Beam catching device for a processing machine

A capture device, processing machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems affecting cutting beams, etc., and achieve the effects of easy exclusion, direct collision prevention, and adhesion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

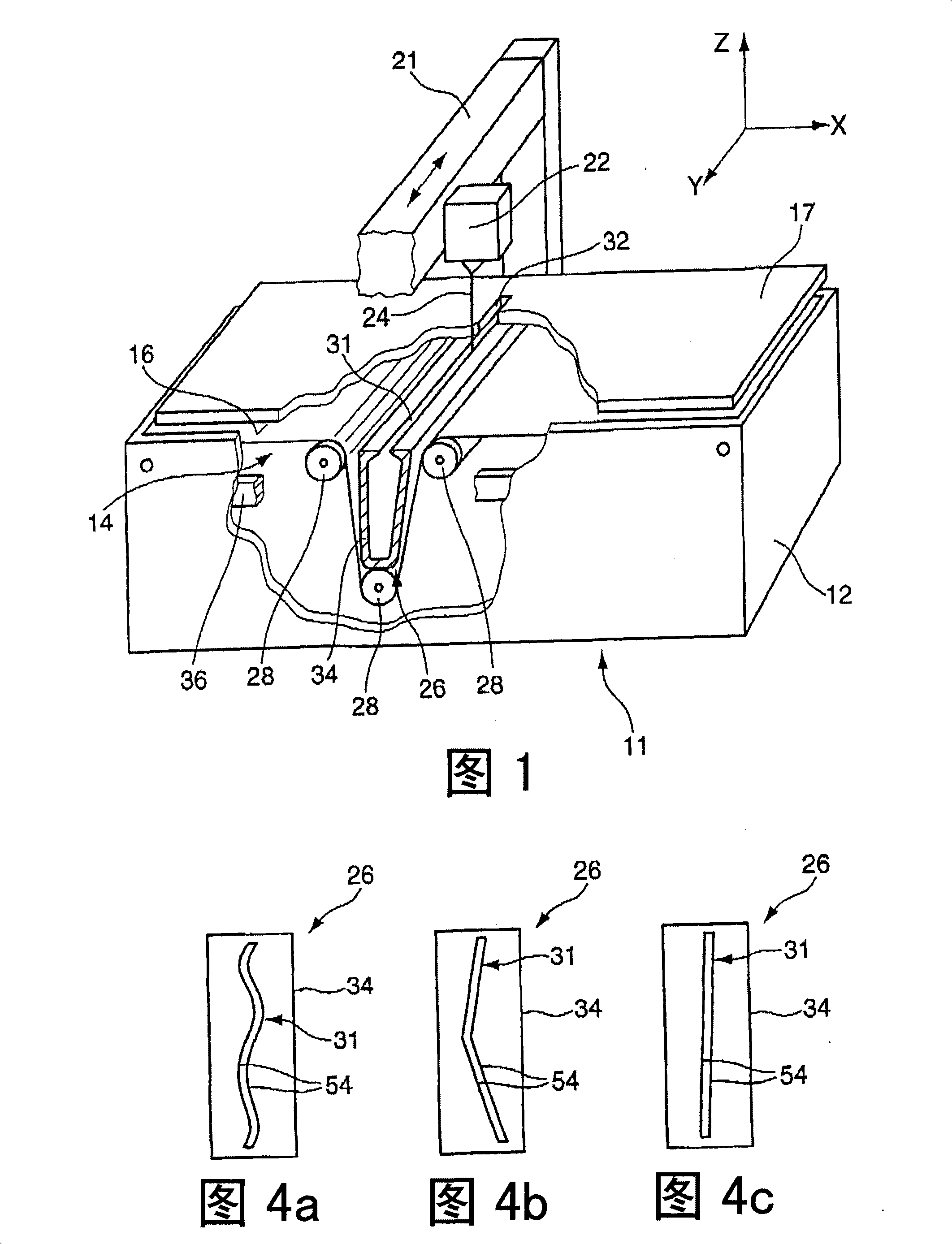

[0048] The processing machine 11 is shown in perspective in FIG. 1 . The processing machine 11 is preferably designed as a laser cutting machine. Alternatively, plasma cutters or flame cutters can also be formed. The machine bed 12 includes a workpiece support 14 which is formed, for example according to FIG. 1 , by a support belt 16 which is held stationary in the machine bed 12 . In an alternative embodiment, the carrier belt can also be driven movably and can additionally fulfill a transport function. The cutting head 22 is movable in the Y direction via the linear axis 21 and forms the working area of the cutting head 22 . Additionally, a rectilinear axis can be provided that can traverse back and forth with respect to the X direction. Furthermore, it is also possible to provide linear axes which can be moved vertically. A cutting beam 24 is directed from the cutting head 22 onto the workpiece 17 in order to carry out machining.

[0049] On the underside of the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com