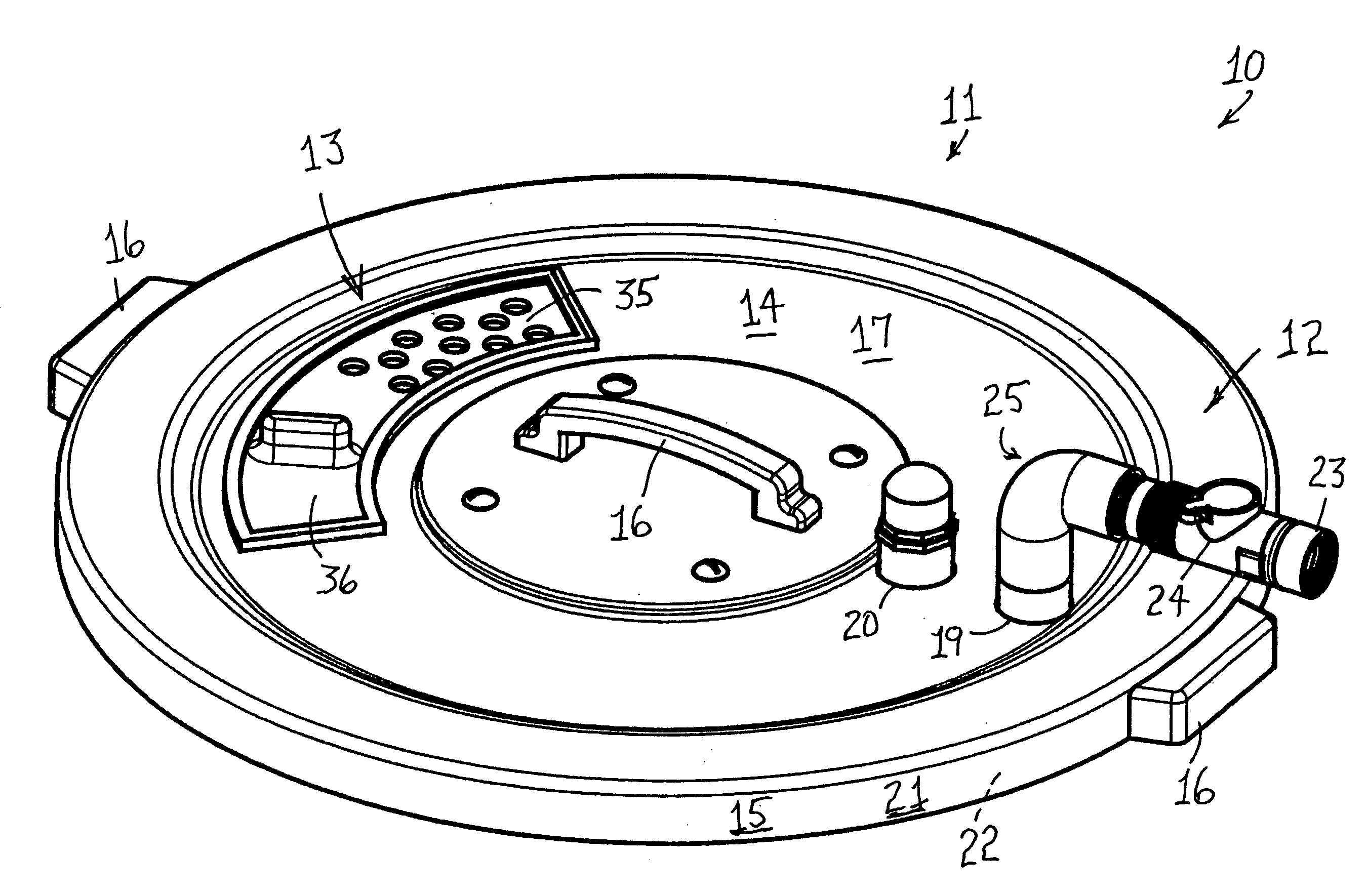

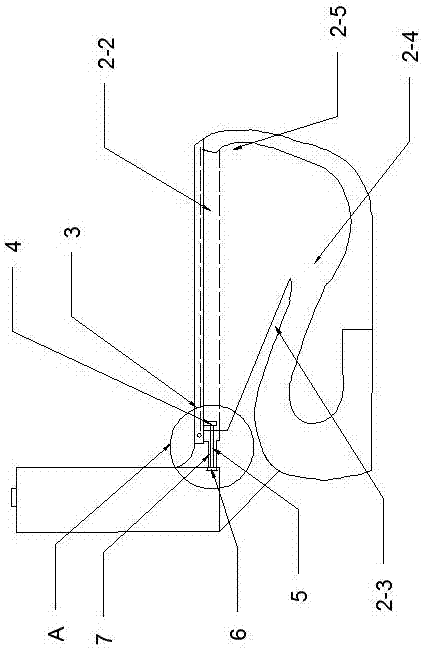

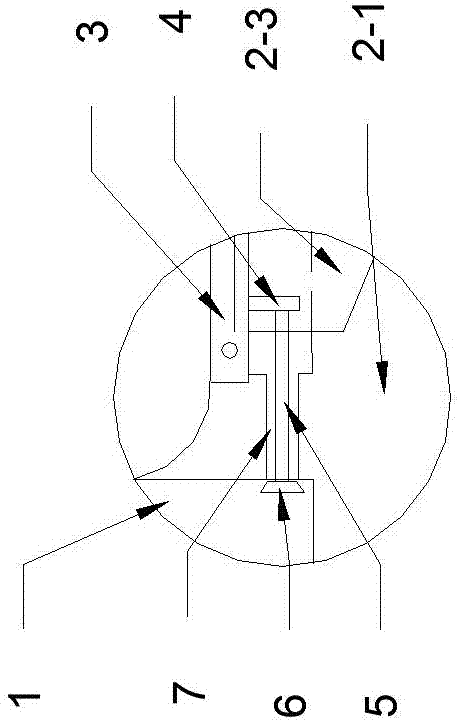

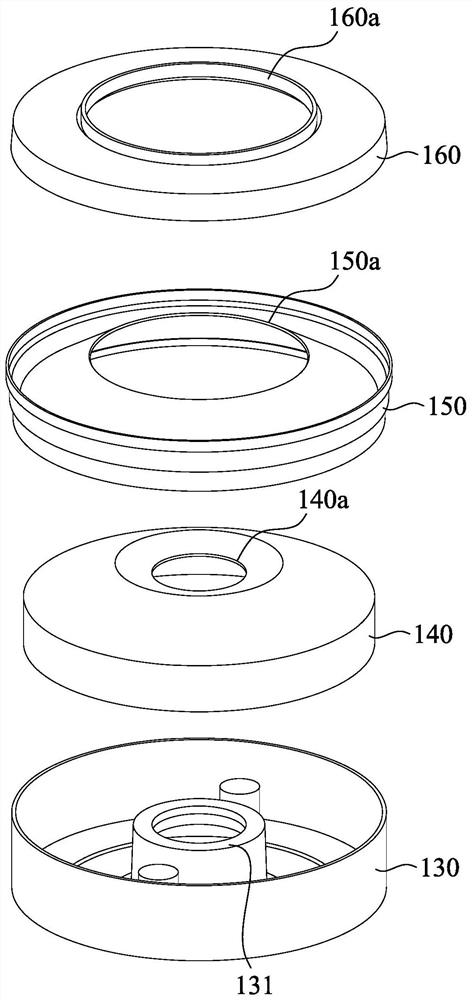

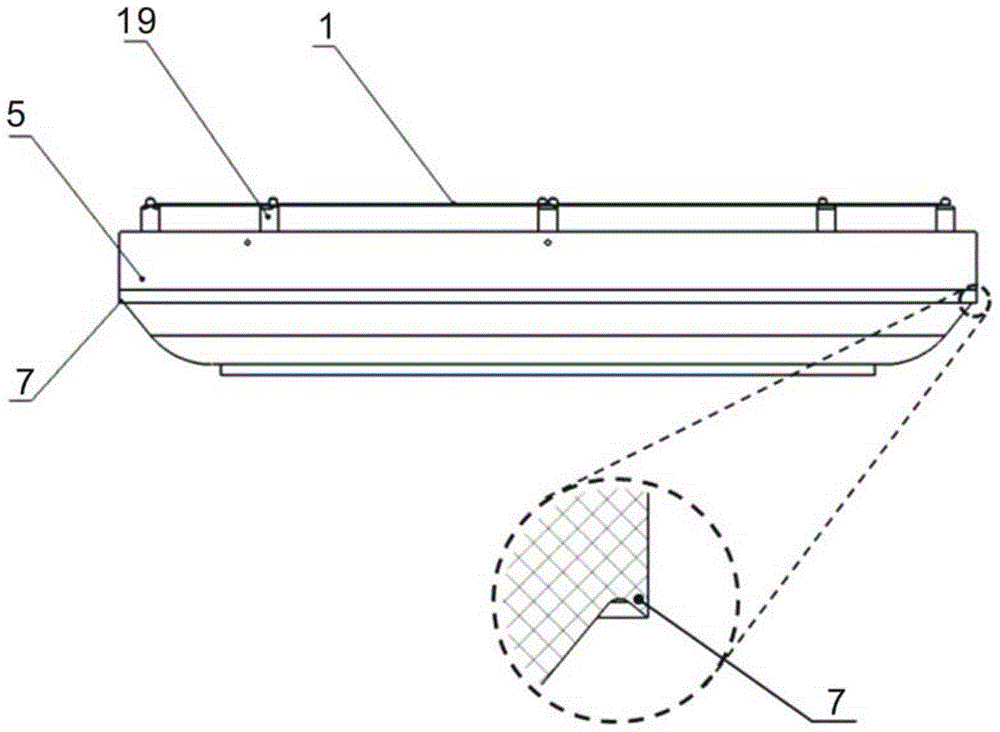

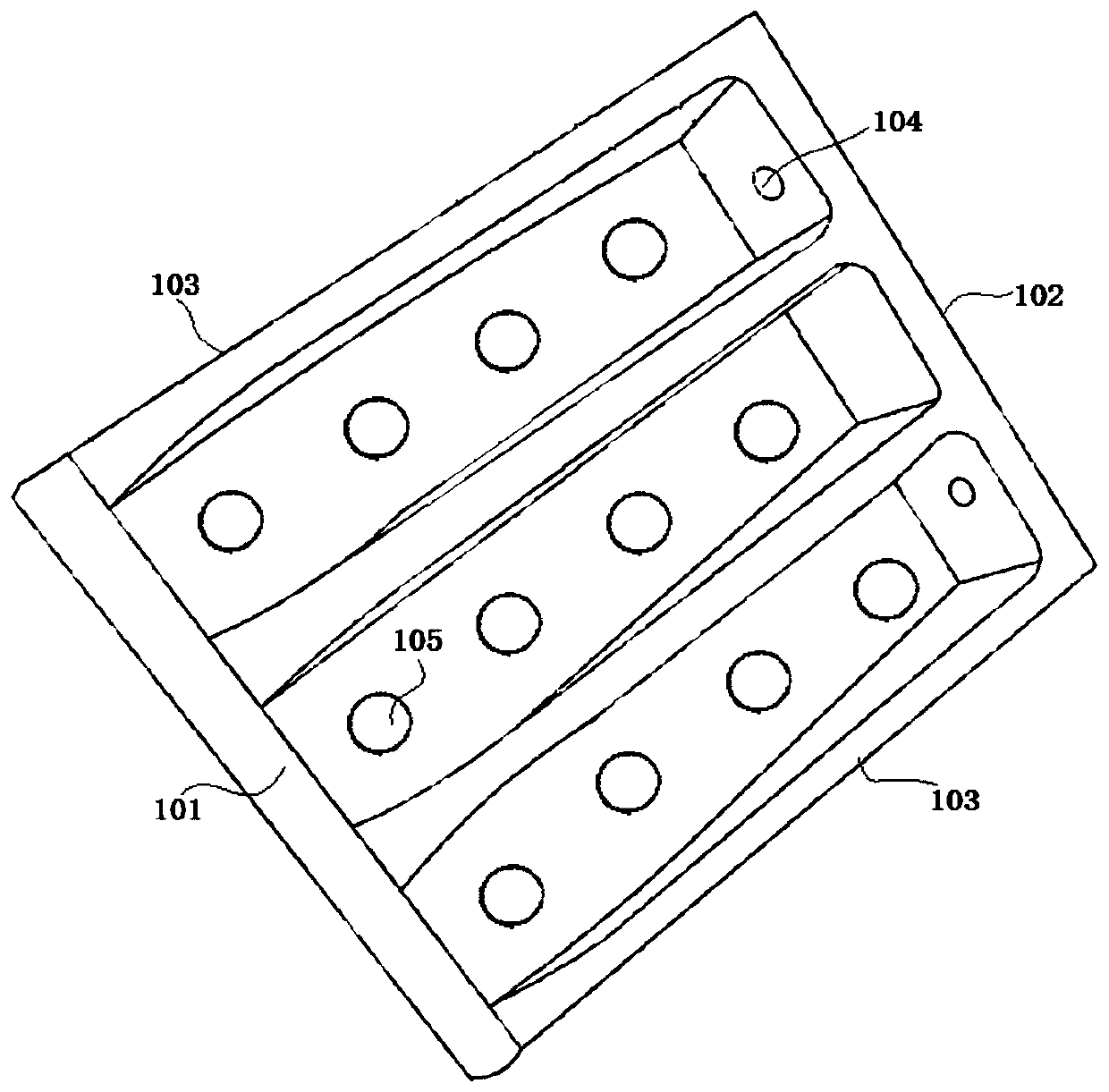

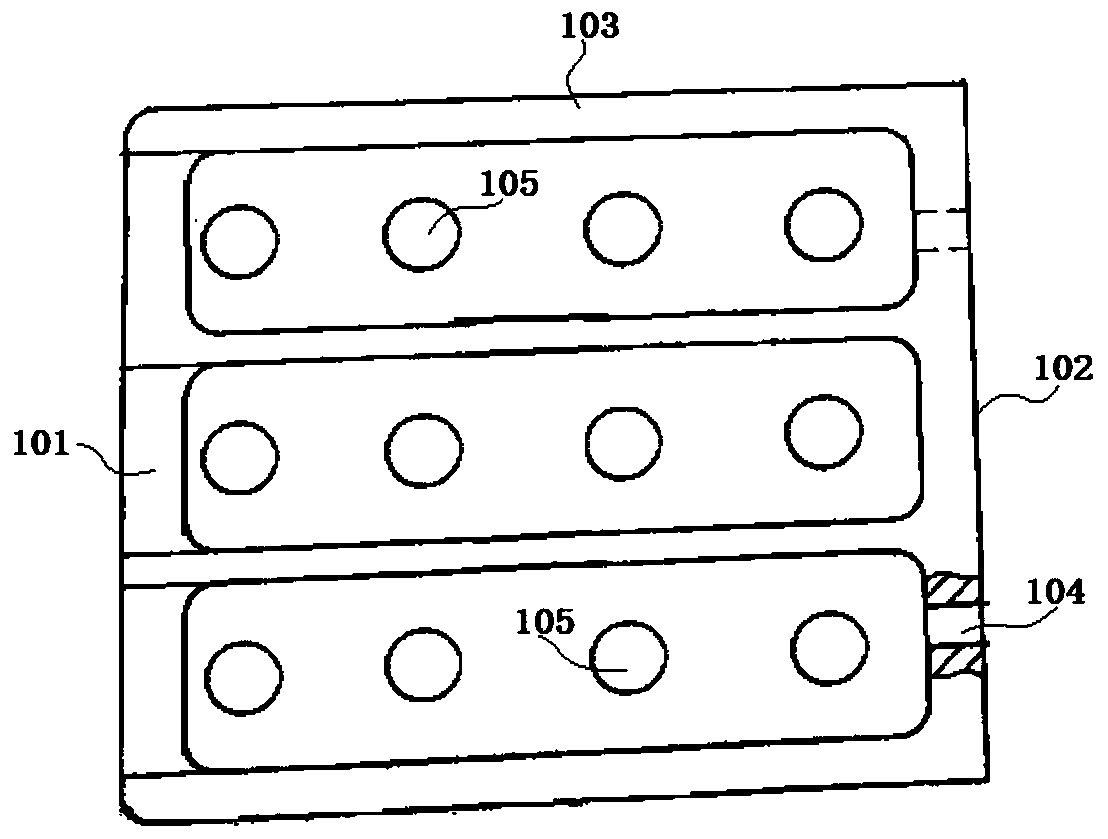

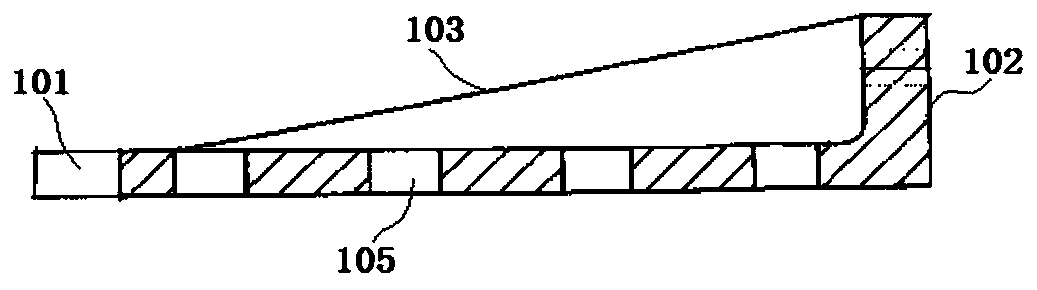

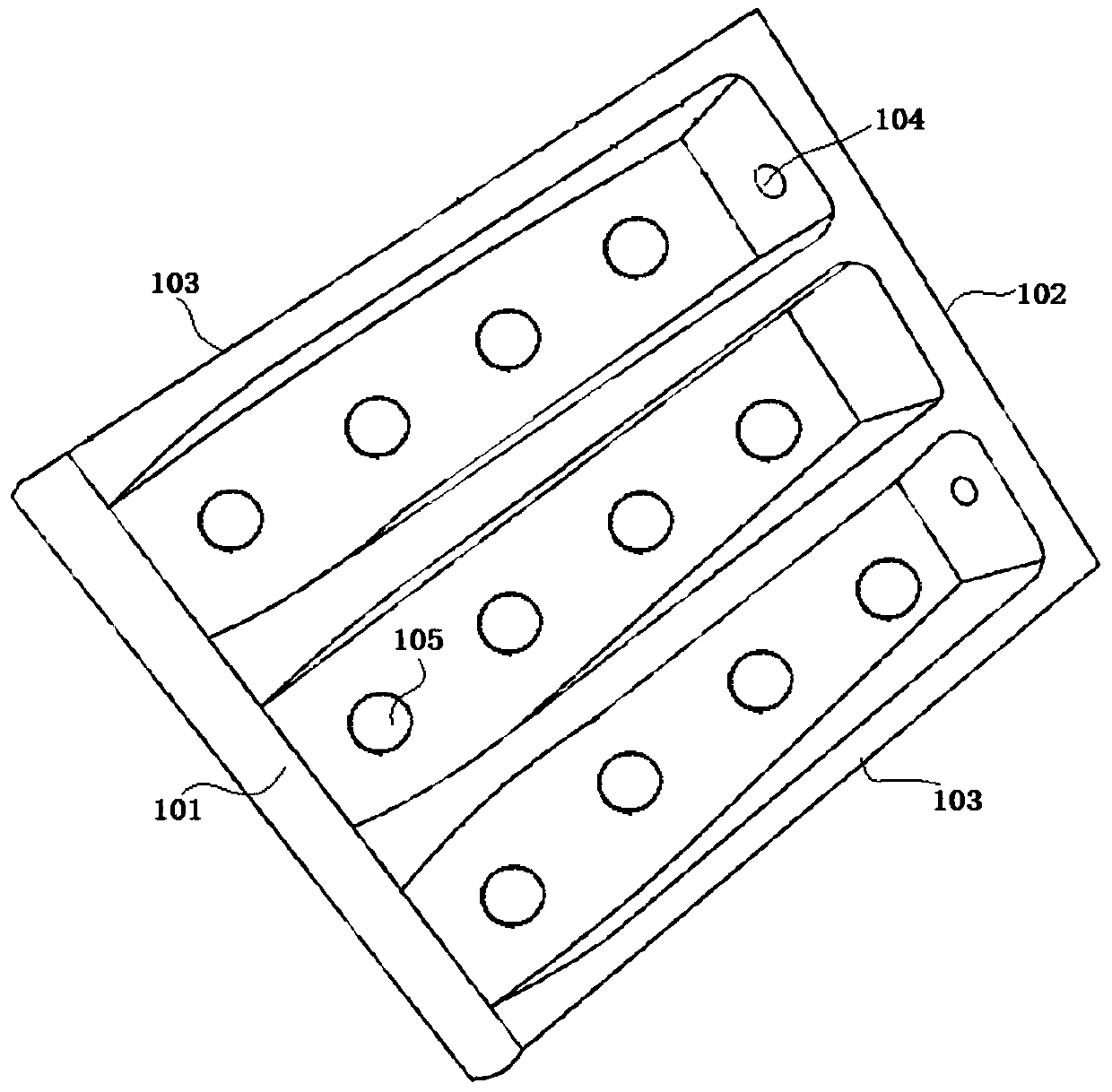

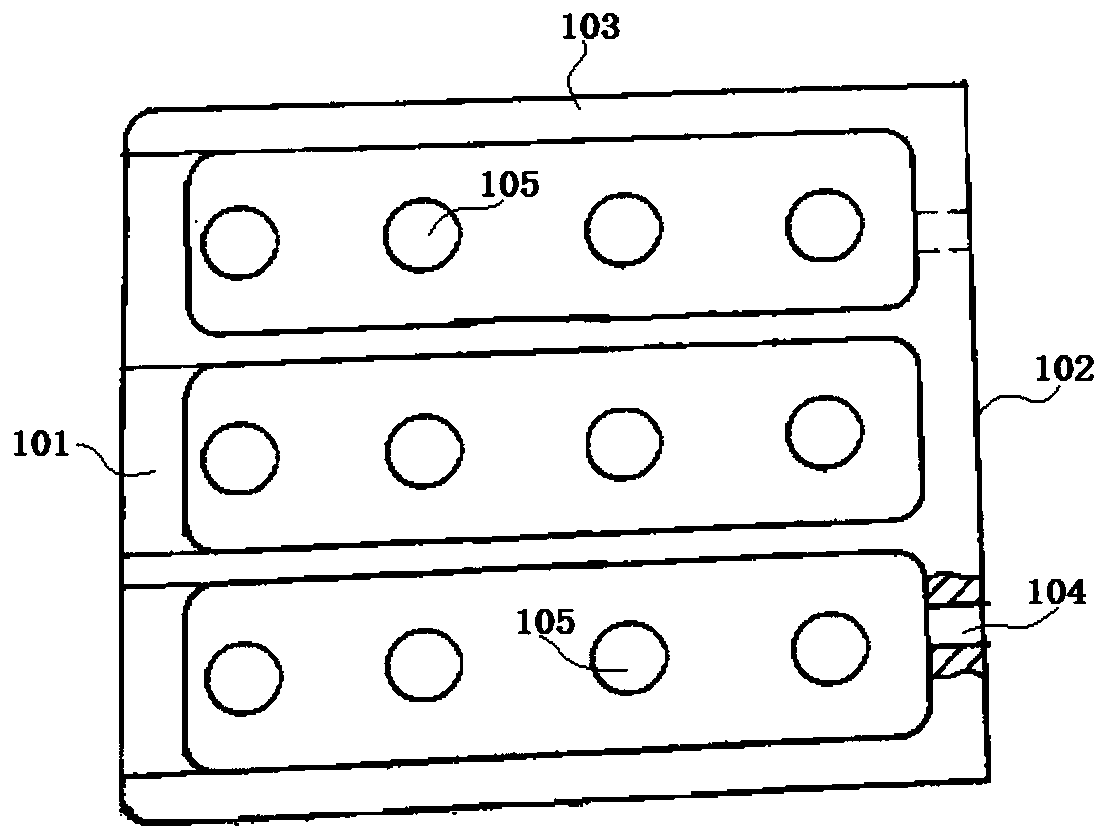

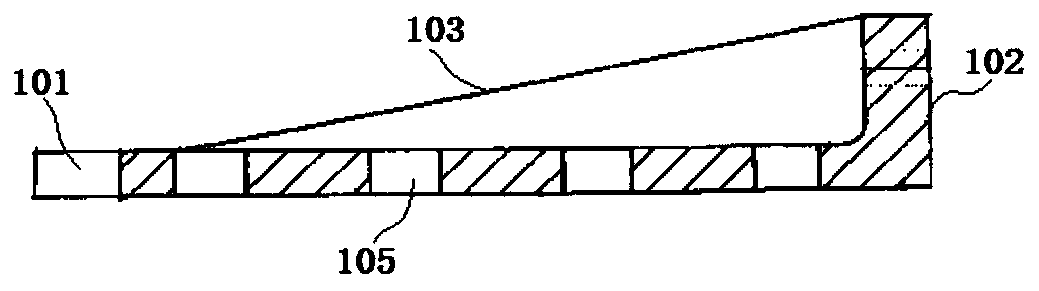

Anti-splash and anti-adhesion type process cavity of TRACK machine glue evening unit

ActiveCN104979238ABacksplash suppressionReduce leveling defectsSemiconductor/solid-state device manufacturingEngineeringPhotoresist

The invention relates to a process cavity of a glue evening unit, and specifically relates to an anti-splash and anti-adhesion type process cavity of a TRACK machine glue evening unit. The anti-splash and anti-adhesion type process cavity comprises an upper process cavity, a middle process cavity and a lower process cavity, wherein the upper process cavity and the middle process cavity respectively cooperate with the lower process cavity to form one integral body, the inner-side surface of the upper process cavity is provided with an anti-splash groove and a coating hydrophilic layer, the anti-splash groove comprises an upper-portion anti-splash groove and a lower-portion anti-splash groove which are successively recessed upwards along the inner surface of the upper process cavity from top to bottom, and a wafer is disposed between the lowest edge of the upper-portion anti-splash groove and the lowest edge of the lower-portion anti-splash groove. According to the invention, splashes generated when a photoresist bumps into a CUP can be effectively prevented, through changing the hydrophilic and hydrophobic characteristic of the inner wall of the CUP, the adhesion of the photoresist on the inner wall of the CUP is reduced, and the performance of the glue evening unit can be effectively improved.

Owner:SHENYANG KINGSEMI CO LTD

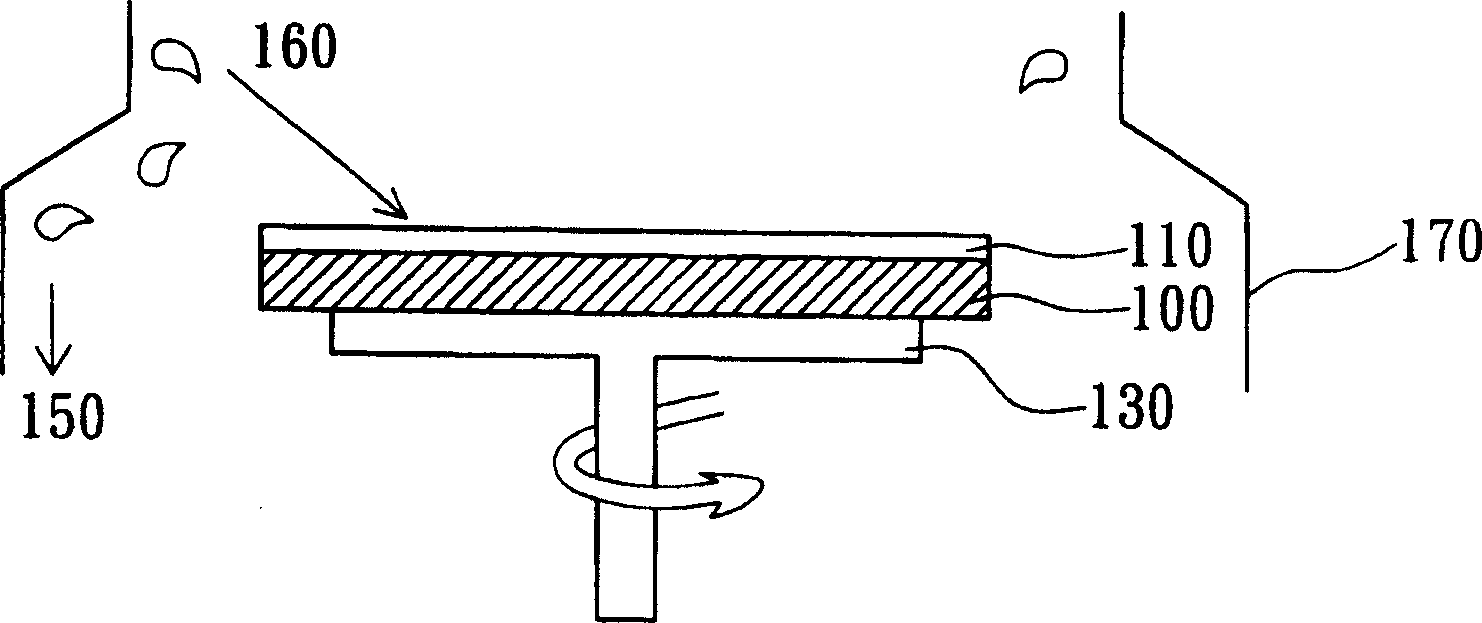

Apparatus for preventing liquid spitting back

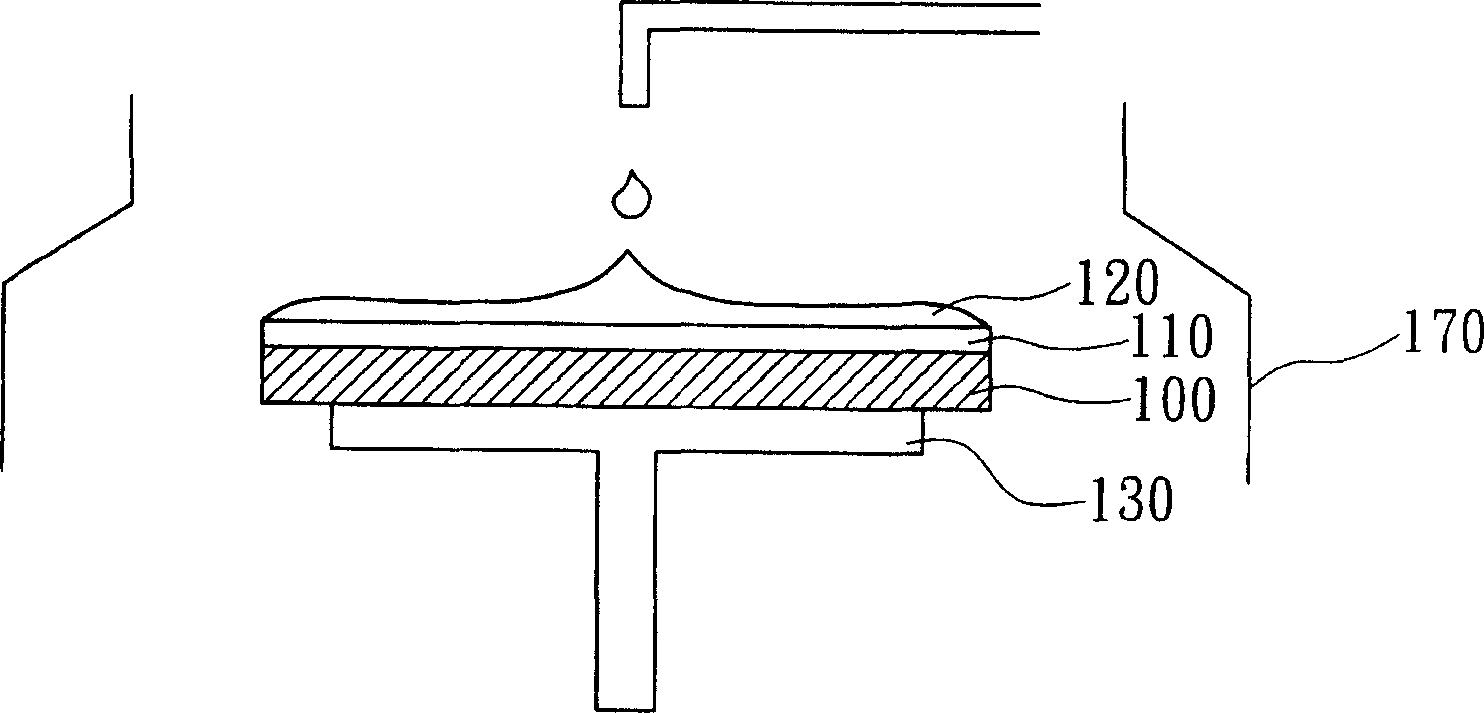

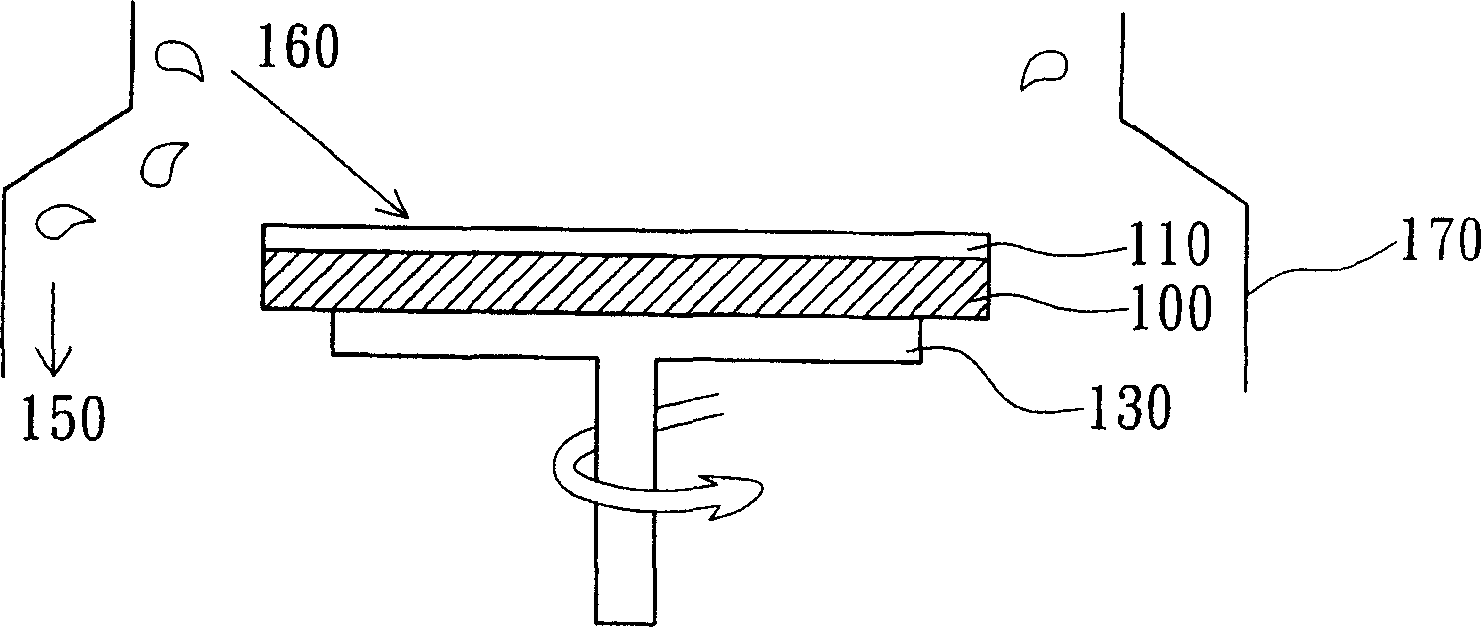

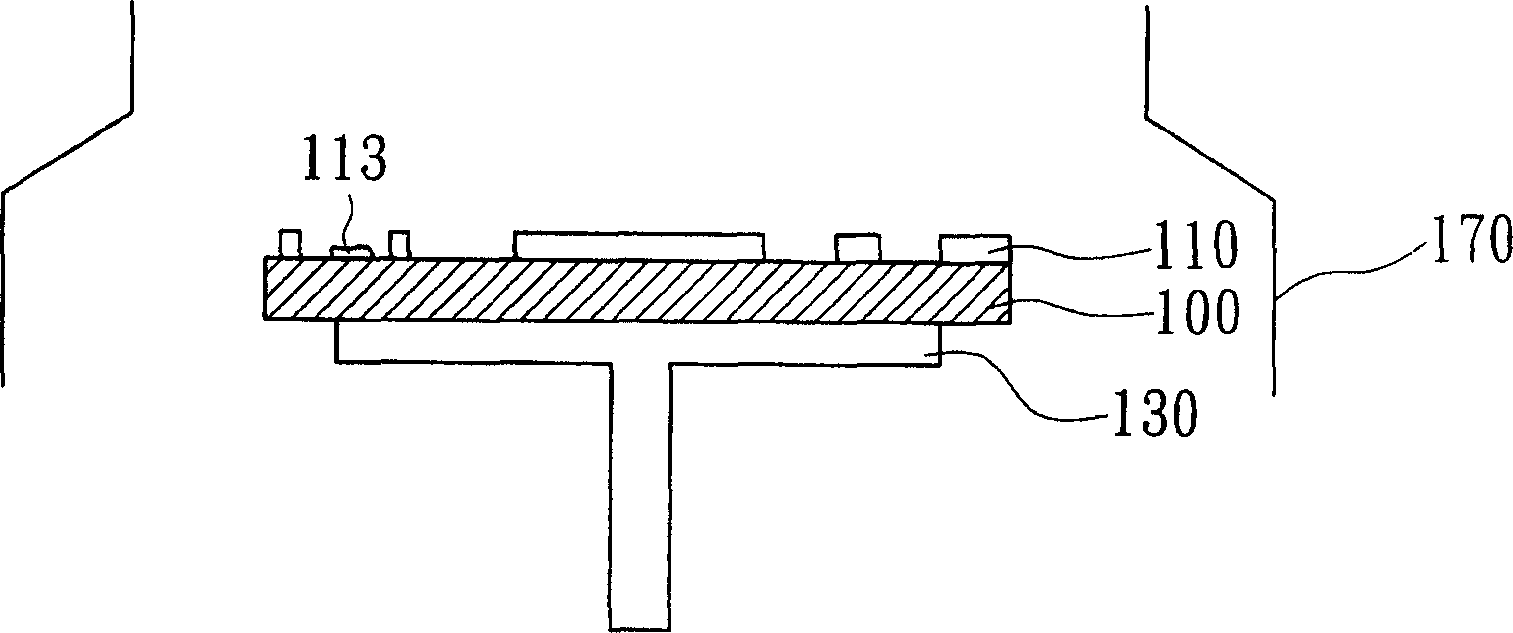

InactiveCN1567093AAvoid backsplashHigh precisionSemiconductor/solid-state device manufacturingPhotosensitive material processingEngineeringForming processes

Owner:AU OPTRONICS CORP

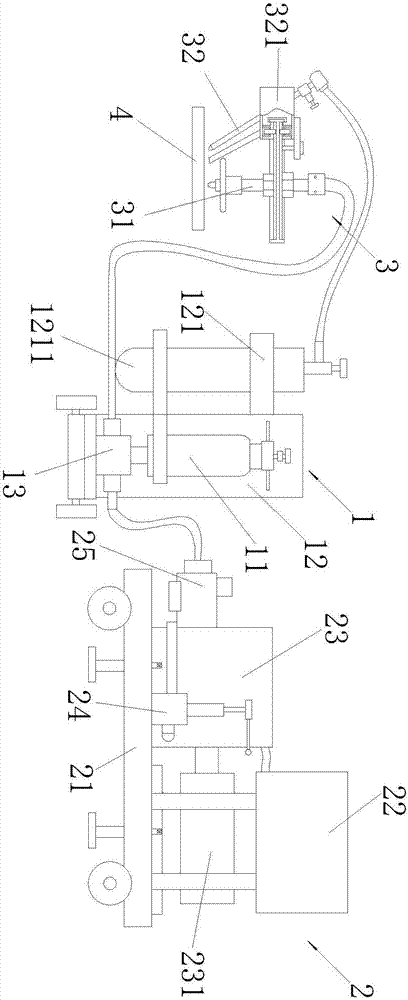

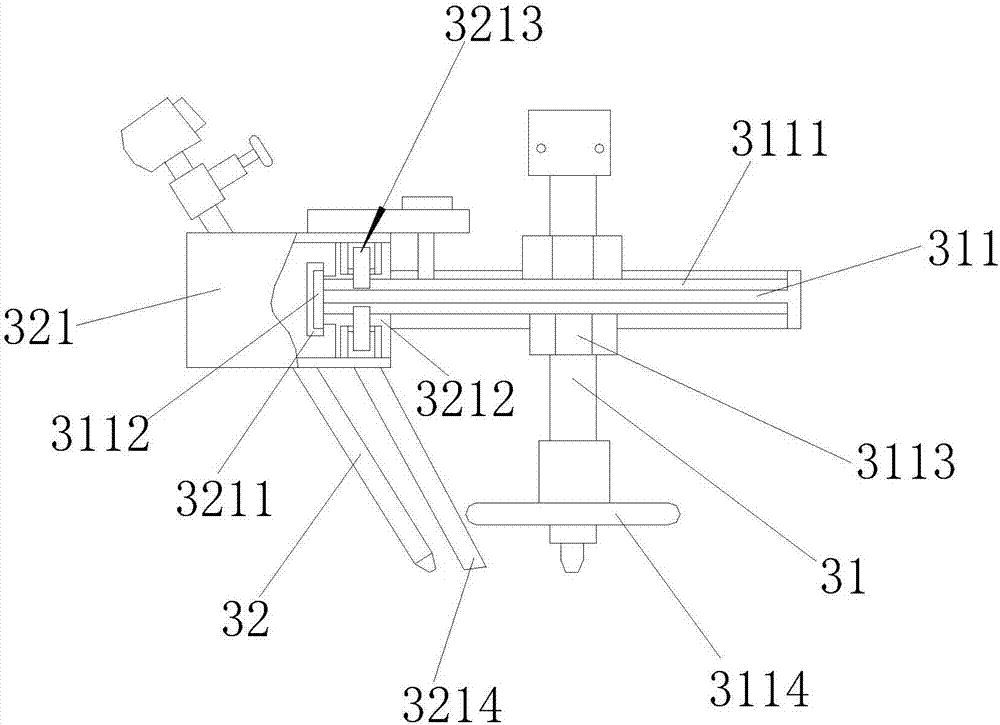

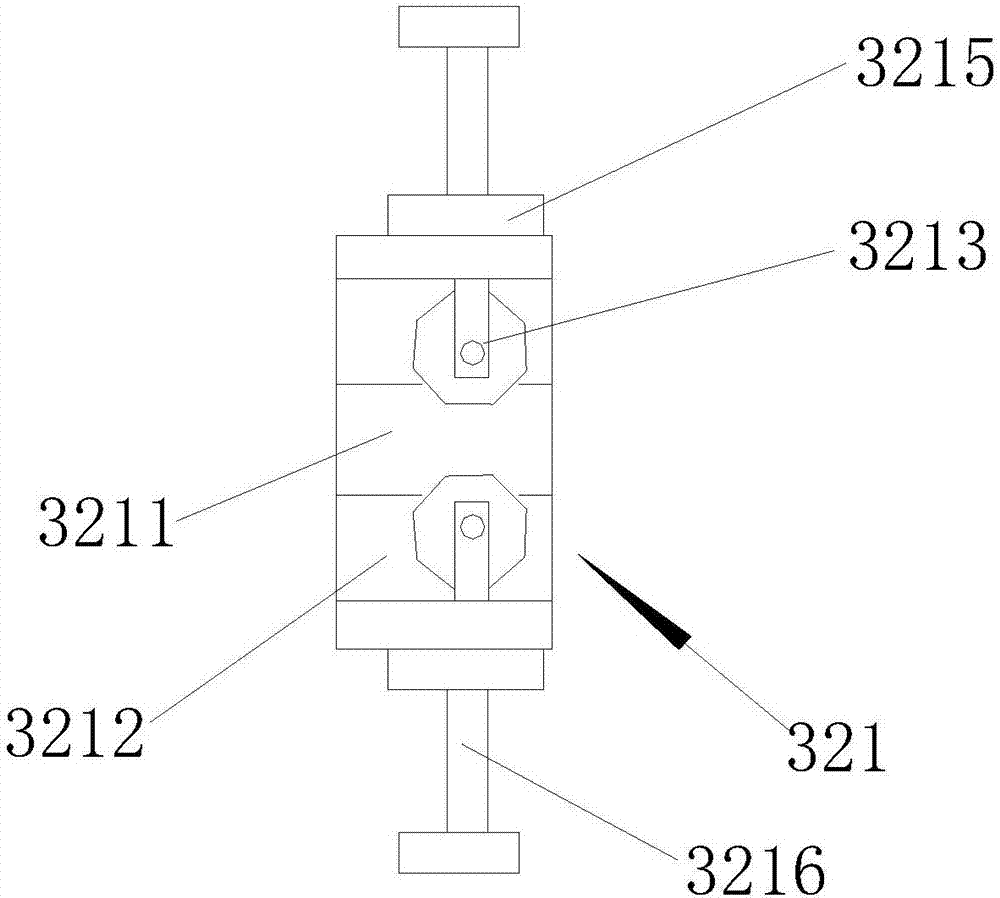

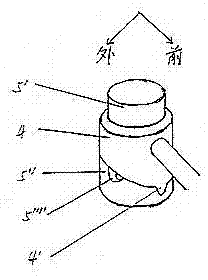

Melt cutting grinding material jet flow equipment for pre-heat mixed grinding material jet flow based on function of arc heat effect

ActiveCN106926142AReduce work stressImprove cut qualityBlast gunsAbrasive feedersSpray nozzleHot melt

The invention discloses melt cutting grinding material jet flow equipment for a pre-heat mixed grinding material jet flow based on the function of the arc heat effect. The equipment comprises a portable generator, a high-pressure pumping station, a target and a hot melt cutting device. The hot melt cutting device comprises a cutting nozzle and tilting hot melt nozzles; the cutting nozzle is arranged vertically; an adjusting fixing disc is mounted in the middle of the cutting nozzle through a thread; annular gear rings and annular limit blocking rings are arranged at the outer circle of the adjusting fixing disc; and the annular gear rings are further symmetrically distributed on the two sides of the adjusting fixing disc and located on the inner sides of the annular limit blocking rings. Adjusting fixing nuts are mounted on the two sides of the adjusting fixing disc correspondingly; and further mounted in the middle of the cutting nozzle. It can be realized that a position to be cut of the target is always under the function of the arc heat effect, the working pressure of steel cutting is greatly reduced, the cutting quality of the target cutting end face is obviously improved, and it is guaranteed that the target to be cut is under the function of the arc heat effect.

Owner:ANHUI UNIV OF SCI & TECH

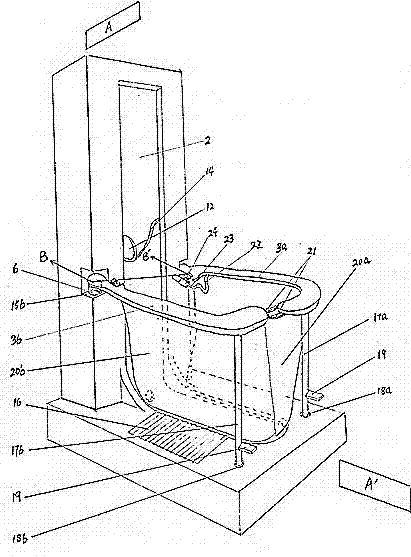

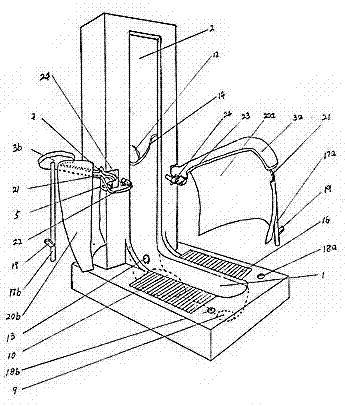

Squatting, standing and sitting three-purpose pan

ActiveCN103572821AEasy to cleanDoes not interfere with cleaningUrinalsWater closetsPhysical medicine and rehabilitationPhysical therapy

The invention discloses a squatting, standing and sitting three-purpose pan. The squatting, standing and sitting three-purpose pan mainly comprises a squatting pan, a urinal and two sitting plates, wherein the squatting pan is integrally formed; the two sitting plates are arranged at human body sitting places on the two sides of the urinal and can be optionally unfolded outwards and retracted inwards; the squatting pan is the pedestal of the urinal; an interlayer type urine hopper with an opened upper end and an opened lower end which prevents the urine from splashing outwards is arranged on the lower part of the urinal; the sitting plates can be connected with the urinal by vertical rotating shafts; when being inwards folded, the two sitting plates can serve as the squatting pan, and when being respectively unfolded outwards, the two sitting plates can serve as the urinal and the squatting pan, so that the squatting standing and sitting three-purpose pan is convenient to clean; supporting legs for supporting the sitting plates, a baffle plate for preventing feces, urine and flushing water from splashing outwards and a baffle plate flow-guiding pipe provided with a row of flushing holes and closed or connected with outward unfolding or folding of the sitting plates are attached to the downside of each sitting plate. The squatting standing and sitting three-purpose pan has the beneficial effects of preventing the ground from being wetted by water dripping, preventing buttocks from being wetted by water splashing, preventing the body, the clothes and trousers of a user from contacting the public pan sitting plate when the user squats, so that venereal disease transmission is controlled, cleaning human power and water consumption are reduced, and the mounting rate and the utilization rate of the pan in a public toilet in unit area are improved.

Owner:董谢平 +1

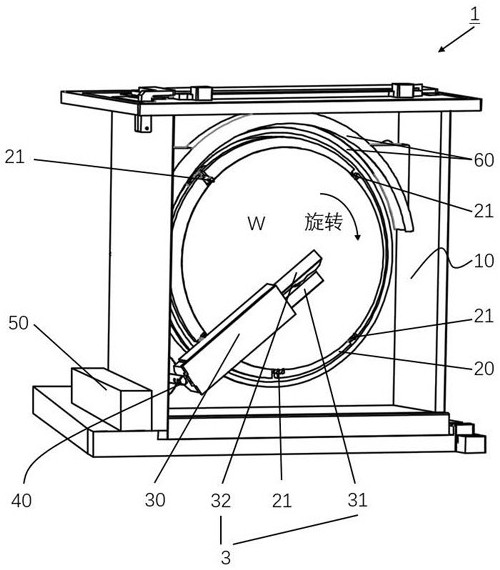

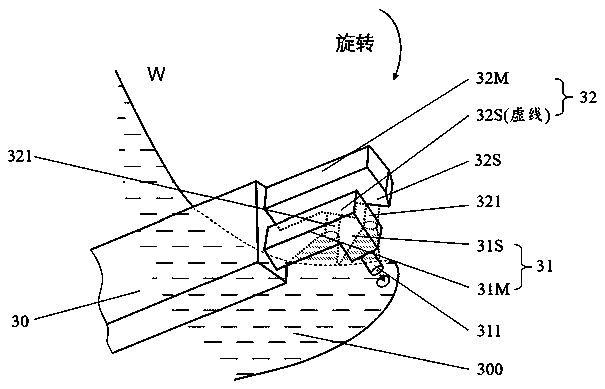

Vertical Marangoni Wafer Handler

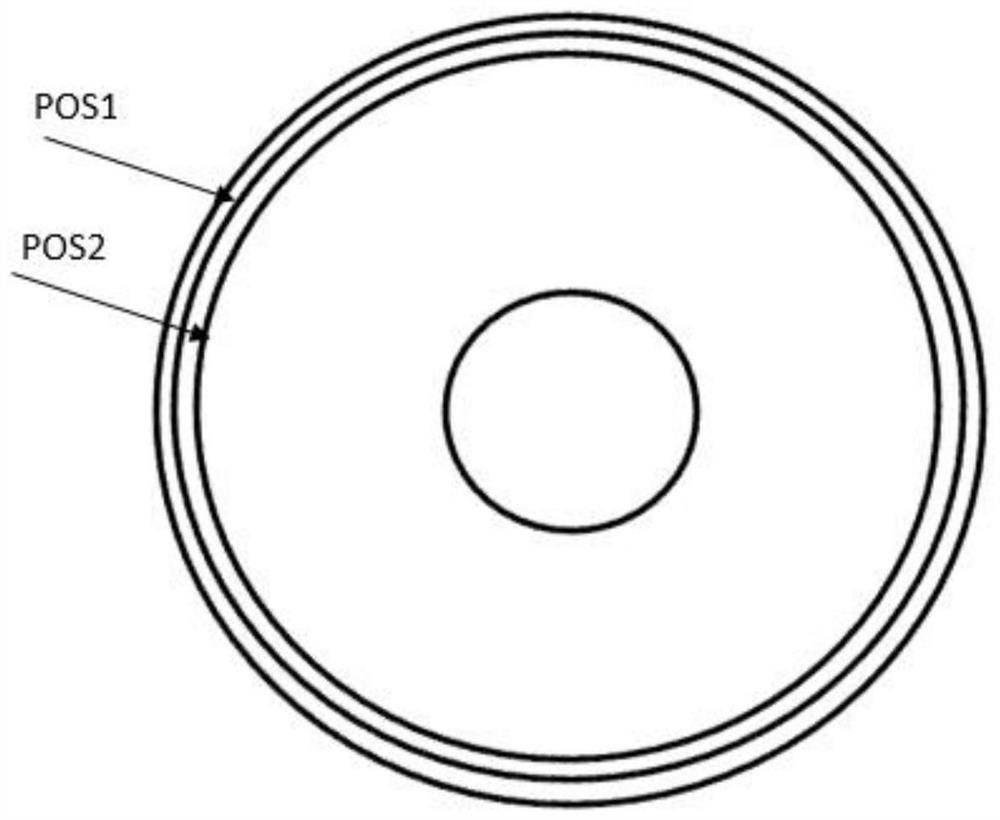

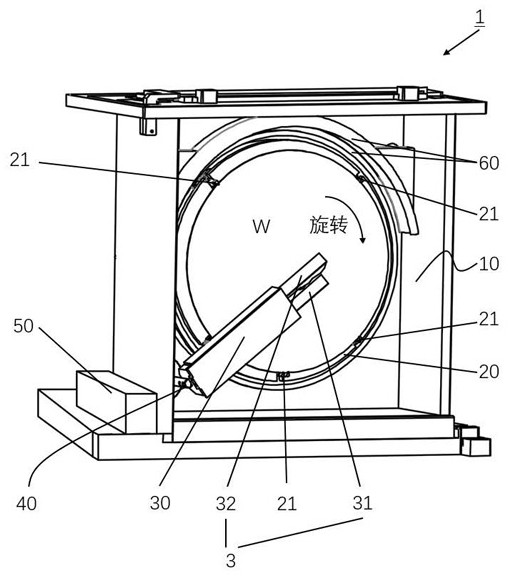

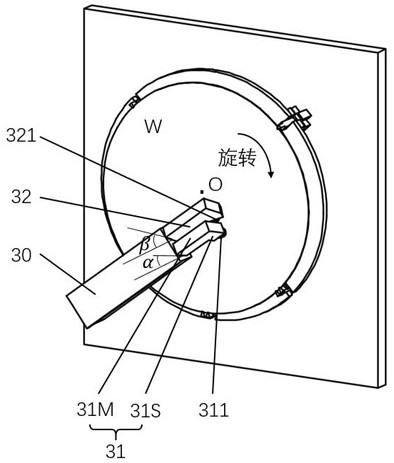

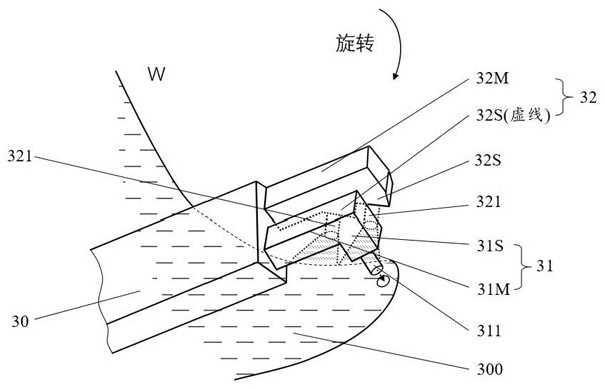

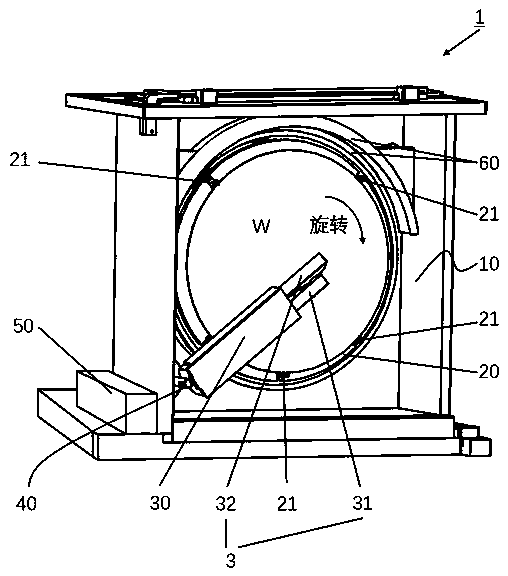

ActiveCN111540702BSave valuable spaceSave spaceSemiconductor/solid-state device manufacturingWaferEngineering

A vertical Marangoni wafer processing device, comprising: a drive mechanism for driving the wafer to rotate vertically, a supply arm for transporting fluid, and a box body, the supply arm can swing vertically and is arranged on A nozzle assembly at its free end supplies fluid onto the wafer; it is characterized in that the nozzle assembly includes a first nozzle arm and a second nozzle arm with nozzles, the first nozzle arm and the second nozzle arm along the The supply arm is extended and rotatably fixedly arranged at the free end of the supply arm.

Owner:TSINGHUA UNIV +1

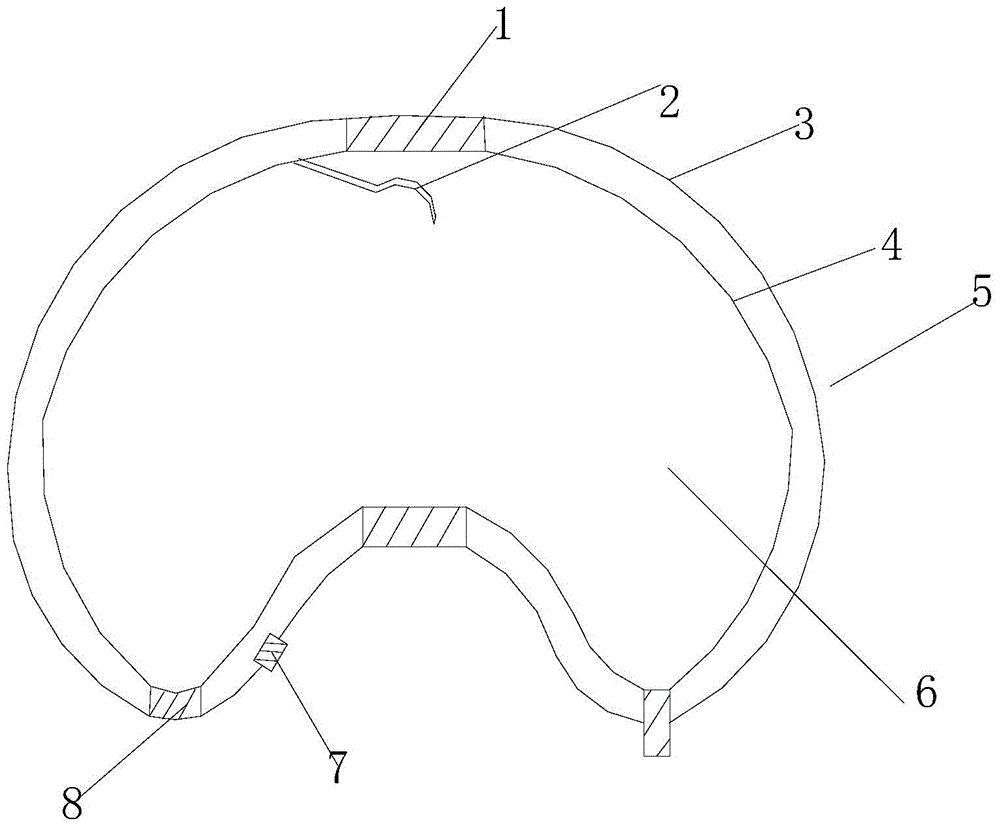

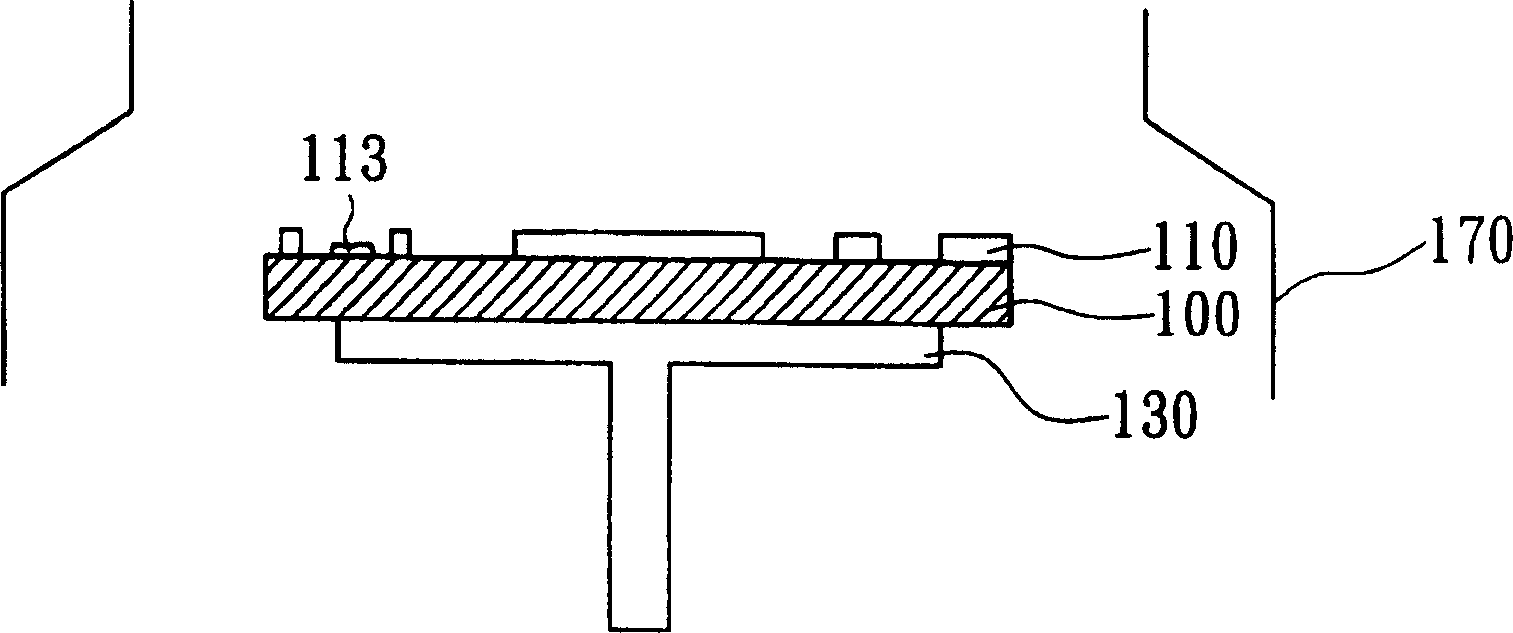

Device for preventing liquid from splashing back

InactiveCN102825051AImprove deformation resistanceOvercome secondary pollutionCleaning processes and apparatusEngineeringOrganic film

The invention provides a device for preventing liquid from splashing back. The device comprises a chuck for placing an object, a rotating shaft and a side wall, wherein the rotating shaft is fixedly connected with the chuck and is used for driving the chuck to rotate; the side wall is annularly arranged around the chuck; liquid on the object is spin-dried by rotation of the chuck; the side wall is used for preventing the liquid thrown away from the object against splashing out of the side wall; an organic film is arranged on the inner side of the side wall; and the anti-deformation ability of the liquid is increased by the organic film, so that the liquid from the object is prevented against splashing back to the object via the side wall, and secondary pollution to the object is avoided.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

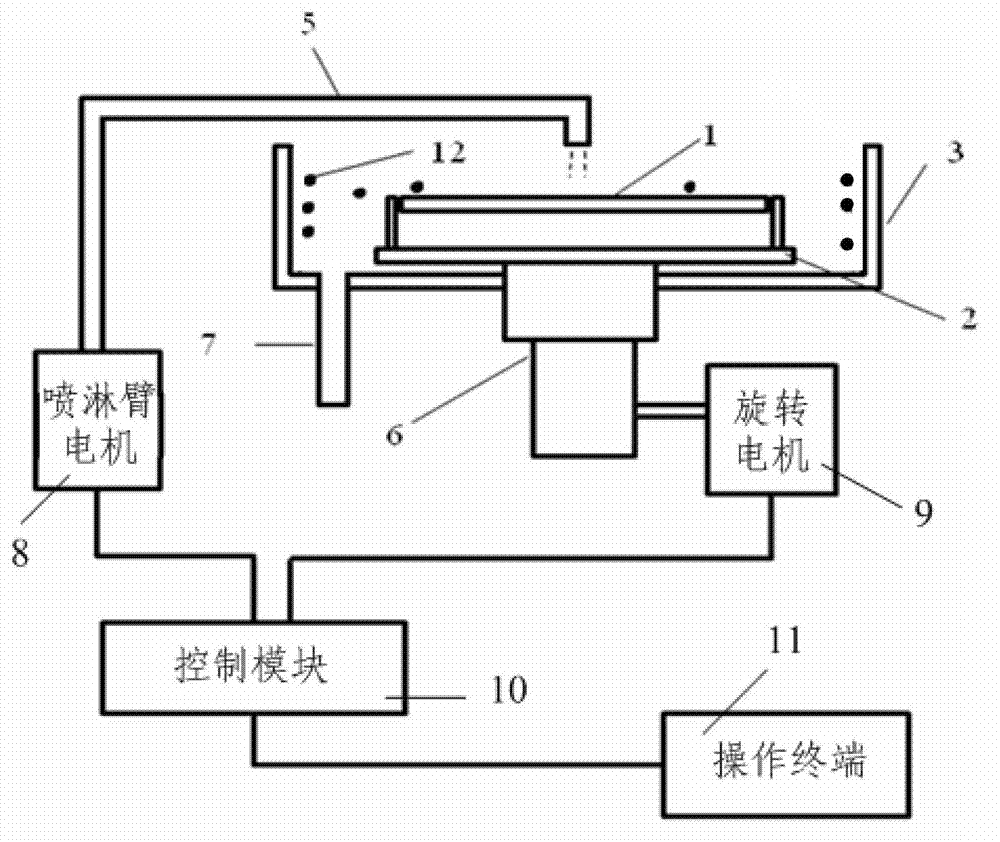

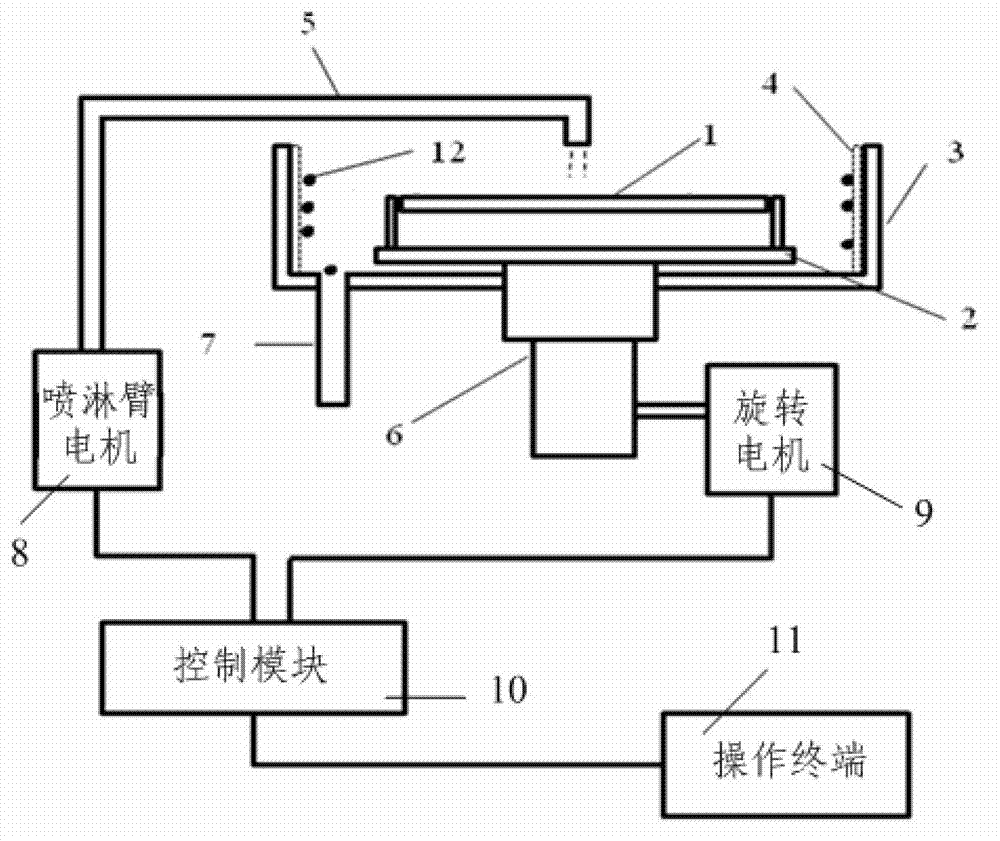

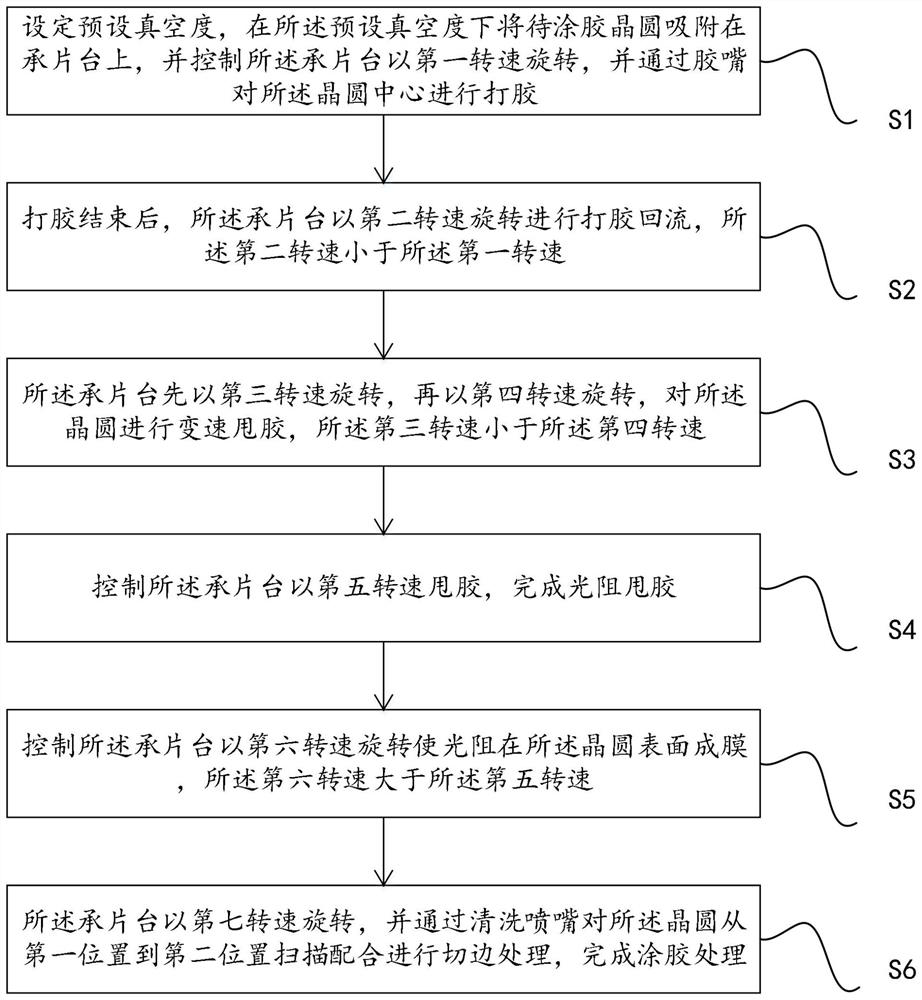

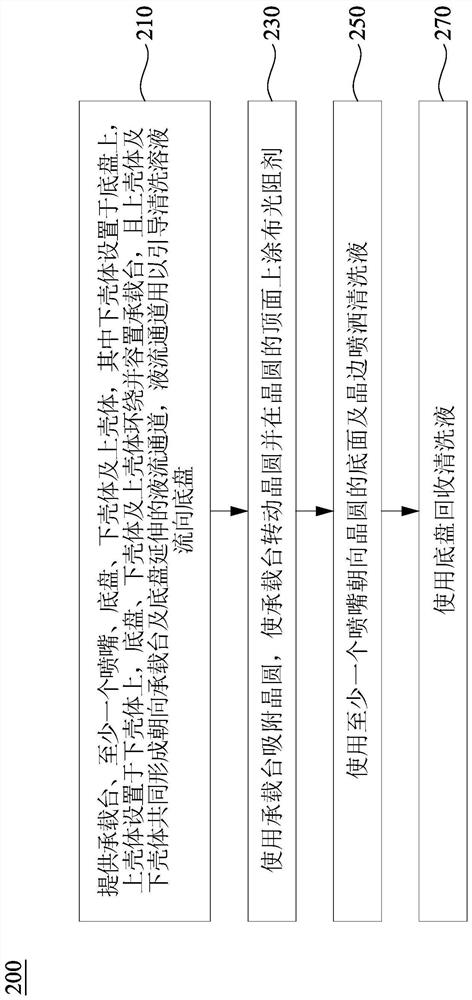

Gluing method for thinning-type wafer

ActiveCN111604236AUniform adhesionAvoid Stacked DefectsLiquid surface applicatorsSpraying apparatusSpinningWafer

The invention provides a gluing method for a thinning-type wafer. The gluing method comprises the following steps that S1, a preset vacuum degree is set, a to-be-glued wafer is sucked on a wafer holding table under the preset vacuum degree, the wafer holding table is controlled to rotate at a first rotation speed, and the center of the wafer is glue-applied through a glue nozzle; S2, after glue-applying is finished, the wafer holding table rotates at a second rotation speed to conduct glue-applying reflow, wherein the second rotation speed is less than the first rotation speed; S3, the wafer holding table rotates at a third rotation speed first, and then at a fourth rotation speed to perform glue spinning at variable speeds on the wafer, wherein third rotation speed is less than the fourthrotation speed; S4, the wafer holding table is controlled to conduct glue spinning at a fifth rotation speed, and the photoresist spinning is completed; S5, the wafer holding table is controlled to rotate at a sixth rotation speed to make photoresist form a film on the surface of the wafer, wherein the fifth rotation speed is less than the sixth rotation speed; and S6, the wafer holding table rotates at a seventh rotation speed, and the wafer is scanned from a first position to a second position through a cleaning nozzle for trimming treatment. The uniformity of the photoresist on the surfaceof the wafer can be improved, and the photoresist accumulation and liquid splashing are avoided.

Owner:SHENYANG KINGSEMI CO LTD

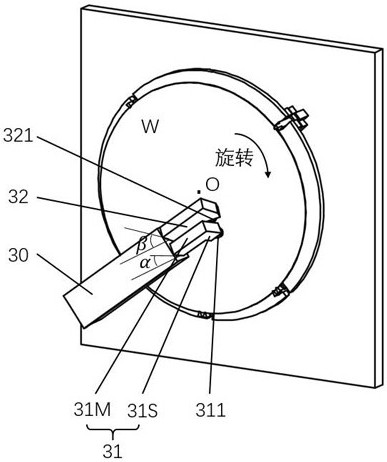

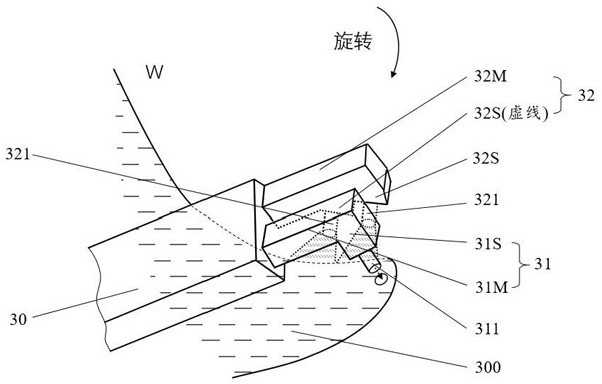

Marangoni dryer with adjustable jet angle

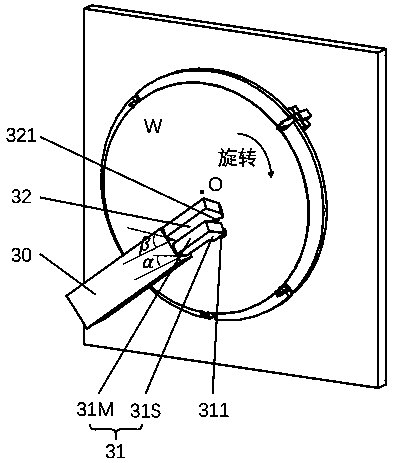

ActiveCN111536783BSave valuable spaceSave spaceDrying gas arrangementsSemiconductor/solid-state device manufacturingFluid supplyPhysics

A Marangoni drying device with adjustable spray angle, comprising: a driving mechanism for vertically rotating wafers, a supply arm for transporting fluid, and a box; the supply arm can swing vertically and is arranged on A nozzle assembly at its free end supplies fluid onto the wafer; the nozzle assembly includes a first nozzle arm having nozzles and a second nozzle arm extending along the supply arm , rotatably fixedly disposed at the free end of the supply arm; the first nozzle arm is located below the second nozzle arm, the first nozzle arm has one nozzle and the second nozzle arm has two nozzles; and the The nozzles of the first nozzle arm are perpendicular to the axis of the first nozzle arm, and the nozzles of the second nozzle arm are arranged obliquely on the second nozzle arm with a hook back or a nose.

Owner:TSINGHUA UNIV +1

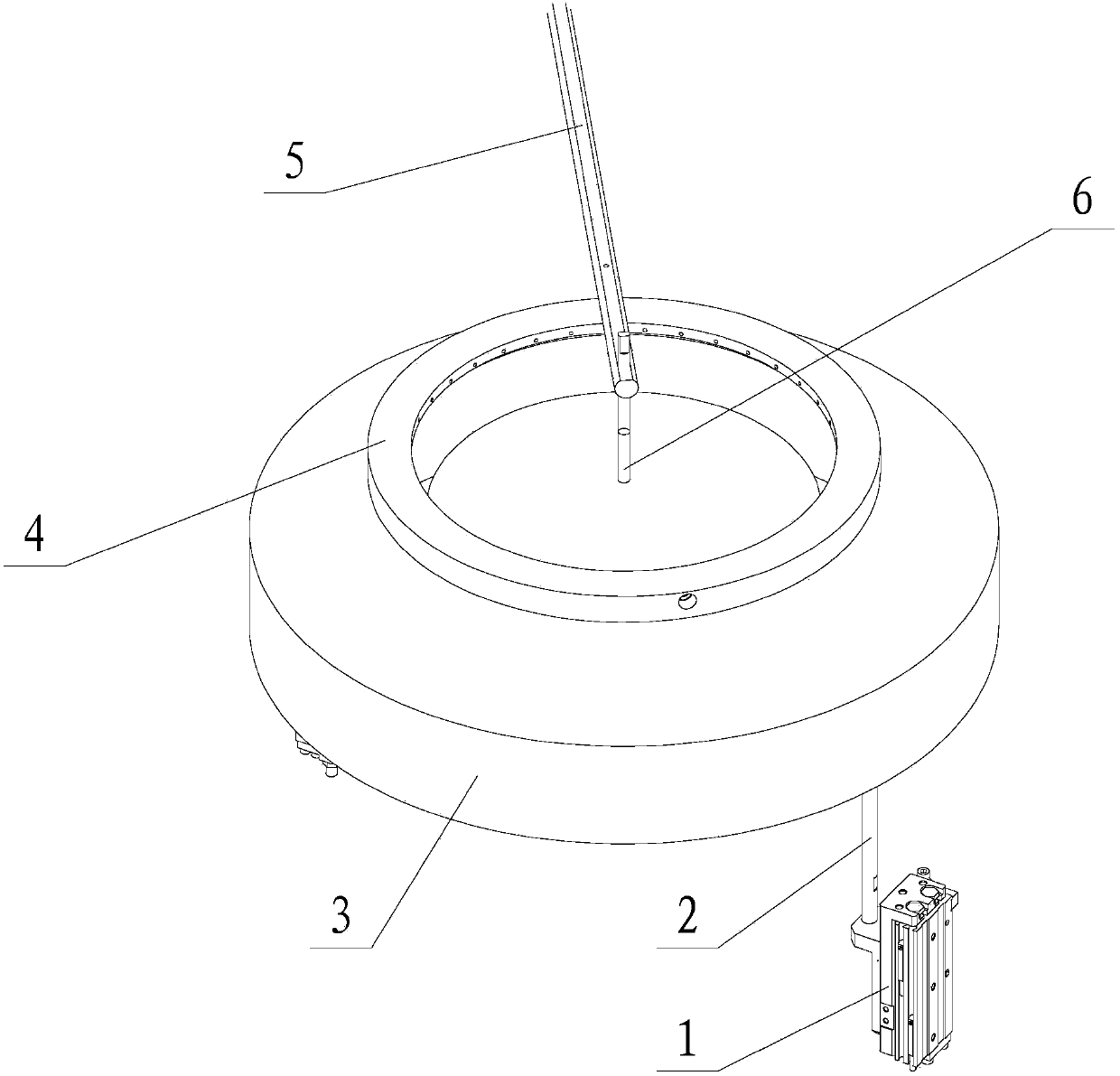

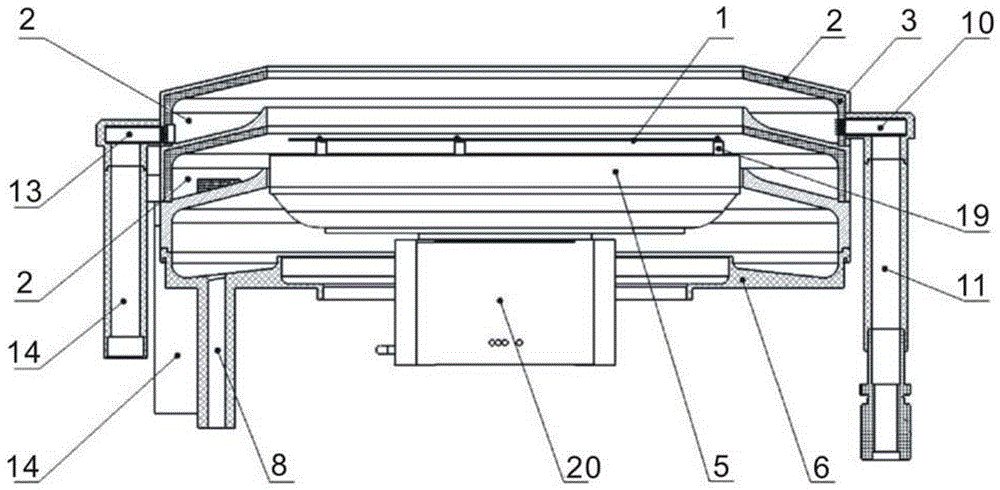

Device for preventing backwash liquid from polluting wafer

ActiveCN107768270AAvoid pollutionAvoid backsplashSemiconductor/solid-state device manufacturingGas passingEngineering

The present invention belongs to the field of semiconductor industry wafer wet processing, and specially relates to a device for preventing backwash liquid from polluting a wafer. A lifting CUP, a swing arm, a nozzle and a wafer carrying table are located in a process cavity, a power source is installed below the process cavity, an output end of the power source is connected with the lifting CUP,the wafer carrying table is located at the internal portion of the lifting CUP, and the nozzle is installed on the swing arm to swing with the swing arm; a gas protection ring is installed at the topportion of the lifting CUP, a plurality of gas outlets are uniformly distributed at the circumference of the inner side of the gas protection ring, at least one gas inlet is arranged at the circumference of the outer side of the gas protection ring, the at least one gas inlet and the gas outlets are communicated through internal gas rings arranged in the gas protection ring, the at least one gas inlet communicates with a gas supply source, gas is ejected through the internal gas rings and the gas outlets, a gas protection layer is formed at the inner side of the gas protection ring, and backwash liquid is renewedly flown into the lifting CUP. The device for preventing backwash liquid from polluting a wafer can prevent the liquid from being subjected to backwash at the surface of the swingarm to form liquid drops, can avoid that the liquid drops drop to the surface of the wafer in subsequent process steps so that the wafer is prevented from being polluted.

Owner:SHENYANG KINGSEMI CO LTD

Multifunctional bed-pan for elderly care

InactiveCN108904122AImprove breathabilityAvoid backsplashBodily discharge devicesCatheterElderly care

The invention discloses a multifunctional bed-pan for elderly care. The multifunctional bed-pan includes a bed-pan body, the bottom of one side of the bed-pan body is communicated with an excrement guide device, the bottom of the excrement guide device is spirally connected with an excrement guide pipe through a first internal spiral pipe, the position of the bottom end of the other side of the bed-pan body is communicated with a urine guide device, the bottom of the urine guide device is spirally connected with a catheter through a second internal spiral pipe, and the excrement guide pipe andthe other end of the catheter are communicated with a connector. In the multifunctional bed-pan for elderly care, the bed-pan body is communicated with the connector through the excrement guide device and the excrement guide pipe, and the bed-pan body is communicated with the connector through the urine guide device and the catheter; at the same time, the connector is communicated with an excrement storage bag through an external spiral pipe, so that excrement and urine are guided into the same excrement storage bag, and disposal cleaning is facilitated; the excrement guide device and the catheter are each of a detachable structure and can be dismantled randomly from a part, thereby facilitating cleaning.

Owner:李璐璐

Marangoni drying device with adjustable injection angle

ActiveCN111536783ASave valuable spaceSave spaceDrying gas arrangementsSemiconductor/solid-state device manufacturingWaferEngineering

The invention provides a Marangoni drying device with an adjustable injection angle. The device comprises a driving mechanism for vertically rotating a wafer, a supply arm for conveying a fluid, and abox body, wherein the supply arm is vertically swingable and supplies the fluid onto the wafer through a nozzle assembly provided at a free end thereof; the nozzle assembly comprises a first nozzle arm with a nozzle and a second nozzle arm with nozzles, wherein the first nozzle arm and the second nozzle arm extend along the supply arm and are rotatably fixed at the free end of the supply arm, thefirst nozzle arm is positioned below the second nozzle arm, the first nozzle arm is provided with the one nozzle, the second nozzle arm is provided with the two nozzles, the nozzle of the first nozzle arm is perpendicular to the axis of the first nozzle arm, and the nozzles of the second nozzle arm are obliquely arranged on the second nozzle arm in a backwards-hooked or forwards-stretched mode.

Owner:TSINGHUA UNIV +1

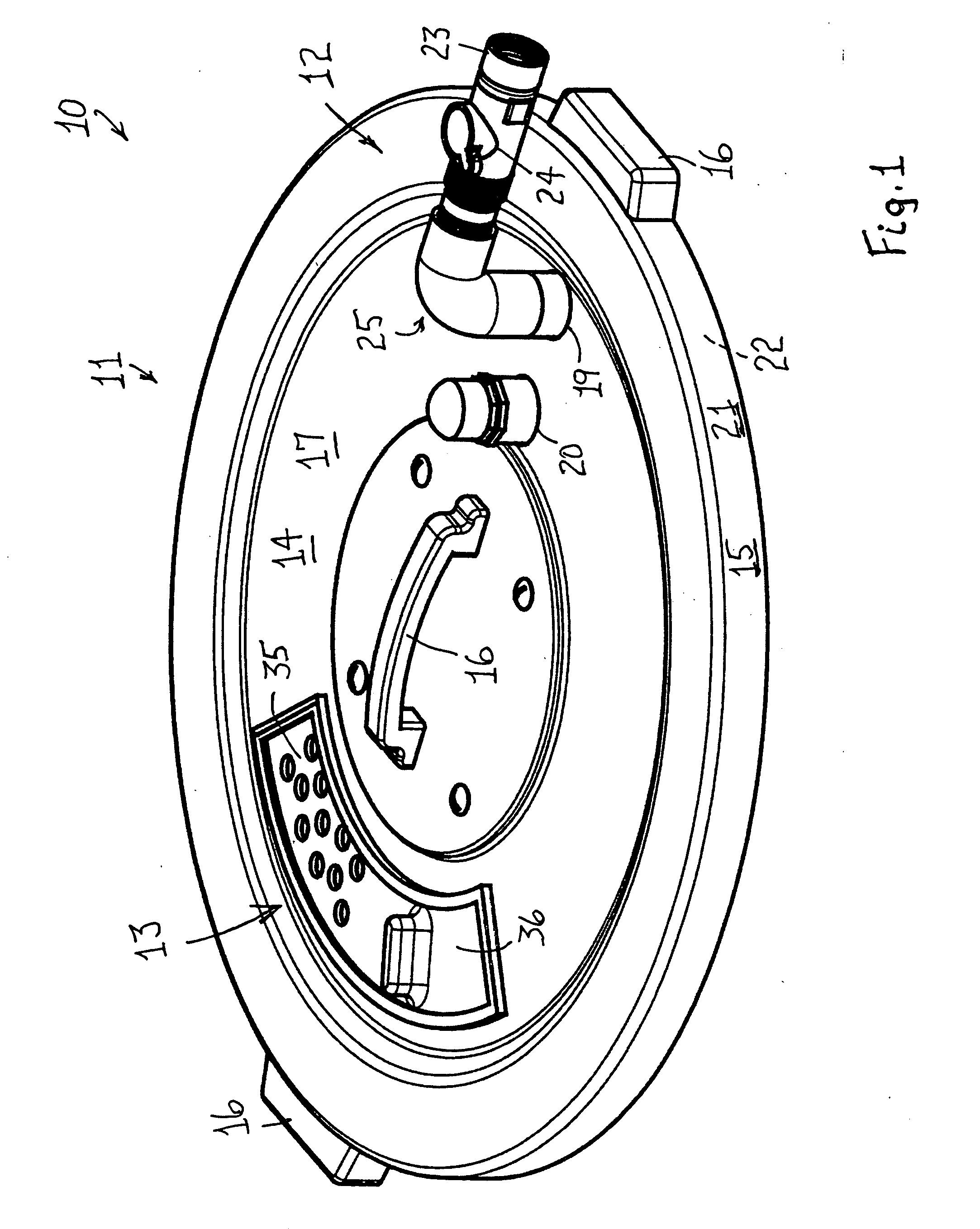

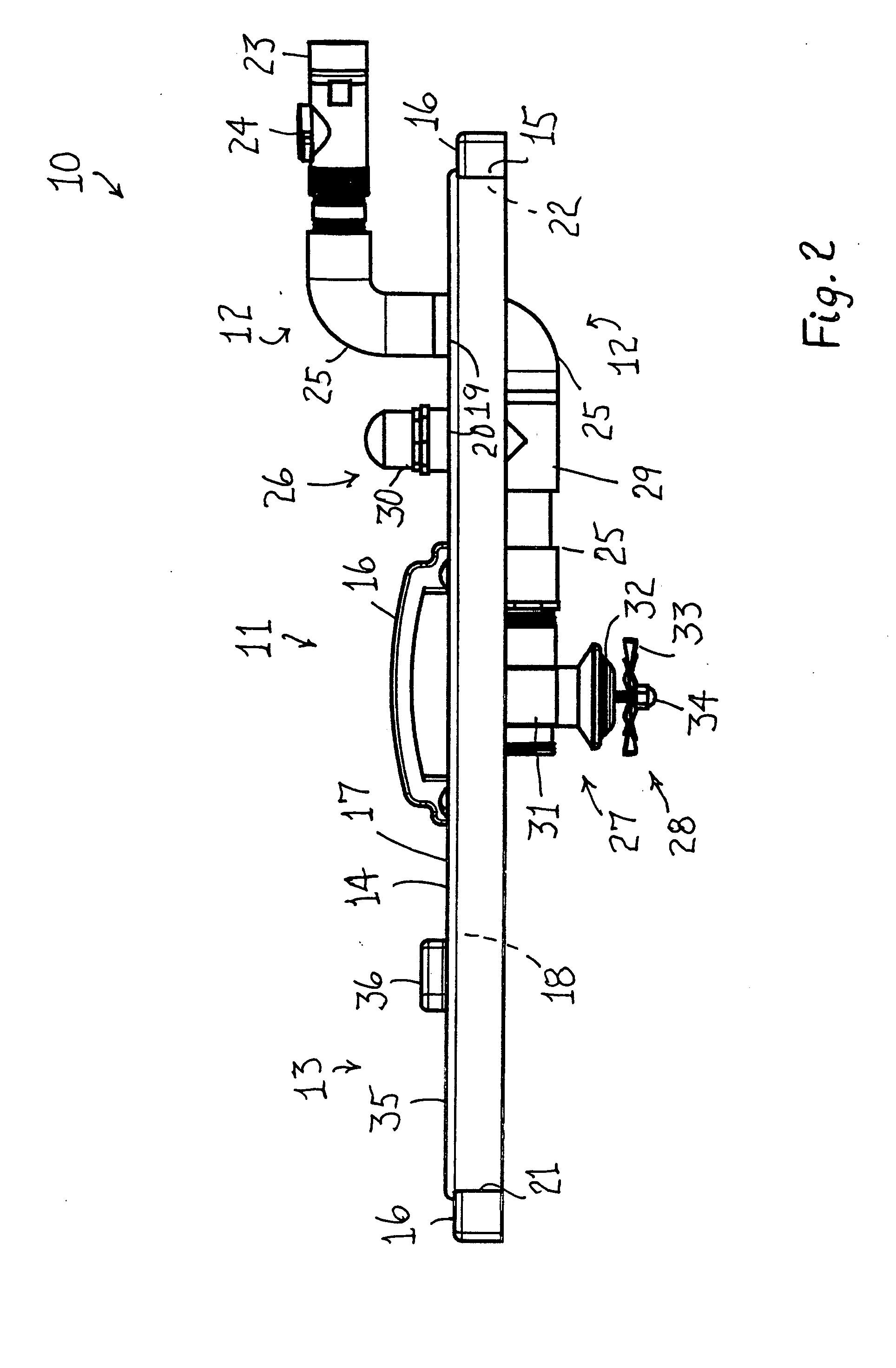

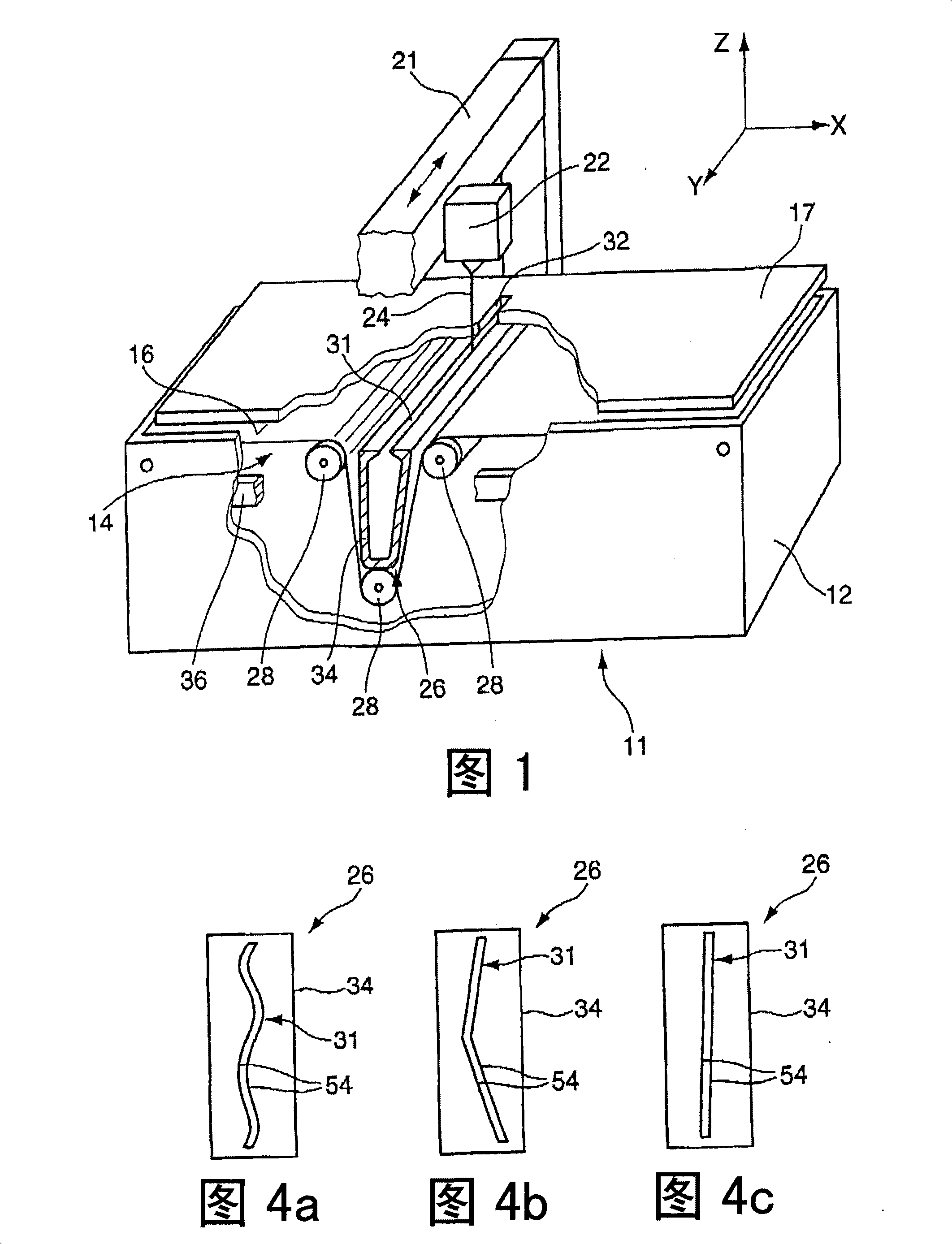

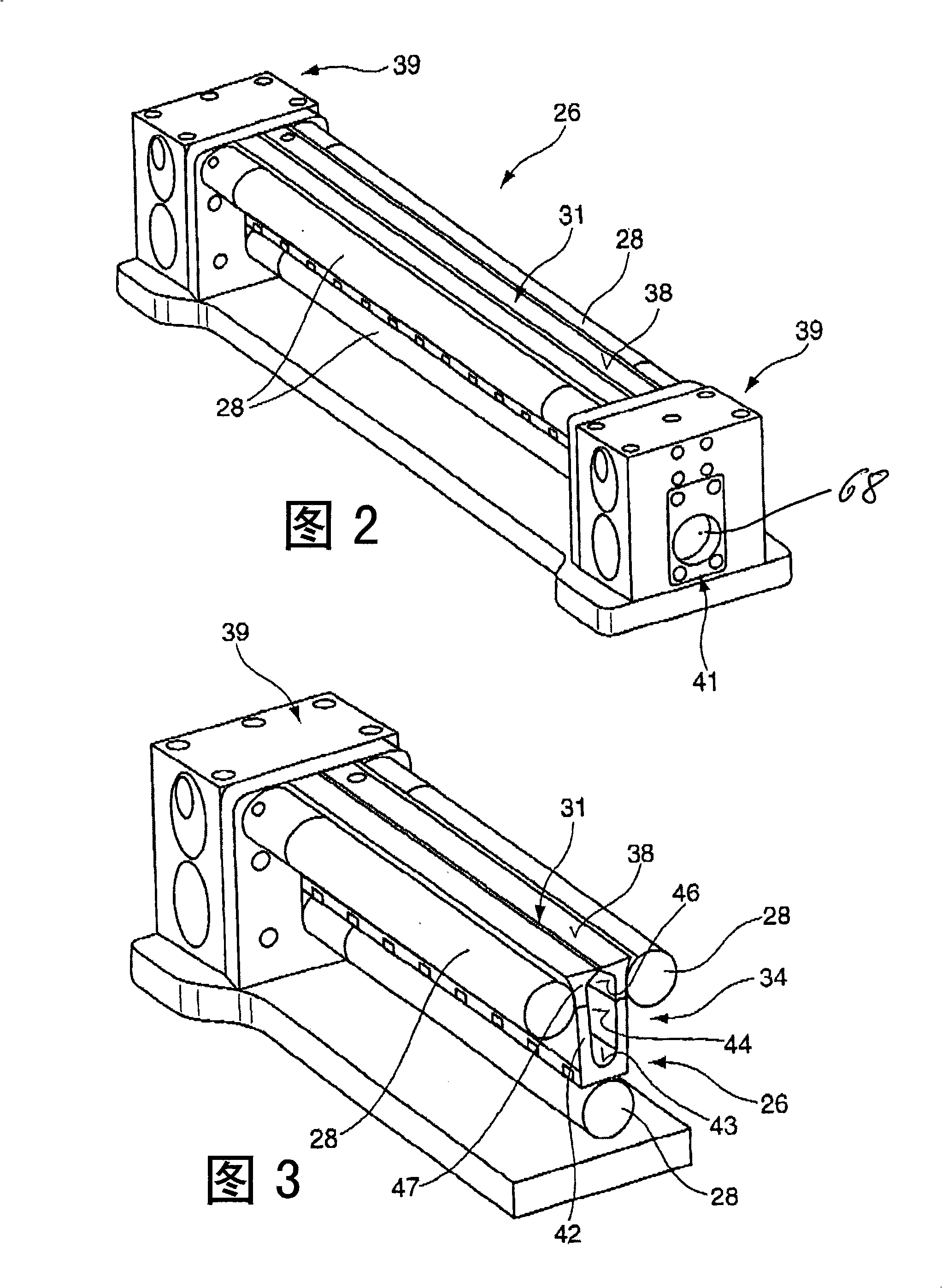

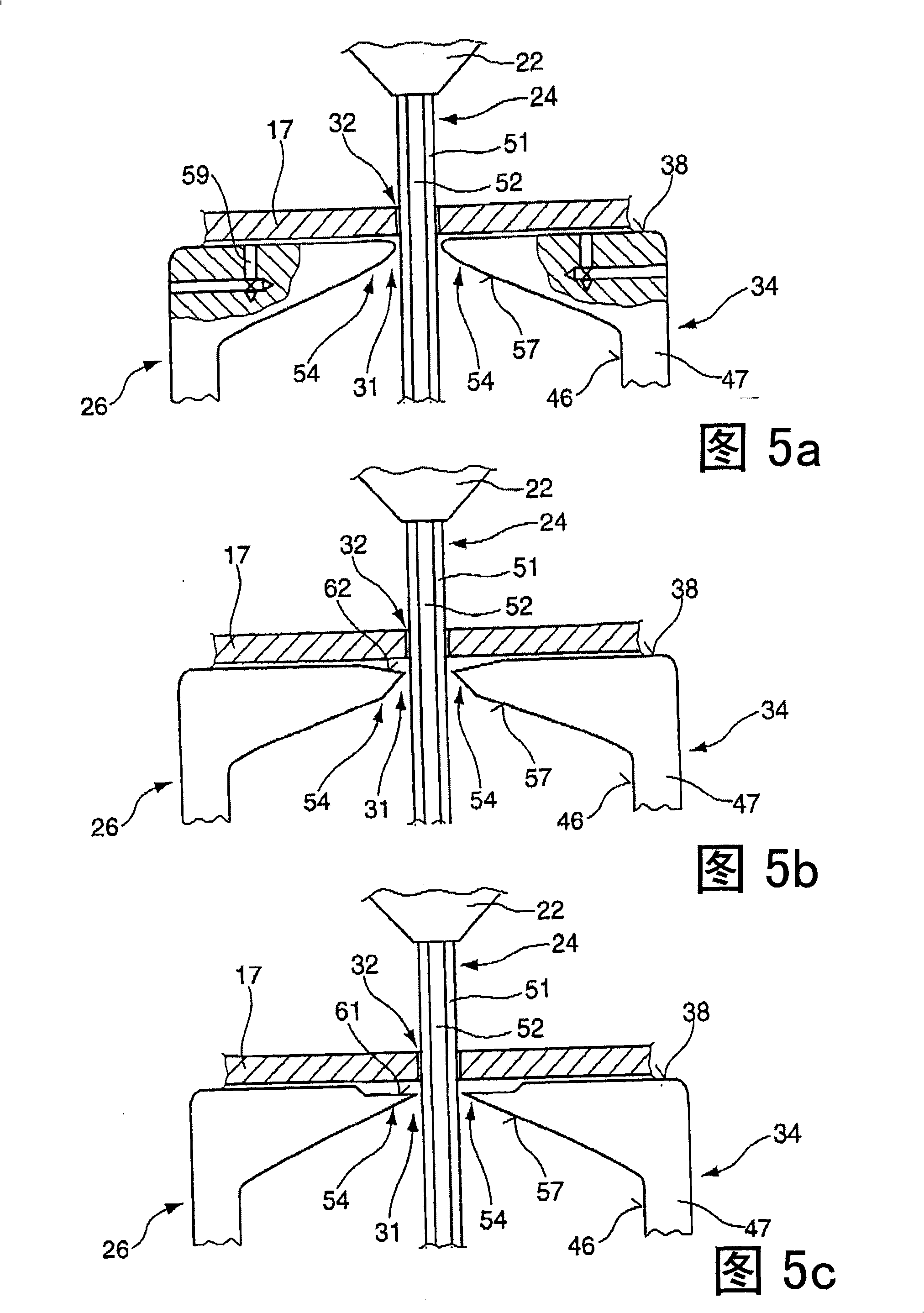

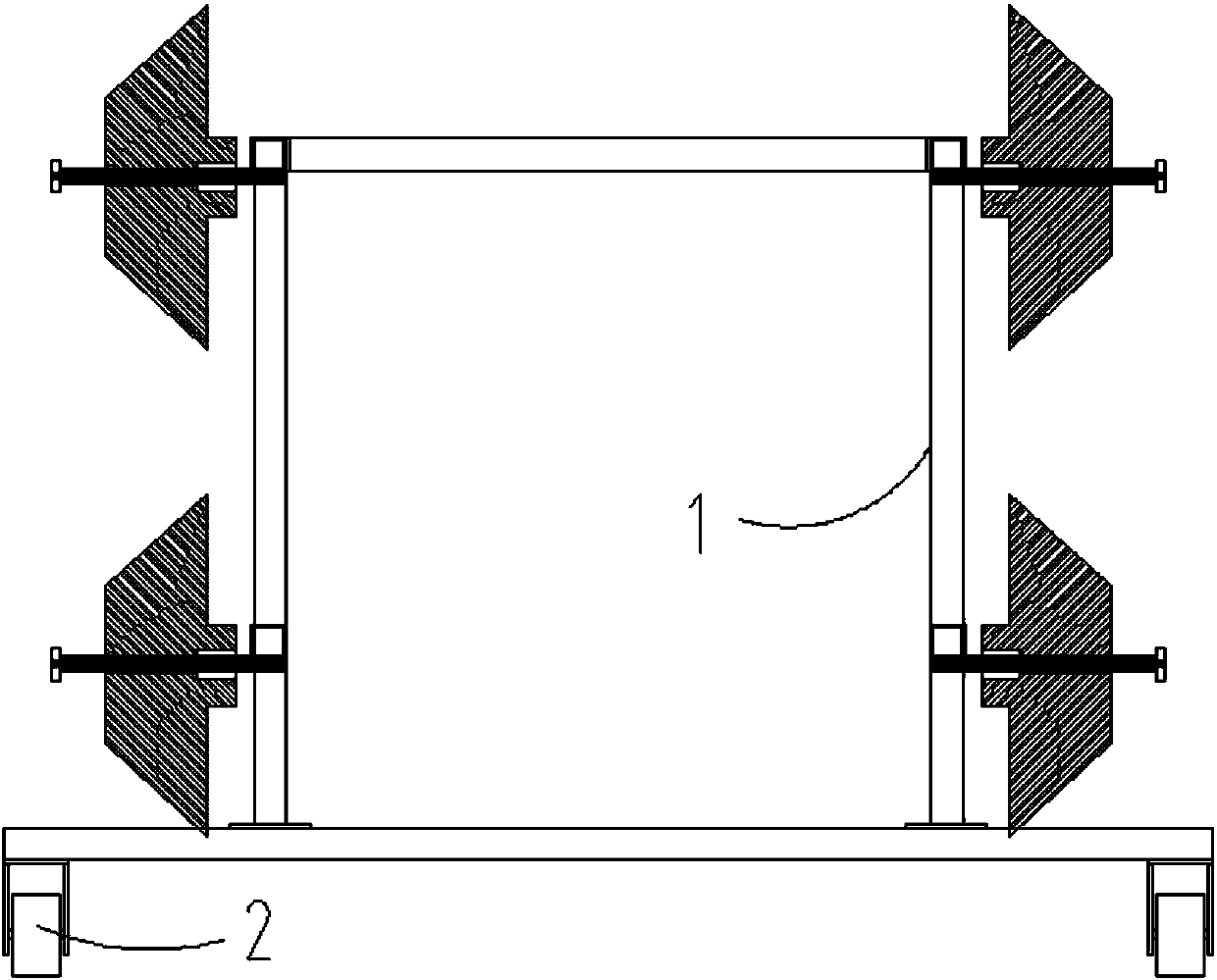

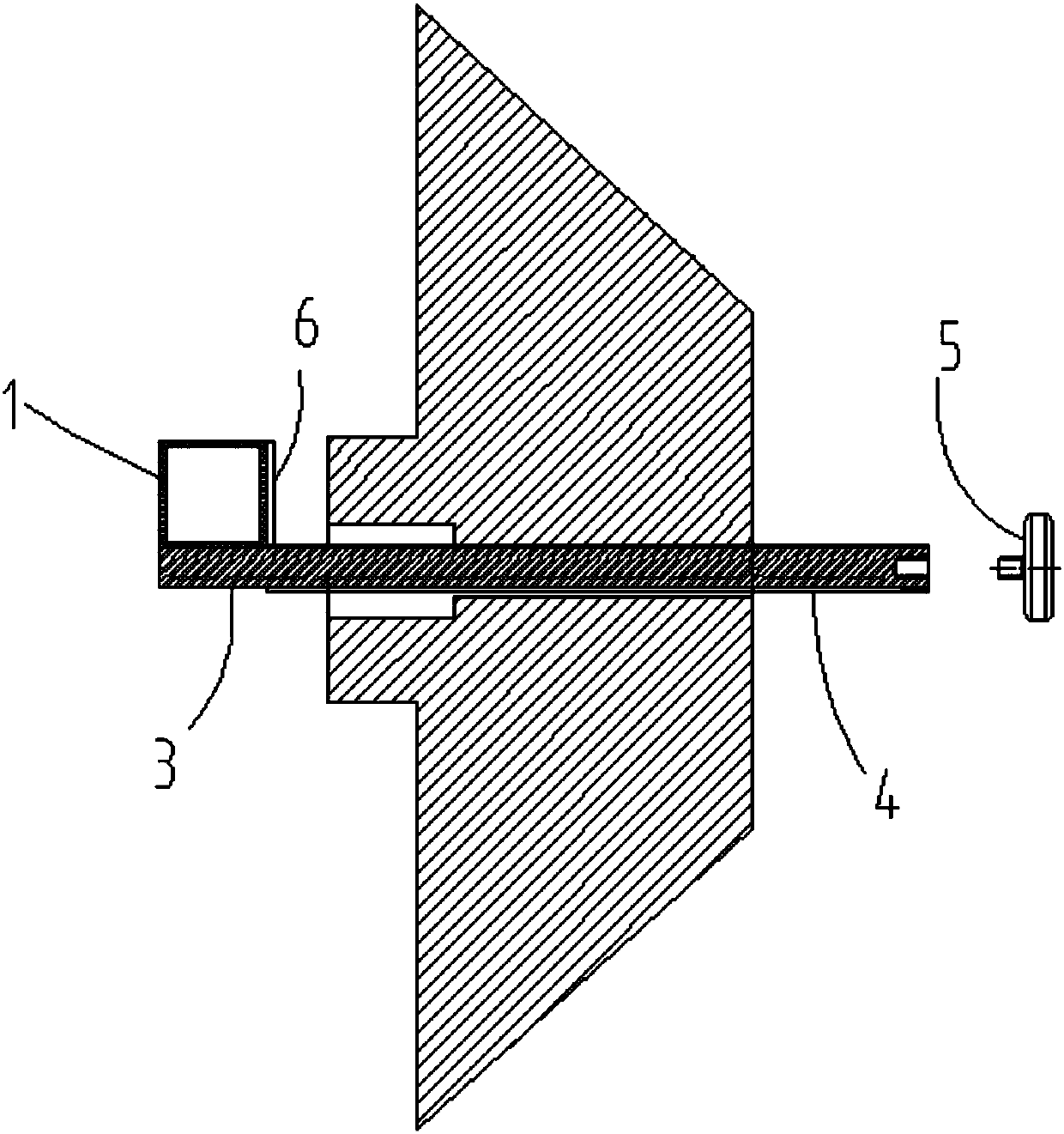

Beam catching device for a processing machine

InactiveCN101304834AReduce kinetic energyAvoid stickingMetal working apparatusGas flame welding apparatusEngineeringNozzle

The invention relates to a beam catching device for a beam cutting processing machine comprising a housing (34) provided with an opening (31) arranged in front of a cutting beam (24), wherein, during processing a workpiece (17), the cutting beam (24) exits from the workpiece (17) lower side and enters through the opening (31) a beam trap chamber (35) arranged in the housing (34), at least one nozzle (63, 76) is positioned on at least one wall section (56, 44, 46, 47) of the housing (34) and injects into the beam trap chamber (35) a fluid jet (64) in the form of a free jet in such a way that said fluid jet (64) crosses the cutting beam (24).

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

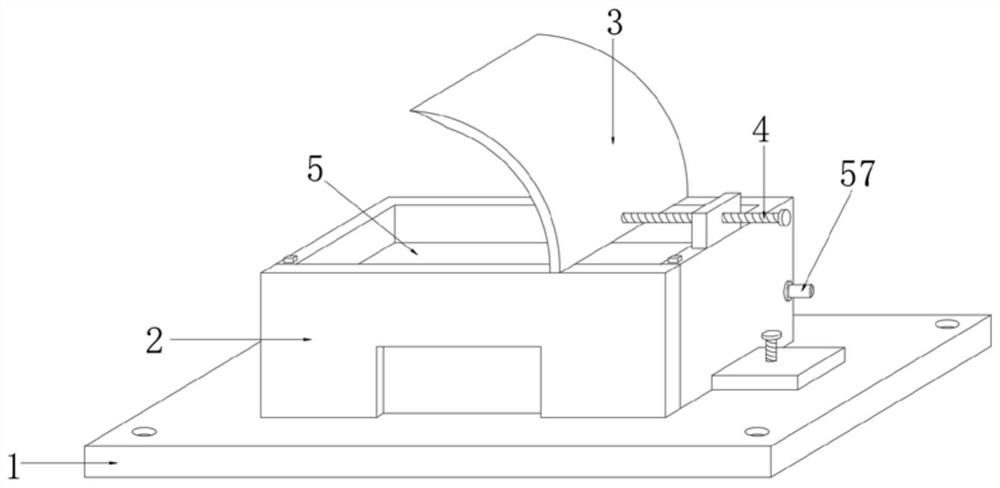

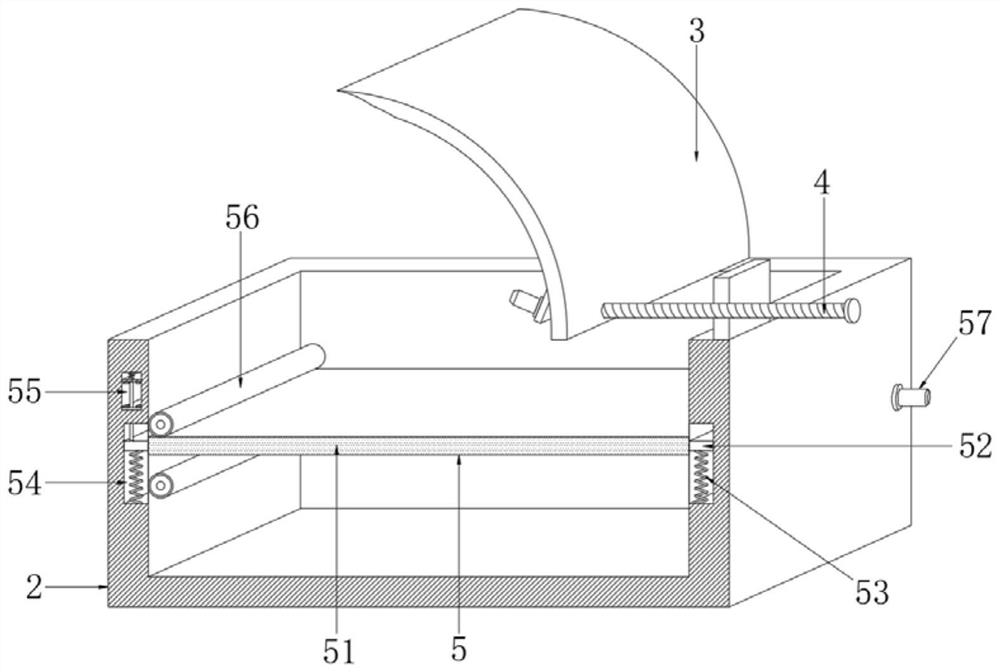

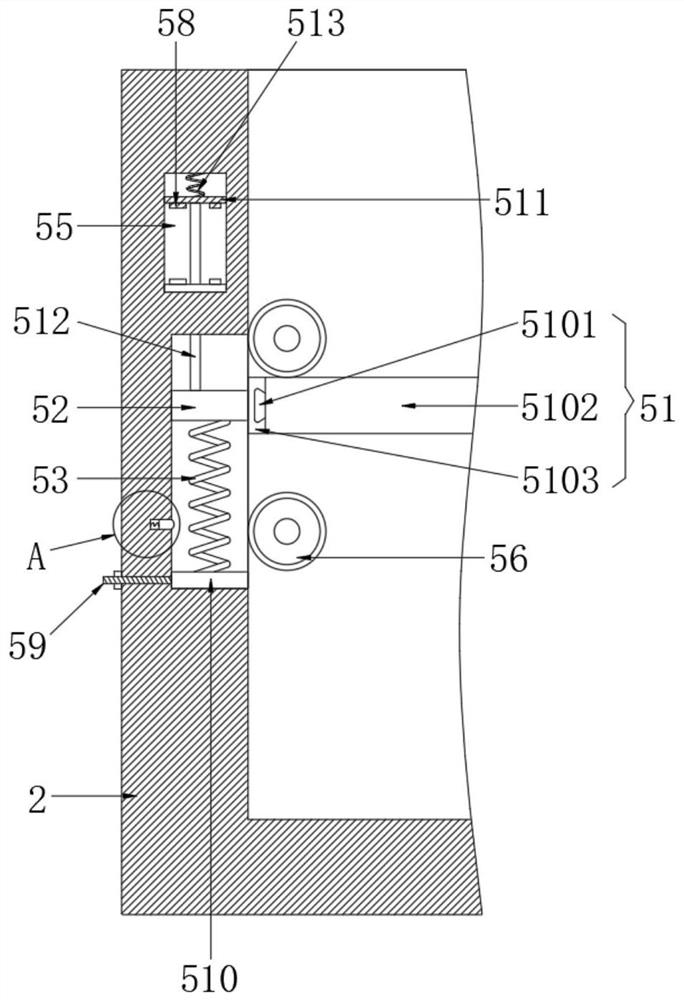

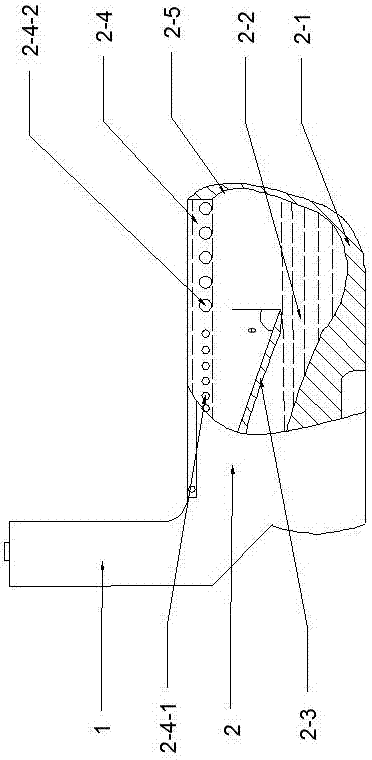

Printing roller ink scraping device with cleaning function and using method of printing roller ink scraping device

InactiveCN113022129AReduced chance of splashbackQuality assurancePrinting press partsStructural engineeringSewage

The invention discloses a printing roller ink scraper with a cleaning function and a using method thereof in the technical field of printing roller ink scraping devices.The printing roller ink ink scraping device comprises a mounting plate, a collecting box and a shielding cover, the collecting box is fixedly mounted on the outer wall of the top of the mounting plate, and the shielding cover is slidably mounted on the outer wall of the top of the collecting box. A mounting seat is mounted on the right outer wall of the top of the collecting box, a screw is in threaded connection with the right outer wall of the mounting seat, the left end of the screw penetrates through the mounting seat and is rotatably connected with the right outer wall of the shielding cover, a nozzle is mounted on the left outer wall of the shielding cover, a water pump is mounted on the rear outer wall of the collecting box, and the water pump communicates with the nozzle through a guide pipe. An anti-splashing device is arranged in an inner cavity of the collecting box, water falling during washing is absorbed through a sponge plate of the anti-splashing device in the device, the probability that the water falls into the collecting box and is splashed backwards is reduced, the probability that sewage is attached to the surface of the printing roller again is reduced, and the cleaning quality is guaranteed.

Owner:刘志平

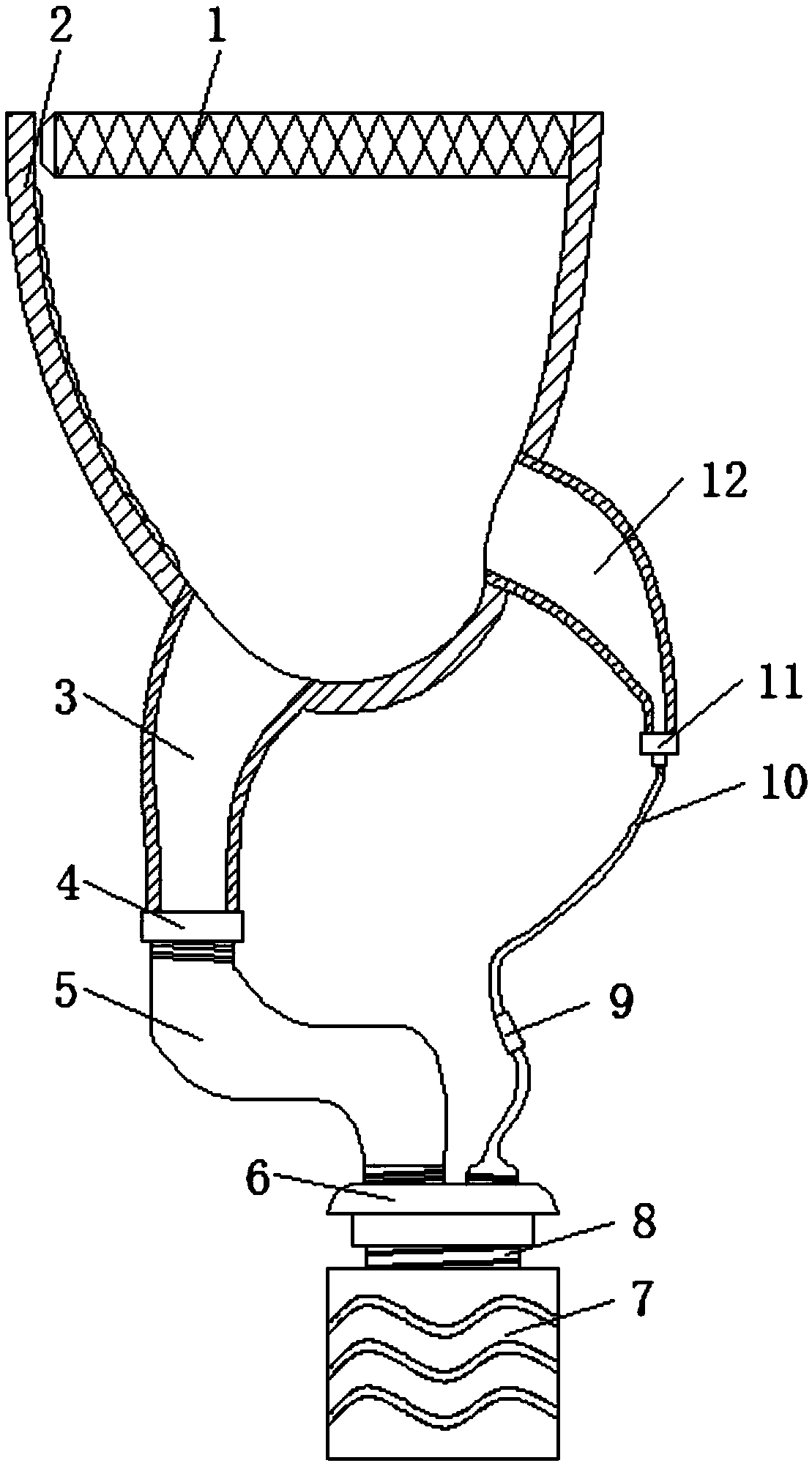

Closestool capable of preventing sewage back-splashing and sanitary in use and using method thereof

The invention discloses a closestool capable of preventing sewage back-splashing and sanitary in use and a using method thereof. The closestool comprises a water tank and a closestool body, the closestool body comprises a closestool wall, a sewage discharging passage, a dirt falling plate, a water draining passage and a water-permeable component, an arc-shaped concave slope is arranged on the inner side, away from the water tank, of the closestool wall, and the lower end of the arc-shaped concave slope is tangent with a pipe wall of the sewage discharging passage; the dirt falling plate is arranged at a position, close to the water tank, in the closestool wall, and the lower end of the dirt falling plate contacts with stored water in the sewage discharging passage; the water draining passage is arranged on the upper portion of the closestool wall, water draining holes I and water draining holes II are formed in the water draining passage, and hole diameter of the water draining holes I is smaller than that of the water draining holes; the water draining holes I encircle the dirt falling plate, the water draining holes II encircle the sewage discharging passage, and the water-permeable component is mounted on the closestool body and communicates the water draining passage with the water tank. A dirt falling area is limited through the dirt falling plate, so that dirt is avoided directly contacting with water in the sewage discharging passage, and back-splashing of sewage is prevented.

Owner:HENAN INST OF ENG

Safe motorcycle fuel tank

Owner:常州市文每机械配件厂

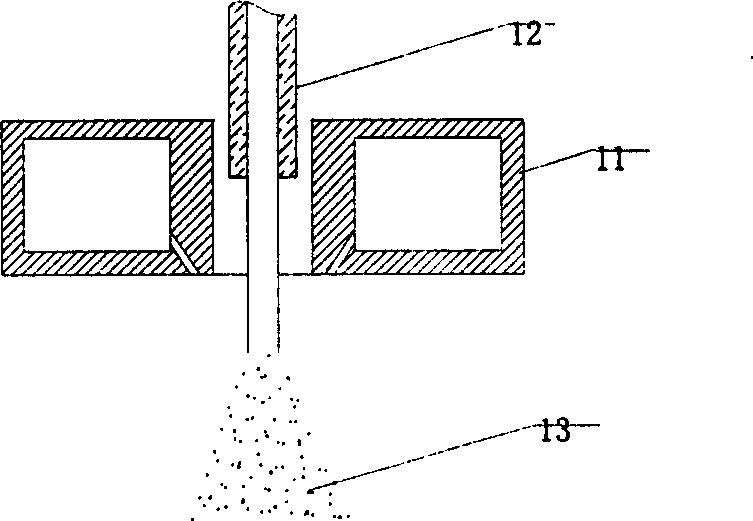

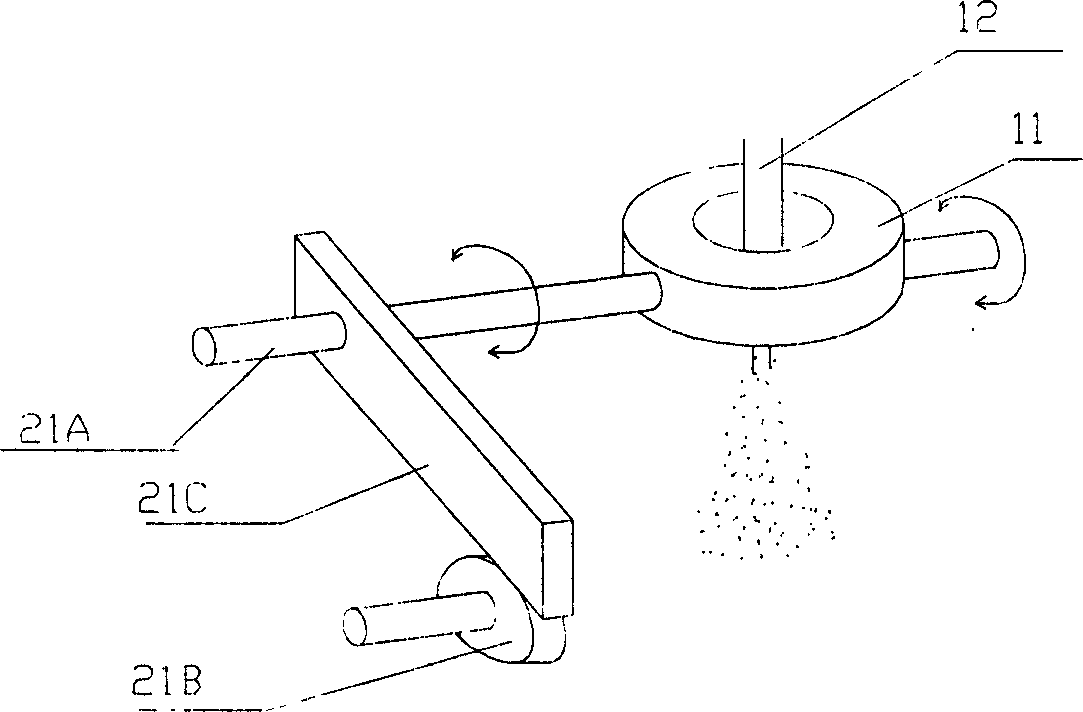

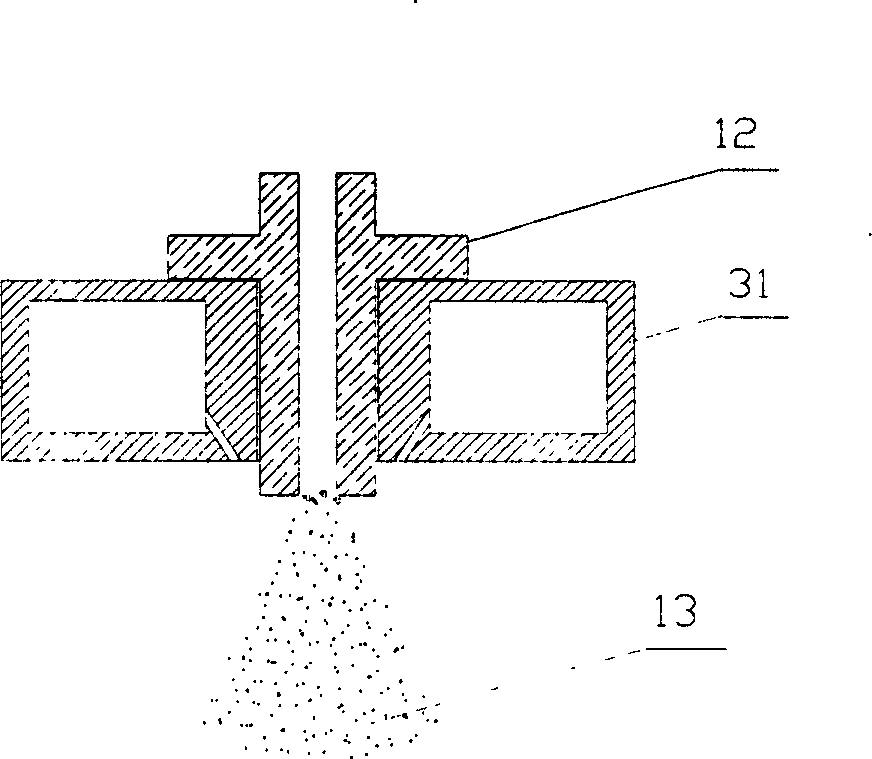

Restricted scanning gas atomizing system

The present invention relates to a restrictive scanning gas-atomizing system. It is formed from gas-atomizing nozzle, guide mechanism and scanning-swinging mechanism. Said guide mechanism is positioned in the centre of gas-atomizing nozzle, said gas-atomizing nozzle is connected with scanning-swinging mechanism by means of connecting component, and the axis of the described guide mechanism is coincided with the axis of said gas-atomizing nozzle. Said invention can improve atomizing effect, and can raise the quality of spray-formed blank, and can be used for spray-forming wide-width plate blank, pipe blank and rod blank.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

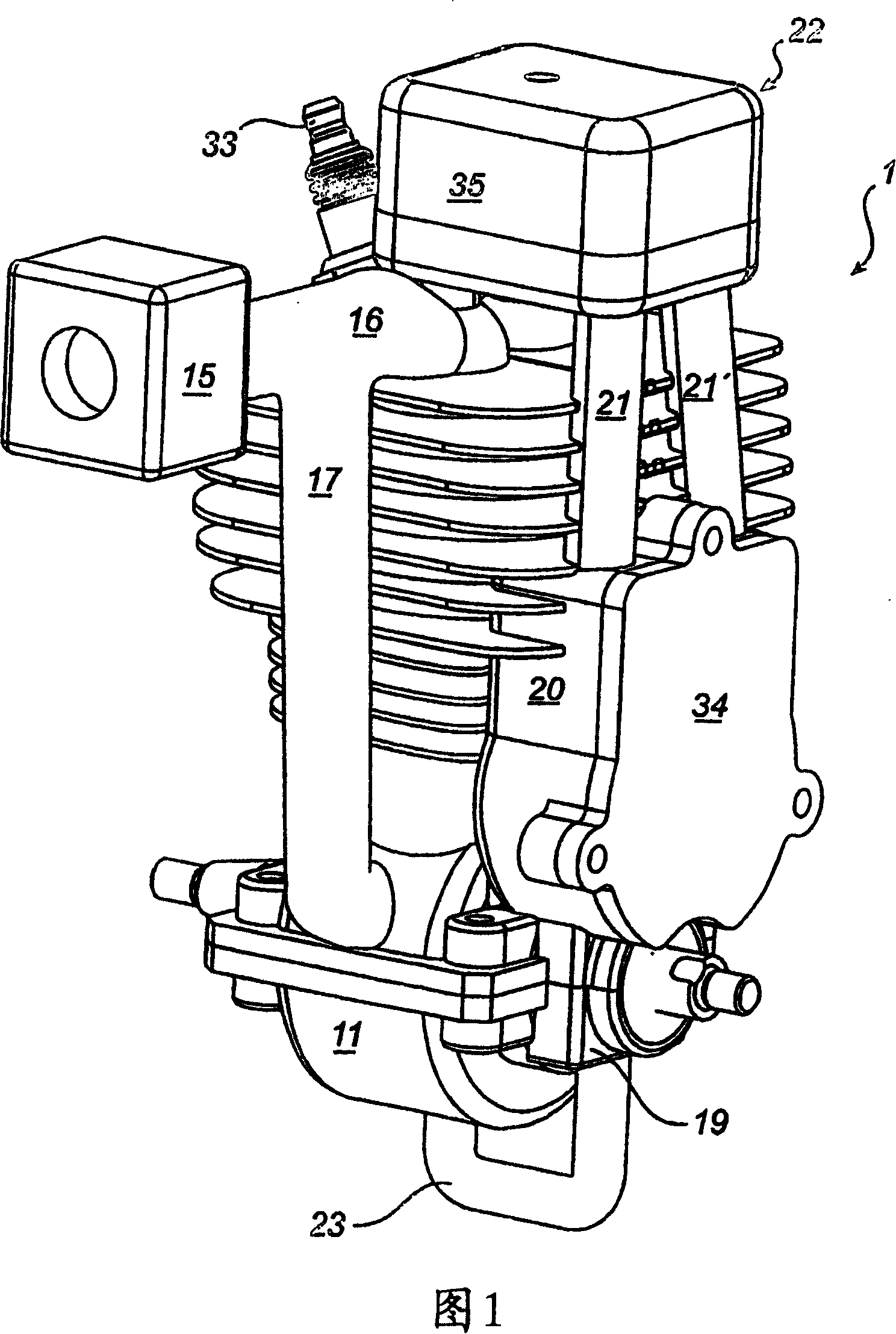

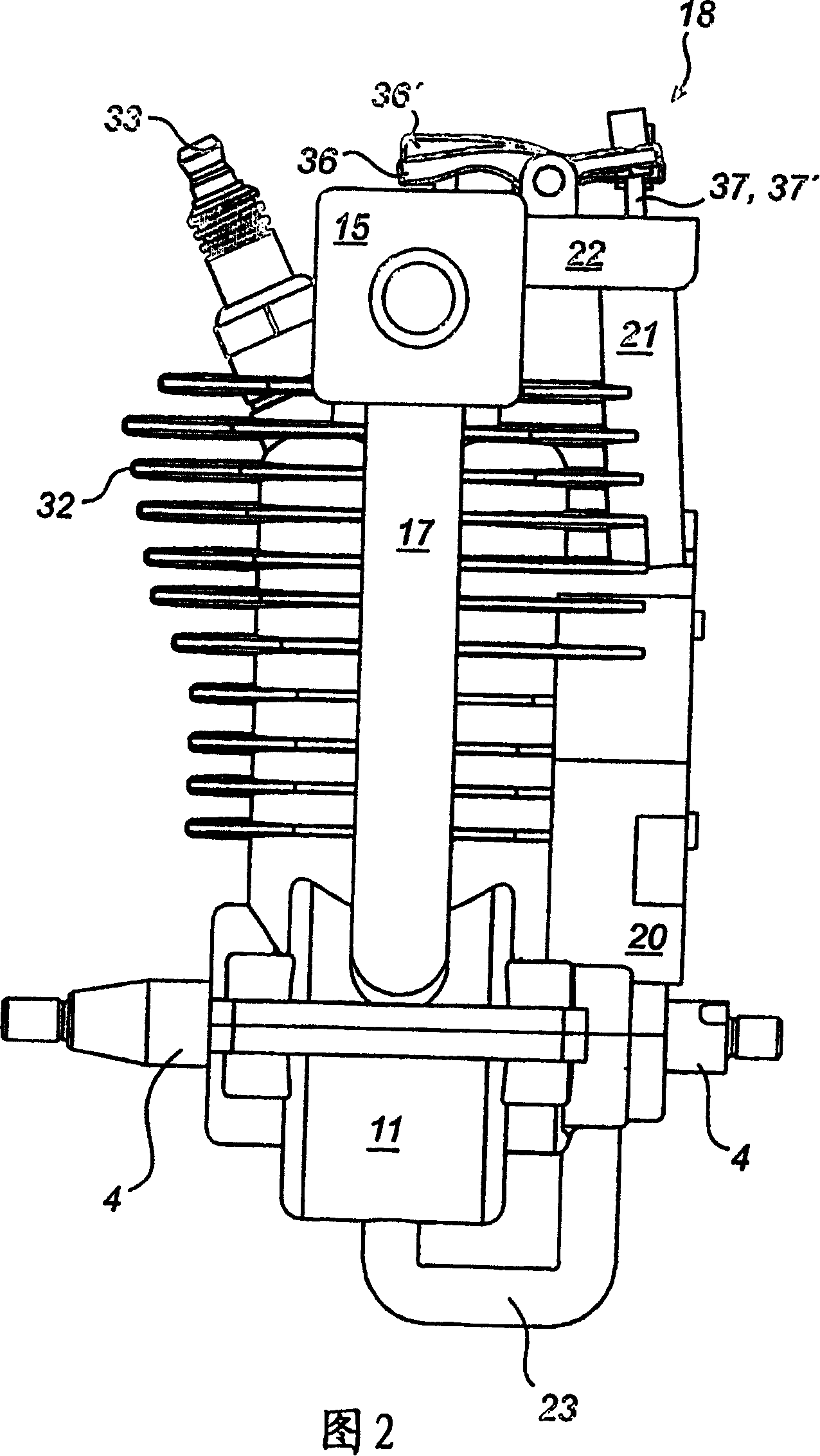

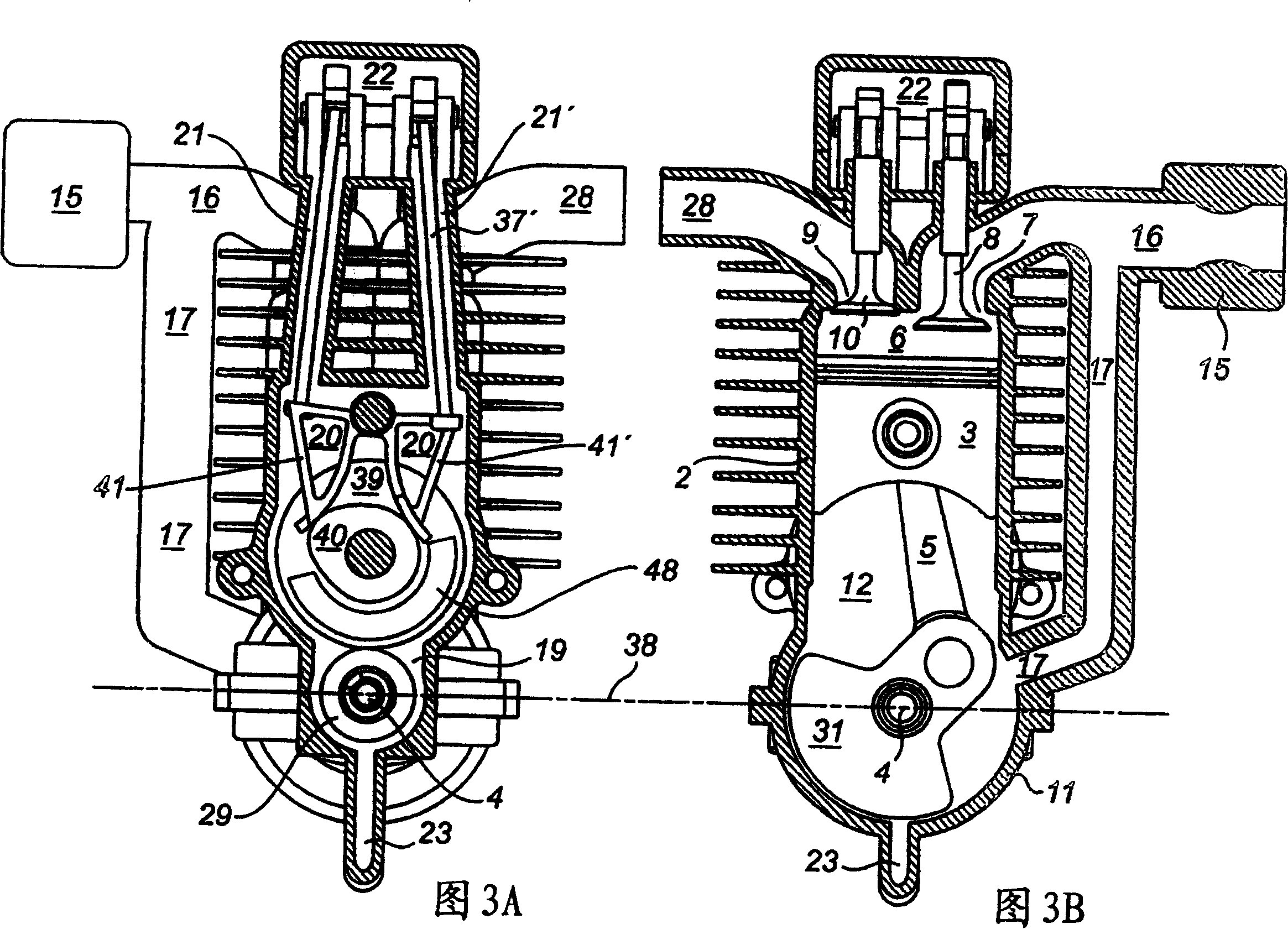

A four-stroke engine

InactiveCN100378302CHigh power outputAvoid backsplashNon-fuel substance addition to fuelInternal combustion piston enginesExhaust valveInlet valve

A four-stroke reciprocating piston internal combustion engine with an intake valve an exhaust valve and a valve drive assembly driven by the crankshaft for actuating the intake valve and the exhaust valve. A mixture-preparation device supplies an air / fuel-lubricant mixture to the crankcase, which together with the piston functions as a pump for the mixture charge. A valve drive assembly housing comprising one or more sections and the intake channel is supplied with a connecting duct communicating with the crankcase volume either by being connected to the crankcase or the cylinder, or by being connected to the valve drive assembly housing, which communicates with the crankcase volume, and the communication from the intake channel to the crankcase volume is arranged through at least one valve.

Owner:HUSQVARNA AB

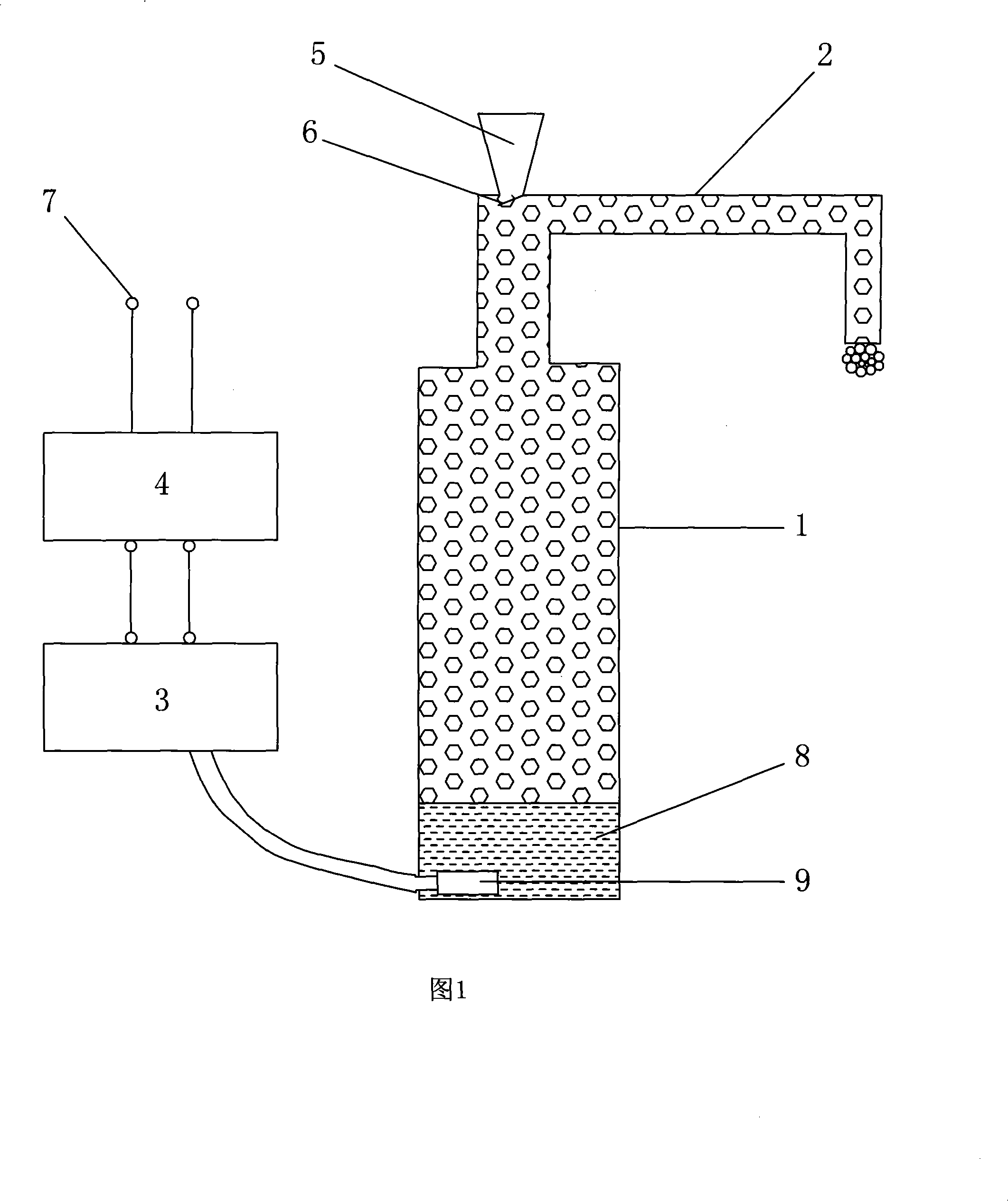

Water-saving method for closestool and closet water saver

The invention provides a closestool water-saving method and a closestool water-saving device, which relates to a flushing equipment with a water tank. The invention is provided with a container to hold an ionic surface active agent, the foam produced by the ionic surface active agent in the container is guided into a pipe, a gas generator, a timer, a fluid gun and a power supply in the closestool, the container contains a surface active agent and an airstone for generating blister, one end of the guide pipe is connected with the outlet of the container and the other end of the pipe is connected with the closestool; the gas generator is respectively connected with the airstone and the timer, the timer is connected with the power supply and the fluid gun is arranged at the connecting point between the container and the guide pipe. When in the practical use, the ionic surface active agent is poured into the container, the gas generator is controlled by the timer, the generated gas produces blister in the container by the air stone and is then guided into the closestool by the guide pipe; the foam forms an isolating layer in the closestool between the filth and the air.

Owner:XIAMEN UNIV

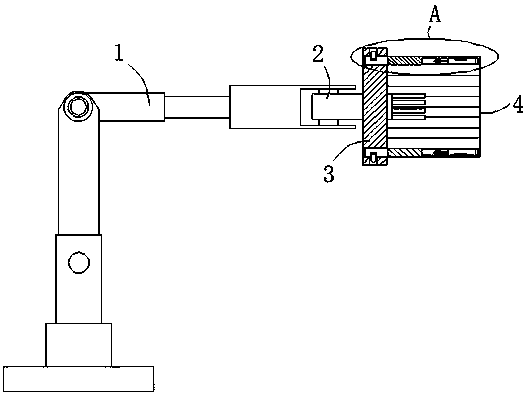

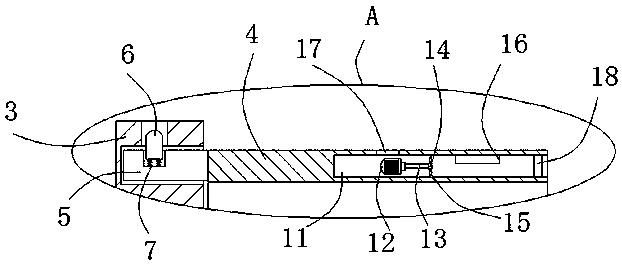

Grab arm device for automobile door spraying

InactiveCN110404716AImprove adsorption capacityAvoid backsplashSpray boothsManipulatorMagnetCar door

The invention discloses a grab arm device for automobile door spraying. The grab arm device for the automobile door spraying comprises a grab arm device main body and a connector arranged at the end of the grab arm device main body, wherein the outer side wall of the connector is fixedly sleeved with an installation block, the outer side wall of the installation block is connected with a cylindrical protective cover by a connecting mechanism, and the protective cover is located outside the connector. When the grab arm device provided by the invention is used, the splashed spraying material canbe absorbed effectively through the cooperation of the protective cover, a connecting block, a clamping block, a spring and a magnet strip as well as using the cooperation of the protective cover andabsorbing cotton; the spraying material is prevented from splashing back to the side wall of the grab arm device main body; the grab arm device main body is convenient to clean and grab; meanwhile, the situation that the rotation part of the grab arm device main body cannot rotate due to the splashed spraying material is avoided; and the spraying cost of an enterprise is effectively reduced.

Owner:YANCHENG GAOYUE MACHINERY

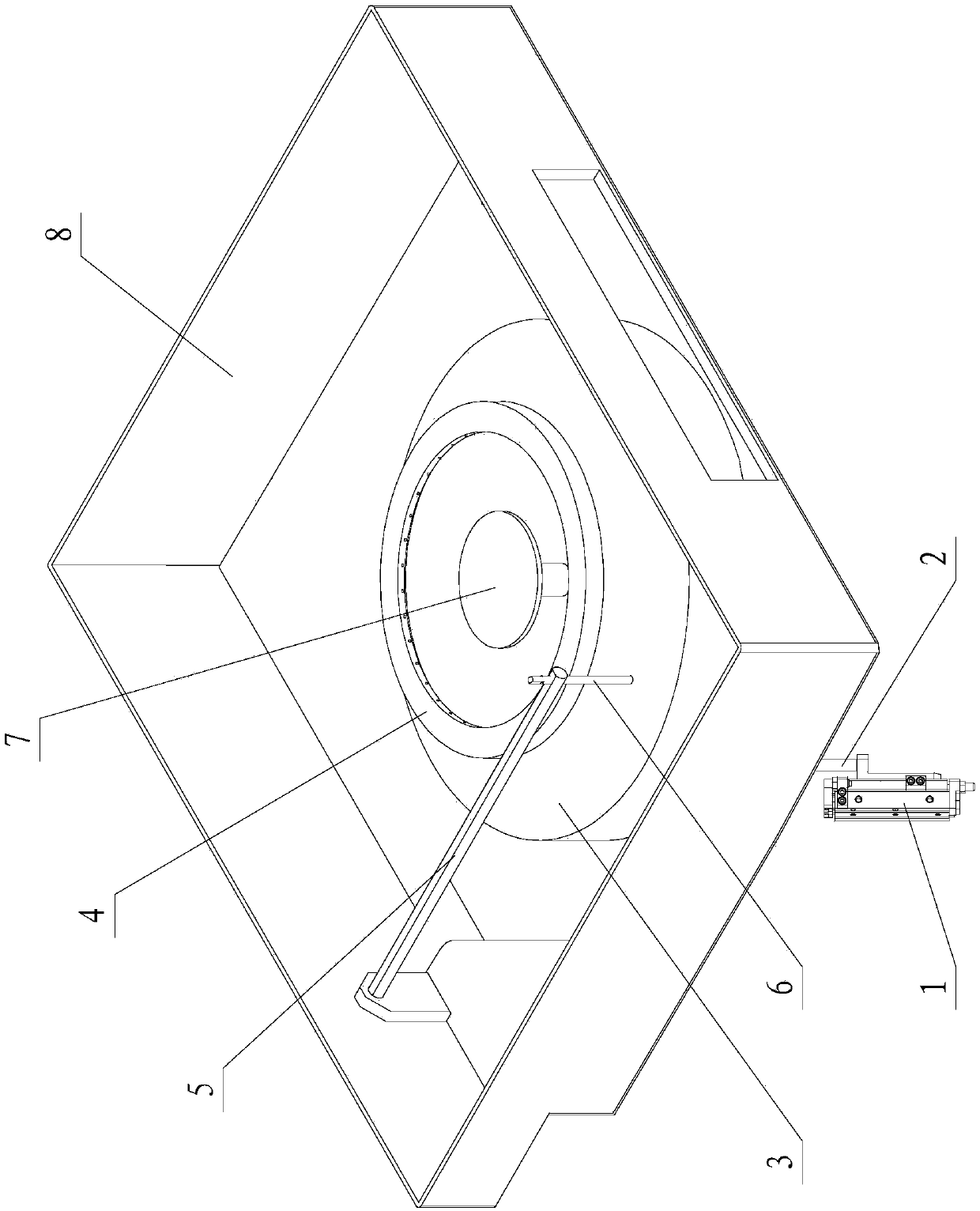

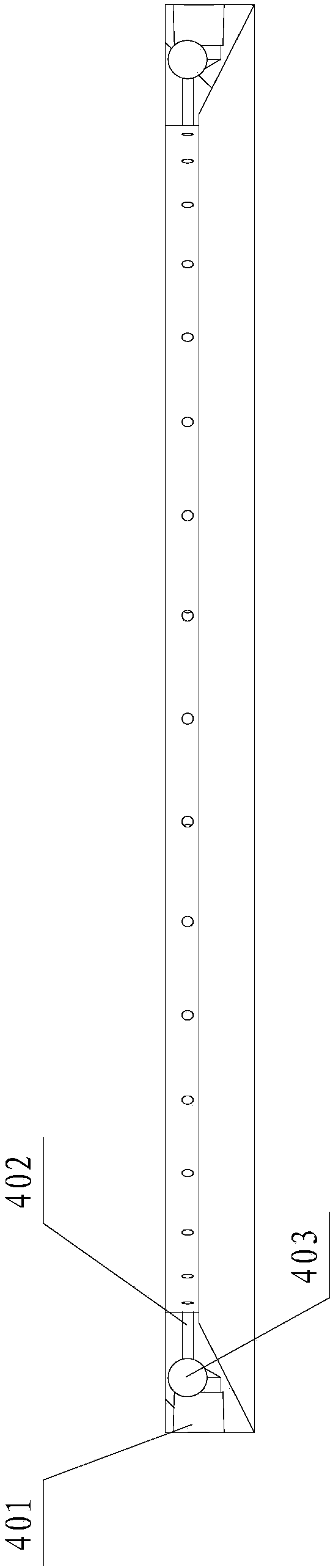

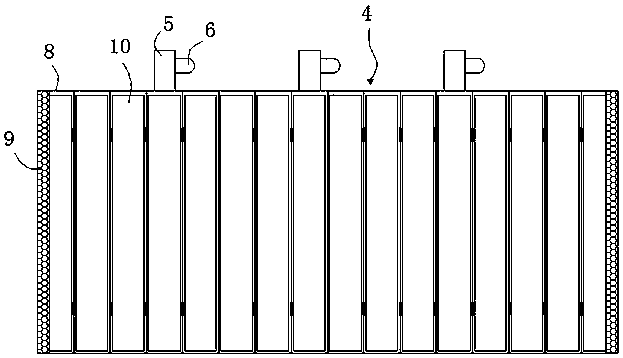

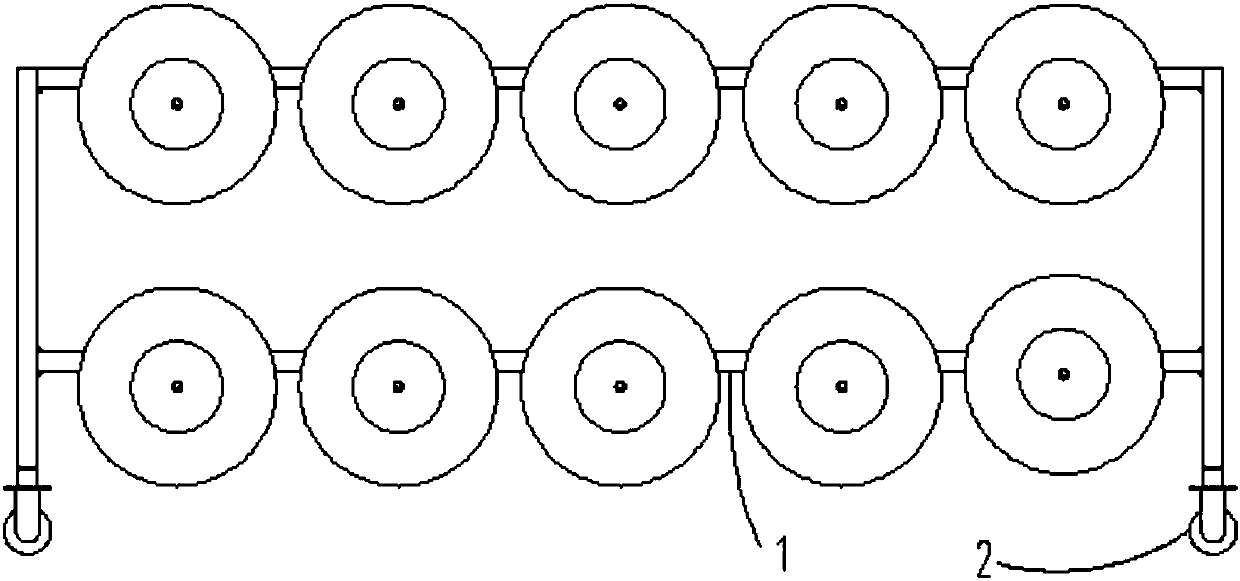

Impeller penetration flaw detection platform

PendingCN108051452AReduce labor intensityAvoid backsplashOptically investigating flaws/contaminationCleaning using toolsImpellerEngineering

The invention discloses an impeller penetration flaw detection platform which comprises a high pressure cleaner and a cleaning frame. The high pressure cleaner is arranged on one side of the cleaningframe, an impeller is hung on the cleaning frame, the cleaning frame comprises a frame body, universal wheels, a plurality of hanging rods, heat-shrink tubes and retaining caps, the hanging rods are horizontally welded on the frame body, the heat-shrink tubes sleeve the hanging rods, the retaining caps are connected to the tail ends of the hanging rods in a threaded manner, and the universal wheels are arranged at the bottom end of the frame body. According to physical characteristics and penetration flaw detection principles of impellers, the impellers are arranged in a stereoscopic hung mode, the high pressure cleaner replaces manual labor to implement final complete cleaning for the impellers, efficiency is greatly improved, water is saved, and the labor intensity of inspectors is reduced.

Owner:NANJING CIGU TECH CORP LTD

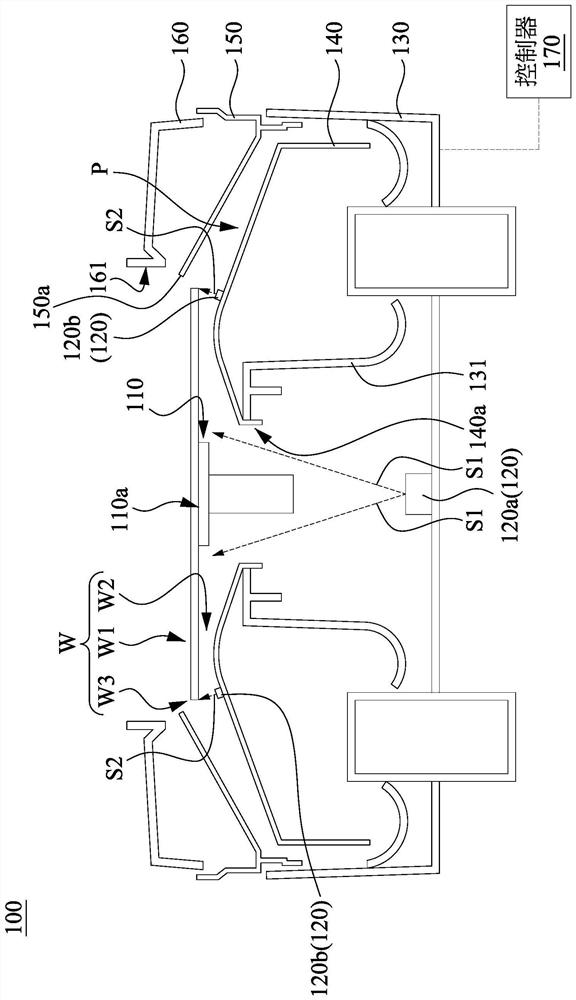

Wafer cleaning device and wafer cleaning method

PendingCN114649233AEfficient recyclingAvoid backsplashSemiconductor/solid-state device manufacturingCleaning using liquidsWaferPhotoresist

The invention discloses a wafer cleaning device and a wafer cleaning method. The wafer cleaning device comprises a bearing table, at least one nozzle, a chassis, an upper shell and a lower shell. The bearing table is used for bearing a wafer, and the top surface of the wafer is coated with a photoresist. The at least one nozzle is used for spraying a cleaning solution towards the wafer. The chassis is used for recovering cleaning solution. And the lower shell is arranged on the chassis. The upper shell is arranged on the lower shell, the base plate, the lower shell and the upper shell surround and contain the bearing table, the upper shell and the lower shell jointly form a liquid flow channel extending towards the bearing table and the base plate, and the liquid flow channel is used for guiding the cleaning solution to flow to the base plate. Therefore, the wafer cleaning device can effectively spray the cleaning solution to the wafer and recover the cleaning solution.

Owner:NAN YA TECH

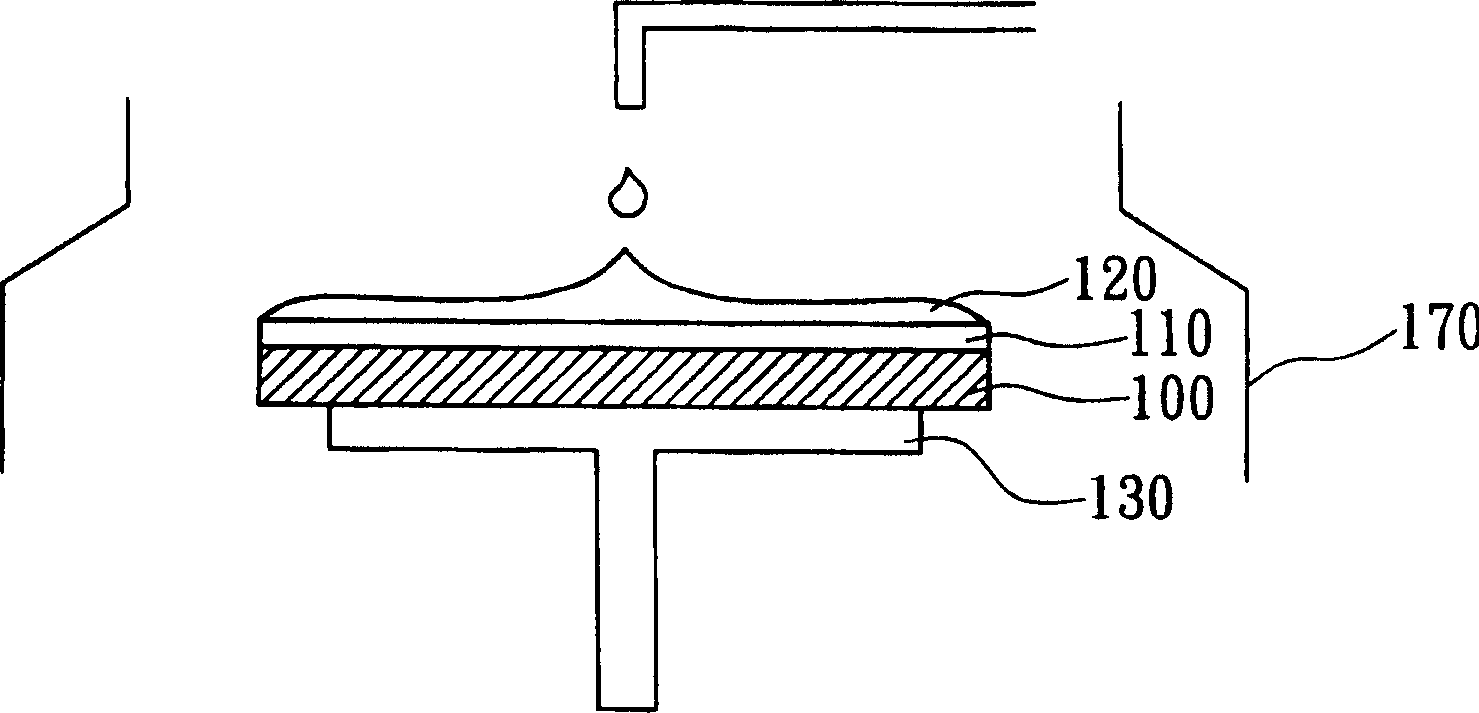

Apparatus for preventing liquid spitting back

InactiveCN1257438CAvoid backsplashHigh precisionSemiconductor/solid-state device manufacturingPhotosensitive material processingEngineeringMechanical engineering

Owner:AU OPTRONICS CORP

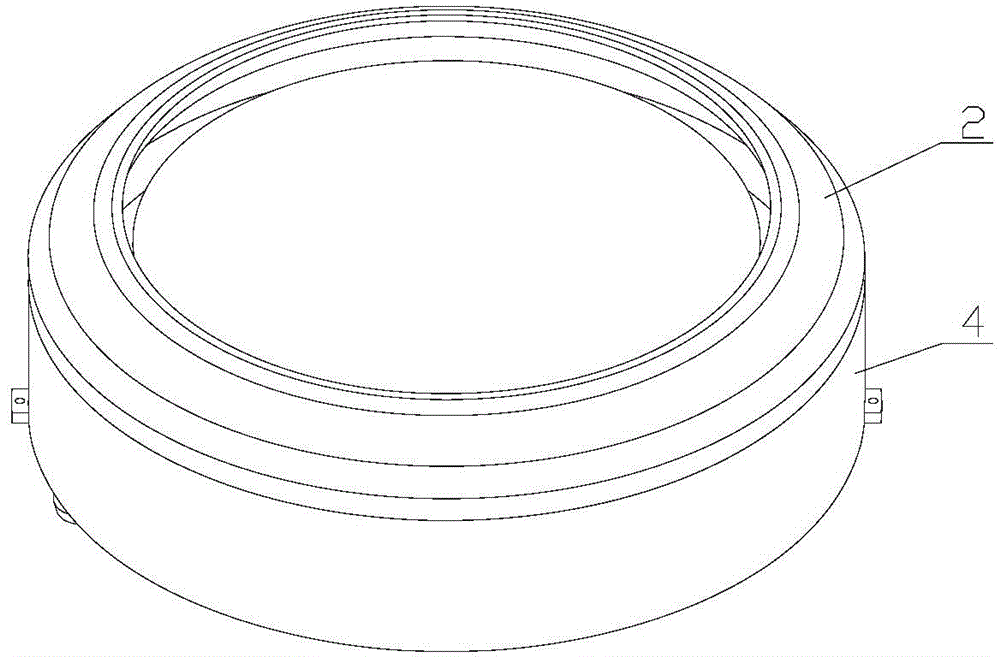

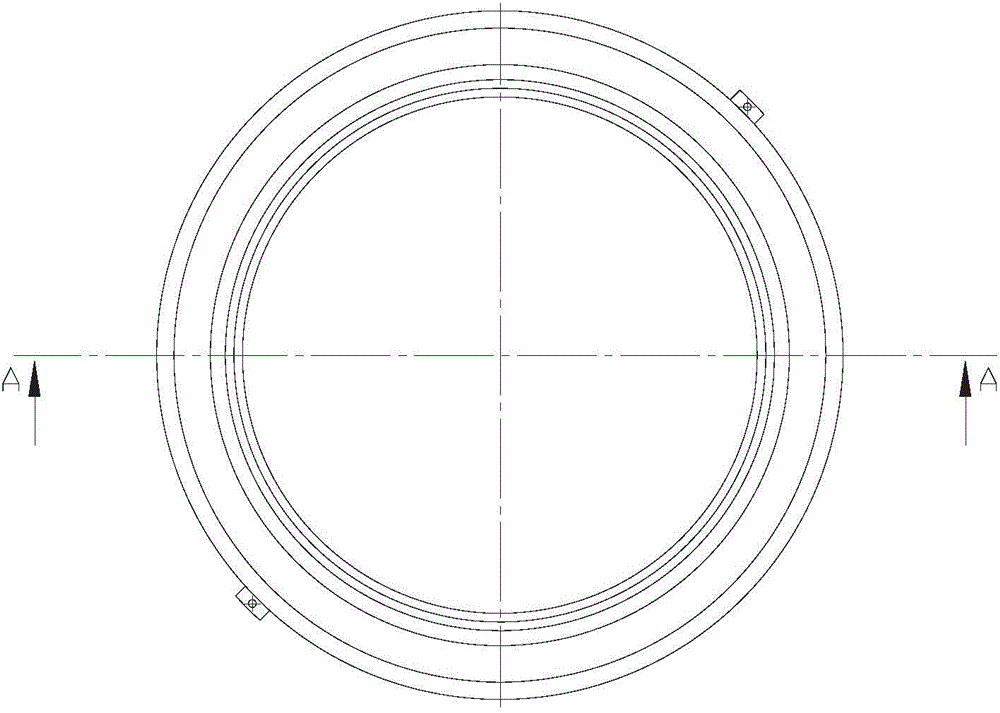

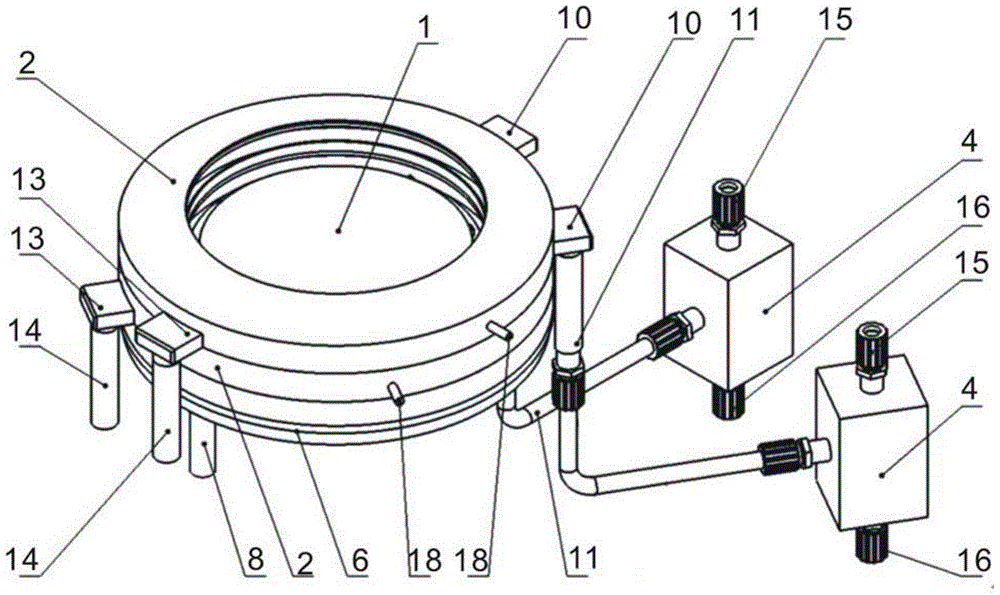

A cleaning medium collection device

ActiveCN104841679BImprove recycling efficiencyAvoid backsplashCleaning processes and apparatusMechanical engineeringHigh frequency vibration

The invention provides a cleaning medium collecting device and relates to the technical field of semiconductor wafer processes. The cleaning medium collecting device is used for collecting cleaning media after cleaning during the cleaning process of wafers borne on a rotary body and comprises a cleaning medium collecting structure, an annular cavity, a piezoelectric ceramic ultrasonic atomizing device, an exhaust component, a liquid discharge component and a condensation recovery device. The annular cavity is arranged at the peripheral edge of the rotary body. The high-frequency vibration performance of the piezoelectric ceramic ultrasonic atomizing device is utilized to atomize the liquid cleaning media tossed out during the cleaning process, liquid cleaning medium back splashing is prevented, secondary pollution is avoided, and wafer quality is further increased. Meanwhile, the atomized cleaning media are recycled through the exhaust component and the condensation recovery device, the cleaning media not atomized are recycled through the liquid discharge component, the recycling efficiency of the cleaning media is increased greatly, and cost is saved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

A kind of lost foam casting processing method of vehicle front panel seat

ActiveCN108080569BEasy to operateReduce labor intensityFoundry mouldsFoundry coresMolten steelUltimate tensile strength

The invention discloses a lost foam casting machining method of a vehicle front slave plate base and belongs to the field of pouring machining. The method includes the following steps that firstly, molten steel is smelted, wherein the molten steel is prepared from, by mass, 0.25-0.3% of C, 0.2-0.5% of Si, 0.5-0.9% of Mn, 0.4-0.5% of Ni and 0.3-0.4% of Cu; secondly, a foam mold model and a pouringsystem are manufactured, and the foam mold model is subjected to vibration ramming in a sand box; thirdly, the smelted molten steel is poured, so that the foam mold model in the sand box disappears, and a casting is formed; fourthly, after being cooled, the casting is taken out, and following cleaning is carried out. The defects that in the prior art, the machining labor intensity of the vehicle front slave plate base is high, and the machining efficiency of the vehicle front slave plate base is low are overcome, the machining labor intensity can be effectively reduced, the machining efficiency is improved, structural distortion of the front slave plate base can be avoided, the machining precision is guaranteed, and the machining percent of pass of products is effectively improved.

Owner:MAANSHAN SANFENG MACHINERY MFG CO LTD

Toilet stool and control method thereof

InactiveCN112144625AReduce flushing water consumptionClean upWater closetsMechanical energy handlingFecesWater rinsing

The invention belongs to the field of bathroom accessories, and particularly discloses a toilet stool and a control method thereof. The toilet stool comprises a shell, a control module, a conveying assembly arranged in the shell and a water spraying assembly; the shell comprises a sewage inlet and a sewage outlet communicated with a drainage pipeline; the conveying assembly comprises a bearing part and a transmission part, the bearing part is used for receiving dirt falling from the dirt inlet, and the control module is used for controlling the transmission part to rotate to drive the bearingpart, so that the bearing part moves around the transmission part, and the dirt falls from the bearing part to enter the dirt outlet; and a water spraying port of the water spraying assembly faces thebearing surface of the bearing part. Most excrement such as faeces falls into a sewer line under the action of gravity through movement of the bearing part, only a small amount of water is needed forflushing, a small amount of residual excrement remains, the water consumption for flushing the toilet is reduced, meanwhile, the problem that the toilet cannot be flushed cleanly or even cannot be flushed is solved, and spreading of infectious viruses, bacteria and the like is prevented to a certain extent.

Owner:HUAZHONG UNIV OF SCI & TECH

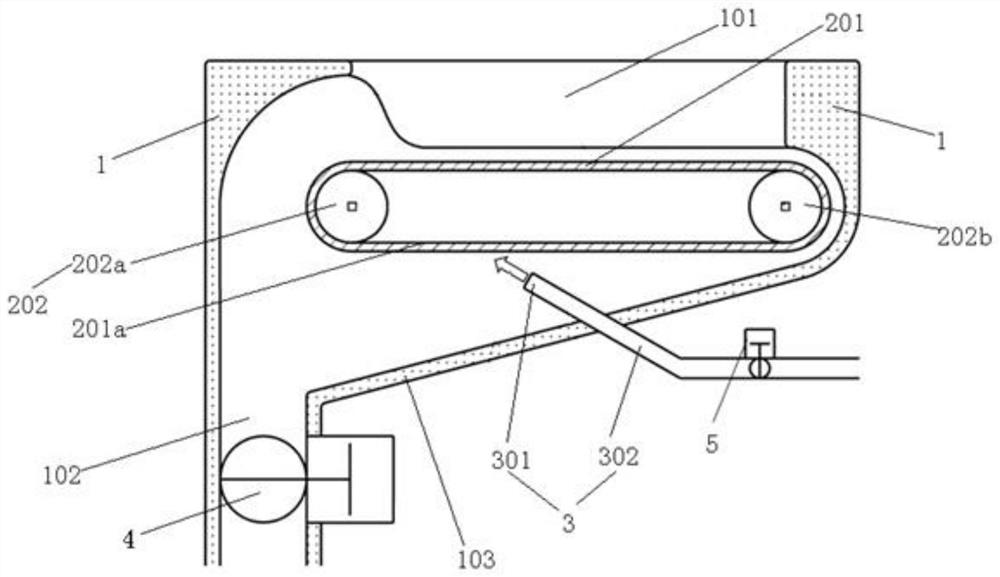

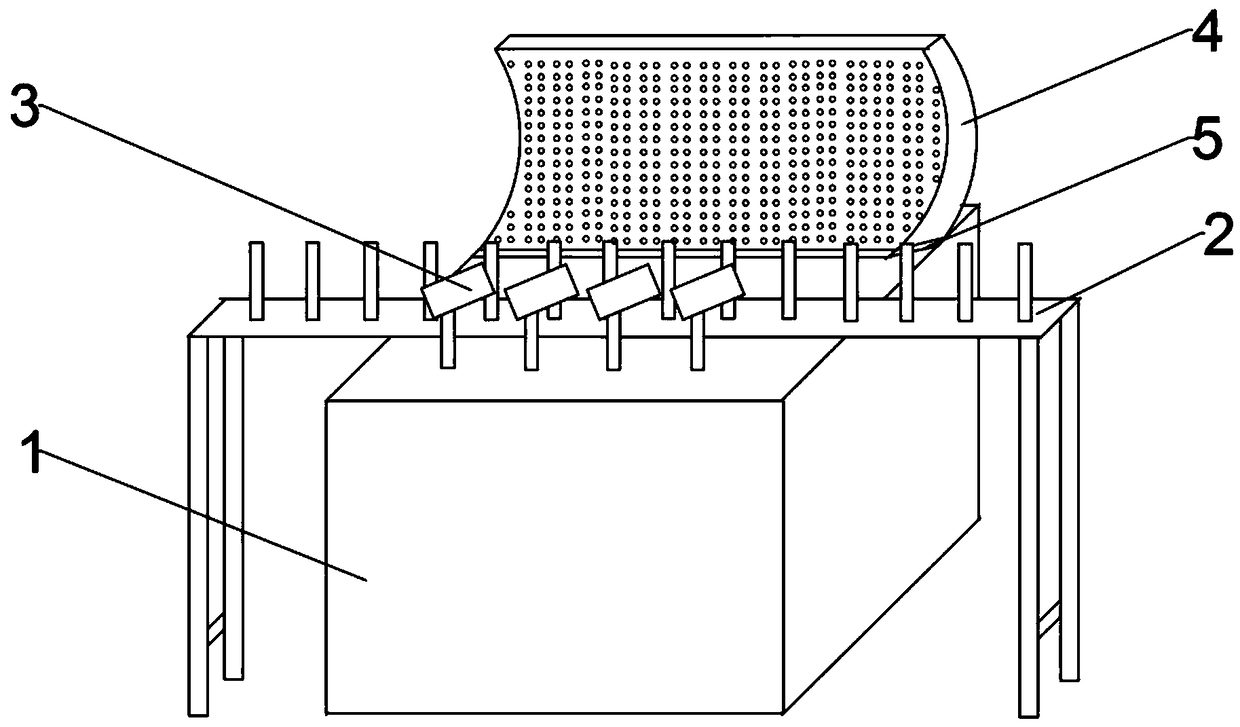

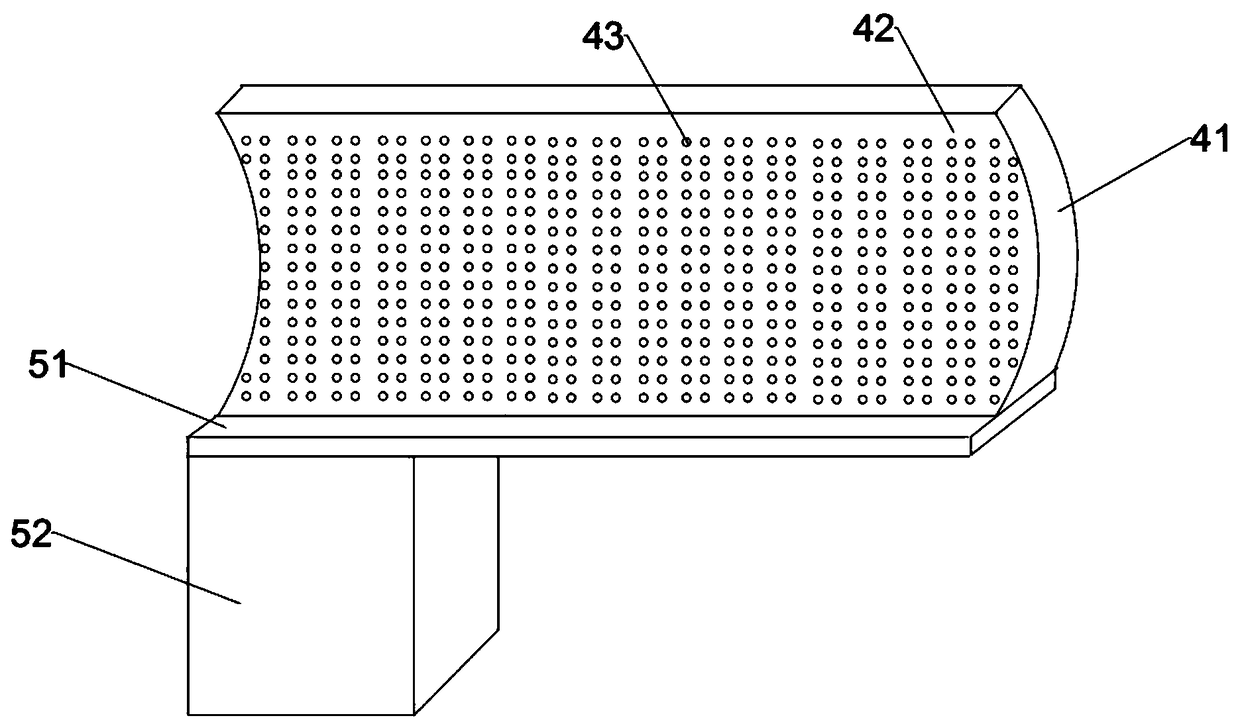

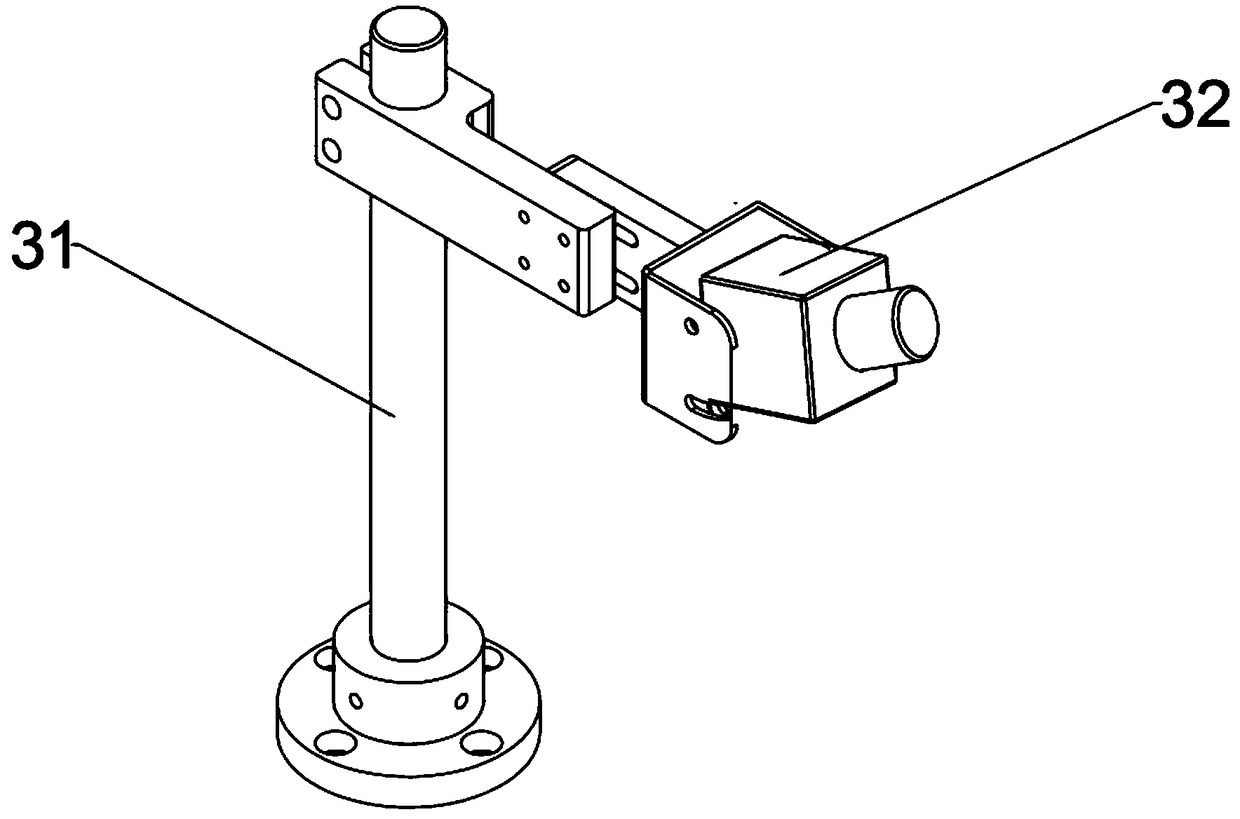

Spraying system and using method thereof

The invention discloses a spraying system. The spraying system comprises a lower machine frame, a conveying device, a spraying device and a collecting device, the conveying device is horizontally arranged on the lower machine frame, the spraying device is arranged on one side of the conveying device, the collecting device is arranged at the position, corresponding to the spraying device, on the other side of the conveying device, the spraying end of the spraying device is arranged corresponding to the conveying device, and a coating recovering device is arranged below the collecting device. The invention further discloses a using method of the spraying system. According to the spraying system and the using method, the design is reasonable and ingenious, the spraying and recovering processes can be realized in a full-automatic mode, the collecting device of the arc-shaped structure effectively prevents a coating from being splashed back, moreover, the collecting device realizes synchronous recovering of the inner layer and the outer layer, so that through the spraying system and the method, the waste of the coating is reduced, the recovery efficiency is high, the environment-friendly recovering goal is achieved, the structure is simple, the practicability is high, and the spraying system and the method are suitable for large-scale production.

Owner:东莞市明业新材料科技有限公司

A preparation process of a vehicle front panel seat

ActiveCN108015232BEasy to operateReduce labor intensityFoundry mouldsFoundry coresStructural deformationMolten steel

The invention discloses a manufacturing process for a vehicle front draft lug, and belongs to the field of casting processing. The manufacturing process comprises the following steps: step I, smeltingmolten steel which comprises the following components in percentage by weight: 0.25-0.3% of C, 0.2-0.5% of Si, 0.5-0.9% of Mn, 0.4-0.5% of Ni and 0.3-0.4% of Cu; step II, manufacturing a foam mould sample and a casting system, and vibrating and compacting the foam mould sample and the casting system in a sand box, wherein the casting system comprises a straight pouring gate, a transverse pouringgate and a branch pouring gate, the branch pouring gate is connected with the foam mould sample, and a non-axisymmetric pouring cup is arranged on the top of the straight pouring gate; step III, casting the smelted molten steel for enabling the foam mould sample in the sand box to lose and to form a casting; and step IV, cooling the casting, and taking out the casting to clear. The manufacturingprocess overcomes the defects such as high labor intensity and low processing efficiency of the vehicle front draft lug in the prior art, effectively reduces processing labor intensity, improves processing efficiency, avoids structural deformation of the front drug lug, guarantees processing precision, and effectively increases the product processing qualification rate.

Owner:MAANSHAN SANFENG MACHINERY MFG CO LTD

Blowing-free emulsion residue removal method

ActiveCN101829693BImprove surface qualityReduce noise pollutionRollsWork cleaning devicesEmulsionRolling mill

The invention belongs to the technical field of cold-rolled emulsion spot treatment, and in particular relates to a blowing-free emulsion residue removal method, which is applied to various cold-rolling mills. The blowing-free emulsion residue removal method is characterized by comprising the following steps of: 1) blocking low inertia force return of the emulsion; 2) blocking side fluid channeling of the emulsion; 3) blocking fluid channeling of intermediate roll shifting empty emulsion; 4) blocking the condensate of the emulsion; 5) rapidly draining the injection beam of the emulsion; and 6) preventing splashing. The blowing-free emulsion residue removal method has the advantages of simpleness and excellent treatment efficiency.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com