Wafer cleaning device and wafer cleaning method

A technology for cleaning devices and wafers, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., capable of solving problems such as silicon wafer surface pattern defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Various embodiments of the present invention will be disclosed below with accompanying drawings, and for the sake of clarity, many practical details will be described together in the following description. It should be understood, however, that these practical details should not be used to limit the invention. That is, in some embodiments of the invention, these practical details are unnecessary. Besides, for the purpose of simplifying the drawings, some well-known and conventional structures and elements are shown in a simplified and schematic manner in the drawings.

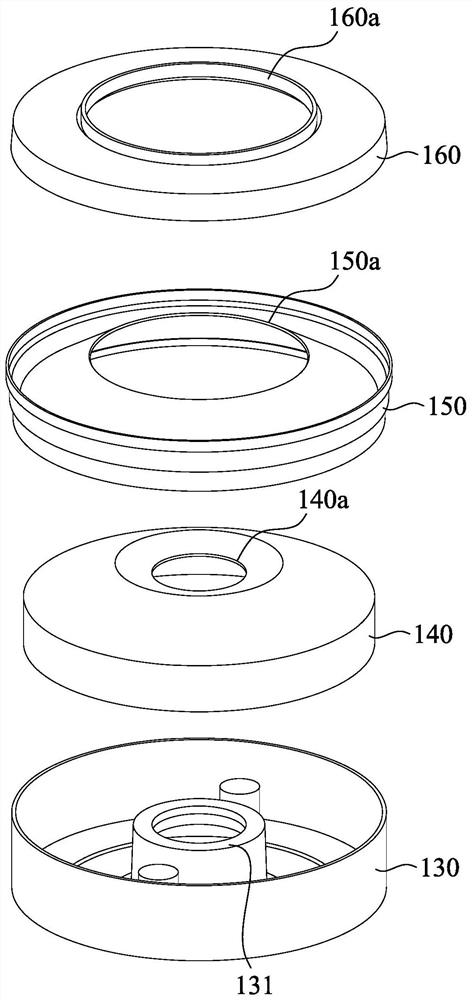

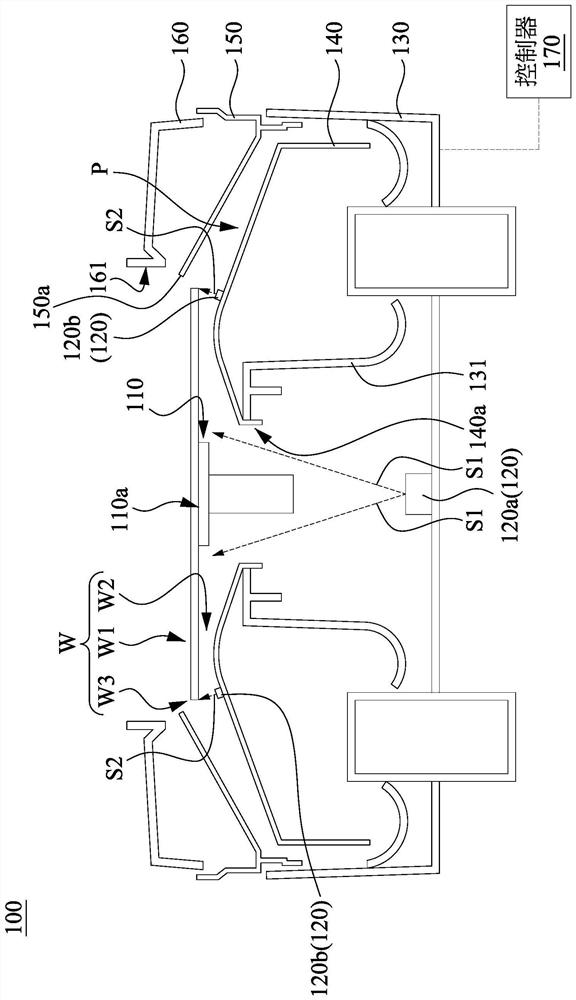

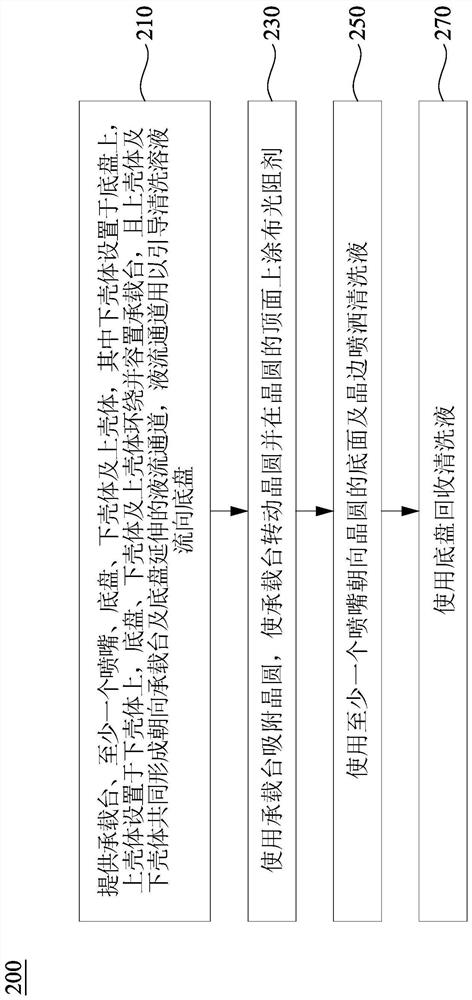

[0026] Please refer to figure 1 and figure 2 . figure 1 According to one or more embodiments of the present invention, a three-dimensional schematic diagram of some components of the wafer cleaning apparatus 100 is shown. figure 2 A schematic cross-sectional view of the wafer cleaning apparatus 100 is shown. In some embodiments of the present invention, the wafer cleaning apparatus 100 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com